Hi everyone! This is Top 3D Blog with another enlightening addition on the matter of the rapidly evolving additive manufacturing world. This time, we are going to tell you everything there is to know about the Nexa3D NXE400 — an innovative industrial-grade 3D printer that employs a proprietary Lubricant Sublayer Photo-curing (LSPc) printing technology alongside state-of-the-art structured light matrix, letting you produce a dozen of dimensionally accurate hard-to-break parts with excellent mechanical properties (those of ABS-like materials) and smooth surface finish. The main advantage of this machine, however, is its unparalleled printing speed. This incredible device offers six times the speed of any other industrial 3D printer, letting you drastically reduce the manufacturing time and benefit from all the productivity gains. Unbelievable, isn’t it?

In this article, we are going to break down the LSPc printing technology, find out the reason behind the machine’s lightning-fast printing speed, analyze the main specs and features of the printer, highlight its pros and cons, and present some photos and videos of the models printed with it. If you’d like to learn more about this cutting-edge industrial 3D printer, we invite you to proceed with the review. Let’s dive right in!

Nexa3D is a California-based team of passionate additive manufacturing specialists devoted to the development of cutting-edge 3D printing solutions. Having created two different high-speed professional 3D printers powered by LSPC and QLS technologies from scratch, the company is dedicating itself to continue introducing game-changing innovations into the additive manufacturing market. Besides, Nexa3D has partnered up with first-class 3D printing materials suppliers like Henkel, DSM, and Evonik to create the most powerful and efficient printables for their 3D printers to extend their application range even more.

The Nexa3D NXE400 is an industrial LSPc resin-based 3D printer that, thanks to being powered by such groundbreaking 3D printing technology, can output a batch of dimensionally accurate parts with an incredible surface finish in a matter of mere minutes. More precisely, it is capable of printing a 39 mm tall part in less than 4 minutes, which is remarkable even for a professional machine. Besides, it offers a large build volume of 275 x 155 x 400mm (10.8 x 6.1 x 15.7 inches) that lets you print just about anything, including simultaneous production of dozens of medium-sized parts. The NXE400 is compatible with a variety of proprietary printable materials including general-purpose, ABS-like, and biocompatible resins, making it a perfect solution for almost any professional application.

The Nexa3D NXE400 is a sturdily built machine that is supplied in a fully assembled state and doesn’t require calibration. It is a large and heavy industrial 3D printer with outer dimensions of 710 x 710 x 1675 mm (28 x 28 x 66 inch) and a weight of 160kg (350lb), meaning that it has to be moved by more than two people.

Source: YouTube.com

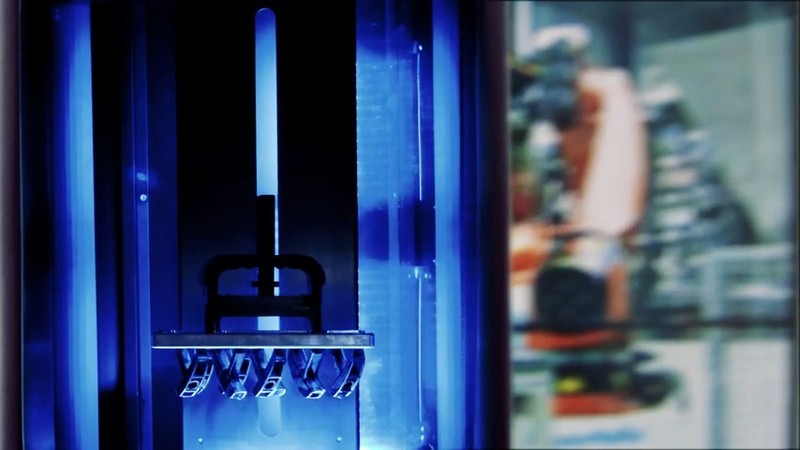

Despite being such a large machine, the NXE400 boasts its refined and futuristic appearance provided by a sleek black frame, which, alongside its build chamber, is illuminated by blue lights, making the machine noticeable even in a completely dark room.

