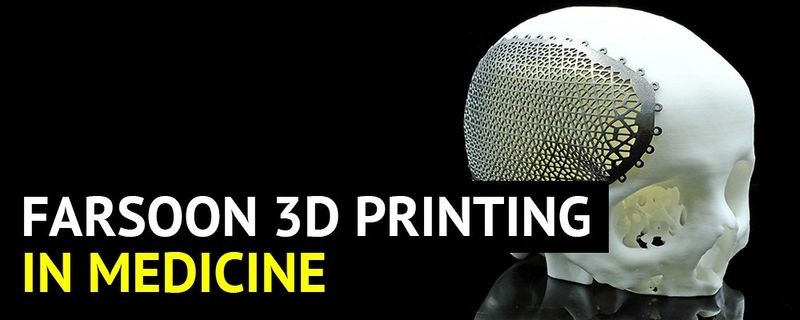

In this article, we will look at how Farsoon equipment is used in medicine, what kind of parts are usually printed with it, and what advantages 3D printing provides for endoprosthetics and dentistry.

Farsoon headquarters in Changsha National High-Tech Industrial Zone, Hunan, China

Farsoon Technologies is one of the world's largest suppliers of industrial additive manufacturing systems for polymer and metal laser sintering. The company's founder Xu Xiaoshu was formerly the CTO of DTM Corporation, now known as 3D Systems, the first company to use laser sintering in the early 1990s.

Farson HT1001P using Continuous Additive Manufacturing Solution technology

Farsoon has forged a world-class team of experts in all areas of knowledge required for producing industrial 3D printers: electrical and mechanical engineering, laser, scanning and optical equipment, thermal control systems, software development and materials for 3D printing.

