When it comes to FDM 3D printing, one of the critical components is an extruder. With the right one at hand, even the most demanding projects will not present any difficulties, regardless of the required temperature and speed.

Today, we would like to take a look at professional high-performance extruders by Dyze Design — a Canada-based company specializing in producing hotends, extruders, sensors, and other accessories that control the supply and deposition of the raw 3D printing material.

The Canadian company Dyze Design develops and manufactures high-performance extruders, hotends, tungsten carbide nozzles, as well as auto-calibration and filament detection sensors. It is particularly known for its high-flow systems designed for industrial applications — Typhoon and Pulsar.

Credit: dyzedesign.com

Aiming for the position of the world’s leading supplier of extrusion systems, Dyze Design provides high-quality products based on cutting-edge technologies that improve the reliability and usability of 3D printers as well as open up opportunities for new printable materials.

The afore-mentioned Typhoon and Pulsar are industrial extruders for large-format FDM 3D printers targeted at cost-effective processing of high-temp filaments and pellets, including composites. Let’s find out more about them.

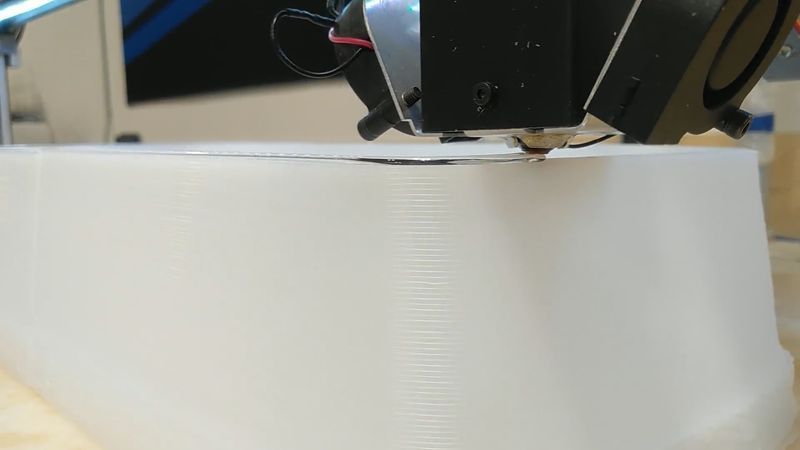

The Typhoon extruder uses filaments with a diameter of 2.85 mm and can apply up to 200 mm³ of material per second or about 900 g per hour. With the integrated NEMA23 motor and quad pinch system, it can easily handle fast and even flow even with soft and flexible filaments.

The maximum temperature of the liquid-cooled hotend is 500 °C, which makes it possible to work with high-temperature engineering thermoplastics such as PEEK or PEI. In addition, the extruder offers precise temperature control thanks to the efficient dual heating system, which guarantees quality printing with the most demanding materials.

As a bonus, Typhoon is fully compatible with your standard firmware that greatly simplifies its use.

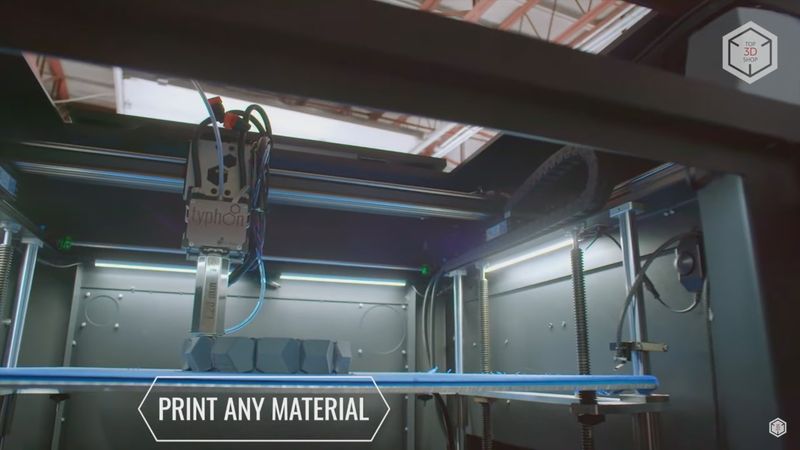

The Pulsar extruder is designed to print in pellets. Like the Typhoon, it is equipped with tungsten-carbide nozzles and a hotend that can reach 500 °C. Due to an innovative three-level temperature control system, the extruder ensures quality printing with materials requiring uniform temperature throughout the process.

Materials are fed by a screw with a diameter of 16 mm and a length of 235 mm rotating at up to 100 times per minute. The throughput rate of the Pulsar extruder is 500 mm³ per second, or 2.5 kg per hour.

At the moment, it is one of the fastest portable pellet extruders on the market. So, with the available nozzle sizes from 1 to 5 mm, you can produce parts with complex geometry and detailed composition at exceptionally high speeds.

Another lineup called DyzeXtruder Pro is equipped with DyzEnd Pro hotends and tungsten carbide nozzles.

The compact form factor, high pushing capability of up to 10 kg of force, and maximum printing temperature of 500 °C make the DyzeXtruder Pro suitable for industrial-grade desktop 3D printers to process high-temp composites.

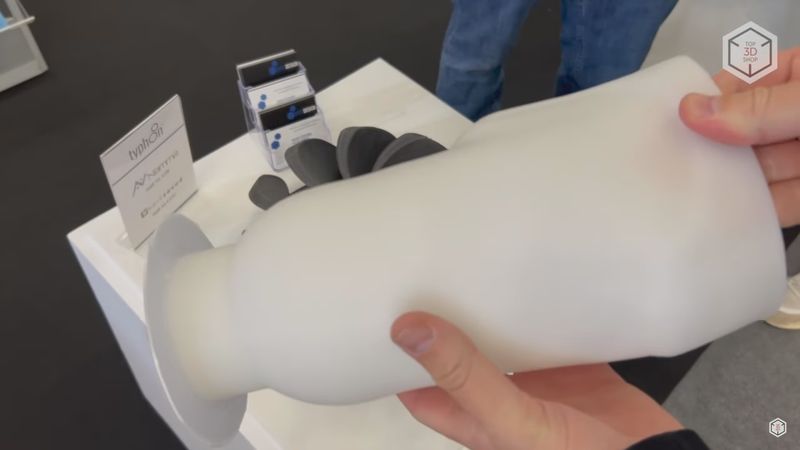

The following items clearly demonstrate the enhanced capabilities of high-flow extrusion systems from Dyze Design:

Thanks to their universal compatibility, Dyze Design extrusion systems, such as Typhoon and Pulsar, can be effectively used with industrial large-scale 3D printers or robot arms. With their reliable construction and multiple advanced features, these high-performance devices are ideal for diverse professional applications in manifold spheres, including functional prototyping, engineering, mass production, design, etc.

Update your browser to view this website correctly. Update my browser now

Write a comment