The FLUX HEXA is the latest addition to the company’s line of laser cutting and engraving machines, targeting the professional market. With its 33% larger working area, compared to the Beambox Pro model, the increased laser tube power and lifespan, and the unbelievable engraving speed of 900 mm/s, the HEXA combines incredibly high performance and ease of use, which makes it an ideal tool for those starting or expanding an engraving business.

This is Top 3D Shop, and today we are going to review the FLUX HEXA CO₂ laser cutter and engraver, the company’s flagship designed for fast and efficient mass production.

With the FLUX HEXA launch at the end of 2021, the company has turned towards the professional market still more, providing their customers with all the functions needed for efficient and smooth workflow.

The name HEXA has not been chosen accidentally and stands for six key features of the machine that ensure its high performance and versatility.

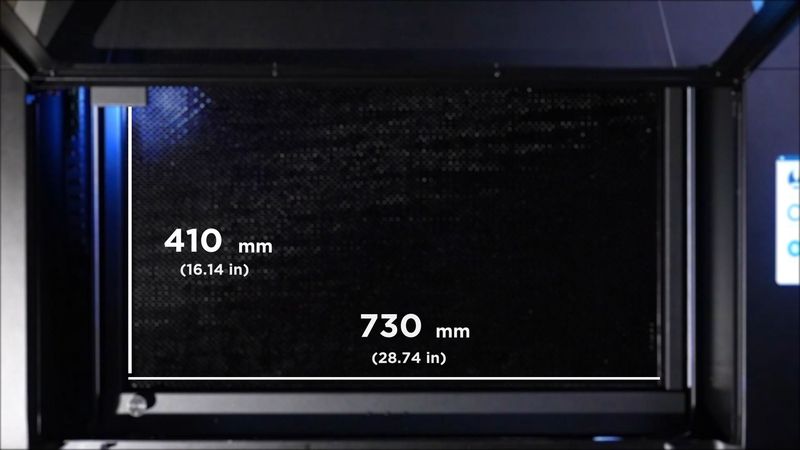

The working volume of 730 x 410 x 125 mm is 33% larger than that of the Beambox Pro model. Such capacity meets the demands of any business project, allowing cutting and engraving bigger items or multiple objects at a time.

The machine is equipped with a new Cortex M4 core chip and operates three times faster than its predecessors, reaching an incredible engraving speed of 900 mm/s.

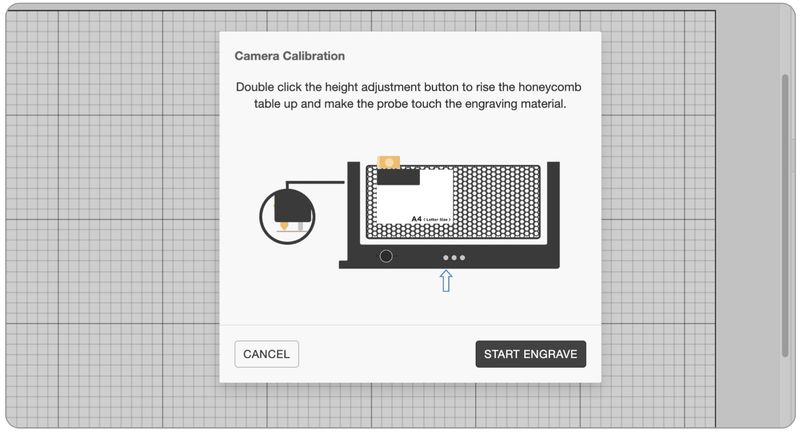

The smart autofocus function with the BLTouch probe ensures consistent accurate results every time you are using the machine. You only need to double-tap the autofocus button, and the electrically elevated platform will be automatically adjusted to the optimal height.

FLUX pays great attention to safety, which becomes especially important if the machine is being used at schools or universities. The built-in safety sensors warn the user in case of any unplanned movement, overheat, or if the material accidentally catches fire, and the operation is put on hold at once. The open lid will also make the machine pause, and the process resumes only when the lid is closed.

The 60W powerful CO₂ laser tube has an increased lifespan of 10,000 hours and ensures long high-performance operation without additional costs.

Last but not least is various connectivity options and the intuitive and easy-to-use Beam Studio software which now has the web version and the Beam Go mobile app, allowing for the use on any platform.

