Laser cutting and engraving machines are becoming more and more popular, not only with professionals but also with hobbyists who want a fresh experience and more impressive results with their craftwork. The Makeblock company offers several laser cutters under the xTool brand featuring different laser technologies for different budgets, as well as a whole range of options and materials to inspire their customers for creation.

This is Top 3D Shop, and today we are going to review the xTool Laserbox 40W CO₂ Laser Cutter with Rotary Attachment, which might become the best option for starting a small business.

The Makeblock company was founded in 2012 by Jasen Wang. An enthusiast maker, the Makeblock founder and CEO was looking for the best way to turn a creative idea into reality. The company was focused on STEAM education, having developed a block-based coding platform and a series of educational robots for underage students. In 2019, the company made the Laserbox, their first cutting and engraving machine that supported the concept of finding new ways for creation. Under the xTool brand, the company started developing and producing laser cutters and all necessary tools and materials as well as software products for their machines. The xTool laser cutters have soon become highly appreciated by customers, and now there is a large community of xTool users who share their projects and ideas for inspiration.

The xTool Laserbox 40W is a CO₂ laser machine capable of fast and precise cutting and engraving a variety of materials, and designed to meet the needs of small business owners as well as hobbyists and professional designers. The machine comes with a rotary attachment for engraving cylindrical objects and can be equipped with some optional accessories we will tell you about later.

Let us look at the most interesting features of the Laserbox in more detail.

The powerful 40 W CO₂ laser allows cutting a basswood plate up to 15 mm thick at a lightning-fast speed of 350 mm/s with 0.05 mm precision. The internal closed-loop liquid cooling system prevents the laser tube from overheating.

With the built-in 5 MP ultra wide-angle camera attached to the lid of the device, the user gets a live preview of the working area, which allows aligning the design precisely with the workpiece. The visible area provided by the camera lens is 490 x 290 mm, which is just a bit smaller than the entire working area of 500 x 300 mm.

The camera also works for other smart features, such as intelligent AF, material recognition, and image extraction, more of them below.

All official xTool materials are marked with a circular barcode identifying the type and thickness of the material. When a workpiece is placed in the machine, the camera scans the barcode and automatically sets the optimal processing parameters and adjusts the focal length.

When working with third-party materials, the machine uses visual identification, detecting material thickness and adjusting the AF.

With the image extraction function you can turn any inspiring design into a unique creation. The camera captures the image from any surface, and you only need to select the image in the software and use it in your projects.

A great thing about the Laserbox is that it can work without an internet connection. The user can just draw a picture with red and black markers on a sheet of paper or right on the material to be processed, and the machine will do the job, recognizing black lines for engraving and red ones for cutting.

The Laserbox features a high protection level and can be safely used even by children under adult supervision. It is in no way possible to operate the machine with the open lid, and it is immediately put on hold if the lid opens while working, yet saving your progress. Eight safety sensors alert the user about every potential risk in case of overheating, filter clogging, and others.

The rotary tool that comes with the Laserbox extends the capabilities of the machine with 360° engraving on cylindrical objects with a diameter of 3–70 mm. This allows you to make customized glasses, jewelry items, wine bottles, toys, and a lot of other things you can think of.

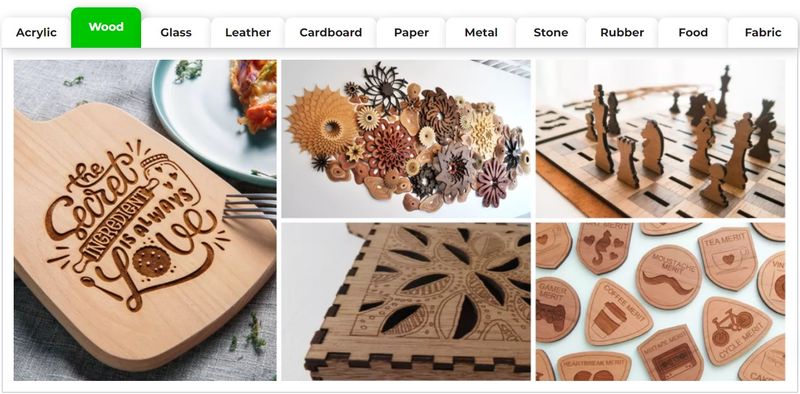

With the Laserbox CO₂ laser machine you can cut and engrave a lot of materials, such as paper, corrugated paper, cardboard, different wood types, acrylic, fabric, leather, rubber, cork, and plastic. There are also materials not suitable for cutting, but good for engraving, like sandpaper, food, glass, delrin, ceramic, coated metal, stone, and others. The full list of materials with recommended settings you will find on the manufacturer’s website.

The Laserbox comes fully assembled and all you need to do is connect the exhaust pipe, take its other end out of the window, plug in the power cable, and turn on the machine with the Start button.

To connect the device to the computer, use a USB or Ethernet cable. Run the Laserbox software, select your device, and establish the connection. The use of Wi-Fi allows connecting the machine to up to 40 computers sharing the same network, which is especially convenient if the Laserbox is used by a number of people in a workshop or at school.

The Start button on the Laserbox has an LED annular indicator which changes color in different situations. After establishing a successful connection, it turns solid white.