Due to the Nexa3D NXE400’s lightning-fast printing speed, 4K (3840 x 2160) resolution, and a pixel pitch of just 76.5 microns, the machine can print accurate and well-detailed models with the excellent surface finish while greatly improving productivity gains and decreasing production costs.

Thanks to its extended build volume and a variety of printable materials, the machine can be successfully used in a dozen of professional applications like rapid prototyping, reverse engineering, dental 3D printing, industrial manufacturing, automotive, aerospace, and other industries that require non-stop production of industry-grade parts with excellent mechanical properties made with millimeter-precision.

Source: YouTube.com

The Nexa3D NXE400 uses high-performance photoplastics that print parts with extreme accuracy and exceptional surface finish. Offering excellent characteristics to meet unique application requirements, the materials were designed to meet strict industrial demands, survive harsh environments, and help build fully functional parts fresh off the printer. The materials come in 5 and 10 kg jerry cans for safe and convenient transportation. They can be used to print fully functional prototypes, automotive parts, robotic assemblies, strong and durable biocompatible items, personalized audio products, wearables, diving gear, parts, and mechanical assemblies, and so on. Please note that wearing protective equipment is mandatory when working with photoplastic materials.

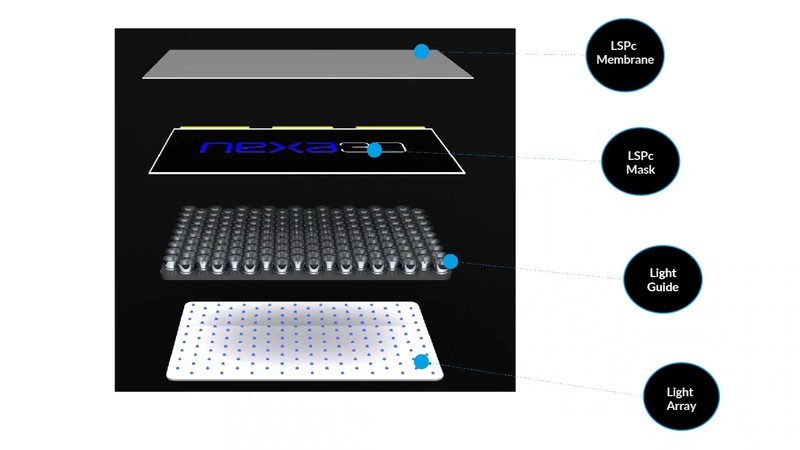

The heart of the Nexa3D NXE400 is its innovative resin-based LSPc 3D printing technology that makes this machine a game-changer in the 3D printing world.

Source: YouTube.com

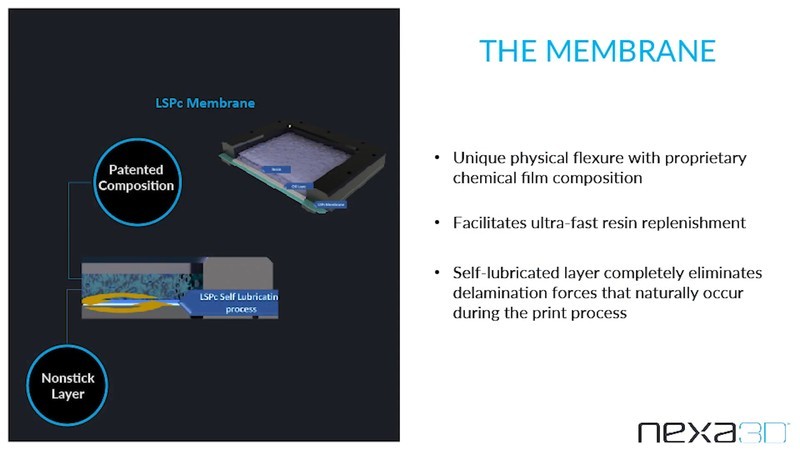

It all starts with a rapid projection of light from a proprietary high-performance photoplastics print engine that releases the light guides to ensure uniform UV light distribution across the entire 16-liter build area. Then, the light travels to the LSPc mask, where it gets pixelated, providing edge-to-edge accuracy and consistency for all the outputs. The final stage of the process is powered by the unique, flexible self-lubricated membrane that makes your print solidify while suspended.

