In this article, we will talk about Farsoon industrial metal 3D printers, the utilized printing technology, materials, capabilities, and applications.

Find out more from the review.

Farsoon Technologies is one of the largest manufacturers and suppliers of industrial selective laser sintering and metal melting systems, founded in 2009. The founder of the company, Dr. Xu Xiaoshu, has unique experience in the field. He was the CTO of DTM Corporation, now known as 3D Systems, one of the pioneers in the industrial 3D printing market.

Farsoon is constantly engaged in the development and improvement of equipment, with research projects engaging up to 40% of the staff. The company's team of experts specializing in the field of additive and related technologies, including the development of software and materials, allows Farsoon to maintain a leading position in the sector.

Today, the Chinese National Laboratory for Additive Manufacturing operates on the basis of Farsoon facilities, and the United States and European countries are among the main buyers of the company's equipment.

Farsoon industrial metal 3D printers use selective laser fusion technology. The material (a fine dispersed spherical powder made of metal or alloy) is fed layer by layer into the print chamber and onto the base plate. The laser projects a pattern on each layer fusing powder particles together. This technology allows manufacturing parts that are not inferior to casted parts in terms of their mechanical properties. Such parts can also have much more complex shapes compared to casting or milling. As a rule, the printing process is carried out in an inert gas environment, which allows the use of highly reactive materials without oxidation and deterioration of properties.

Cobalt-chromium maintains excellent mechanical properties at high temperatures and is well known for its biocompatibility.

Stainless steel with good processability and magnetization resistance.

Standard stainless steel with exceptional weldability and good corrosion resistance.

Titanium alloy. Exceptional strength to weight ratio with outstanding corrosion, heat and magnetization resistance.

Good oxidation and corrosion resistance, excellent mechanical properties; various properties can be obtained by heat treatment.

Excellent mechanical properties and biocompatibility, exceptional corrosion resistance.

Remarkable mechanical properties, good corrosion resistance; various properties can be obtained by heat treatment.

High nickel content alloy with excellent mechanical properties, resistance to oxidation and corrosion at high temperatures and loads.

Nickel-chromium alloy with excellent tensile strength, creep flow and fatigue resistance. Good resistance to oxidation and corrosion. Can be hot- and cold-formed and easily welded.

Copper alloy with excellent corrosion resistance, thermal and electrical conductivity.

Stainless steel with enhanced hardness and abrasion resistance.

Tool steel with good mechanical and welding properties.

Aluminum alloy with good corrosion resistance and high thermal and electrical conductivity.

Titanium alloy. Exceptional strength to weight ratio with outstanding corrosion and heat resistance, and non-magnetic properties.

The current Farsoon metal 3D printing lineup includes six industrial systems and their modifications. The models differ in print chamber size and features.

Print chamber: 620 x 620 x 1100 mm

Lasers: 1000W fiber laser or 4 x 500W lasers

With a 620 × 620 mm print chamber base and over a meter in height, the FS621M is one of the largest metal 3D printers in the laser metal fusion equipment market.

Metal 3D printing of products of such scale opens up new opportunities for production. It is used in the aerospace sector, oil and gas and many other industries.

The FS621M comes with one 1000W laser or four 500W lasers for enhanced productivity. It is an open platform that allows the user to customize print settings and use virtually any metal powder material available. It also has all the main advantages of previous models described below, such as a printed parts handling system, powder sifting module, and an efficient air filtration system.

Print chamber: 720 × 420 × 420 mm

Lasers: 2×500W or 4×500W

With a print area of 720 x 420 x 420 mm, combined with either two or four 500W lasers, the FS721M is able to significantly ramp up productivity in high-volume part production and large-scale 3D printing.

Advanced control software and the Farsoon Precision Scanning System ensure consistent performance across multiple laser overlap areas.

Continuous powder supply, optimized gas flow and a built-in filter module ensure metal powder melting uniformity.

Extended print process controls and real-time monitoring ensure efficiency and high-quality output.

The integrated conveyor system, cleaning station and advanced powder collection system of the FS721M ensure efficient and safe relocation of the collection cylinders (replaceable print chambers) and a completely sealed powder removal process.

Advanced calibration and electrical leveling simplify the workflow. The FS721M is an open platform offering the user the flexibility to customize print settings for industrial applications and cost-effective additive manufacturing.

