The Original Prusa i3 MK3S+ is the latest iteration of Prusa Research’s legendary i3 FDM 3D printer. Since the release of the Original Prusa i3 in 2015, the printer has undergone a lot of changes, but it still adheres to the company’s open source philosophy and, like other Prusa products, offers a unique user experience and great attention to detail.

This is Top 3D Shop, and in this review, we are going to find out what changes the “plus” in the printer name adds to the i3 MK3S model, and how you can upgrade it to get a more versatile and exciting printing experience. Read on to learn more.

The Original Prusa i3 MK3S+ is a remarkable FDM 3D printer from the well-known Prusa Research company, founded in 2012 by a Czech inventor Josef Prusa. In 2010, Josef Prusa designed the Prusa Mendel 3D printer as part of the open RepRap project. Its third iteration, featuring among other upgrades a completely new frame, appeared in 2012 and evolved into the Original Prusa i3 model, launched in 2015.

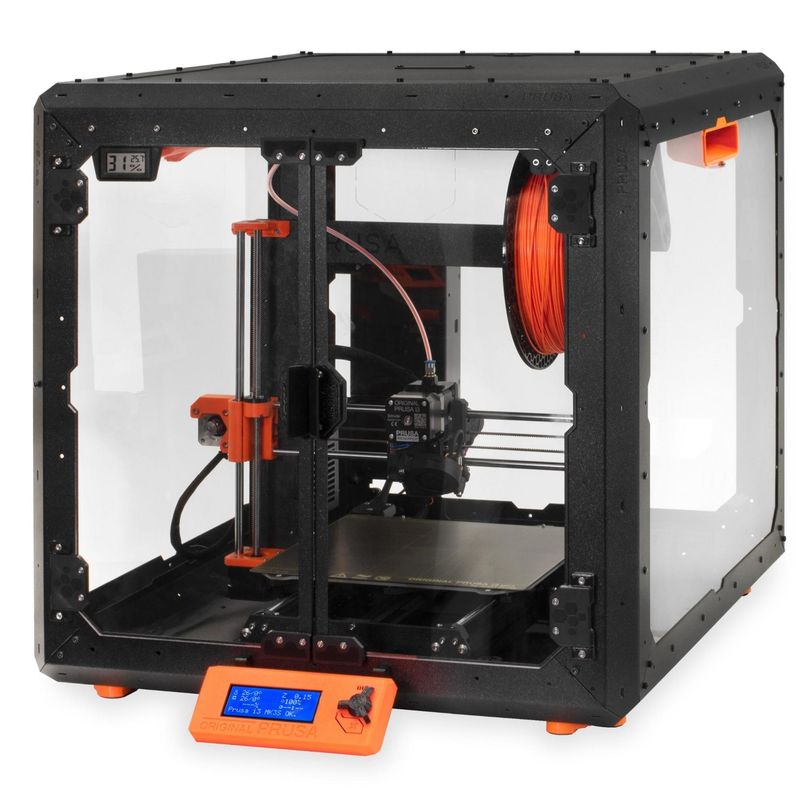

The latest generation of the famous machine is, probably, one of the best open-frame FDM 3D printers in the market. Equipped with a build volume of 25 x 21 x 21 cm, the i3 MK3S+ provides consistent high-quality printing results with a wide variety of filaments. The i3 MK3S+ is built on the 8-bit Einsy Rambo board, featuring TMC2130 silent stepper motor drivers, allowing for sensorless XY homing, live Z-axis adjustment, power panic function, and silent operation with an even quieter Stealth mode (though at the cost of slightly increased printing time).

There are two shipping options available for the Original Prusa i3 MK3S+, which are a DIY self-assembly kit or a more expensive fully assembled version.

Speaking of the changes in the i3 MK3S+ over the previous MK3S model, we should notice that there are just a few, and none of them is crucial. The improvements are mostly minor design tweaks and aimed at a bit more reliable and smooth user experience with the printer.

Like with the Prusa MINI+ upgrade, one of the improvements is the new SuperPINDA sensor for automatic mesh bed leveling function. Another upgrade, similar to the MINI+, is metal clips for Y-axis bearings instead of previously used U-bolts. And there is also a set of plastic holders for smooth rods to replace zip-ties used before the upgrade.

