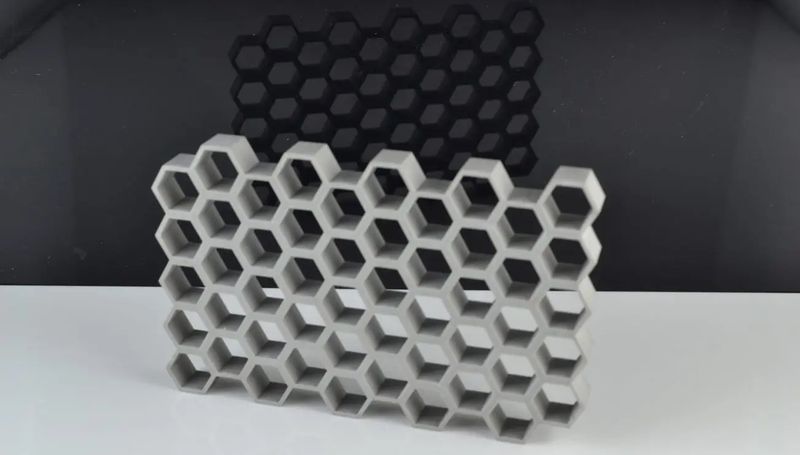

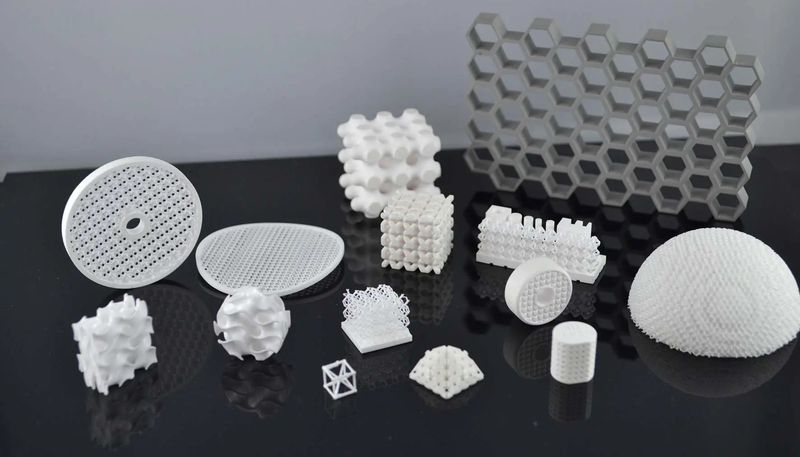

Ceramics are definitely a major step in industrial 3D printing. Compared to traditional AM techniques, these materials provide the user with greater construction flexibility, extended complexity of shapes without sacrifices in quality, and customized compositions with individual components adding certain properties to the printed items. Overall, it seems like ceramic printing has a lot to offer to those interested in both cost-effective and environmentally-friendly manufacture.

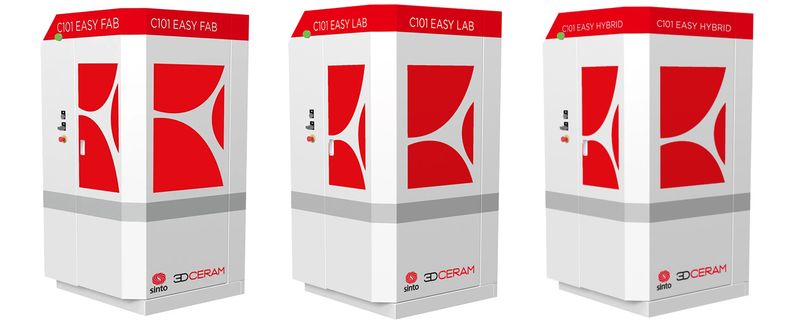

This is Top 3D Shop, and today we are going to tell you about 3DCeram Sinto — the French company developing professional-grade 3D printers working with technical ceramics and metals that boast high performance, ease of use, and eco-friendly orientation.

French company 3DCeram based in Limoges has been developing 3D printers and ceramic pastes as well as offering unique scientific expertise since 2001. From additive manufacture of ceramic parts to creation of the Ceramaker printer and further integration into the Sinto group, the enterprise has traveled a long way of creative search and self-perfection.