Source: YouTube.com

This one of a kind membrane completely eliminates the need for traditional extraction tilting, while also providing optimal thermal management qualities to help with the heat build-up caused by high-speed printing. All of this allows the Nexa3D NXE400 to produce injection molding-quality outputs at an incredibly fast pace of one vertical inch every two and a half minutes.

Source: YouTube.com

Being an industry-grade device, the NXE400 offers a variety of connectivity options. You can access the printer from afar by using Ethernet or WiFi, or use a USB cable or a USB drive. Its large high-resolution touchscreen offers intuitive and easy to use UI, making for effortless standalone operation.

Source: YouTube.com

Thanks to its manufacturing-ready modular design, the NXE400 has been equipped with a variety of easily interchangeable and upgradable parts to prevent hardware obsolescence, meaning that there will be no problems in upgrading or repairing the machine in the time of need.

To help you post-process all the printed parts at once, there is the Nexa3D xCure curing station. This tool provides post-processed items with consistent dimensional accuracy and structural integrity while also reinforcing their molecular structure. Its chamber can contain up to three build plates at once with the option to cure printed parts directly on the build plate or place them in a curing basket for individual curing. All in all, the Nexa3D xCure curing station helps reduce total post-processing time, guarantees better part performance, and increases printing productivity by optimizing the manufacturing time.

The printer ships in a fully assembled state and doesn’t require calibration. In addition to the machine, the shipping box contains the essential parts to operate the printer and a set of useful tools and accessories:

For some items, package content may change. In case of any questions, please get in touch.

The Nexa3D NXE400 is supplied in an assembled state and doesn’t require calibration, so all that’s left to do after unboxing is to equip it with the remaining parts, connect the power cord to the device, turn it on and run a couple of test prints to ensure that everything is up and running.

Source: YouTube.com

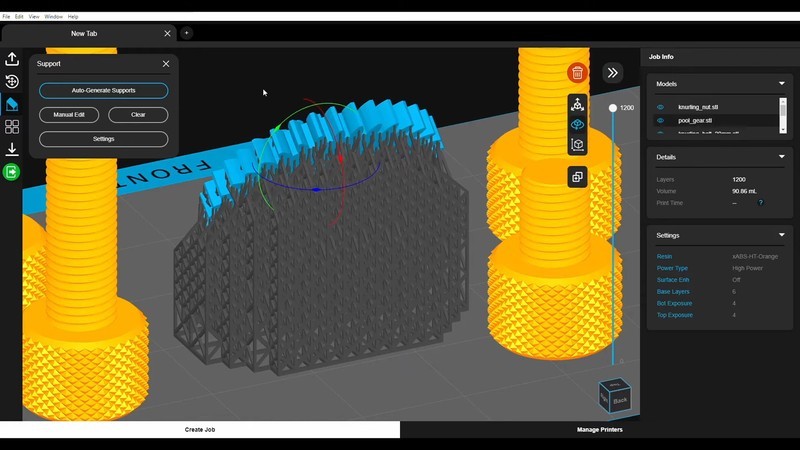

The Nexa3D NXE400 is powered by a proprietary Nexa X software that, unlike many other slicers, features a remarkably simple interface.

This advanced slicing software delivers production consistency ensured by innovative vision algorithms and validated workflows. There is also an automated support generation system, manual scaffold support editing options, easy access to basic and more advanced printer parameters, 3D model duplication, manipulation, and endless editing possibilities. The Nexa X is user-friendly software with a plethora of visual guides and indicators to help organize your production workflow in a streamlined and reliable way.

