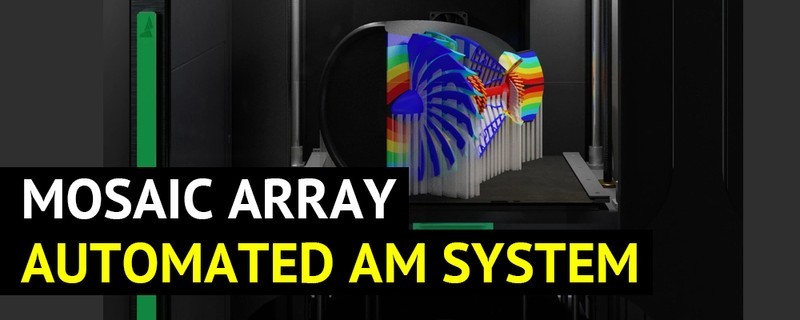

Canadian-based company Mosaic Manufacturing produces several unique AM solutions, such as Palette filament splicers for multi-material 3D printing from a single nozzle, Element and Element HT FDM printers, and the Array automated system, which can work autonomously for up to three days. Let’s take a closer look at what this system is capable of.

By concept, the Mosaic Array is a compact 3D printing farm that combines four independent Element HT 3D printers and a robotic gantry-type manipulation system responsible for changing the print beds. With the main goal of facilitating mass-production 3D printing and combining expertise in multifilament management, Mosaic designed a standalone unit for scalable production of quality plastic parts.

One operator can manage up to 250 printers linked into one Mosaic Array network, resulting in a tenfold overall productivity increase. After a part is finished on one of the printers, the robotic mechanism moves the print bed with the objects to the storage compartment and installs a new one in its place to launch the next printing sequence.

Each of the four printers in the Array system is equipped with a dedicated filament feed unit capable of holding eight spools of material. The capacity of the entire raw-materials storage compartment is 32 containers. In case of a failed print or malfunction, the Array shuts down and addresses the issue only in the failed 3D printer while the whole system keeps on operating.

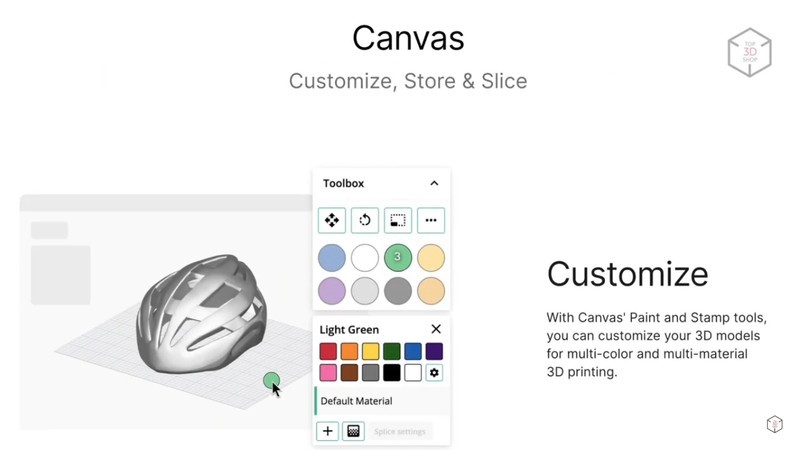

All work processes are automated and are easily managed via proprietary Canvas software which allows the user to select materials for printing and set the queue. All this can be done remotely. Automatic shutdown is also available for reduced power consumption when required.

