The FLUX Beamo is the world’s smallest yet powerful laser cutter and engraver featuring a reliable system for safe, smooth, and versatile use by operators of any level. Thanks to its convenient software and simplified working mechanism, even children can easily learn crafting and enjoy creative freedom.

This is Top 3D Shop, and in today’s article we are going to explore the technical characteristics, main functions, and applications of this high-performance device.

The FLUX Beamo is an extremely compact laser cutter and engraver for professional, school, and home use. Due to its powerful CO₂ laser, compact size, affordable price, advanced modules, and multiple mechanisms for safe and convenient work, the device is ideal for dealing with almost any material.

First off, let’s quickly go over the features that make the FLUX Beamo perfect for a number of creative applications.

Apart from that, handy add-ons making up the whole FLUX ecosystem can facilitate your tasks and open new design possibilities.

The FLUX Beamo comes shipped in a single box that can easily be handled. Inside, you will find the device itself, thoroughly wrapped up in a protective sheet and containing everything you need to set it up.

Credit: CNC Kitchen / YouTube

First of all, you will find there a vent hose for guiding the process fumes away from the machine.

Credit: CNC Kitchen / YouTube

Next, the package includes a user manual. Apart from a stylish cover, it provides all the necessary information on the setup process, software, materials, maintenance, and troubleshooting.

Credit: CNC Kitchen / YouTube

In addition to the already mentioned items, the Beamo is supplied with laser engraving and laser cutting heads, power cord, toolbox, and some spare parts for convenient long-term usage.

Credit: CNC Kitchen / YouTube

The engraver comes with pre-aligned laser mirrors and is ready for almost immediate use right out of the box.

Credit: CNC Kitchen / YouTube

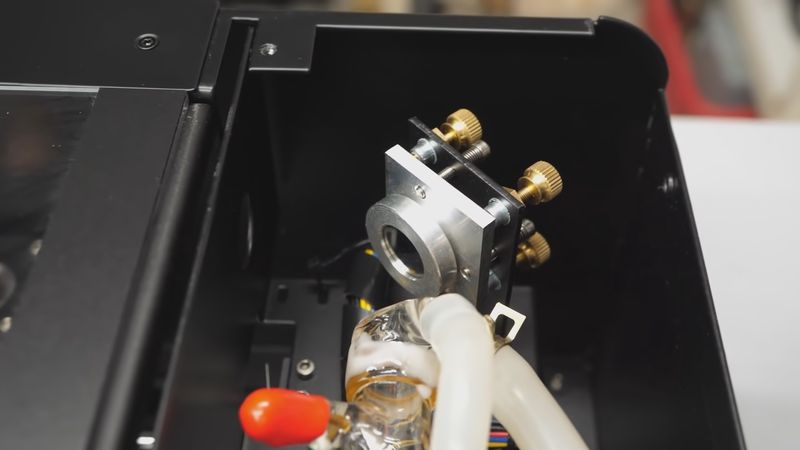

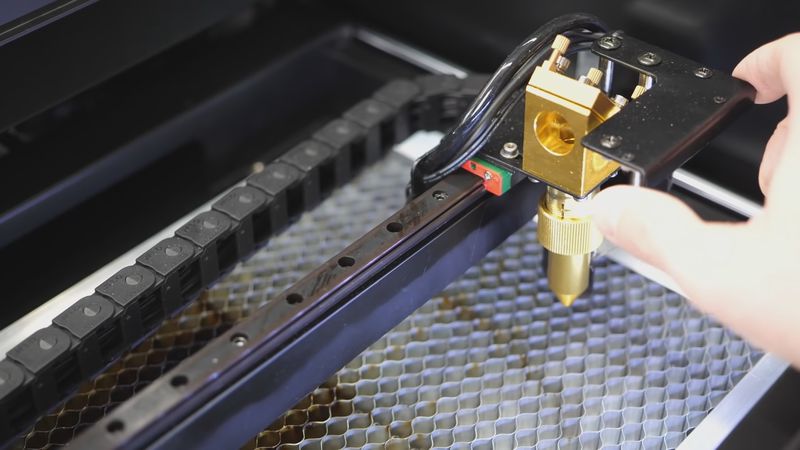

As for the laser itself, the laser tube is equipped with a water cooling system and an air pump making up for quality operation. Compressed air comes out of the laser nozzle and cleans the cut from smoke and debris, which ensures better results.

Credit: CNC Kitchen / YouTube

Make sure that the device has enough distilled water in the reservoir. Otherwise, you might want to add some to improve cooling.

Credit: CNC Kitchen / YouTube

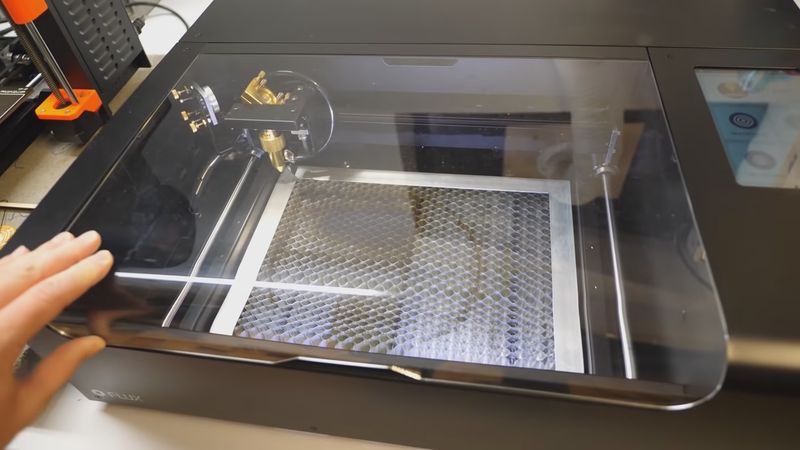

As we have already mentioned in the previous section, the machine is engineered with a special switch that will not let the laser turn on when the lid is open. Thanks to this feature, you do not need safety goggles to work with the laser cutter.

