Nexa3D specializes in designing and manufacturing high-speed resin 3D printers. Still, in 2020, the company acquired NXT Factory, expanding its 3D equipment product range with a new line of industrial SLS printers. This resulted in the release of the brand new Nexa3D QLS 820 3D printer aimed at unprecedented production speed, throughput, and flexibility. Let’s look at its main features and technical specifications.

The Nexa3D QLS (Quantum Laser Sintering) 820 is an SLS 3D printer with an open and highly customizable platform. It applies four 100W CO2 lasers at once, which takes thermoplastic 3D printing to a whole new level. The machine is ready for integration into Industry 4.0 complex systems for consistent and highly economical 24/7 operation.

Due to its powerful laser system and in-house engineering know-how, the QLS 820 3D printer delivers one of the highest performances on the SLS market.

The outer dimensions of the SLS unit are 200 x 140 x 200 cm, while it weighs 750 kg.

The design of the QLS 820 3D printer is based on a removable build chamber with a print volume of 350 x 350 x 400 mm. This solution significantly reduces downtime — when the print is complete, the removable module with the finished parts is sent for post-processing, while another swappable build chamber is loaded into the machine, ready for further printing. The whole replacement procedure takes just a few minutes.

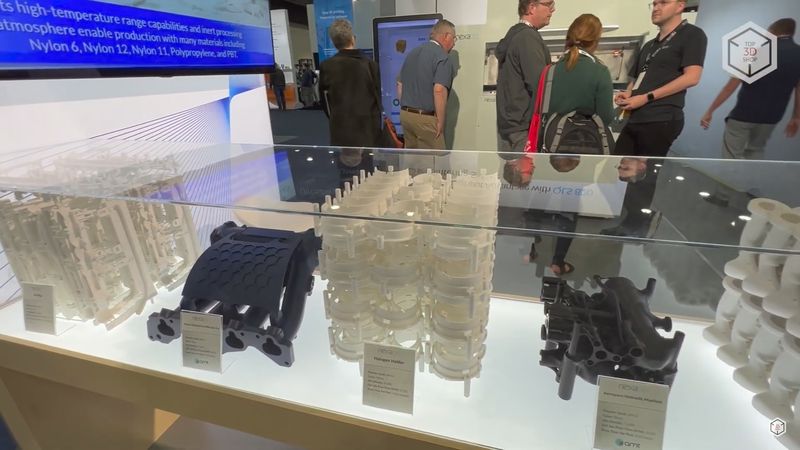

The introduced modular material processing station (MMPS) covers all manufacturing stages, from powder containment and blending to breakout, powder reclamation and sieving, in a completely safe, clean, and efficient way. With the multiple optional components, the system can be scaled according to the user’s requirements and application.

One of the most important features of the QLS 820 3D printer is its ability to process heat-resistant materials. The machine can safely print with such consumables as polyamide-6, where processing temperatures can reach 240 °C.

The list of readily available materials also includes polyamides 11 and 12, as well as polybutylene terephthalate (xPBT) reinforced with glass or aluminum.