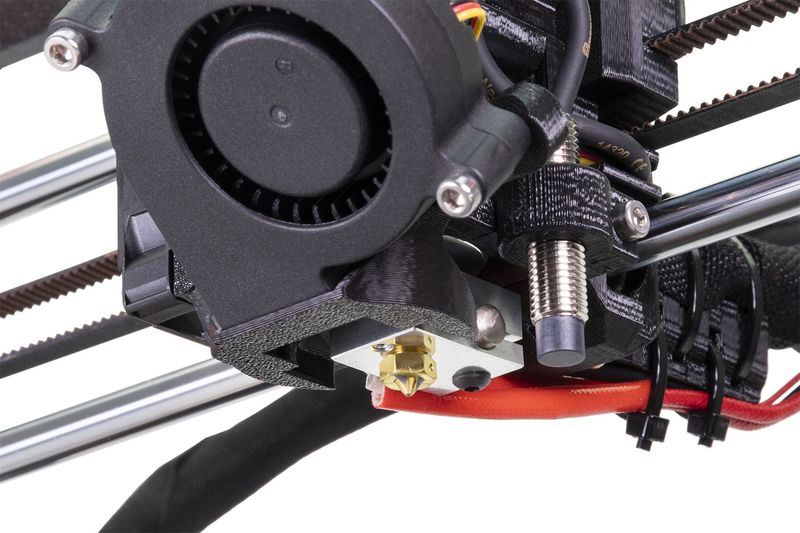

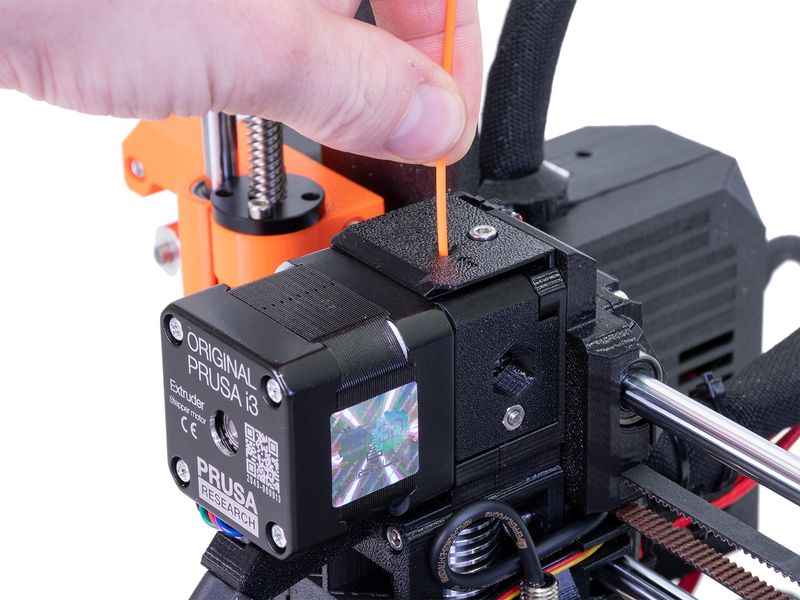

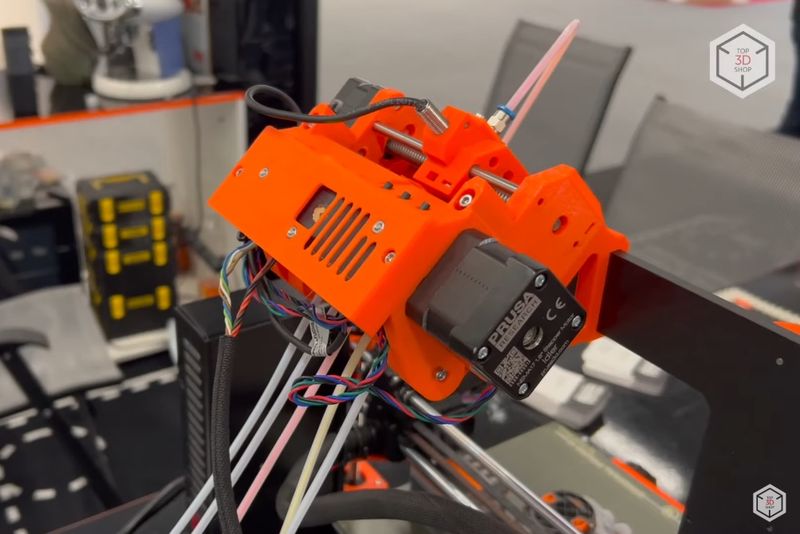

Other changes concern the i3 MK3S+ extruder. The filament path has become tighter for better handling of flexible materials, and the idler door now opens wider to provide an easier access to the Bondtech gearing. The fan shroud now has two attachment points instead of one for better cooling and improved heat resistance of the extruder parts.

The owners of the Original Prusa i3 MK3 or MK3S can purchase the MK3/S to MK3S+ upgrade kit. Note, that plastic parts are not included in the upgrade kit, and you need to 3D print them on your own. A spool of PETG filament is included in the kit.

The new SuperPINDA sensor is used as a probe for automatic mesh bed leveling instead of the P.I.N.D.A. V2 installed on the i3 MK3S model. The new sensor is temperature-independent and does not need a thermistor, which ensures more accurate sensor performance while measuring the proximity to the build plate. It is also equipped with a higher quality more durable cable.

The Original Prusa i3 MK3S+ is equipped with an in-house developed direct drive extruder with Bondtech dual-gear filament feeding and E3D V6 hotend.

Reaching a maximum nozzle temperature of 300 °C, the i3 MK3S+ can print not only with common filaments, such as PLA, ABS, PETG, and others, but also with engineering-grade nylon and PC. It is also compatible with more exotic composite materials, like metal or wood-filled thermoplastics. The extruder is equipped with a filament runout sensor. As the machine sports an open-frame design, you may want to add an optional enclosure to reliably print with high-temp materials.