Credit: CNC Kitchen / YouTube

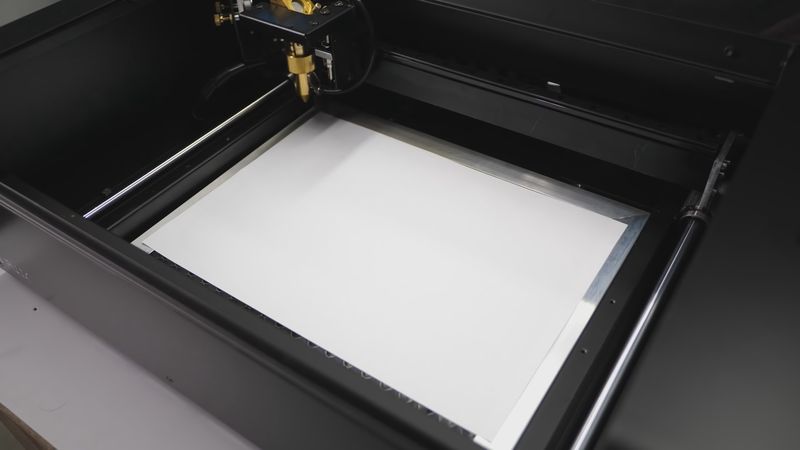

The available working area for the Beamo is 300 x 210 x 45 mm, which is roughly equal to an A4 paper size. It is not too big, but generally enough for small and medium-scale design projects.

Credit: CNC Kitchen / YouTube

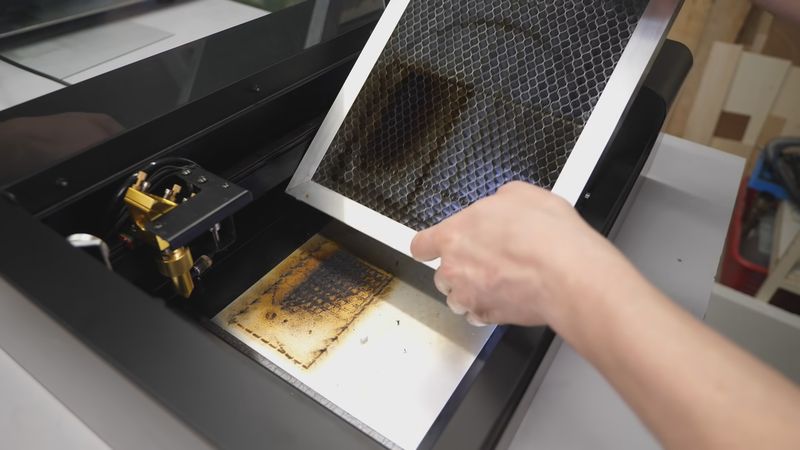

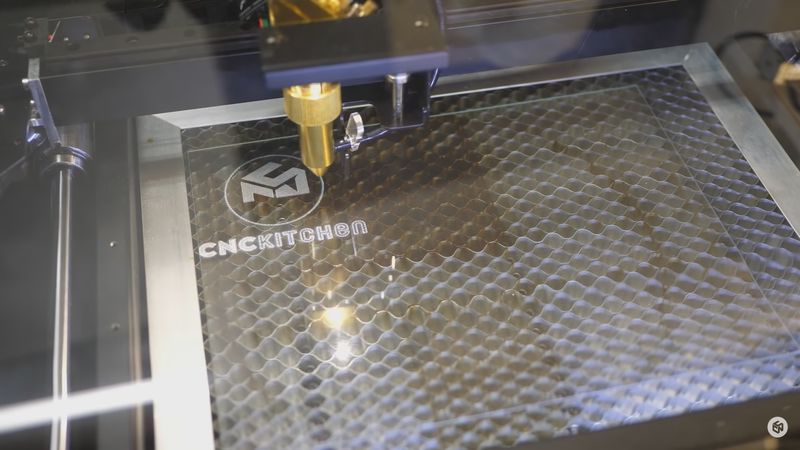

On the base of the working chamber, you will find a honeycomb mesh for placing a workpiece. It can be easily removed for cleaning. The very bottom can also be taken out, if you decide to install the rotary add-on, which we will describe later on.

Credit: CNC Kitchen / YouTube

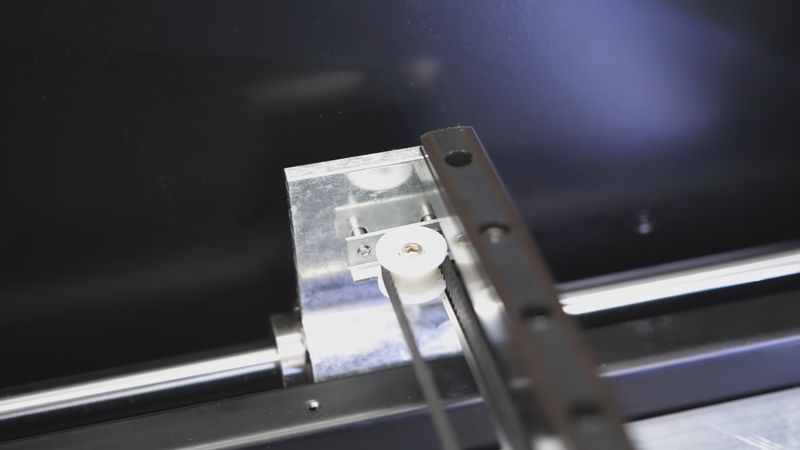

The machine’s motion control system consists of a linear rail for the X-axis and sturdy smooth rods for the Y-axis.