Currently, it is headed by Christophe Chaput and Richard Gaignon and produces several SLA and FFF printer models, including hybrid modifications, and ten proprietary printing materials with customized compositions available.

By modern standards, 3DCeram is a small research and production company. It has 30 highly qualified specialists, among them doctors, engineers, technicians, and others. Thanks to their experience and competence, the company has achieved impressive results in implementing ceramic 3D printing in various spheres, from aerospace to implantology.

Also, 3DCeram offers a number of additional services, including individual production strategy development, customer-specific ceramic formulation, and maintenance.

Due to the ease of use of 3DCeram’s equipment and high quality of finished products, the company has built a solid reputation and a well-developed partner network around the world. Among their clients are such manufacturing giants as Safran, Air Liquide, Zeiss, Thales, Swatch Group, Apple, and CHU de Limoges.

At the moment, the company produces four lineups of SLA devices that vary in terms of size, power, and functionality. Their basic differences are given in the table below:

|

C101 |

C900 |

C1000 |

C3600 |

|

|

Dimensions |

1020 x 1005 x 1976 mm |

1060 x 2250 x 2040 mm |

1150 x 1850 x 1950 mm |

2100 x 1800 x 2500 mm |

|

Weight |

600 kg |

1450 kg |

1250 kg |

4000 kg |

|

Build volume |

100 x 100 x 150 mm |

300 x 300 x 100 mm |

320 x 320 x 200 mm |

600 x 600 x 300 mm |

|

UV wavelength |

405 nm |

355 nm |

405 nm |

405 nm |

|

Layer thickness |

0.020–0.125 mm |

0.010–0.125 mm |

0.025–0.125 mm |

0.025–0.125 mm |

|

Laser spot diameter |

60 µm |

35 µm |

60 µm |

60 µm |

|

Number of lasers |

1 |

1 |

1 / 2 (optional) |

4 |

|

Electric power |

300 mW |

2 kW |

2 kW |

4 kW |

The C101 EASY model is mainly aimed at research, development, and small serial production. It comes in three versions differing in basic functionality. The most versatile of them is the EASY FAB machine that serves as an accessible introduction to ceramic 3D printing and can be further upgraded to the large-format C3600 solution. Similar to other two variations, it boasts lightweight, mobile design accessible to persons with reduced mobility and compact build volume of 100 x 100 x 150 mm. Among the printer’s unique features is a precise feeding mechanism, special system of minimum consumption of materials (SAM), peristaltic pump for smart ceramics management, and fast setup: it takes no more than 30 minutes to start the printing process. Thus, this version is perfect for quick and efficient print runs.

As for the EASY LAB device, it is intended for research and production with a small amount of substance. This objective is achieved thanks to the open parameters, dedicated Lab Mode for advanced developments, and optimized printing precision elements, both mechanical and optical. Due to the built-in SAM system, the machine is able to start a print run with only 10 ml of ceramic (in contrast to minimum 60 ml without SAM), which makes it ideal for small labs, research centers, and universities.

The HYBRID version enables multi-material printing with ceramics and metals. With this new system, it is possible to simultaneously print with two types of consumables for better reliability and support in case of complex structures requiring sacrificial layers. The printer provides flexible options for the deposition of materials, while all the necessary hybrid functions are integrated into its software allowing one to control the process without additional programs.

The C900 FLEX is a professional ceramics-based SLA 3D printer for prototyping and small-series production as a beneficial alternative to conventional AM methods. Thanks to the integrated Lab Mode, the device will also come in handy for research applications. Interestingly, it was the first company’s printer developed with their long-term industrial experience.

The model is characterized by its universal nature, advanced features, and traditional ease of use. It introduces a special system of minimum consumption of materials — SAM (Small Amount of Material), which makes it possible to start a print session with only 100 ml of ceramic. Since the company’s materials can be reused after filtering, this makes for increasingly cost-effective green manufacturing.

Also, there is a hybrid version of the model available. Like with the C101 EASY, the machine can print up to four materials at once including both ceramics and metals.