Powered with 24V, the print bed quickly heats up to 120 °C. The bed is equipped with neodymium magnets that firmly hold the swappable double-sided print sheets with different surface textures. There are three variants you can choose from, namely the Smooth, Satin, and Textured Steel Sheets. Each of them works better with specific filament types and gives a different first layer surface finish. All print sheets are flexible and can be bent for easier printed part removal.

First layer, printed on the Smooth, Satin, and Textured sheets (left to right)

Featuring the power loss recovery function, the Prusa i3 MK3S+ saves user’s time and material. In case of a sudden power outage, the printer stops heating the print bed and extruder and saves the print in order to resume from where it left off, when the power is back on.

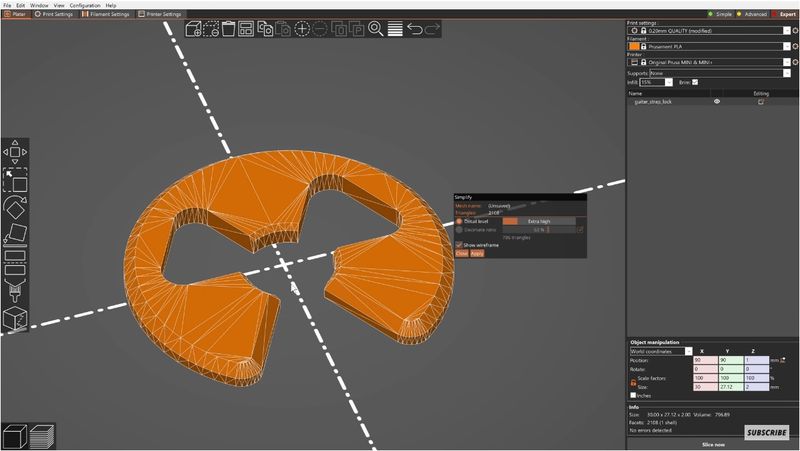

Prusa Research has developed the PrusaSlicer software recommended for use with Original Prusa machines. The software has a large library of optimized profiles for proprietary and third-party materials and 3D printers. It also provides various print settings profiles for printing with different quality and speed values. The intuitive and easy-to-use program interface offers Simple, Advanced, and Expert modes. In Simple mode, you can configure only basic printing parameters, which is convenient for beginners not to be overwhelmed by a lot of complicated settings. The Advanced and Expert modes allow you to fine-tune the printer’s settings more precisely.

Those who want to create more sophisticated projects with the Prusa i3 MK3S+ can purchase the optional Multi Material Upgrade 2S (MMU2S) kit, a multi-material addon allowing printing with up to five colors at the same time. The MMU2S is an upgrade over the MMU2.0, featuring easier calibration process, a new filament sensor, and a filament buffer designed to prevent filament tangling. The device comes with a direct drive feed with a single PTFE tube and a motorized selector head with a built-in blade for cutting off the filament in case it gets stuck while unloading. Apart from PLA, PETG, or ABS, the MMU2S can build soluble support structures using PVA or BVOH filaments. In a single mode, the MMU2S works just as a usual i3 MK3S+ 3D printer.

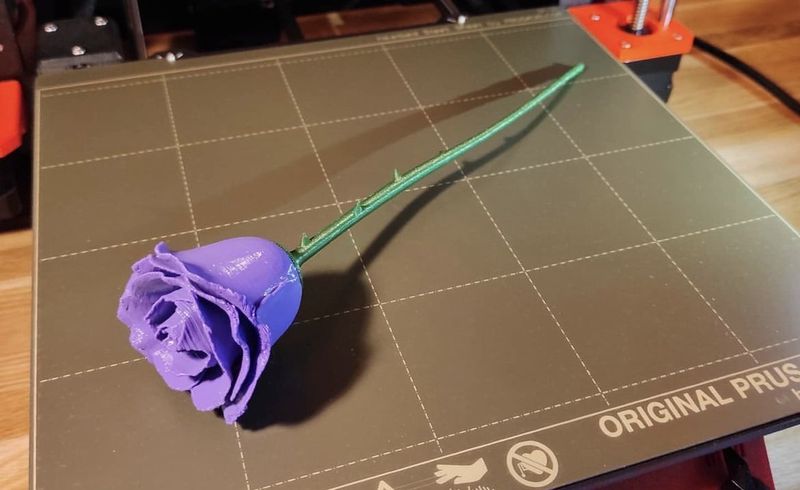

Below are some nice examples of models printed on the Original Prusa i3 MK3S+.

Credit: @m_p_3d / Instagram

Credit: @3d_druck_helfrecht / Instagram

Credit: @kohma.props / Instagram

Credit: @poly_the_3d_printist / Instagram

Credit: @poly_the_3d_printist / Instagram

Credit: @creyczak / Instagram

Being one of the best options in its price category, the Original Prusa i3 MK3S+ offers outstanding print quality, great usability, and incredible customer support, traditional for the Prusa Research company. The Prusa ecosystem including, apart from the printer itself, the optimized PrusaSlicer software, Prusament filament line, and vast user community ensures a fantastic printing experience both for beginners and advanced makers.

Update your browser to view this website correctly. Update my browser now

Write a comment