Credit: CNC Kitchen / YouTube

As for the belt system, it has some minor flaws and is overall inferior to the achievements of contemporary 3D printers.

Credit: CNC Kitchen / YouTube

First, the belt is not entirely parallel, which might lead to small distortions in outer regions of the bed.

Credit: CNC Kitchen / YouTube

Then, there is a plastic idler that can be tightened a bit, but it would require removing two side panels, which is not the best solution.

Credit: CNC Kitchen / YouTube

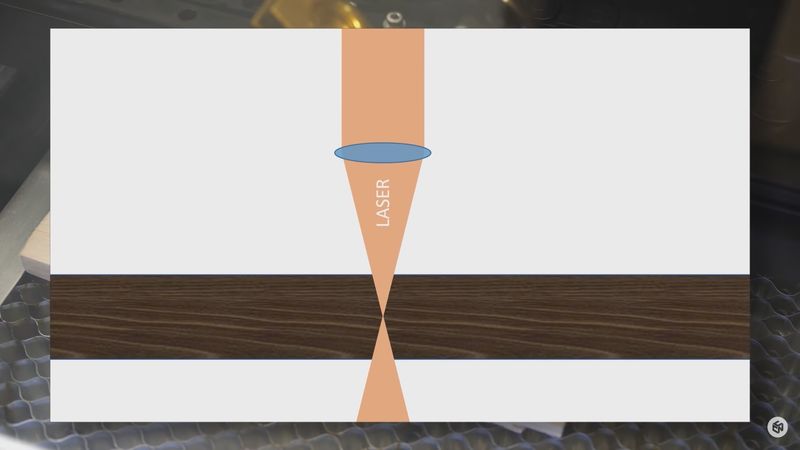

The laser needs to be focused on the workpiece. The procedure is quite simple and straightforward. You should swing down the focus arm (shown in the photo), loosen the focus ring, slide the mechanism up and down until the right position is found, and tighten the focus ring again.

Credit: CNC Kitchen / YouTube

In the back, you will find several connectivity ports and a big fan with a 120 mm exhaust for smoke removal during the laser cutting and engraving process.

Credit: CNC Kitchen / YouTube

Before you start using the FLUX Beamo laser engraver, you need to set it up. This is a really simple procedure that can be performed through the built-in color touchscreen with a simple and neat-looking UI.

Credit: CNC Kitchen / YouTube

The machine supports USB, Ethernet, and Wi-Fi connectivity. In addition, the Beam Go mobile app for iOS and Android allows you to control the Beamo remotely.