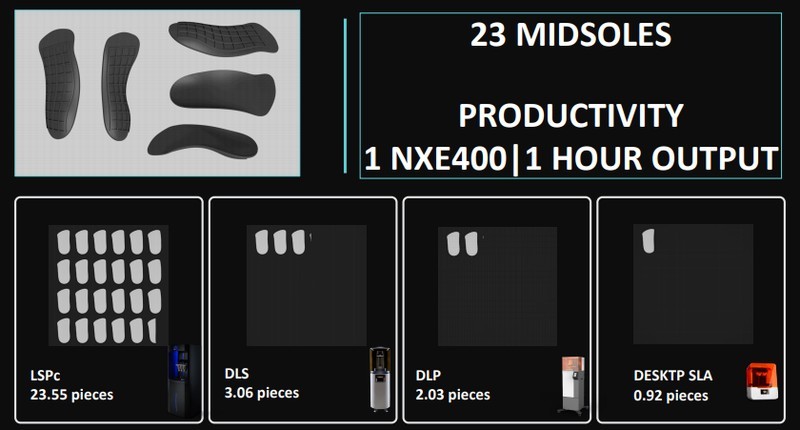

Below are some of the quality parts printed with the Nexa3D NXE400. First, we’ll highlight the productivity gains that you could benefit from printing on the Nexa3D NXE400 as compared with other 3D printers.

For instance, it took the NXE400 only an hour to 3D print a batch of 23 fully functional midsoles. The 2nd place was taken by the Caron3D’s DLS 3D printer that could only produce 3 pieces at a given time.

Next up is a batch production of venturi tubes. In a matter of one hour, the NXE400 has been able to output 112 pieces, while its closest competitor managed to produce only 15.

Now, let’s take a closer look at the injection molding-quality parts that the machine produces.

The first batch consists of millimeter-precise dental impressions printed using the xCE-White high-performance polymer.

Next up are fully functional car interior parts printed with the xCE-Black, a single cure polymer with incredible flexure strength and temperature resistance.

Take a look at these mechanical parts 3D printed using the 3843-xABS Black, a material with excellent flexural and tensile physical properties alongside remarkable elongation and outstanding heat resistance.

As you can see, the NXE400 can create fully functional industry-grade parts that can be used fresh off the printer.

Pros

Cons

Having reviewed the fastest 3D printers in the world, let’s quickly compare their capabilities.

|

Nexa3D NXE400 |

Carbon3D M2 |

|

|

Build volume |

275 x 155 x 400 mm (10.8 x 6.1 x 15.7 inches) |

189 x 118 x 326 mm (7.4 x 4.6 x 12.8 inches) |

|

Printing speed |

35cm3/minute |

20 cm/hour |

|

XY resolution |

75 µm |

75 µm |

|

Min. layer thickness |

50 µm/100 µm |

50 µm |

|

Connectivity |

Ethernet, Wifi, USB |

Wifi / Ethernet |

|

Printables cost |

$100 - $450 / liter |

$50 - $399 |

As you can see, both printers can print at a minimum layer thickness of just 50 microns, letting you create astonishingly detailed injection molding-quality outputs with a remarkably smooth surface finish. As per the build volume, the NXE400 can print bigger and taller parts. In the case of non-stop batch production of small or medium-scale items, its extended build volume accounts for an increased productivity gain. Besides, it prints at a considerably faster pace.

|

Nexa3D NXE400 |

Carbon3D M2 |

|

|

Thanks to their fruitful partnership with the world’s leading manufacturers of printable materials like Henkel, DSM, and Evonik, the team was able to create state-of-the-art resins for their 3D printers. The current lineup consists of printable resins with ABS-grade properties alongside biocompatible, translucent, and a plethora of other 3D printable resins of various colors. |

The Carbon3D M2 3D printer uses Programmable Liquid Resins designed to be used in engineering and dental fields. With a nice name indeed, these programmable resins gain their properties by means of heat activation, which, in essence, is nothing new as compared with most photocurable printing materials that are powered by UV and heat treatment. |

Carbon3D M2

Employing a subscription model, the Carbon3D M2 will cost you $50,000/year with a minimum 3-year subscription, and mandatory purchase of the “Accessory Pack” that comes at $12,500, meaning that you’ll have to spend $162,500 in total. In case you’d like professional installation and training provided by the company staff, add $10,000 more. Finally, all of the parts printed with the M2 have to be washed, and getting the Carbon Part Washer will cost you another $10,000/year.