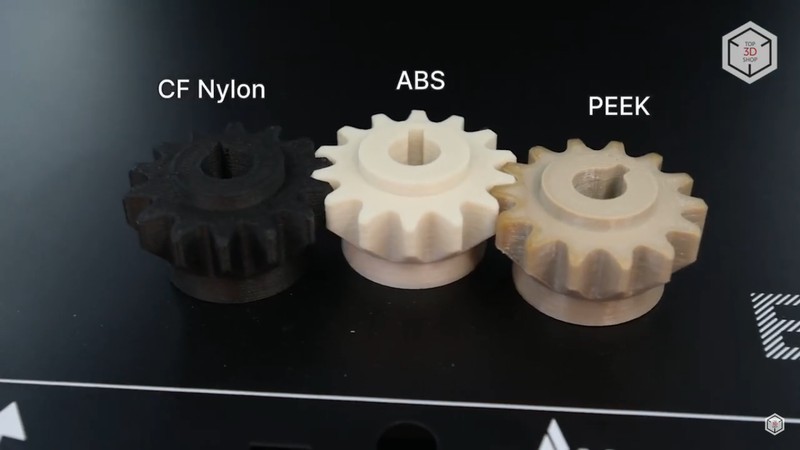

The Element HT 3D printers, integrated into the platform, are geared up to process high-temperature and industrial-grade materials such as PEEK, PEKK, ULTEM, and others.

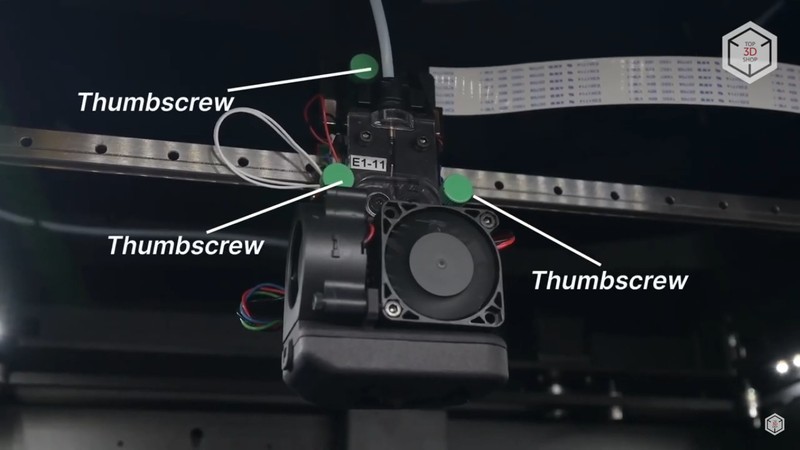

The modular design of the printers reduces downtime from hours to minutes and allows the replacement of whole sections of components, speeding up the maintenance.