Credit: CNC Kitchen / YouTube

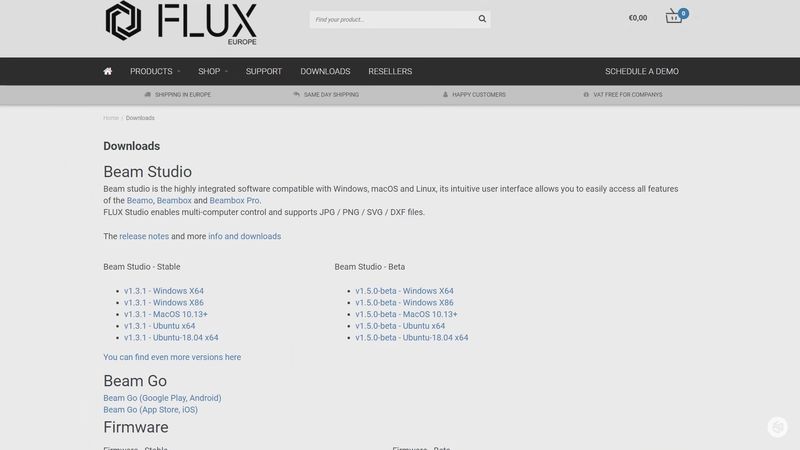

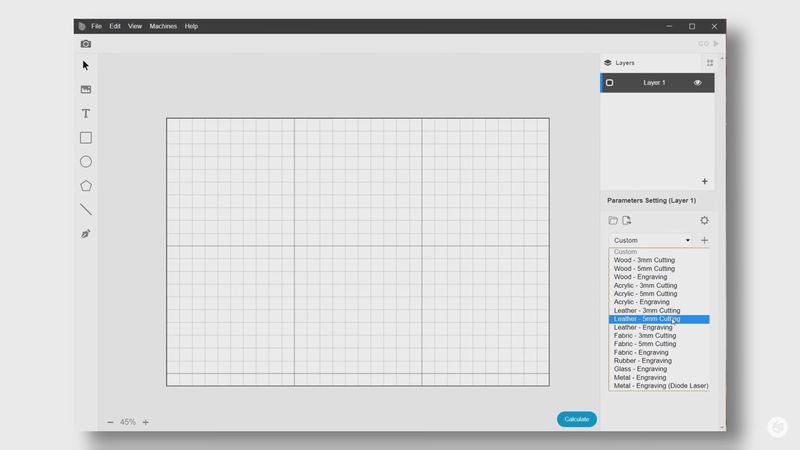

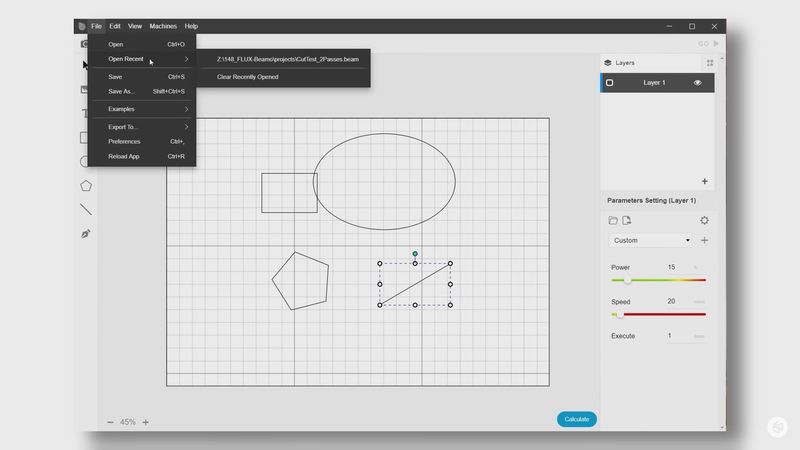

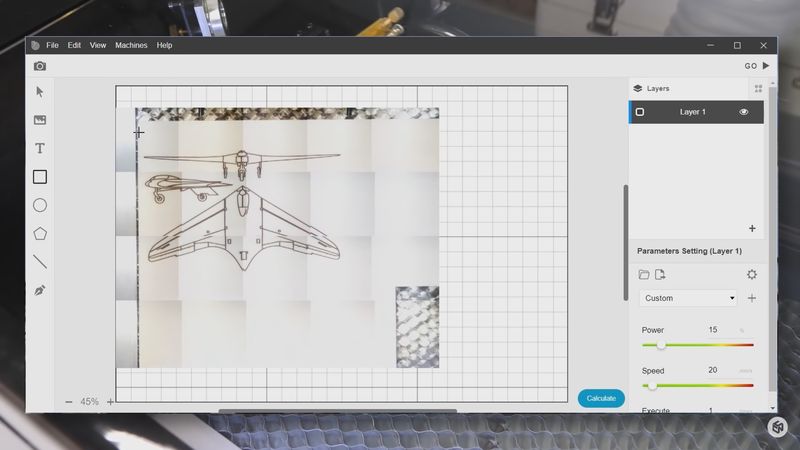

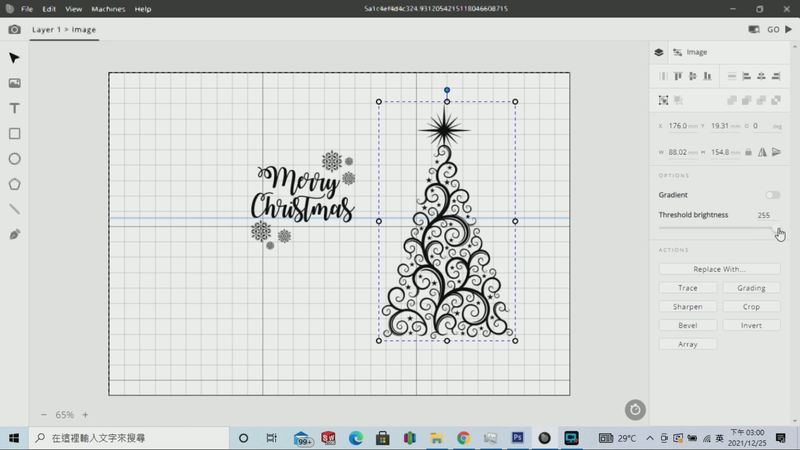

The device is powered by the Beam Studio software developed by FLUX. It is used to create laser projects with various design options.

Credit: CNC Kitchen / YouTube

The program is very clear and easy to master. Among other user-friendly functions, it provides you with a great number of presets for different materials.

Credit: CNC Kitchen / YouTube

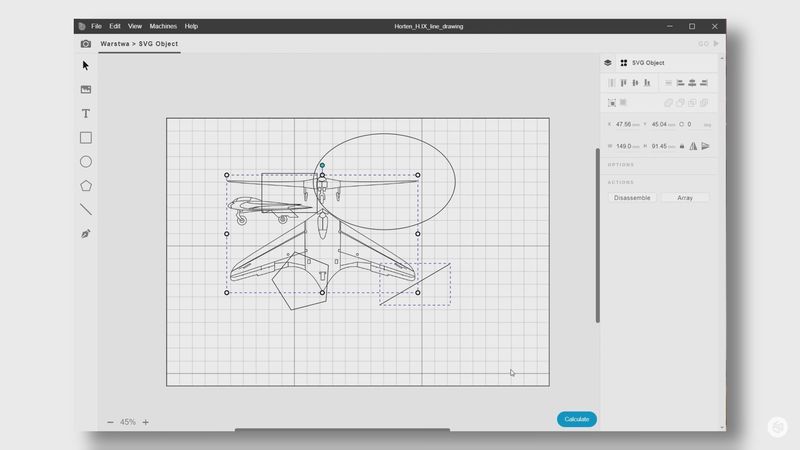

The set of tools includes basic shapes for designing simple parts. Apart from this, you can import vector formats, like SVG or DXF.

Credit: CNC Kitchen / YouTube

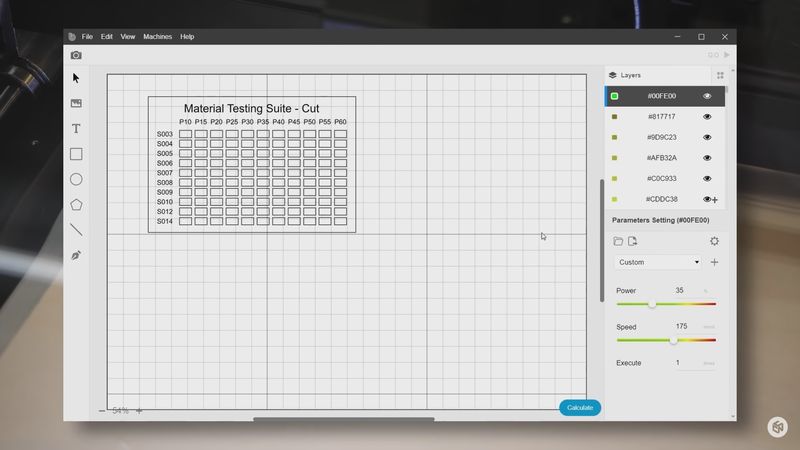

Your projects can be arranged on different layers, with individual parameters assigned. In addition, the order in which your design is processed can also be regulated. For example, sometimes you might want to start with engraving and then move on to cutting out your part.