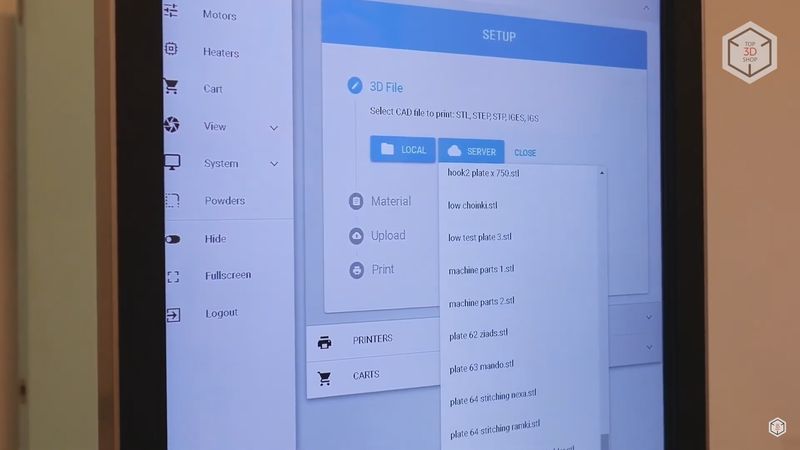

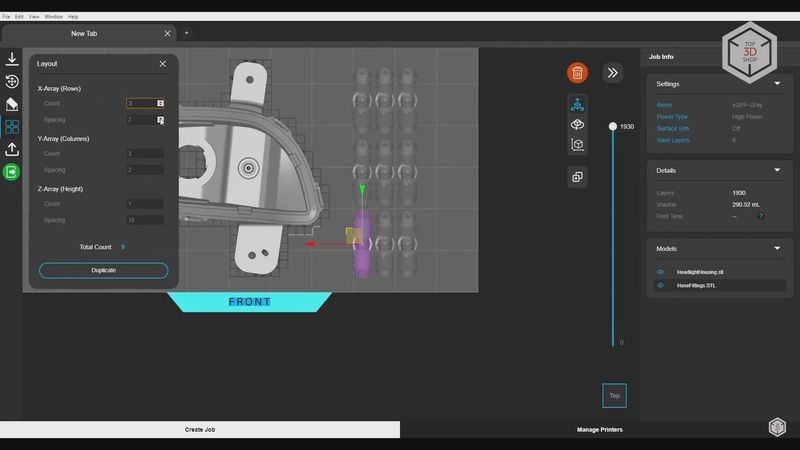

The Nexa3D QLS 820 is connected to a proprietary cloud service and is fully compatible with factory automation industrial programmable logic controllers.

Source files are processed and sent to the printer’s memory through the NexaX proprietary software, which also allows for real-time process monitoring using the intuitive web interface.

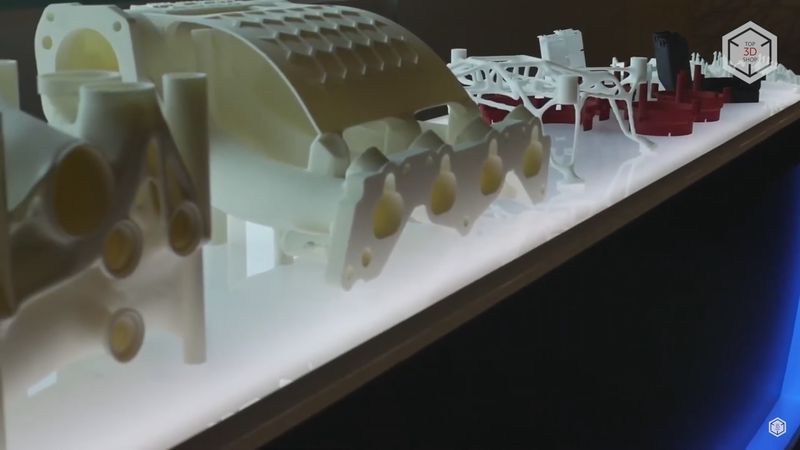

Considering the above mentioned features, the Nexa3D QLS 820 3D printer is ideal for professional use in manifold spheres, including automotive, aerospace and defense, industrial manufacturing, medical, consumer goods, etc. It is great for functional prototyping, production of high-temperature components as well as durable end-use parts, and can serve as an effective alternative to injection molding.

The Nexa3D QLS 820 model boasts a powerful laser source, spacious build volume, flexible upgradable structure, and capacity for smooth 24/7 operation. Due to high temperature support, the machine is able to process a vast variety of materials covering all user’s needs, from general purpose prototyping to industry-specific manufacturing at scale. With an automation-ready structure, scalable system, and advanced fleet management software, the QLS 820 is clearly aimed at time- and cost-efficient massive production.

Update your browser to view this website correctly. Update my browser now

Write a comment