The Prusa Research company was founded in 2012 by Josef Prusa, a Czech maker and inventor. Since the very beginning, the company’s 3D printers have been designed with makers in mind, providing a lot of smart features for a smooth and intuitive printing process. The company has always supported and developed the idea of completely open-source architecture of their machines, and today the Prusa users community is one of the strongest in the additive manufacturing market.

This is Top 3D Shop, and in this article, we are going to review the Original Prusa MINI+ FDM 3D printer and see how it is different from the previous MINI model.

The Original Prusa MINI+ is the most compact of the Prusa FDM 3D printers, made for beginners. However, its incredible print quality and a carefully thought-out design with a lot of useful functions meet the requirements of more experienced users who do not mind its limited build volume of 18 x 18 x 18 cm. The machine is also ideal for schools as it combines reliable print results with extreme ease of use and does not take much installation space.

The MINI+ features a streamlined “single-arm” design with a rigid aluminum extrusion frame that prevents any possible vibrations during printing, and 3D printed plastic parts. The use of a Bowden extruder with a 3:1 gear ratio reduces the load on the X-axis, adding to printing stability.

There are two available shipping options for the MINI+, which are a semi-assembled version or a DIY kit. The former comes with a printed assembly manual and basically requires connecting three main parts of the printer. For the kit version, the clear and detailed assembly instructions can be found on the manufacturer’s website. And you are sure to find a bag of Haribo bears in the box — which you should empty by the end of the assembly process. Do not miss these steps in the assembly instruction!

The MINI+ does not differ much from its predecessor, the MINI model, which is no longer produced. In fact, there are two things that differ, one of them being a new SuperPINDA mesh bed leveling sensor. This temperature-independent probe does not require a thermistor and is much more efficient than the M.I.N.D.A. sensor used in the MINI model. SuperPINDA allows for precise auto bed leveling, compensating for slightest unevenness of the print bed surface. The user is only left to adjust the Z-axis height by printing a calibration layer, and then always get a perfectly flat first layer with strong adhesion.

The other upgrade of the MINI+ is not that obvious and made for those who will prefer the self-assembly kit version of the printer. The new design of Y-axis bearing clips simplifies the assembling process and provides slightly better support for the bearings.

If you already have the Prusa MINI model, you can upgrade to the MINI+ version by purchasing the MINI to MINI+ upgrade kit which contains the SuperPINDA sensor.

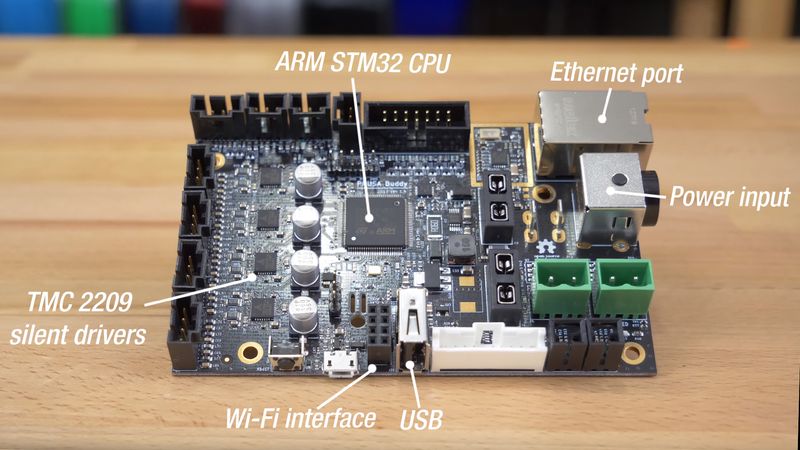

The MINI+ features a custom-made 32-bit Buddy motherboard based on the ARM STM32F407 chipset and equipped with silent Trinemic 2209 drivers, making for sensorless X and Y homing and quiet operation. The use of a 32-bit control board makes it possible to employ the print farm management software in case you are going to print a lot and build a farm of MINI+ machines. It also features an Ethernet port and has ESP support allowing you to install an optional ESP Wi-Fi module to extend the connectivity options. Besides, the use of the Buddy board provides a lot of opportunities for further upgrades.