Credit: CNC Kitchen / YouTube

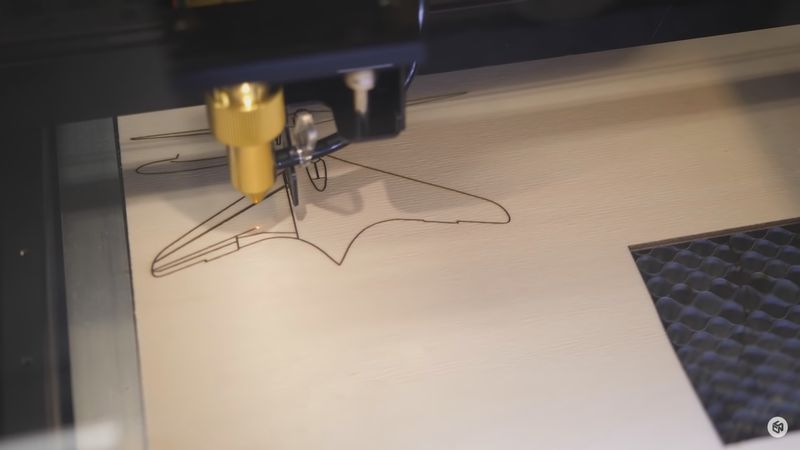

Vector engraving and cutting imply basic mechanics: the laser follows the designated lines and forms a certain pattern.

Credit: CNC Kitchen / YouTube

However, with the Beamo you can also create raster engravings, when a simple outline is not enough, you want to remove a bigger area, or a project requires etching a grayscale image.

Credit: CNC Kitchen / YouTube

In this mode, the laser head travels in a narrow meandering pattern, and the laser itself quickly turns on and off to only mark the specified areas. To improve the quality of grayscale images produced by the Beamo (for instance, JPG ones), you can modulate the laser power.

Credit: CNC Kitchen / YouTube

Another great feature offered by the machine is the integrated HD camera for scanning the working area. It allows you to precisely align and position workpieces for more accurate results.

Credit: CNC Kitchen / YouTube

As soon as your project gets uploaded on the Beamo, it is saved in the device’s inner storage. You can always select one of the previous jobs and even adjust laser power and speed.

Credit: CNC Kitchen / YouTube

But let’s see how Beamo actually succeeds, especially in laser cutting.

If you have had experience only with diode laser engravers, you will surely be pleased with the Beamo’s performance. To find out the machine’s strengths and weaknesses, let’s look through several laser cutting tests on materials with different properties.