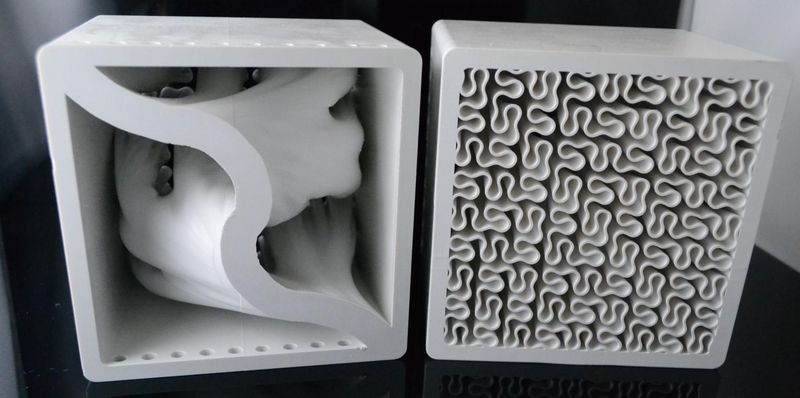

The C1000 FLEXMATIC is a relatively new addition to the company’s product line that marks their focus on semi-automatic production and introduces ceramic 3D printing to the industrial field. Being a part of the Smart Ceramic Factory concept, the machine offers a variety of handy functions: a removable tank to accelerate the manufacturing process, smart feeding with a dedicated pressure tank for uniform material distribution (up to two subsequent print runs), automatic cleaning system, and recycling mechanism for the materials used. With a two-laser version available and a large build area of 320 x 320 x 200 mm, the C1000 provides high-quality printing of robust components, increased production speed, and effective use of consumables.

The C3600 ULTIMATE model is consistent with its name: the printer represents a large-format industrial machine for mass optimization and serial production of high-quality ceramic parts. Unlike its predecessors, the C3600 is equipped with an impressive build volume (600 x 600 x 300 mm), four potent independent lasers, and a smart feeding mechanism involving a capacious pressure tank and automatic cleaning system. All these features make the device great for large-scale manufacturing with quick, automated, and environmentally friendly focus.

Moreover, one can always upgrade the smaller C101 EASY FAB model to the ULTIMATE version due to their similar feeding mechanism.

The Raptor is an industrial FFF 3D printer dedicated to producing top-quality functional parts with metal and ceramic filaments. The machine was developed in collaboration with Tiwari Scientific Instruments to which Sinto group is the main shareholder. The company is now known as 3DCeram Sinto Tiwari.

The model is equipped with a cubic build area of 200 x 200 x 200 mm that is enough to print small-to-medium parts as a whole. With the fully enclosed chamber, high-temperature capabilities, and integrated cooling system, the machine provides accurate and consistent outputs while ensuring reduced warping, temperature stability, and printing repeatability. Due to the unique extrusion head with enhanced abrasion resistance, the Raptor can smoothly print with technical ceramics (Silicon Carbide, Alumina, Zirconia) and metals, such as Titanium, Stainless Steel, and Copper.

Overall, the printer fully complies with the requirements of modern industries and aims to fulfill 3DCeram’s concept of Smart Ceramic Factory.

The M.A.T. is an innovative Multi Additive Technology device that is capable of integrating several 3D printing technologies, for example, FFF, machining, robocasting, and more depending on the user’s needs. The machine is characterized by a sufficient 200 x 200 x 200 build volume, closed chamber effective when working with high-performance engineering materials, flexible build plate ensuring easy print removal, built-in cooling function, and reliable extrusion system with high-performance components. As for the consumables supported, the FFF-version of the M.A.T. is compatible with both ceramic and metal filaments.

This recently announced breakthrough device will be a perfect tool for efficient production of end-use parts in multiple spheres, from biomedical to aerospace.