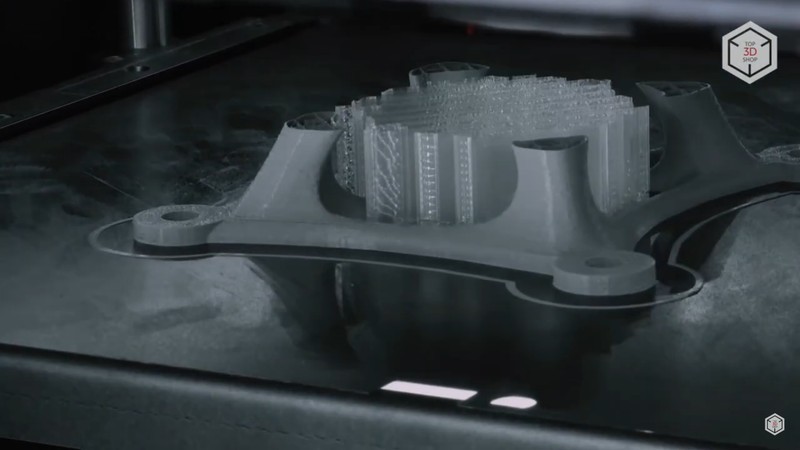

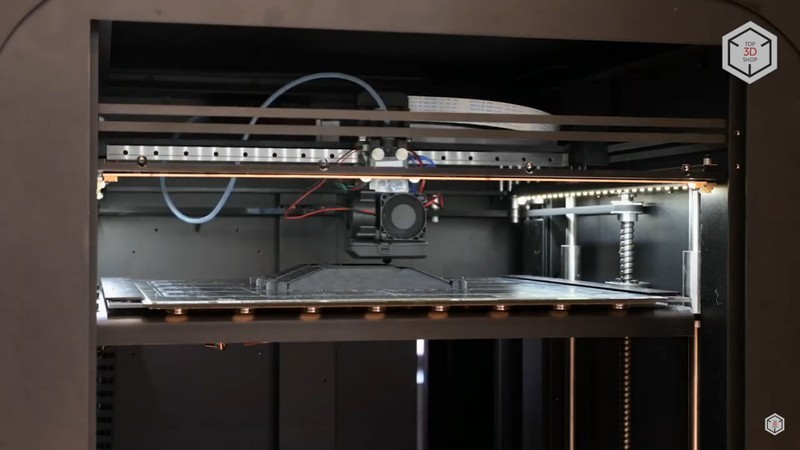

The build volume of each of the printers is a cube with a side of 355 millimeters; the chamber can heat up to 80 °C, while the maximum hotend temperature is 500 °C.

Each of the four printers is equipped with a proprietary Palette X filament feed unit, which is a unique solution for consequential printing with several available filaments, reinforced for reliable use when running highly abrasive materials.

Credit: mosaicmfg.com

Thus, the Palette X is a filament mixer that enables creating multi-color and multi-material parts from several filament feeds.

The finished parts storage compartment was designed for maximum space saving. The printed objects are stacked in accordance with their dimensions along the Z-axis. All the user has to do is load the filament containers, clean the beds after the print sequence, and relocate the finished parts from the storage compartment which is moved around on casters for faster parts relocation.

Internal lighting and a built-in webcam along with Wi-Fi connectivity make remote monitoring of the processes in the system a lot easier.

The Mosaic Array is equipped with an air-filtration system for removing and filtering hazardous fumes, thus securing a safe production environment.

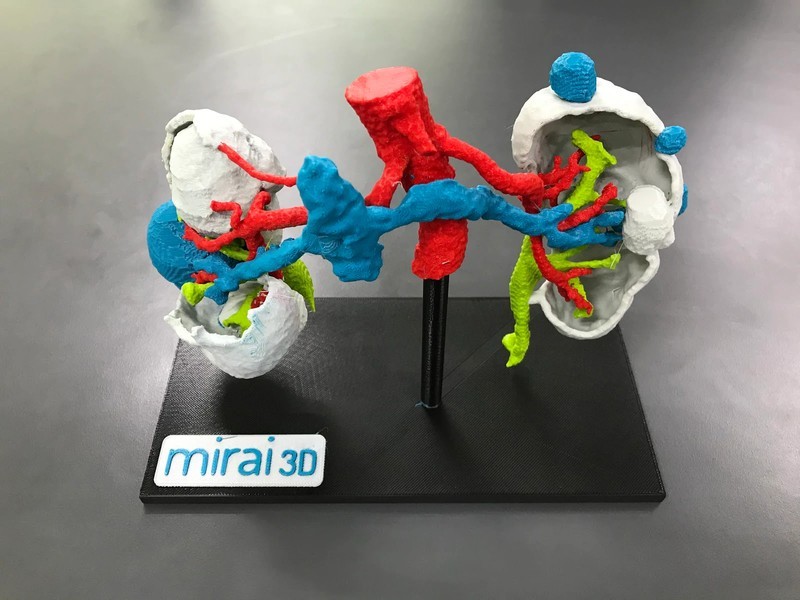

The vast capabilities of the Array in handling multiple materials and processing high-temperature filaments make it a powerful solution for scaling up production for industrial applications and areas relying on stronger stress-resistant thermoplastics.

Credit: mosaicmfg.com

High resolution and print speed combined with the multilateral handling approach generate an almost seamless workflow for mass-production of intricate and complex objects.

Credit: mosaicmfg.com

When looking at the tangible benefits of incorporating the Array into a production environment, the most prominent would be the reduced operator load and labor hours required. It lowers the cost per part and massively improves the overall throughput of the production process.

By investing in automated equipment like the Mosaic Array and removing the bottlenecks associated with the current manufacturing procedures, businesses can reduce the number of required operators, which frees up the workforce, effectively creating additional means for expanding production throughput.

Update your browser to view this website correctly. Update my browser now

Write a comment