Hey everyone! This is Top 3D Shop, and today, we are going to tell you about the Element HT 3D printer from Canadian-based company Mosaic Manufacturing, which is known for its unique 3D printing solutions redefining the usual industry patterns with the proprietary Series Enabled Multi-Material Extrusion (SEME) technology. Currently, Mosaic’s portfolio includes the Palette filament splicer capable of feeding multiple filaments through a single nozzle, the Array additive system that can work autonomously for up to three days, and the Element FDM printers available in two versions. Let’s take a closer look at the HT model.

The key differences between the high-temperature Element HT and the basic Element are a hotend that can heat up to 500 °C, a print bed with the maximum temperature of 120 °C, and a build chamber capable of heating to 80 °C. The extruder of the standard model can only reach 300 °C, while the build chamber does not have active heating at all.

Both printer versions are equipped with integrated Palette X feeding modules for printing with eight different filaments consequentially. This is the most productive version of the company’s splicers so far capable of working with high-temperature materials and soldering together filaments with a melting point of up to 500 °C.

The impressive technical characteristics and manifold useful functions make the Element HT a perfect device for professional use in many spheres, including small-scale manufacturing, functional prototyping, industrial part design, artistic architecture, and more.

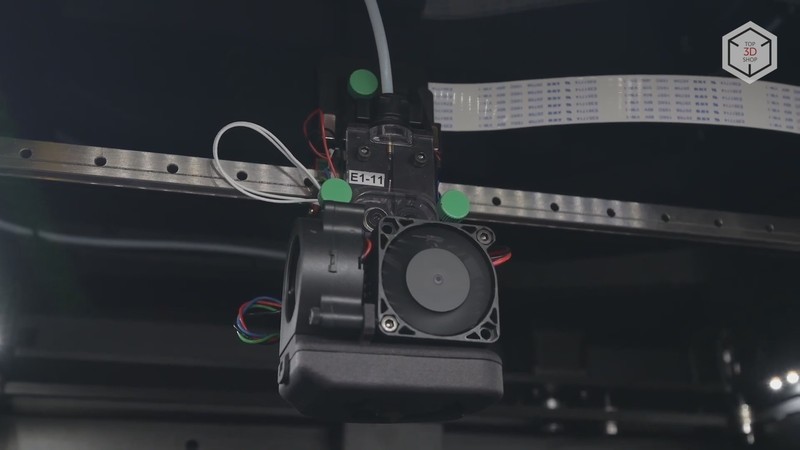

Due to the print head modular construction, it takes only 1–2 minutes to replace the extruder when needed. Besides, they are equipped with hardened steel nozzles 0.4 mm in diameter.

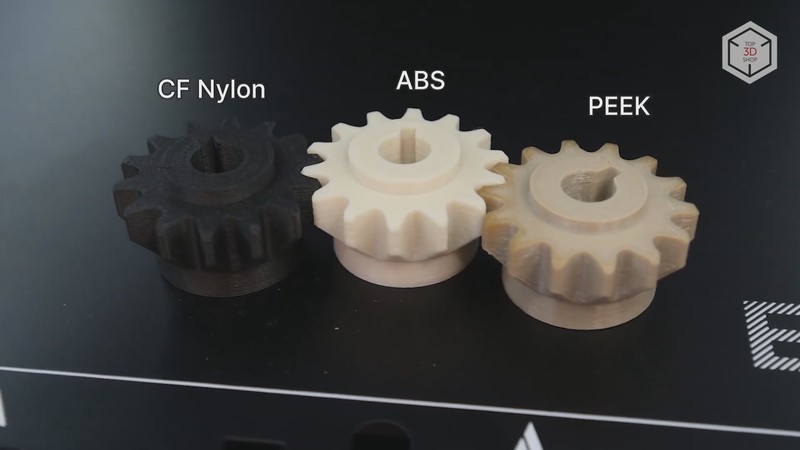

In contrast to its counterpart, the Element HT extruder is upgraded to process high-temperature materials, such as PEEK, PEKK, Ultem, etc.