There are even more smart features that make the HEXA an outstanding cutting and engraving machine, and we will take a closer look at them further in our review.

The package contains the FLUX HEXA and an accessory box with all the additional tools. Here is the full list of items you will find in the box:

For some items, package content may change. In case of any questions, please get in touch.

The machine comes fully assembled, so you only need to complete a few simple steps before you are ready to start. The first thing to do is connect the power cord. Then you need to attach the vent hose to the exhaust port of the machine using the supplied clamp. Run the other end of the hose out of the window to avoid dust and hazardous fumes while working.

Now turn on the device and set up the Internet connection. You can use the built-in Wi-Fi module, Ethernet port, or connect the HEXA to the PC via a USB cable.

An important step is to fill the water tank to 80% with distilled water to ensure the proper operation of the cooling system. You will find the detailed instructions in the video.

The FLUX HEXA is equipped with a built-in 2 MP camera providing the live view of the working area — a really useful feature as it allows you to precisely line up your design with the physical object. It is recommended to calibrate the camera before the first use of the preview function to get the most accurate view of what you are about to engrave.

In the Beam Studio software go to Menu > Machine, then select the name of your HEXA and choose the Calibrate Camera option. Follow the step-by-step instruction to complete the calibration process or watch the tutorial below.

In the Beam Studio software go to Menu > Machine, then select the name of your HEXA and choose the Calibrate Camera option. Follow the step-by-step instruction to complete the calibration process or watch the tutorial below.

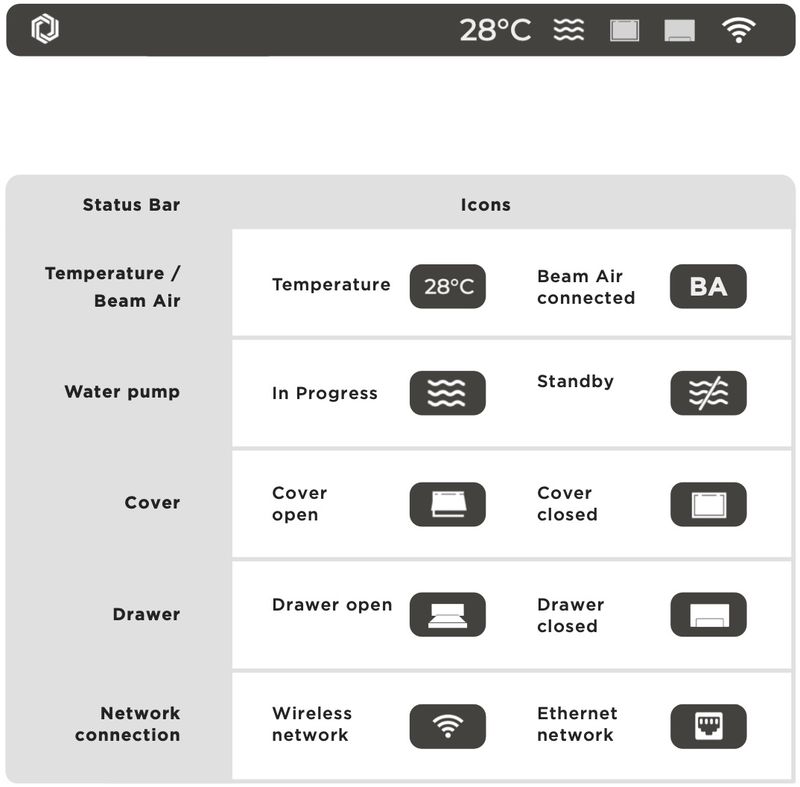

The HEXA features a 7" touchscreen that allows adjusting the machine settings and checking the current status of the device and network connection, as well as gives access to the maintenance menu and the help center. The status bar on top of the screen shows the current temperature, the water flow in the cooling system, the lid and tray opening/closing status, and the network connection type.