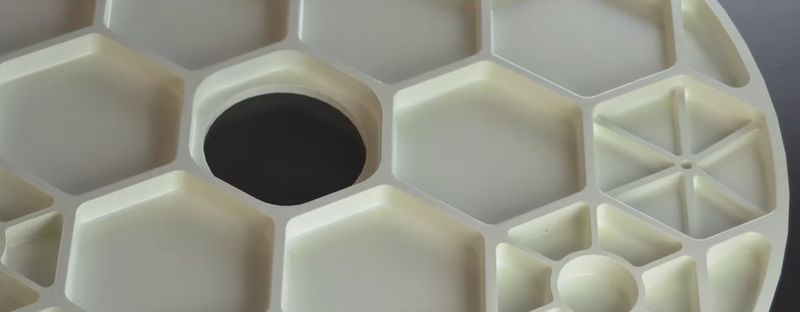

3DCeram offers their own brand of ceramic consumables to be printed on the company’s AM machines — 3DMIX. They represent ready-to-use ceramic pastes with certain properties, such as good strength, increased dimensional stability, low density, high resistance to abrasion and corrosion, great chemical stability, etc. The 3DMIX ceramics guarantee a quality level preferred by the most demanding industries. A wide selection of available materials allows the user to choose a ceramic according to their personal specifications.

Key properties: decent mechanical strength, good thermal conductivity, high electrical resistance, exceptional hardness, increased durability, chemical inertness

Application: electric insulators, laboratory and telecommunication equipment, electronic devices, foundry cores, space tools, optical instruments

Key properties: exceptional mechanical properties, chemical inertness, high durability

Application: jewelry, horology, electronic and biomedical equipment, implants

Key properties: good mechanical resistance, porous structure, excellent leachability, stability at high temperatures, compatibility with complex shapes and all alloys except cobalt

Application: foundry cores

Key properties: outstanding durability, abrasion and thermal resistance, biocompatibility

Application: implants, teeth, wear-resistant parts

Key properties: low CTE (Coefficient of Thermal Expansion), low thermal conductivity, high durability, ideal for vacuum operations

Application: optical parts for aerospace, metrology

Key properties: ionic conductivity, oxygen-ion conductivity, good thermal insulation

Application: fuel cell

Key properties: biocompatibility, bioresorbable material

Application: implants

Key properties: decent leachability

Application: foundry cores

Key properties: biocompatibility, excellent bioactivity, remarkable osseointegration