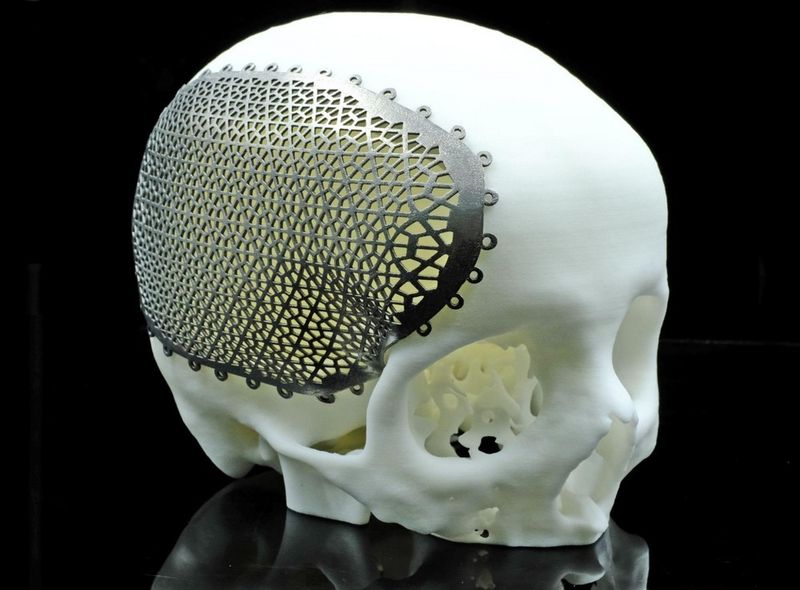

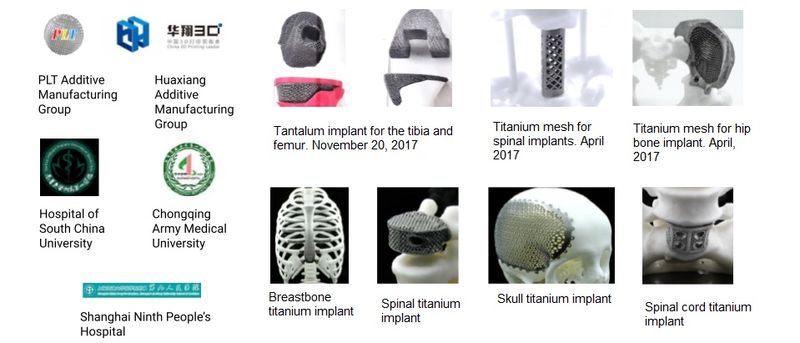

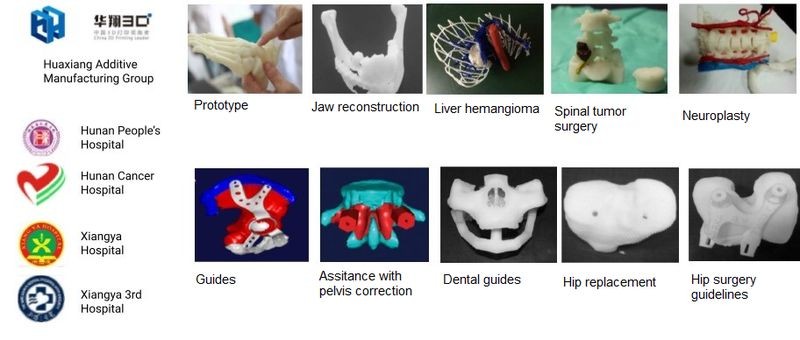

Farsoon equipment is used in medicine for 3D printing of biocompatible metal and plastic parts, mainly implantable endoprostheses, prototypes, surgical templates and guides.

Farsoon system: FS271M

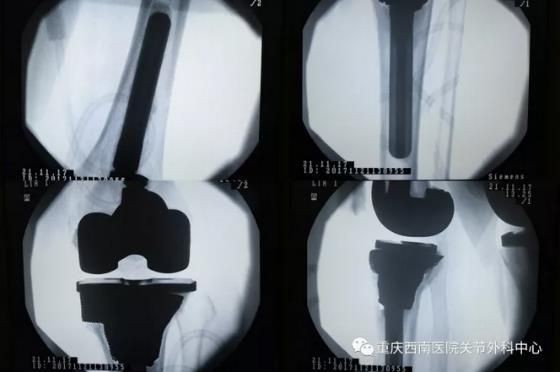

Material: Tantalum (Ta)

Partnership of Huaxiang Group and Challenge Hospital in China.

The patient is 84 years old. The biocompatibility of the 3D printed prosthesis, its strength, weight and load distribution within the entire bone is of key importance.

Tantalum is a biocompatible hard metal with a high melting point (3,020 °C), making it difficult to use in AT technologies.

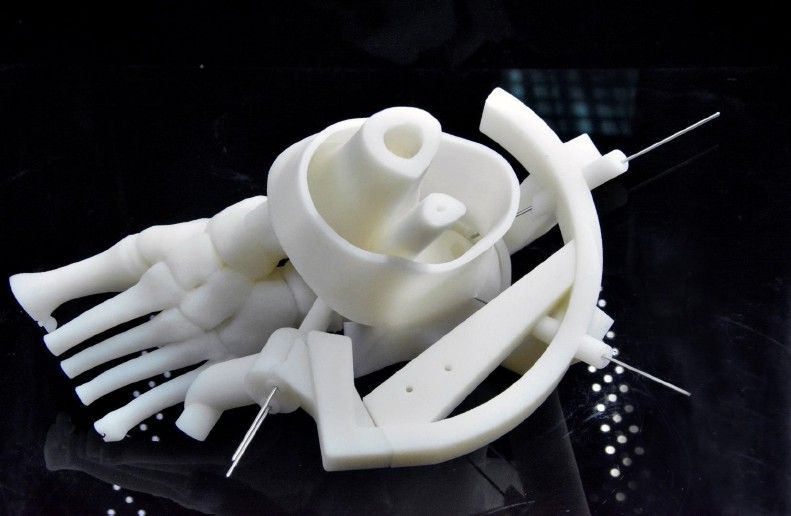

An optimized porous 3D model was created using CT imaging data, to address the patient's knee injury. At 70–90% of pours in the implant, the porous structure is reminiscent of bone tissue, reducing weight and optimizing the implant’s structure. The manufacturing process parameters have been developed specifically for tantalum and integrated thanks to Farsoon's open parameter strategy.

According to the porosity structure study, when the porosity is 70%, the compressive strength and modulus of elasticity (100-200 MPa, 3-10 GPa correspondingly) are close to the parameters of human cortical bone. A set weight of the implant can be obtained by adjusting the structure and size of the pores.