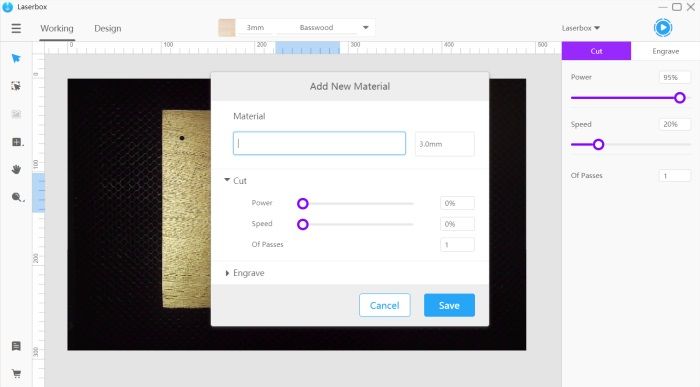

The machine is compatible with the xTool Laserbox software which runs on Windows and macOS. It provides a standard set of tools for image editing and allows for firmware updates. There are also predefined material settings which are automatically selected when using xTool official materials. Otherwise, the user can save custom settings for new materials for future use.

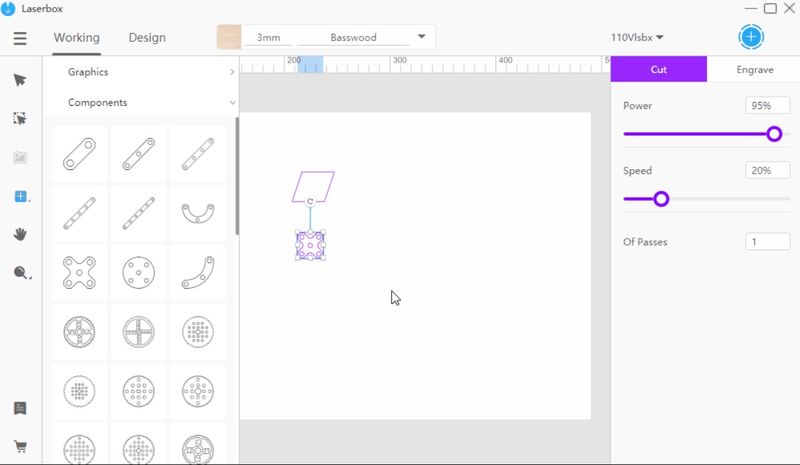

To create your design in the Laserbox software, you need to create a new project or choose to open a recent one. Here you can import images and edit them using text or shape insert function, vector paths drawing, and such common tools as align, array, and others. The Marquee tool enables image extraction from the camera by selecting the area you want to extract.

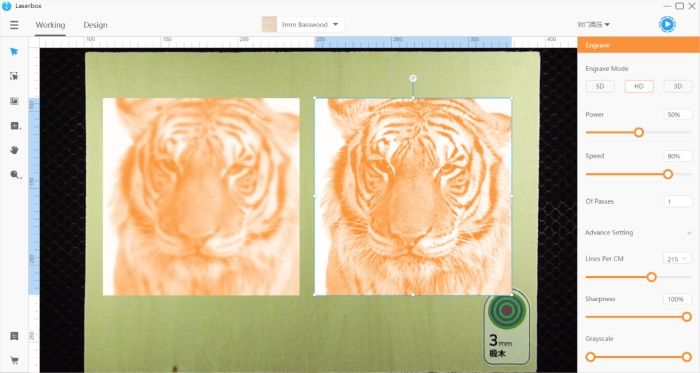

Parameter settings include engraving, cutting, and custom parameters. Bitmap images can not be cut, so only engraving parameters are available for such images. For vector images you can set both cutting and engraving parameters. You can choose processing power, speed, and a number of passes. For bitmap images you can additionally set the engraving mode, resolution, sharpness, and grayscale options.

Once your design is ready, place the material onto the working panel and check the position of your design on the workpiece. Then click Send and wait for your project to be processed. You may pause the job at any moment by pressing the Start button on the device, and then resume processing. To cancel the current job, long press the Start button.

Apart from creating a new project in the Laserbox software, you can make use of the above mentioned image extraction feature or simply draw your design and then process it.

To ensure safe operation and eliminate toxic fumes, odor, and dust, xTool offers two models of smoke purifiers to be used with the Laserbox.

The xTool Smart Smoke Purifier is connected to the Laserbox with an aviation cable and exhaust pipe. Another pipe should be connected to the air outlet of the device and taken outside. It automatically turns on when the Laserbox starts working, efficiently filtering dust particles and fumes. The compact device is equipped with a replaceable filter that lasts for 7–8 hours of continuous working, has dimensions of 260 x 528 x 268 mm, and weighs 10.5 kg.

The xTool Smoke Purifier is equipped with a large, 250 x 195 x 390 mm, three-layer filter including activated carbon and HEPA filters. It absorbs dust particles, toxic fumes, and odors. The device allows adjusting the suction power and works very quietly, with the noise level not exceeding 55 dB. The Smoke Purifier is connected to the Laserbox with an exhaust pipe and should be connected to a power source.

With the xTool Laserbox, it is easy to start creating things, and a lot of Laserbox users turn their hobby into a maker’s business, selling their projects on Etsy.

Ashley May Lacroix makes nice things using her xTool Laserbox. In this video Ashley is talking about her handmade crafts business.

These are some more of Ashley’s projects.

Credit: @on_point_creations_by_ashley / Instagram

A slightly unexpected application for the Laserbox — food decoration.

Credit: @tokyo_360 / Instagram

The xTool Laserbox 40W CO₂ laser cutter with rotary attachment is an outstanding machine combining a number of smart features, ease of use, and industrial-grade performance. Due to its stylish design and safe operation, the Laserbox can be used in any environment, be it a living space, classroom, or workshop.

Update your browser to view this website correctly. Update my browser now

Write a comment