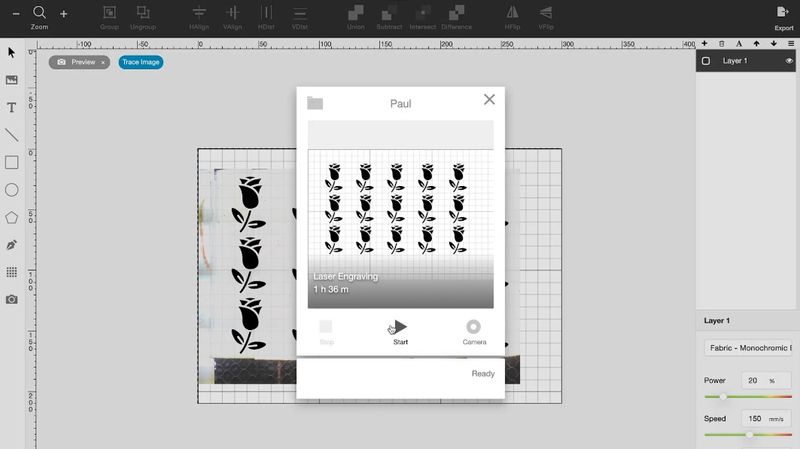

To start engraving, you need to transfer the working task to the machine, which you can do either via the Beam Studio software or using a USB stick. After you select the file from the Start menu, you will see the image preview and the estimated processing time as well as the current power and speed rate. The HEXA allows adjusting the power and speed right on the go, at any moment of the process.

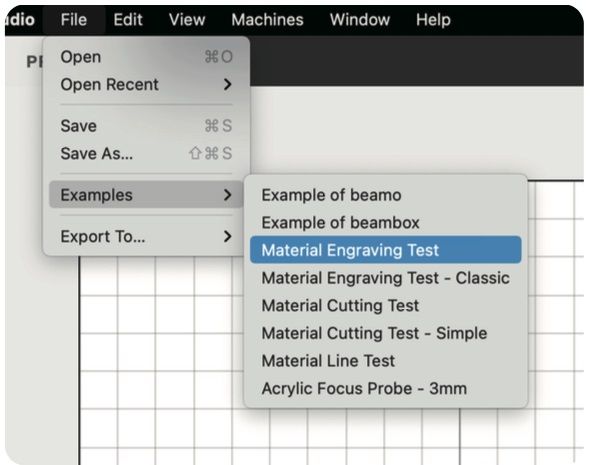

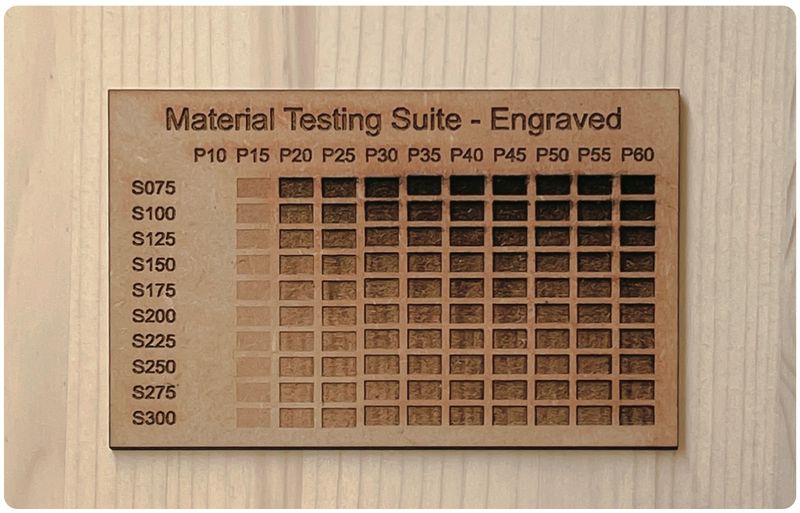

Beam Studio provides presets for cutting and engraving various materials. You may also want to do the test when working with a new material to find the optimal settings before you start the project. In the Menu > File > Examples > Material Engraving Test there are test files for both cutting and engraving.

And this is what the test result looks like.

The table below shows the list of compatible materials both for cutting and engraving.