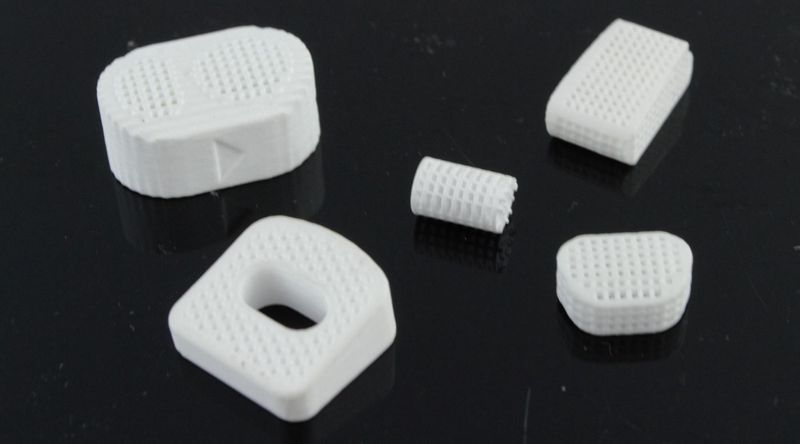

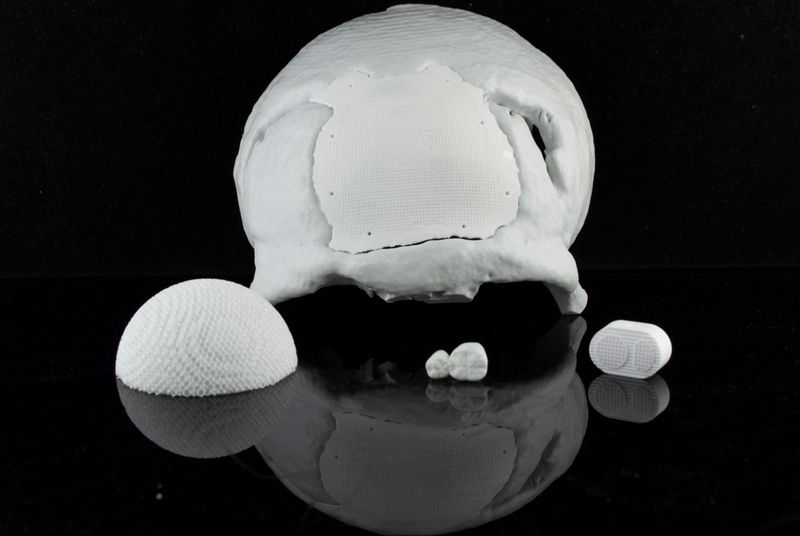

Application: tibial osteotomy wedges, intervertebral cages, cranial implants, bone substitute, spine implants, orthopedic implants

Key properties: good thermal conductivity, electrical insulation, high mechanical strength

Application: electronic devices

Key properties: excellent resistance to thermal shocks, exceptional durability and strength, low wettability against molten metals, good electrical insulation, resistance to corrosion (liquid and gas)

Application: semiconductors, heating tubes, pump and valve components

3DCeram provides with their printers a versatile software tool used for ultimate file preparation for 3D printing. This plug-in with an intuitive interface is called Build-It and includes a wide range of user-friendly and time-saving instruments making the process quick and easy: basic repair, auto-remove function, thickness analysis, duplication, Z compensation, editing shells, supports, pockets, ribs, and more. Also, the program comes with the innovative Free Link technology — a smart support adapted to complex geometries exclusive to 3DCeram. However, it works with the STL format only.

You can watch the official introductory video about Build-It to find out more about its main features and biomedical application:

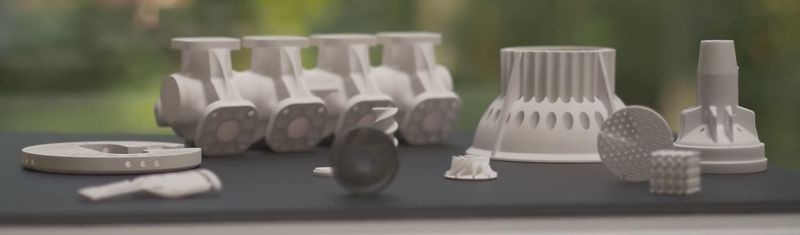

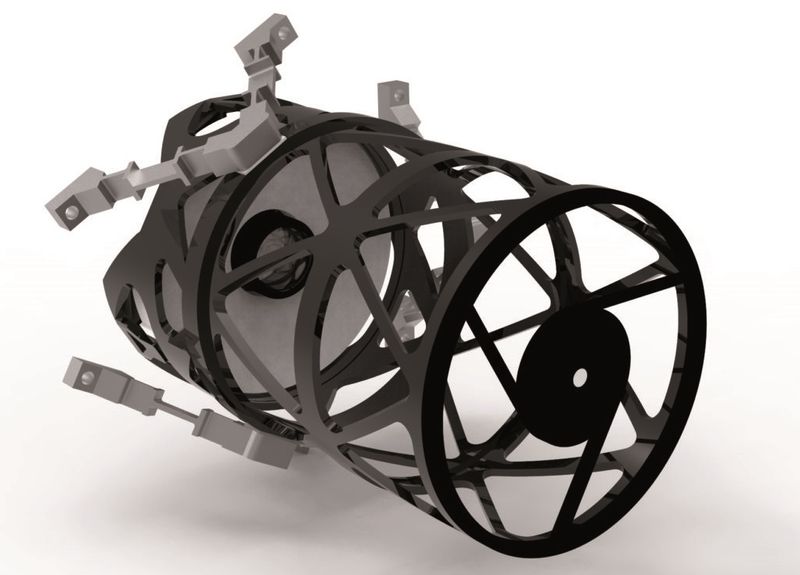

Due to their prominent physicochemical properties, such as high corrosion resistance, electrical insulation, and so on, ceramic 3D printing materials are a real find for the aerospace sector, which is always striving for new technical advances, reduced mass and development times. Here, ceramics are used to optimize the performance of high-tech space equipment, including satellites, measurement tools, optical instrumentation, etc.