Print chamber: 425 x 425 x 420 mm

Lasers: fiber lasers, 2×500W or 1×500W

With a 425 x 425 x 420 mm print chamber, the FS421M metal laser sintering system is capable of producing large metal parts from a wide range of powder materials, metals and alloys.

The large build chamber volume, combined with the multi-laser and all-digital optical system, ensures increased production speeds, while the internal rail system allows for quick swapping of interchangeable print chamber cylinders, allowing continuous production even during cleaning.

The FS421M is equipped with a new advanced industrial powder handling system. Powder feeding, 3D printing and screening are carried out in an inert atmosphere. The powerful and highly efficient air filtration system of the FS421M handles chemically active materials and employs replaceable filters.

Like all Farsoon systems, FS421M gives users complete freedom of action. This means that all the machine’s settings are unlocked for the user, and the system is compatible with third-party materials, not only the ones developed by Farsoon.

Farsoon's proprietary software is easy to use both through an advanced user interface and touch screen based production interface for everyday operation.

Print chamber: 305 × 305 × 400 mm

Lasers: fiber lasers, 2×500W or 1×500W

The FS301M was highly ranked by a customer from a US-based aircraft company:

“With surface roughnesses of less than 5 µm, exceeding the benchmarks for metal ductility and fatigue tests, the high productivity of the FS301 finally allows cost-effective metal 3D printing without sacrificing part quality.”

Dual laser projection and calibration algorithms increase assembly efficiency due to lasers’ precision control when printing one large part consisting of several small ones. Both lasers can cover the entire print area, and can be used one at a time or for selecting a dedicated laser for a particular object.

Industry-leading signal transition rates and high powder layering speeds ensure minimal delay between coats. The increased volume of the highly productive cylindrical print chamber is 305 x 305 x 400 mm.

With the built-in powder loading dock, the FS301M material feed can be carried out in an inert gas environment, which simplifies the workflow and addresses environmental concerns. A common material container is used during loading, unloading and sifting processes, which provides more convenient powder handling and relocation between stations.

Convenient features such as base plate preheating, electrical leveling and advanced vision systems ensure process stability and quality control.

The FS301M unit occupies an area of only 3.64 square meters. The filtration system can operate for up to 1,500 hours without maintenance. The settings allow to create high-density layouts with minimal lateral spacing for maximum productivity.

Print chamber: 275 × 275 × 355 mm

Lasers: fiber lasers, 2×500W or 1×500W

The FS273M is a high-performance industrial manufacturing platform. The advanced digital optics system, reliable hardware and open settings management provide the user with unparalleled freedom to create highly detailed metal 3D prints.

The FS273M is equipped with an integrated long life filtration system, increasing uptime and reducing filter replacement costs. Removable material containers carry enough powder for a full print run and ensure ease of use and serviceability.

Print chamber: 120 × 120 × 100 mm

Lasers: 200W fiber laser

The FS121M is an affordable compact system offering a choice between multiple laser spot sizes, several powder distribution blades, which, combined with a small footprint and reduced need for additional equipment, allow the FS121M to meet user workspace and material requirements as well as applications.

The FS121M is equipped with a 200W fiber laser and a fully digital projection system. These features, along with the small laser spot size, allow for the creation of intricate details and complex shapes.

Farsoon provides complete freedom to users in operating its machines. The 3D printer’s settings and powder selection are not locked to proprietary Farsoon solutions, enabling previously unimaginable levels of flexibility in MLS 3D printing.

Farsoon industrial metal 3D printers are used in all areas where accurate and fast 3D printing of metal products with enhanced strength and structural stability is required. This is particularly evident in the aircraft and automotive industries, where the highest quality of parts has traditionally been of key importance.

Many aerospace and automotive manufacturers use this equipment. The sample photos speak for themselves.