Credit: CNC Kitchen / YouTube

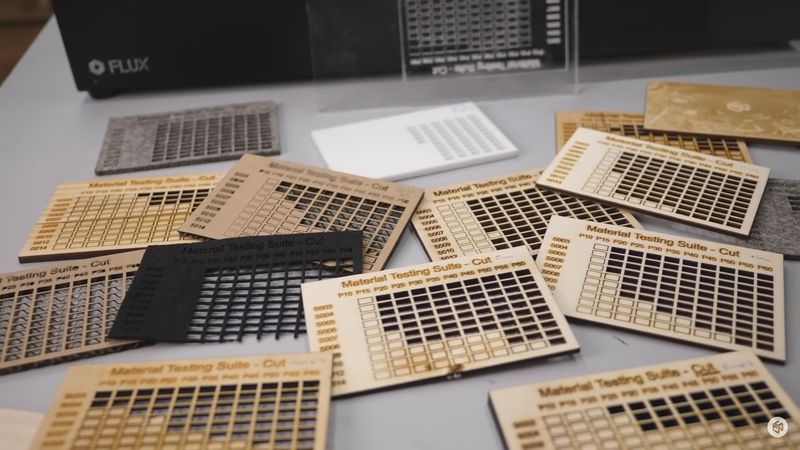

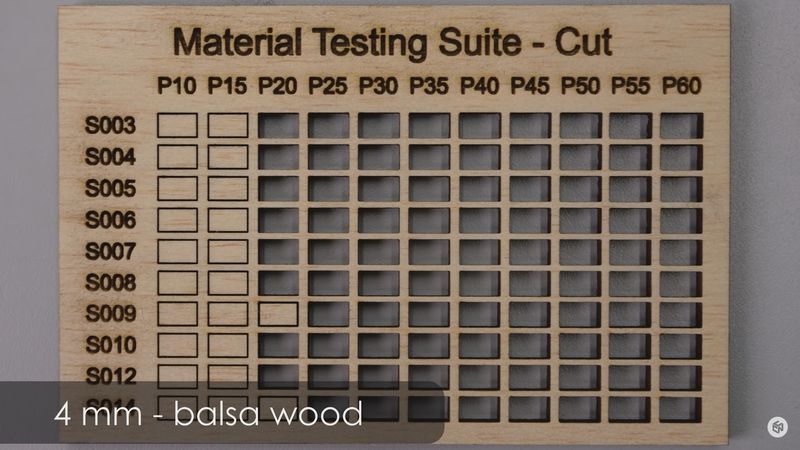

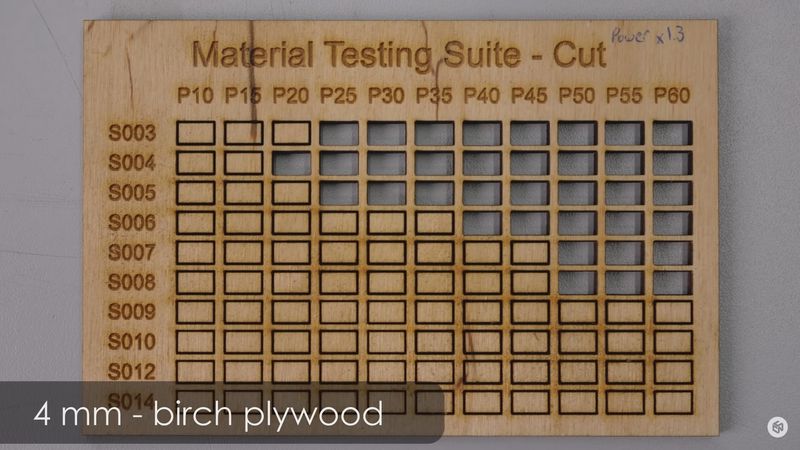

A premade pattern for the demonstrated tests can be found in the Beam Studio menu. To find it, select ‘File’ — ‘Examples’ — ‘Material Cutting Test’. Every rectangle in the scheme corresponds to a certain laser power percentage of the maximum 30W and cutting speed in mm/s.

Credit: CNC Kitchen / YouTube

The softer 4 mm poplar plywood commonly used for various design projects cuts swimmingly even at higher speeds and only one pass.

Credit: CNC Kitchen / YouTube

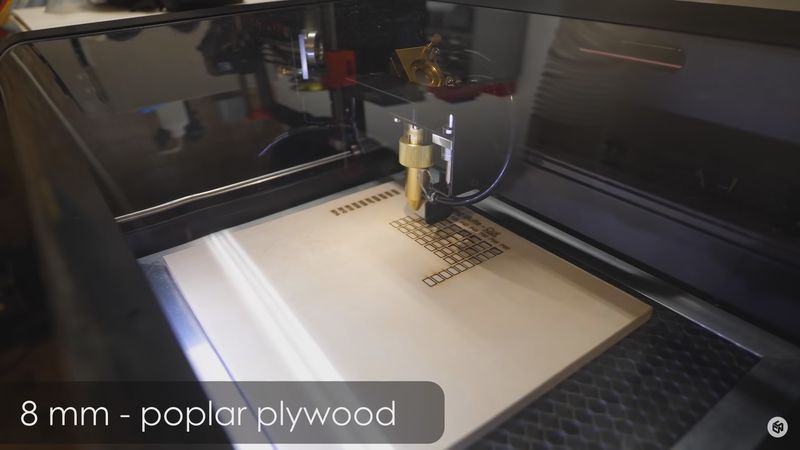

With 8 mm thick plywood, it takes the machine two passes to smoothly cut through the pattern.

Credit: CNC Kitchen / YouTube

Balsa wood generally preferred by model airplane builders cuts with no issues at 4 mm.

Credit: CNC Kitchen / YouTube

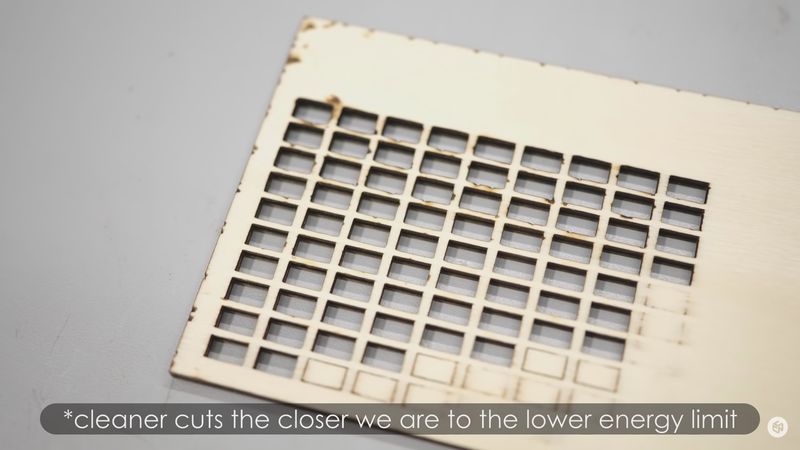

Even at 10 mm the result with this material is quite clean and uniform. Though, it is definitely recommended to find proper parameters beforehand, since the maximum laser power can sometimes cause burning instead of cutting.

Credit: CNC Kitchen / YouTube

According to some real experience, higher speed is usually the better choice for quality results as well as two passes instead of one.

Credit: CNC Kitchen / YouTube

Also, if you want to cut thicker material, set the laser focus slightly below the surface, closer to half the thickness. This will lead to a more even energy density over the cut.

Credit: CNC Kitchen / YouTube

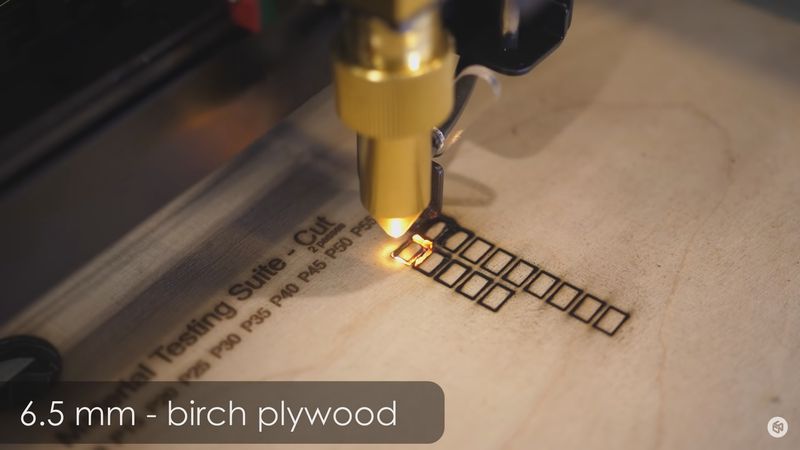

Despite the previous successes, the 30W laser starts struggling a little when it comes to cutting harder wood. With 2.5 and 4 mm birch plywood, there are no problems at lower speeds.