Nexa3D NXE400

Unlike Carbon3D, Nexa3D does not have any subscription-based options. You simply buy the machine for permanent use. The total cost of the NXE400 is $59,900, which is slightly above the costs of a one-year subscription at Carbon3D. For a good starter experience, we highly recommend adding the xCure station to your order for $7,500. It is a large and powerful automatic post-processing tool for your prints that can fit up to three NXE400’s build plates. In case you don’t have the MagicsPrint DLP software, it goes for $4,200 with a lifetime license. Besides, you might also want to include the installation and training services for $1,500, an additional build platform to double the productivity gains for $1,199. Nexa3D also recommends adding printables and other essential items into the mix. The total amount of money you’ll have to invest in case of buying all of the above mentioned items including the printer (a starter kit) will be about $80,000.

To sum up, a 3-year all-inclusive ownership of the Carbon3D M2 and all the preferable subscriptions will cost you about $200,000. At the same time, Nexa3D NXE400 with all the recommended spares and essentials comes at $79,981, and the printer is yours to keep. As you can see, the NXE400 is considerably cheaper to own as compared with its rentable counterpart.

Q: Are test prints free?

A: Yes, the test prints are conducted completely free of charge. Please get in touch to upload the desired 3D model and see what this incredibly powerful 3D printer is capable of.

Q: Which resin is included in the supply package?

A: Any resin of your choice excluding the MEDx412. The default shipping option is the xPRO410.

Q: What exactly is meant by an on-site installation and training?

A: There is a working site planning guide and the printer part checklist that will be shipped to you with a thorough setup, installation, maintenance, and personnel training instructions.

Q: What are the xCare warranty terms?

A: This is a 1-year renewable warranty that covers all the non-consumable parts of the printer, including but not limited to the light engine; all mechanical components, and electrical boards/assemblies.

Q: Can I print with other materials besides the ones offered by NEXA3D?

A: It is not recommended to use other printables since there are no preset printer profiles available and the machine hasn’t been tested on the matter of being compatible with other resins. Besides, the manufacturer offers a solid lineup of all kinds of printable materials, expanding it in a spectacularly rapid fashion.

Q: Am I tied to using the xClean washing solution to post-process the printed items?

A: A solution of ordinary IPA will work just fine, however, the xClean solution is much less flammable, causes less environmental impact, and can process three times the volume of units you would normally process with IPA. Еhe saturation of ISO-is near 7% contamination, while xClean operates effectively to 20%.

Q: Is the MagicsPrint slicer the only available slicer option?

A: To prepare a print job for the NXE400, you’ll have to use MagicsPrint for Nexa. To create a sliced build-file which then goes to the printer, you’ll use the Nexa X software.

Q: Is it useful to have one connector per each material?

A: It is better to use separate connectors for different materials or to clean the connector thoroughly to avoid different material contamination.

Q: How long does an xFilter last?

A: The replacement frequency depends on the facility’s air conditions. Generally, it needs to be replaced once a year.

Q: What is the "accessory kit" included with the printer? Is it the same as the xKit or different?

A: It is the same as the xKit and includes a tray, rinse container, snips, scraper, syringe, pick, squeegee, filters, funnel, and a USB connector.

Q: Is the MagicsPrint DLP printing software a one-time purchase or is it a subscription-based service? Do you offer training for the software?

A: Basic instruction is provided, advanced training can be purchased. Several online tutorials are also available. If you're using any other software from the suite, you'll simply need to buy the standard MagicsPrint DLP software for $4,500.

The Nexa3D NXE400 is a professional high-performance LSPc 3D printer that offers a large build volume of 275 x 155 x 400 mm. Paired with its ability to print incredibly detailed parts with thermoplastic-grade properties in the blink of an eye, this cutting-edge 3D printer indeed is a game-changer that entered the additive manufacturing world with a bang. This industry-grade machine can be used in rapid prototyping, reverse engineering, dental 3D printing, industrial manufacturing, automotive, aerospace, and other industries that require swift non-stop production of industry-grade parts with excellent mechanical properties made with millimeter-precision. In the long run, the machine will greatly contribute to increasing productivity gains and decreasing production costs.

You can purchase the Nexa3D NXE400 from Top 3D Shop. This professional 3D printer comes with the manufacturer’s warranty. Our team will make sure to provide the best service possible, just like we always do.

Update your browser to view this website correctly. Update my browser now

Write a comment