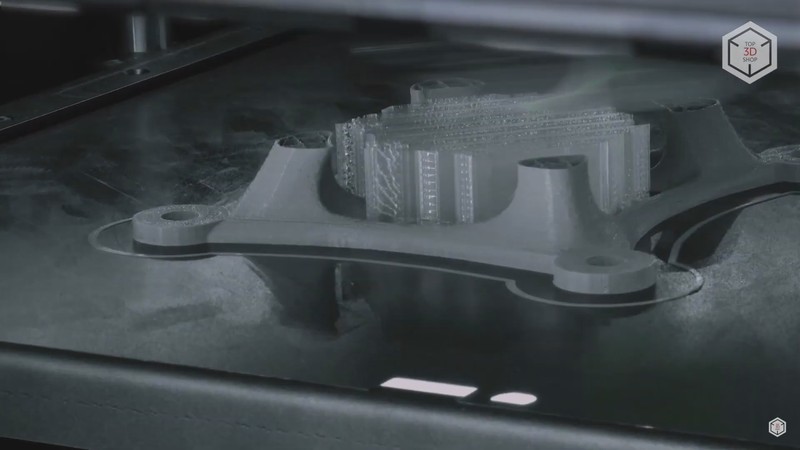

The build volume of the Element HT 3D printer is a cube with an edge length of 356 mm, while the print speed reaches 100 mm per second. The layer thickness can be set from 20 to 230 microns.

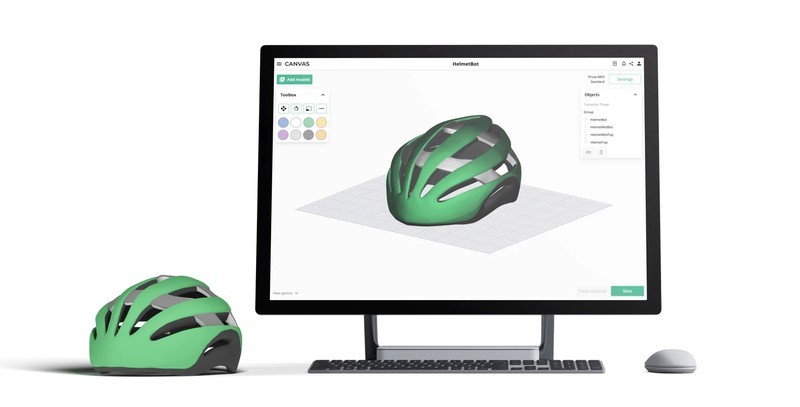

The machine can be controlled via a 5" color touchscreen with a clear and intuitive interface. Moreover, the whole process can be monitored remotely via a built-in camera already installed in the chamber. Apart from this, the printing process can be managed through the Canvas smartphone app.

As for the connectivity options, files can be sent to the printer’s memory through a USB connection, via Wi-Fi, or over a local area network.

All operation procedures are intuitive and easy to access and handle through the dedicated Canvas software that provides all the necessary tools and settings for selecting operation modes and advanced slicing options for rendering 3D models into printable data. The program runs smoothly on Windows, macOS, and Linux operating systems.

Both versions of the Element 3D printers are equipped with sensors that keep track of the humidity in the filament storage compartments, the supply and amount of remaining filament, as well as the temperature.

In addition, the Mosaic Element devices are engineered with a two-tier air purification system combining carbon and HEPA filters for safe and comfortable usage.

The Element HT 3D printers serve as the basis for the Mosaic Array 3D printing farm that houses four independent machines in a single unit powered by a gantry-type robotic system for parts retrieval and storage. The system features easy maintenance ensuring time-effectiveness for scaling up the production.

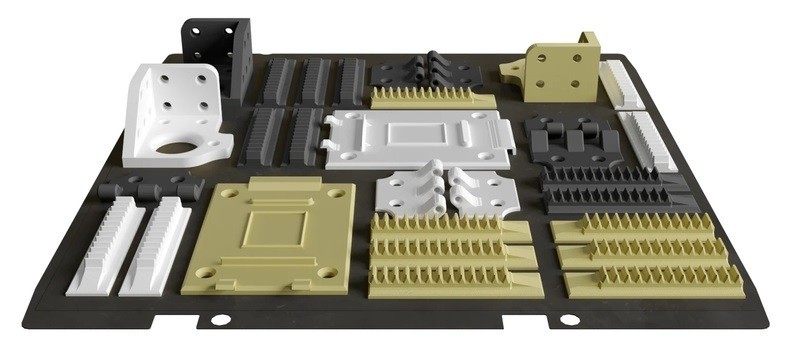

The Element HT 3D printer is able to produce top-quality parts with smooth exterior surfaces, complex geometry, detailed composition, and consistent mechanical properties. Plus, the machine is compatible with a wide range of consumables from Mosaic and 3rd party manufacturers, which results in an immense creative freedom.

With the Mosaic Palette X at hand, you can experience vast possibilities of multi-color and multi-material printing in a truly simple and convenient way.

Considering all the listed features, the Mosaic Element HT model offers significant benefits for professional application and serves as a valuable tool for complex and major projects, especially as a part of the revolutionary Array printing solution.

Update your browser to view this website correctly. Update my browser now

Write a comment