Sinterit is a well-known name in additive manufacturing directly associated with a number of benefits in SLS 3D printing. And now, we are glad to provide a review of the company’s brand new machine that is full of innovation from the start.

The Sinterit NILS 480 3D printer is claimed to change the game in its sphere. NILS stands for New Industrial Laser Sintering, and it articulates the main principles the device is built upon. This is Top 3D Shop, and we suggest you look at the launch of the new Sinterit industrial series.

Sinterit is a major Polish producer of SLS 3D printers and specialized goods. The company was founded in 2014, and ever since it has never ceased to amaze the world of additive manufacturing by high-performance SLS solutions. The fundamental purpose of the company is to support creative professionals and provide them with powerful, easy-to-use, and affordable tools to streamline their production.

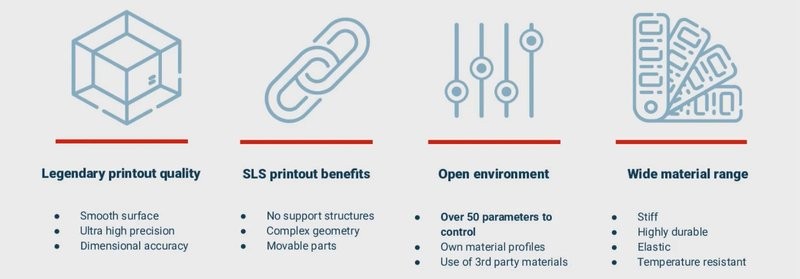

The Sinterit’s primary achievement is the enhancement of SLS (Selective Laser Sintering) technology, which involves a high power laser to sinter polymer powders into solid objects without using support structures. This method provides high quality in combination with ample opportunity due to the open environment and wide material range. Besides, Sinterit offers the whole printing ecosystem consisting of powder management and post processing tools, dedicated software, various powders, and an extensive list of services. You are going to see that all these points are fully covered by the NILS 480.

As the first industrial solution from Sinterit, the NILS 480 is designed to make SLS 3D printing more productive and therefore more profitable. Unlike the previous desktop devices from the company’s compact series, the new printer takes the SLS technology to the next level.

The NILS 480 is designated for high performance, productivity, and cost-effectiveness — the aspects of particular interest for all industrial players. In order to reach the goal, the machine is equipped with a large build volume as well as the mechanisms for continuous operations and autonomous functioning. All these features distinguish it among the competitors.

Sinterit has built a reputation as an outstanding manufacturer thanks to the compact SLS 3D printers line. Despite the major differences, these machines are great for meeting the challenges outside industrial printing, from education to business. Look through the following table to compare the specs of the NILS 480 with other products by Sinterit.

|

Parameter |

Lisa |

Lisa Pro |

Lisa X |

NILS 480 |

|

Build volume |

110 x 160 x 155 mm 4.3 x 6.3 x 6.1 in |

110 x 160 x 245 mm 4.3 x 6.3 x 9.6 in |

130 x 180 x 330 mm 5.1 x 7.1 x 13.0 in |

200 x 200 x 330 mm 7.9 x 7.9 x 13.0 in |

|

Max. print diagonal |

248 mm 9.8 in |

313 mm 12.3 in |

398 mm 15.7 in |

435 mm 17.1 in |

|

Print speed |

3 mm/h |

3 mm/h |

10–14 mm/h |

10–14 mm/h |

|

Laser type |

IR 5 W |

IR 5 W |

IR 30 W |

IR 30 W |

|

Wavelength |

808 nm |

808 nm |

976 nm |

976 nm |

|

Layer height |

0.075–0.175 mm 0.003–0.006 in |

0.075–0.175 mm 0.003–0.006 in |

0.075–0.175 mm 0.003–0.006 in |

0.075–0.175 mm 0.003–0.006 in |

|

Scanning type |

XY |

XY |

Galvo |

Galvo |

|

Laser spot size |

400 μm 0.0157 in |

400 μm 0.0157 in |

650 μm 0.0256 in |

560 μm 0.0220 in |

|

Feed bed capacity |

3.4 L |

5.2 L |

14 L |

30 L |

|

Inert gas control system |

- |

✔ |

✔ |

✔ |

|

Automatic Powder Distribution System (APDS) |

- |

- |

- |

✔ |

|

Continuous Printing System (CPS) |

- |

- |

- |

✔ |

|

Display |

4" interactive touchscreen |

7" interactive touchscreen |

9" interactive touchscreen |

15.6" interactive touchscreen |

|

Connectivity |

Wi-Fi, USB |

Wi-Fi, USB |

Ethernet, Wi-Fi, USB |

Ethernet, Wi-Fi, USB |

The machine comes with specialized tools and necessary equipment to make printing and processing more comfortable and effective. Apart from the printer itself, the basic set contains:

For some items, package content may change. In case of any questions, please get in touch.