Credit: CNC Kitchen / YouTube

However, the 6.5 mm workpiece seems too much for the device, even at multiple passes. The wood is rather burned than cut.

Credit: CNC Kitchen / YouTube

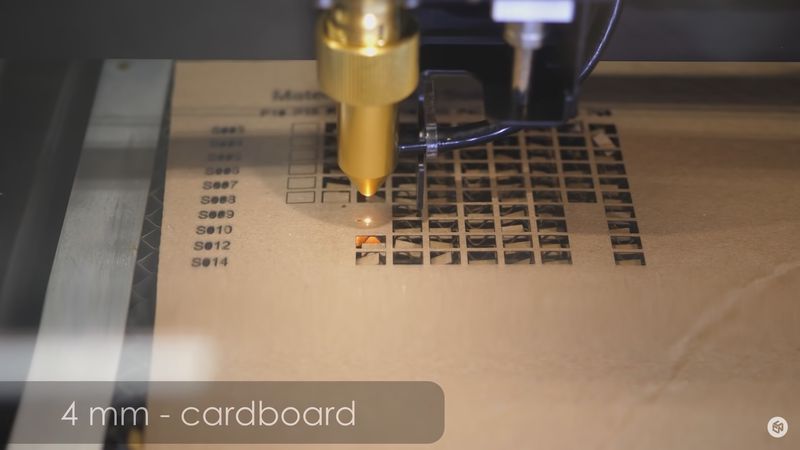

As for cardboard, there are no issues whatsoever.

Credit: CNC Kitchen / YouTube

The same goes for 4 mm felt.

Credit: CNC Kitchen / YouTube

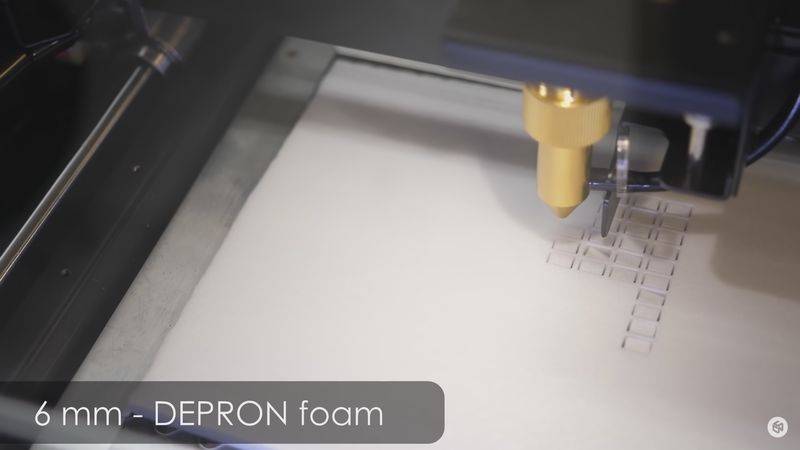

Moreover, the machine copes well with 6 mm Depron foam board at higher speeds and reduced laser power.

Credit: CNC Kitchen / YouTube

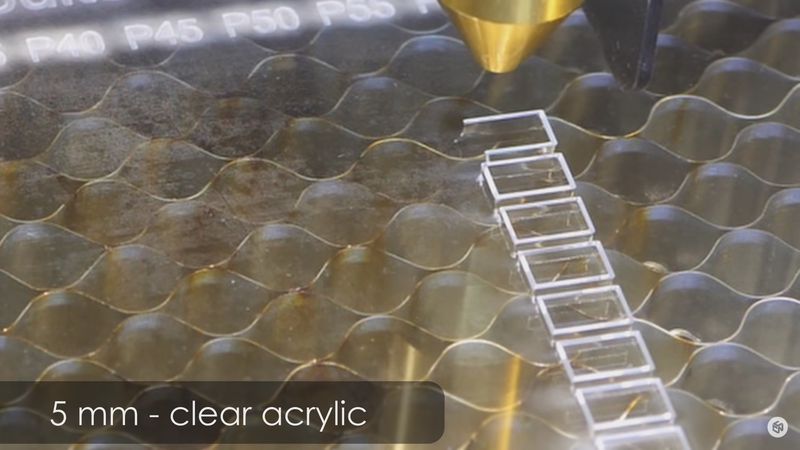

One great thing about CO₂ laser cutters is that they are able to work with transparent materials, such as this clear acrylic. Due to the high wavelength of 10600 nm, things transparent in the visible spectrum are not transparent for CO₂ lasers. They are able to fully interact with such materials and thus can be used for laser cutting and engraving, but mostly at the slowest speed or more passes. The thinner your workpiece is, the better.

Credit: CNC Kitchen / YouTube

With regard to engraving, no issues found here.

Credit: CNC Kitchen / YouTube

Finally, let’s talk about glass. Common blue diode lasers simply cannot work with it. As for the Beamo, it is not capable of cutting glass just like some more powerful lasers, but engraving your own pattern should be easy for the device. The laser creates microcracks at the assigned location and can therefore texture it. This might come in handy for displays and customized glassware, especially if you have the rotary attachment.