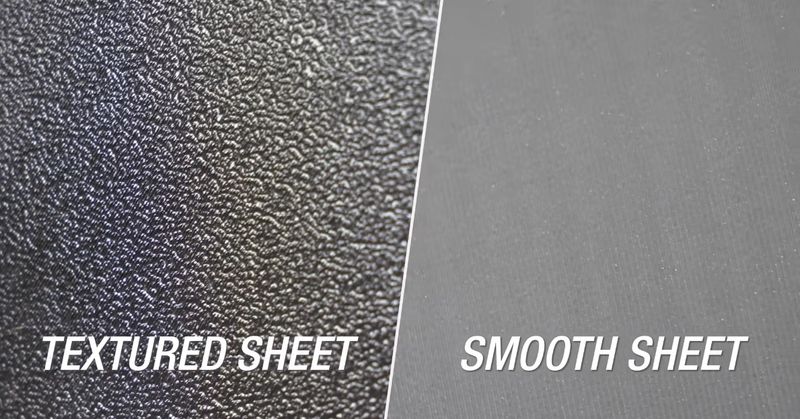

The magnetic print bed of the Prusa MINI+ can heat up to 100 °C for more reliable printing with ABS-type filaments. To facilitate printed parts removal, the bed is equipped with flexible spring steel sheets with different surfaces, such as smooth, textured, or satin sheets, each one suitable for specific filament types. Besides, using swappable build plates saves your time in case of non-stop printing, as you can start building a new model immediately after you take the print sheet with the finished one out of the printer.

Equipped with a 2.8" 65k-color LCD screen, the Prusa MINI+ is conveniently operated due to its simple and well-organized user interface. The display is not touch-sensitive and uses a rotation knob that can be pressed to confirm the selection.

As long as the Original Prusa MINI+ is an entry-level machine, it provides an incredibly streamlined and user-friendly printing experience even for beginners. On inserting a USB drive with a sliced 3D model into the USB slot, you will see the preview window and can immediately start printing by a single click of the knob.

Depending on the shipping option, the Prusa MINI+ comes either as pre-assembled main printer parts, requiring minimal time and effort to assemble, or as a set of all the necessary components for self-assembly, all well-packed into numerous boxes and bags and labeled for your convenience.

Credit: Mason's Workshop / YouTube

Apart from that, in the box you will find a PLA filament sample, all the necessary tools and screws, a 3D Printing handbook and an assembly manual, a USB drive with sample models, and a bag of Haribo bears.

One of the printer parts you will need to assemble is a 3D printed spool holder. Instead of a conventional spool holder mounted on the printer, the MINI+ uses a kind of a bearing for a spool of filament that is placed beside the printer. This design is quite handy but takes up extra space on the table.

There are different custom-made solutions for placing the spool on top of the Z-axes or on the printer side. One of them is a 3D printed base that saves space near the printer and just looks cool. Watch the video below.

Equipped with a 0.4 mm diameter nozzle that can heat up to 280 °C, the MINI+ can print with a wide range of filaments, including PLA, ABS, ASA, PETG, PVB, PP, flexible, and other materials produced by Prusa Research and third-party manufacturers. For models requiring a higher level of detail, the user can switch to an optional 0.25 mm nozzle.

Look at these accurate models, printed on the Prusa MINI+.

Credit: @whitsheupto / Instagram

Credit: @alfin3dm / Instagram

Credit: @defproceng / Instagram

Credit: @3delementprints / Instagram

Credit: @coreyprints / Instagram

The Original Prusa MINI+ is an incredible compact 3D printer with outstanding print quality and wide customization opportunities, which makes it a number one choice both for beginners and enthusiast makers. A huge advantage of buying a Prusa machine is a strong user community and one of the best customer support services in the market. The dedicated PrusaSlicer software is easy to use and offers a lot of optimized material profiles for user convenience.

Update your browser to view this website correctly. Update my browser now

Write a comment