To further enhance operation and user experience, Sinterit offers additional equipment which can be purchased separately or as part of complete sets. We will dwell on it later.

Sinterit tends to keep the recognized benefits of its solutions. In this case, the NILS 480 is no exception. The device continues the company’s traditions in the industrial segment.

Apart from this, the NILS 480 boasts new technologies that make it an impressive tool in terms of productivity.

The machine is ultra-fast: it prints with the speed of 10–14 mm/h. It is a tangible difference for anyone who is familiar with the Sinterit’s previous devices. At that rate, most printouts can be made in less than 24 hours, and the full bed will take around 30 hours to be finished.

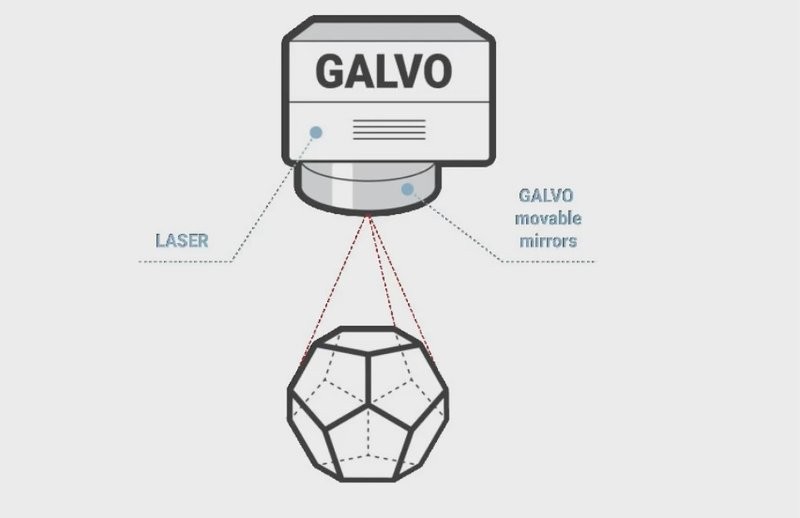

The speed like this is achieved due to the new galvo laser. Compared to the XY laser used in the compact segment, this laser module is not moving during the printing process. The beam is directed onto a system of mirrors, which can point the laser beam in different directions by changing its configuration.

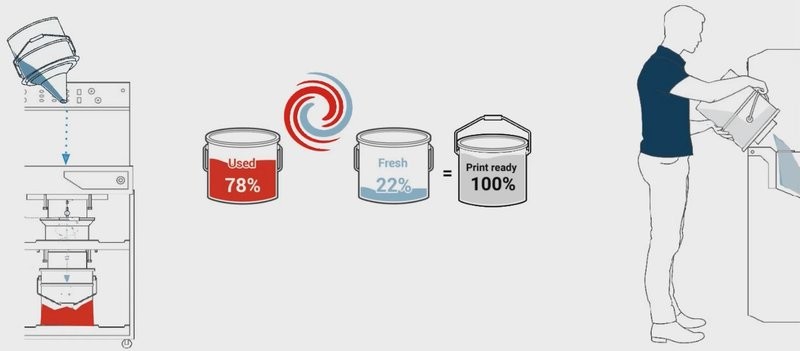

With shorter printing time, the powder refresh ratio can also be lowered up to 22%.

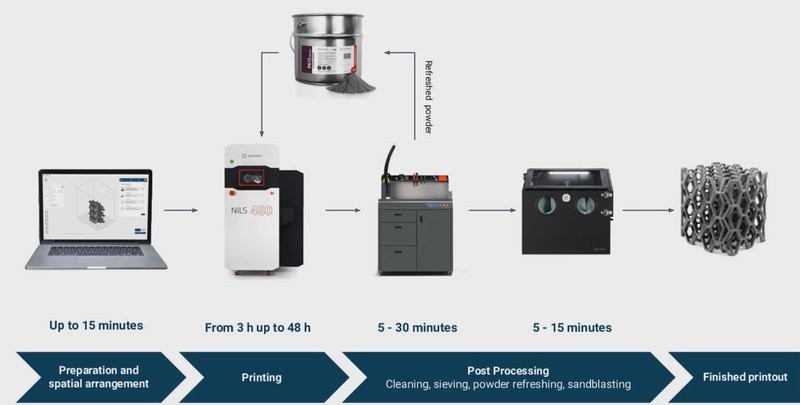

And thanks to the comprehensive set of high-end peripheral products provided by Sinterit, all additional processes will take no more than an hour.