For example, the weight problem is particularly acute for satellite mirrors. Still, it can be solved by additive manufacturing, ceramic 3D printing in particular. Large parts are not an issue for the C3600 ULTIMATE model with its 600 x 600 x 300 build volume.

Furthermore, 3DCeram provides a special service called 3D-AIM. It represents customized support for aerospace companies that plan to switch to additive manufacturing for their future projects. The offer includes individual strategy development for every customer.

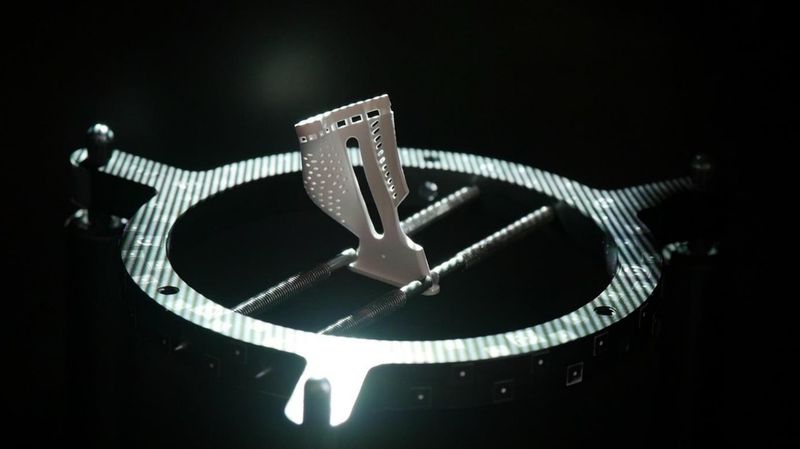

Foundry cores are an essential part of the production of turbine blades for aviation and land-based gas turbines. Currently, there is a demand for complex core design due to a need for smaller, more efficient and cost-effective engines running at higher temperatures. 3DCeram has developed a new optimized method of producing ceramic foundry cores that is far more beneficial compared to the traditional techniques due to decreased build time yet increased cost per core ratio.

Core production requirements include high dimensional accuracy, decent structural strength, surface roughness, and material porosity. All these parameters can be controlled by resorting to ceramic 3D printing. Apart from time savings and enhanced productivity, it provides flexibility in design, better responsiveness, consistent quality of produced cores, and enlarged profitability for the manufacturer.

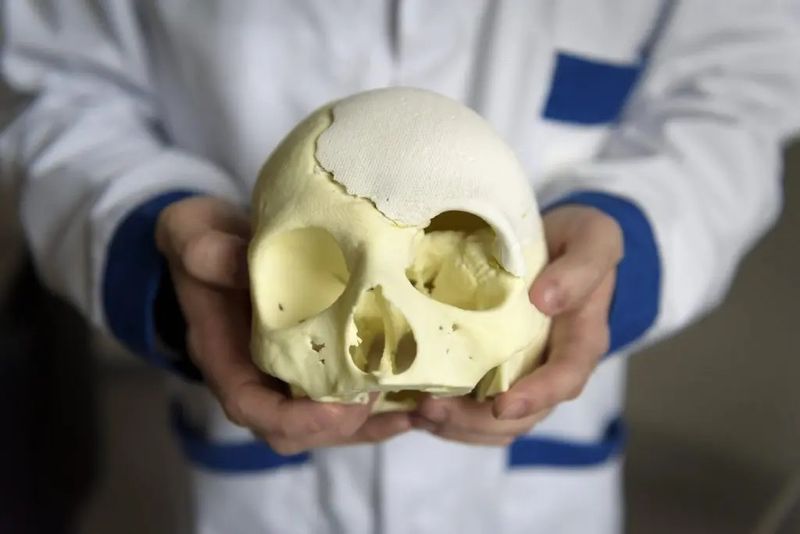

3DCeram has been working on cutting-edge biomedical solutions since 2005. Over the years, the company has reached a level of development that can fully meet the requirements of the medical sphere. With a wide range of ceramic 3D printers and specific biocompatible formulations, 3DCeram has all the necessary supply chain certifications to integrate their innovative technologies in various fields like dental, orthopedic, maxillofacial, and plastic surgery.