|

Material |

Cut |

Engrave |

|

Wood |

up to 10 mm |

+ |

|

Acrylic |

up to 10 mm |

+ |

|

Leather |

up to 6 mm |

+ |

|

Cardboard |

up to 7 mm |

+ |

|

Fabric |

up to 20 mm |

+ |

|

Rubber |

+ |

|

|

Anodized aluminum |

+ |

|

|

Glass |

+ |

|

|

Cement |

+ |

|

|

Stone |

+ |

|

|

Stainless steel (with spray) |

+ |

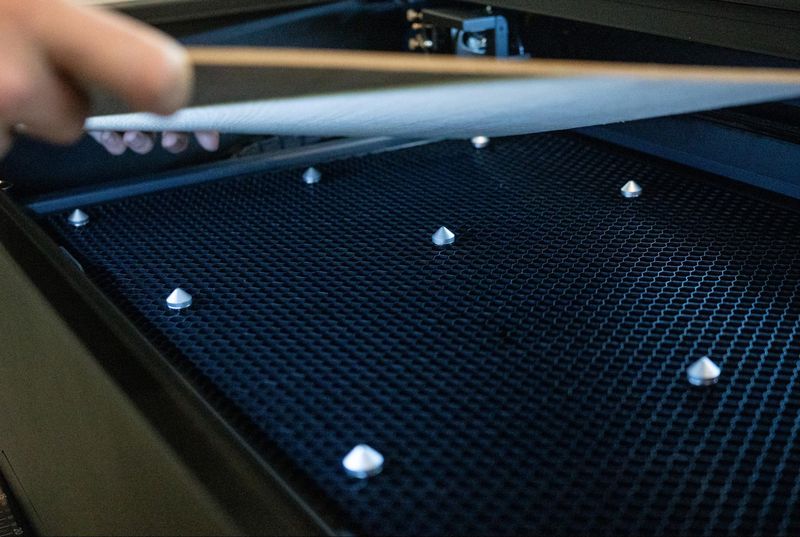

The machine comes with a set of ten magnetic cone spacers which are placed on the honeycomb platform to provide space between the material and the platform, thus allowing you to avoid burn marks on the back side of the material while cutting, and get the clean edges.

A convenient built-in tray collects the waste and facilitates the cleaning process.

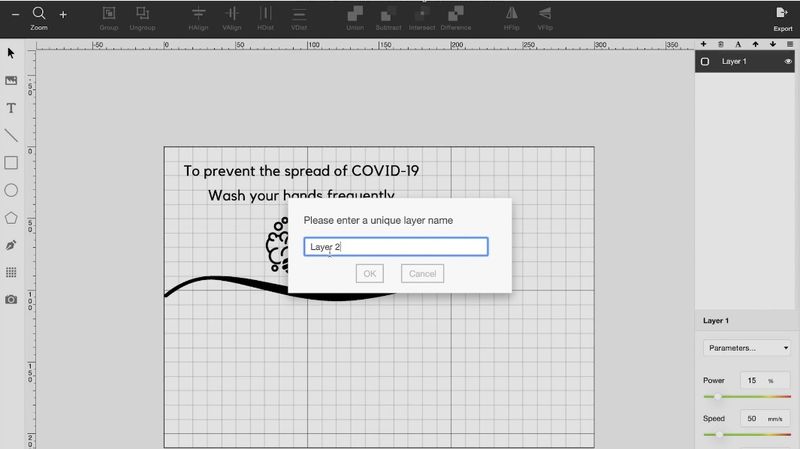

The FLUX HEXA comes with the proprietary Beam Studio software compatible with Windows, macOS, and Linux. The software allows you to import various file formats, such as JPG, PNG, SVG, DXF, AI, and PDF, and provides a decent number of editing tools and various material presets. While editing your design, you may define multiple layers, so the engraving and cutting jobs can be performed in one project. Each layer can be engraved with different settings, such as speed and power. It is always better to do the engraving first and then proceed with cutting.

You can set up the engraving resolution, which defines the spacing between the lines and corresponds to 0.2 mm / 125 dpi, 0.1 mm / 250 dpi, 0.05 mm / 500 dpi, and 0.025 mm / 1000 dpi. The higher resolution lets you have finer details but increases processing time.