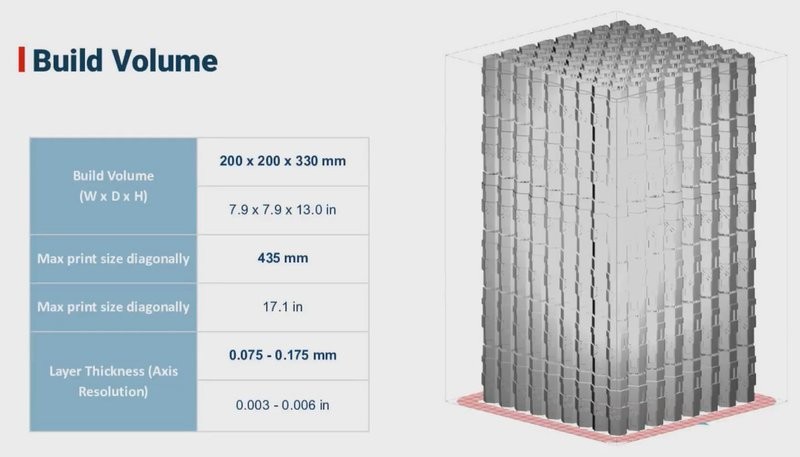

The NILS 480 makes a big difference when it comes to the build size. The model picture here shows the amount of printouts that can be produced by the printer in just one session.

The build chamber like this allows one to print long parts as a whole including: shoes, housing of electronic devices, automotive prototypes, arm orthosis, etc. Optimal packing will be ensured by the auto-nesting function built into the Sinterit Studio software.

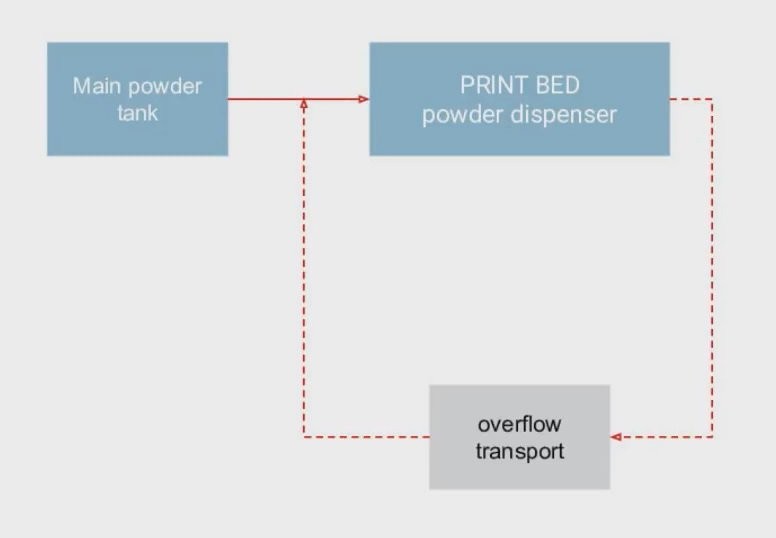

With the NILS 480, Sinterit introduces two new automated systems, which are the key to the printer’s productivity. They are called Automatic Powder Dispensing System (APDS) and Continuous Printing System (CPS).

APDS takes the work with powder to the level of automation known only from the largest machines. The powder from the overflow bin is constantly transported back to the powder dispenser. Thanks to the built-in powder tank, there is no need to fill up before each print job. Moreover, APDS allows lowering the prints’ cost.

CPS handles an autonomous non-stop printing process. After initial cooldown of the finished print (2 hours), the printing bed ejects the cake to the cooling box and starts making a new printout, no further action from a manual worker is required. The system greatly minimizes the downtime of the device.

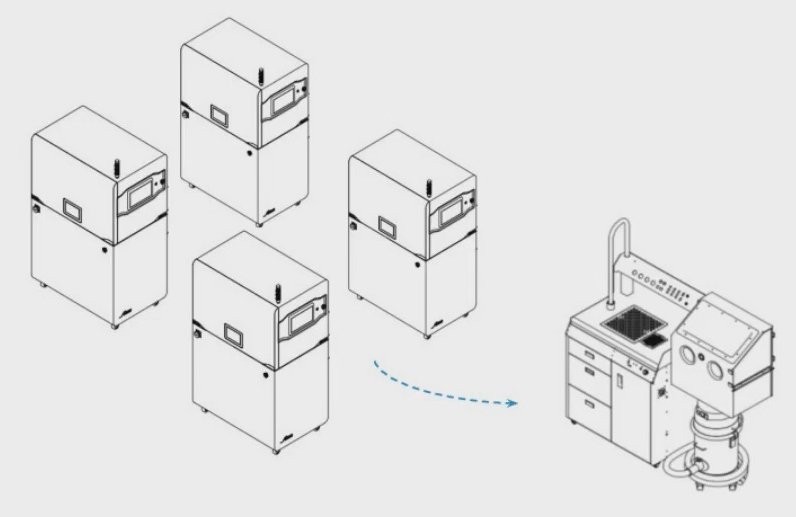

These features open up a possibility to create a multi-printer solution for manufacturing or maintenance centers, service providers, and all kinds of applications when you need several thousands printouts on a daily basis.