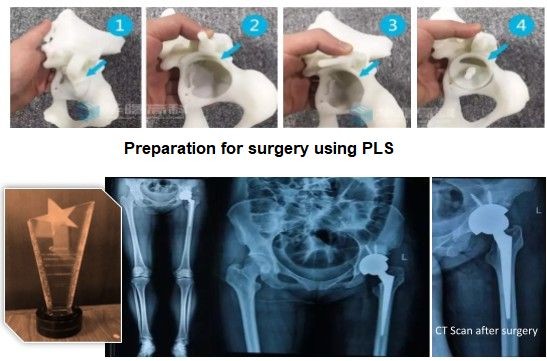

Pre-operation drill using PLS printed prototype.

A fixed guide plate was used to accurately select the insertion position prior to acetabular surgery.

Using the prototype of the acetabulum for preliminary analysis during the initial preparation, it was possible to accurately determine the angle of entry of the guides to fix the place of fasteners.

Farsoon system: SS403P

Material: FS3300PA

Result: more than 40 hip surgeries performed in 18 months with a 100% success rate.

Reduced overall operation time and sequelae rate compared to conventional surgery. Honored by the 2017 Bone Tech Innovation Award at the WOISE Conference.

Partnership with Pairui Dental (China)

Resolved issues:

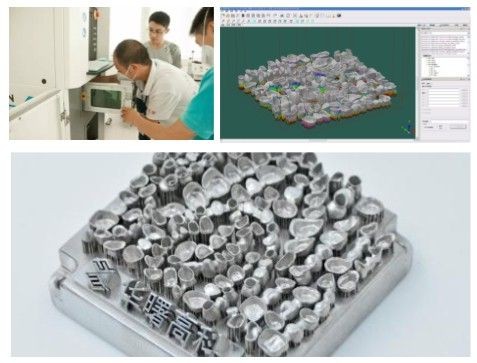

Farsoon system: FS121M

Material: CoCrMoW

Printing time: 6 hours

Solution:

|

Test part |

Test result (traditional production) |

Test result (SLM print on Farsoon FS121M) |

|

Density |

8.5 g/cm3 |

8.65 g/cm3 |

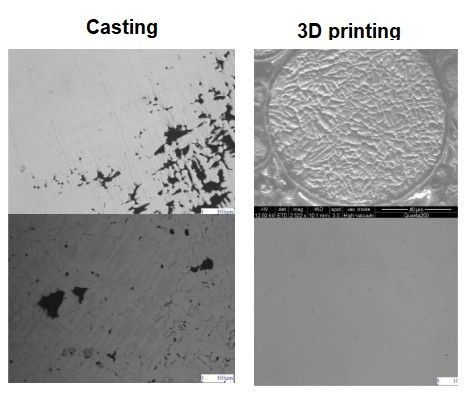

The dental crown made by 3D printing on Farsoon MLS showed higher structure density and uniformity, compared to parts produced by the conventional casting method.

The FS121M model is an affordable and compact system for 3D printing with metal powders, with access to all the necessary settings’ changes, including the size of the laser spot. The dimensions of the printer are small, and in operation it does not require a large amount of additional equipment, so it will suit even a small dental clinic or lab.

Learn more about the Farsoon FS121M.

The FS273M is a high-performance industrial production platform with advanced optical components, easy operation and access to print settings.

Learn more about the Farsoon FS273M.

The Farsoon 403P and Flight 403P 3D printers series are high-performance industrial equipment for 3D printing with plastic materials. The flexibility of settings and advanced features of these series allow the user to print with a wide range of polymer materials, including high-temperature stress-resistant plastics and composites.

Learn more about the Farsoon 403P as well as its advanced series — Flight SS403P and Flight HT403P.

Additive manufacturing is reshaping the medical industry introducing faster production methods and making individually tailored guides, prostheses and implants more accessible at a larger scale.

Farsoon systems gained a lot of ground in the industry, offering advanced medical-focused solutions at the more affordable end of the price range. Although some technology-inherent issues such as high operating and material costs and certification requirements still remain, the vast array of machines in Farsoon’s lineup allow choosing the best fitting solution for your business.

Update your browser to view this website correctly. Update my browser now

Write a comment