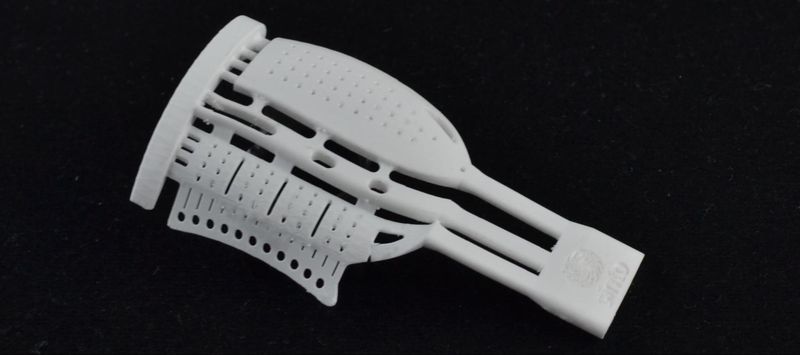

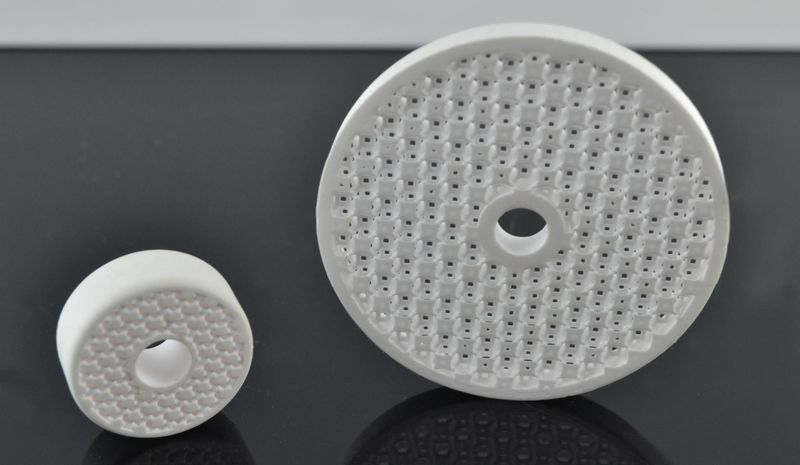

The company is famous for producing small series of bone substitutes (intervertebral cages and tibial osteotomy wedges) as well as cranial and jawbone implants. Additive manufacturing enables the professionals to control porosity of ceramic substitutes. Also, 3DCeram has developed a unique SLA-based technology BioCranium that allows for manufacturing of custom-made bioceramic implants.

Various industrial segments are now taking advantage of unique mechanical, electrical, thermal, and chemical properties of technical ceramic materials. 3DCeram’s AM technology has found increasing popularity in such spheres as chemistry, oil and gas, water treatment, electronic, automotive, and others.

Ceramic 3D printing simplifies the production of complex parts that is beyond the capabilities of older equipment and traditional methods. It reduces downtime and eliminates the need for expensive tools, which is particularly important for modern enterprises and small series production. In addition, flexible design possibilities are great for fast and moldless manufacturing of functional parts.

The aforementioned resistance and various characteristics of ceramic materials, such as their mechanical, magnetic, thermal, chemical and electrical properties, allow one to use them for applications subjected to high stress in harsh environments. The same goes for 3DCeram’s highly functional and reliable AM machines, which results in the rising demand of ceramic 3D printing in studies of major research groups and universities.

Being an innovator in the sphere of industrial manufacturing, 3DCeram has managed to build a seamless 3D printing ecosystem aspiring to the Smart Ceramic Factory concept. The company’s devices expand the horizons of additive manufacturing in the most efficient way that allows professionals of major industries to benefit from both material flexibility and creative freedom.

Due to varying dimensions, build volume, power, and capabilities, every customer is sure to find a model fitting their personal aims and demands. Or, with the M.A.T., one will be able to make their personal asset that will check all the boxes.

Update your browser to view this website correctly. Update my browser now

Write a comment