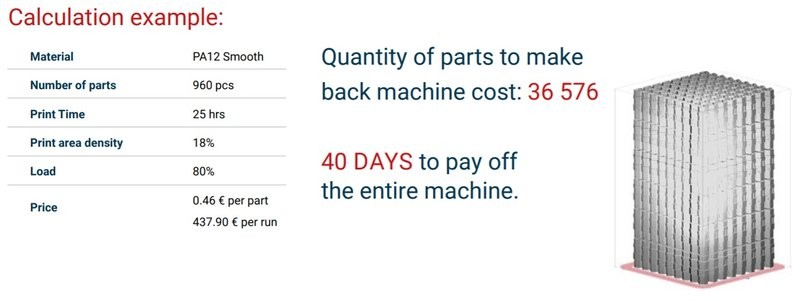

Along with the low maintenance, the machine has optimal printing costs. This includes material price, refreshment ratio, machine downtime, printing time, and the purchase price of the printer. The NILS 480 does win in these areas, and the combination of all advantages makes it a device with great ROI.

Based on the prices from service providers, you can pay off the machine in just 40 days of production.

The NILS 480 utilizes the company’s dedicated slicing software. The program is called Sinterit Studio, and it serves as a perfect tool for working with 3D models of all kinds. Apart from this, one can monitor the status of printing throughout the whole process and adjust up to 50 flexible parameters. The Sinterit Studio allows creating new projects or working on the existing ones in the wide range of file formats: STL, OBJ, 3DS, FBX, DAE, 3MF. The software features:

There are two versions of the Sinterit Studio available — Basic and Advanced. They differ from each other in the scope of supported functions:

Sinterit Studio Basic: offers a standard feature set, such as printing with basic Sinterit powders (PA12 Smooth, Flexa Grey) without additional parameters or 3rd party materials.

Sinterit Studio Advanced: provides access to 50 open printing parameters, experimental settings, and 3rd party materials use.

The difference between two versions is detailed in the table below:

|

Sinterit Studio Basic |

Sinterit Studio Advanced |

|

|

Basic settings |

||

|

Changing Layer height |

✓ |

✓ |

|

Slicing |

✓ |

✓ |

|

Auto-nesting + collision detection |

✓ |

✓ |

|

Advanced settings (open printing parameters) |

||

|

Scale modification |

✓ |

✓ |

|

Printing temperatures modification |

basic |

✓ |

|

Warmup and cooldown modification |

— |

✓ |

|

Laser power modification |

basic |

✓ |

|

Laser movement and geometry modification |

— |

✓ |

|

Skeletons (enhancing fine details) |

— |

✓ |

|

Pre-defined profiles for Sinterit materials |

||

|

Materials available (check availability below) |

|

|

|

Open Profiles |

||

|

Open profiles for Sinterit materials |

— |

✓ |

|

Open profiles for 3rd-party materials |

— |

✓ |

The Sinterit NILS 480 can be purchased separately or as a part of the complete industrial set that includes add-on equipment for all stages of the 3D printing process.

The set comes with:

The NILS 480 covers the complete range of applications where SLS has a competitive advantage. With immense design freedom, high accuracy, great mechanical properties, accessible technology, and a wide range of supported materials, the device becomes a highly productive industrial solution that fits any modern standards.

As indicated in the table below, the model has certain advantages over the compact series, which is relevant to its main purpose.

When it comes to the question who can benefit from the NILS 480, the answer is clear from the aforementioned highlights of the system. The machine will be perfect for medical and automotive spheres, service providers, designers, electronics engineers, and prototyping specialists.

The following prints vividly show the level of quality and detail the NILS 480 is capable of.

Based on the considered advantages, we can conclude that the Sinterit NILS 480 3D printer is an industrial machine of a new generation preserving all the previous achievements of the company. With its reinvented productivity and impressive ROI, the device will become a valuable tool for automated, continuous manufacture of high-quality end-use parts, medical structures, elements of fashion and design as well as functional prototypes.

Update your browser to view this website correctly. Update my browser now

Write a comment