Credit: CNC Kitchen / YouTube

Overall, the FLUX Beamo shows good results in laser cutting, even though the machine has some minor issues when it comes to really thick and dense materials. Other than that, the device has proved its powerful capabilities sufficient for multiple decorative applications.

Apart from dedicated software, FLUX provides additional modules for the Beamo to enhance your laser cutting and engraving experience in a most thoughtful and convenient way.

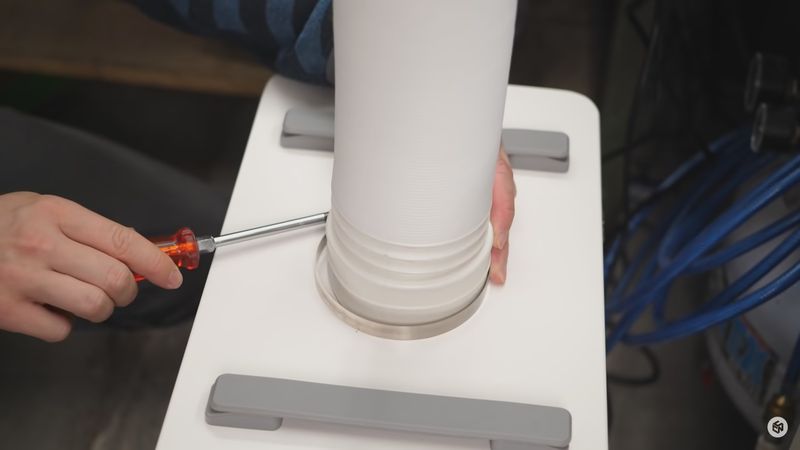

With the rotary extension, you can smoothly engrave on cylinder objects, like thermoses, mugs, pens, wine bottles, glassware, and more.

This add-on not only automatically sets the laser focus based on the project but also lets you adjust the focus position during cutting passes for deeper penetration. This significantly improves cutting efficiency when dealing with thicker materials.

The following hybrid laser attachment makes for faster cutting speeds and deeper penetration, which is particularly important when working with materials like steel.

A special attention should be paid to the FLUX Beam Air purificator, which may definitely come in handy if you decide to keep your workspace cleaner and more “friendly”.

Credit: CNC Kitchen / YouTube

The device represents a 4-layer filtration system with potent air intake aimed to block any harmful particles and odors generated in the working chamber during the Beamo operation.

Credit: CNC Kitchen / YouTube

The Beam Air consists of a pre-filter, medium efficiency filter, activated charcoal filter, and H13 HEPA filter. With a brushless motor and reduced noise level, it guarantees thorough air cleaning and a quiet environment.

Credit: CNC Kitchen / YouTube

The machine boasts a small footprint, handy wheels for smooth transportation, and advanced compatibility with other similar devices. The fumes are guided through a flexible hose that connects the laser engraver with the extractor.

Credit: CNC Kitchen / YouTube

Moreover, by connecting the Beam Air to the Beamo with a USB-B cable, you will ensure that the device turns on automatically when laser cutting starts and off when it finishes.

The FLUX Beamo is a perfect tool for a great deal of creative applications, including customizing, prototyping, design, model building, hand craft, education, etc.

A lot of people share their success stories on the official FLUX website. Many of them have managed to turn creative hobbies into their main source of income. As practice shows, with some skill and Beamo you can express your creativity in every possible way.

As a traveling artist from Manchester, Natasha Stoppel has been exploring the world for years now. She conveys her impressions and tells stories about her adventures in the form of unique accessories made with the Beamo laser engraver.

Natasha combines features of different cultures with her personal style and creates unique, vivid, and emotional works of art.

Apart from accessories and small toys, the artist produces complex pictures, where every fine detail is carefully cut by the 30W laser.

For her stunning works, Natasha mostly prefers wood that looks perfectly smooth after processing with the FLUX Beamo.

Half-Goatee is a Taiwanese team that specializes in designing pop-up books, cards, and other paper goods. They use Beamo for prototyping to reduce the development time for new products and appreciate the machine for its infinite possibilities of precise paper cutting.

Fashion designer and engineer Anouk Wipprecht currently works on the Pangolin Scales Project. It combines laser engraving, 3D printing, and brain-computer interface to create a shirt that can reflect emotions by reading them in a person’s brain.

For instance, it will emit a warm purple when the wearer is thinking, and spread its wings with glowing blue when detecting intense feelings.

It is a true challenge to integrate different elements from fashion and technology, but laser engraving is a potent tool to create innovative yet stunning designs.

With the Beamo, it is easy to surprise your friends with a special gift. For example, the rotary add-on allows you to engrave on cylindrical forms. Declan Chang showed how to add a festive look to a regular wine bottle with the help of the laser engraver.

Credit: Declan Cheng / YouTube

The Beam Studio was used to edit the initial image.

Credit: Declan Cheng / YouTube

Then, the built-in camera helped the user to center the future engraving.

Credit: Declan Cheng / YouTube

It took only ten minutes to finish the job.

Credit: Declan Cheng / YouTube

To make the appearance even nicer, Declan Cheng decided to add a small crystal. Ordinary glue was enough.

Credit: Declan Cheng / YouTube

Of course, you can go further and make your present even more personalized with a special logo. Paper is not an issue for Beamo.

Credit: Declan Cheng / YouTube

This is how you can show your affection and creative streak at the same time.

Credit: Declan Cheng / YouTube

Being a powerful machine engineered with an impressive amount of automated, safety, and simply convenient features, the FLUX Beamo laser cutter and engraver will become a great acquisition for all who want to create unique works of art as well as commercial products from scratch quickly and easily. With this device, you don’t need to possess special skills or expensive consumables — just imagination and a little patience to figure out the scheme. After that, almost any material will be your canvas.

Update your browser to view this website correctly. Update my browser now

Write a comment