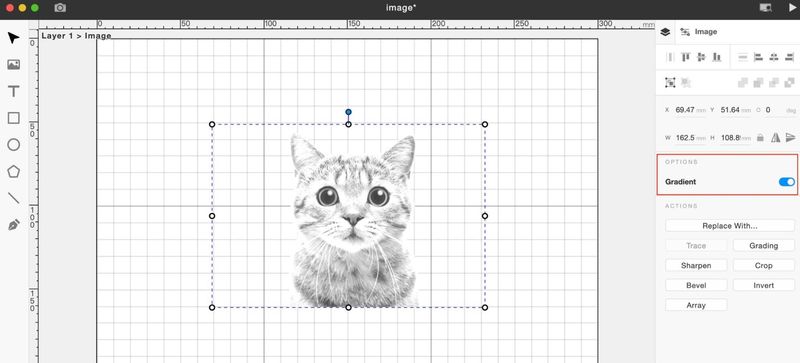

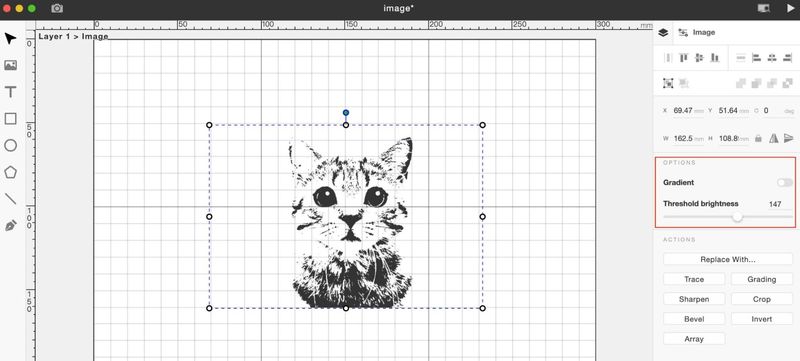

The Gradient function allows you to engrave grayscale images, which is especially helpful for photos, for example. Disabling this feature will transform your image into a monochrome one.

Gradient on

Gradient off

For more complex projects with sophisticated shapes and a lot of details, you can use a number of design software and then export your design to Beam Studio. The list of compatible software includes Adobe Illustrator, Adobe Photoshop, Affinity Design, Autodesk AutoCAD, SketchUp, SolidWorks, Sketch, Corel Draw, and Rhinoceros.

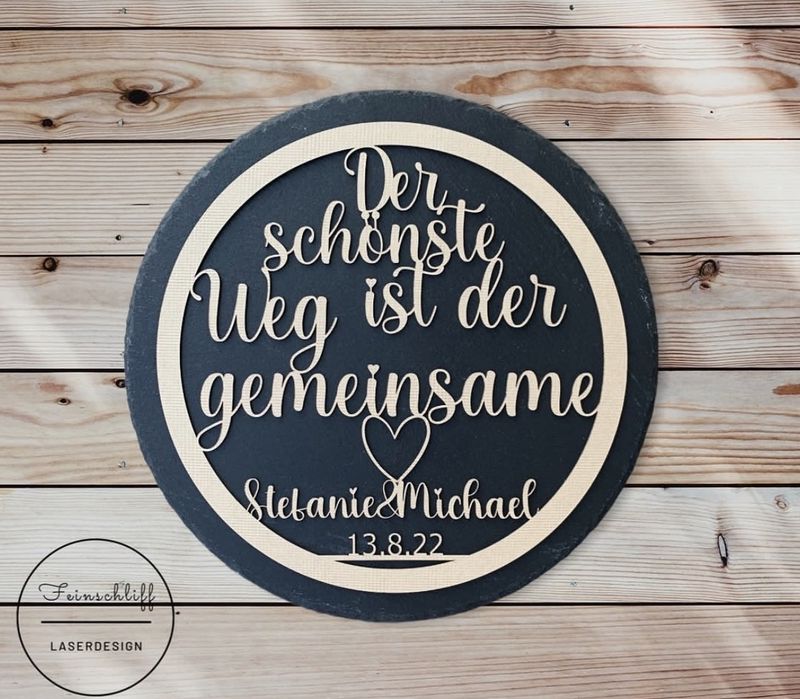

The FLUX HEXA is a laser cutter and engraver ideal for the creators wishing to start or expand their business, as it allows them to work more efficiently and always be sure of the perfect result. The machine is great for producing customized items, like souvenirs, toys, accessories, interior design objects, or jewelry. It is also equally suitable for creating precise architectural models or being used as an incredible educational tool in the classroom.

Credit: @3dprintingwinkel.be / Instagram

Credit: @feinschliff_laserdesign / Instagram

Credit: @feinschliff_laserdesign / Instagram

Credit: @gaafflaserwerk / Instagram

Credit: @cameo_laser / Instagram

The FLUX HEXA laser cutting and engraving machine is a highly versatile tool featuring high performance, ease of use, and a bunch of professional-grade features. Due to its exceptional characteristics, the machine will become a perfect choice for small business owners as well as individual makers and designers wishing to expand their creative opportunities.

Update your browser to view this website correctly. Update my browser now

Comments