Nozzle. Material: IN718. Printer: FS271M

Air cooler cover. Material: CuSn10. Printer: FS121M

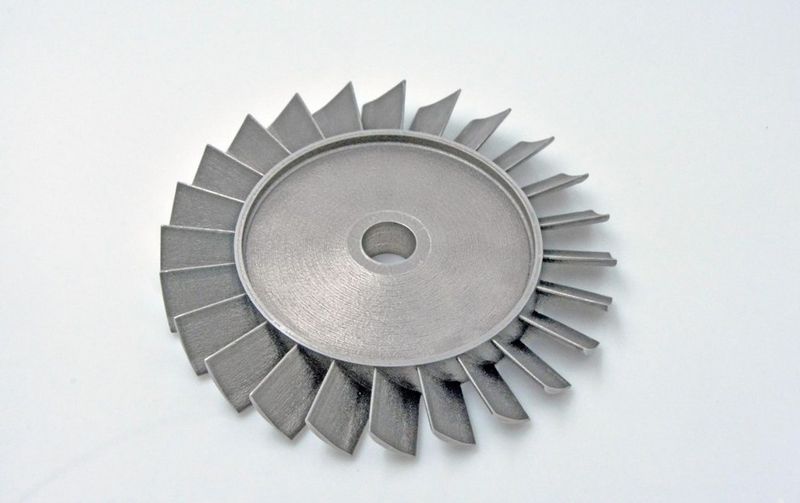

Impeller. Material: AlSi10Mg. Printer: FS271M

Combustion chamber housing. Material: 316L

Drone chassis. Material: aluminum

Turbojet impeller (in housing). Material: Ti64

Turbojet impeller. Material: IN718

Cross-section of an assembled turbojet engine model

Connecting hub. Material: 316L. Printer: FS271M

Suspension strut. Material: Ti6Al4V. Printer: FS271M

Fuel injection unit. Material: AlSi10Mg. Printer: FS271M

Electric car pedal lever. Material: aluminum

Injection system part. Material: aluminum

Bicycle stem. Material: 316L

Bicycle bracket. Material: aluminum

Bracket. Material: 316L

Bracket. Material: 316L

Bracket. Material: 316L

Vertebrae implant. Material: titanium. Printer: FS271M

Tibia and femur implant. Material: tantalum. Printer: FS271M

Pelvis implant. Material: titanium. Printer: FS271M

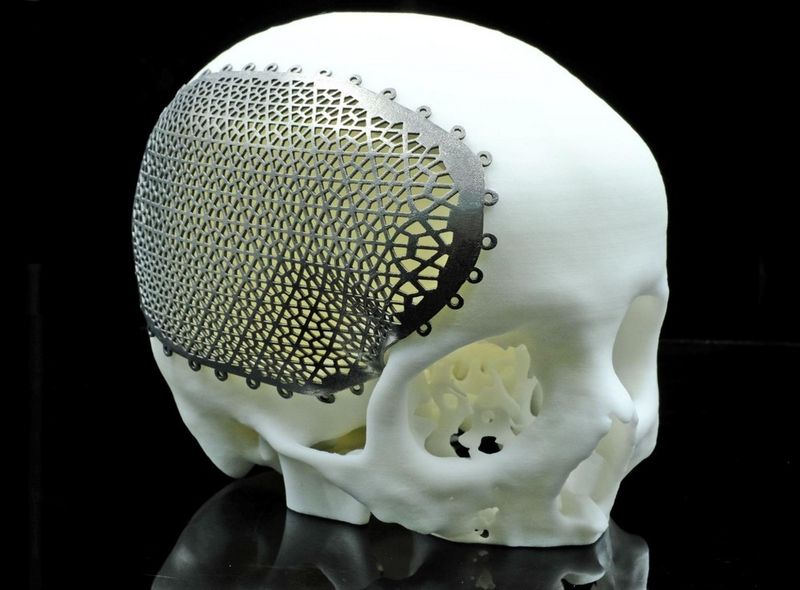

Skull fragment implant. Material: Ti64

Titanium spinal cage implant

Titanium spinal implant

Dental crowns. Material: CoCrMoW. Printer: FS121M

Dental crowns. Material: CoCrMoW

Dental crowns. Material: CoCrMoW

Removable partial denture (RPD). Material: CoCrMo. Printer: FS121M

Rings master models. Material: 316L. Printer: FS121M

Bracelet. Material: copper alloy

Metal 3D printing has been disrupting many industries in the past years offering faster production timelines and design versatility to sectors where casting and milling were used to be the main means of production. The ability to process many metals, from stainless steel to titanium alloys and others, created a feasible additive manufacturing alternative to conventional production methods. Depending on the scale and budget of your project — be it automotive, aerospace or jewelry related — the user can always find the most time- and cost-saving solution within Farsoon’s lineup of metal 3D printing systems.

Update your browser to view this website correctly. Update my browser now

Write a comment