Nexa3D is a company that specializes in designing and manufacturing high-speed resin 3D printers. The key feature of Nexa3D machines is the patented Lubricant Sublayer Photo-curing technology, or LSPc for short, which will be covered further. In today’s article, we are going to talk about the company’s flagship industrial-grade resin 3D printers — NXE 200 and NXE 400.

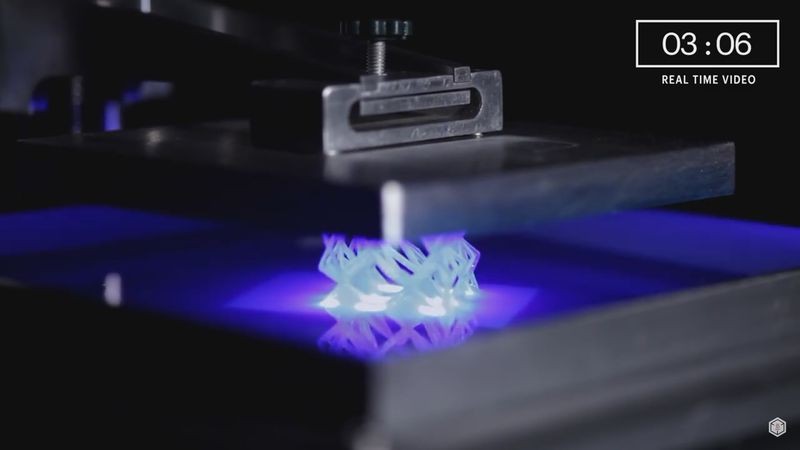

The company’s unique LSPc technology allows printing an object without lifting the build platform for adding the next portion of the resin, as in other stereolithography technologies. The absence of intermediate upward movements is the base for a sharp increase in print speed, which is up to 6.5x faster compared to regular SLA and mSLA devices, 20x productivity gains, and impressive accuracy, while the surface of the model becomes perfectly smooth and free of visible boundaries between layers.

The NXE 400 is one of the fastest resin 3D printers in the world, printing at up to 10 mm per minute. The machine also generates extremely high print accuracy and produces extremely hard-to-break parts with excellent mechanical properties and a smooth surface finish alongside millimeter-precision.

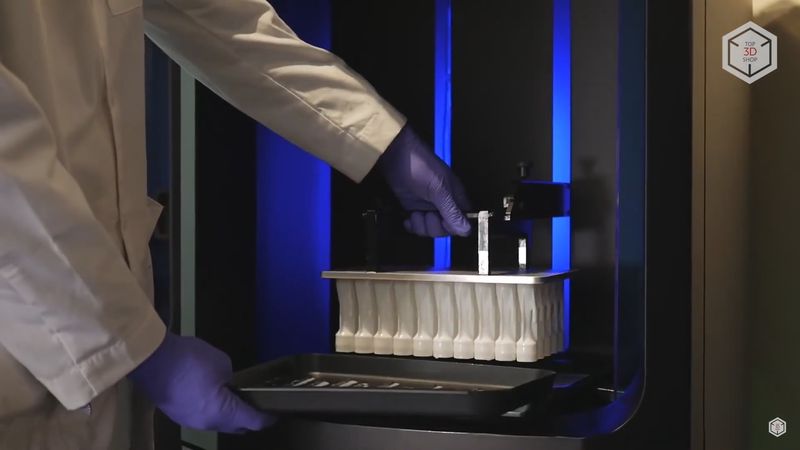

With a large build area of 275 x 155 x 400 mm, the printer is an ideal tool for a wide variety of applications, from prototyping to mass production.

The new model in Nexa3D’s lineup, the NXE 200, is in fact a modification of the NXE 400 with a smaller print volume but the same width and height of the build area. Despite this slight reduction, the new model can still print 85% of desired production parts. Just like with its predecessor, the modular construction guarantees easy maintenance and upgrades to the machine’s components, which provides additional savings over time.

Both NXE models are mSLA machines powered by a 4K monochrome LCD light engine with a pixel size of 76.5 microns. The resin is cured layer-by-layer by an array of UV LEDs with a light wavelength of 405 nm. LSPc technology allows the production of parts with a layer thickness of 50, 100, or 200 microns, which ensures perfectly smooth exterior surfaces, top-quality complex geometry, and detailed composition.

Nexa3D offers a wide range of proprietary materials developed in collaboration with Henkel, Keystone, and BASF. The list of available consumables includes many types of resins for effective production of dimensionally accurate, hard-to-break parts, such as general purpose, flexible, high-strength engineering, temperature-resistant photopolymers, and dental resins.

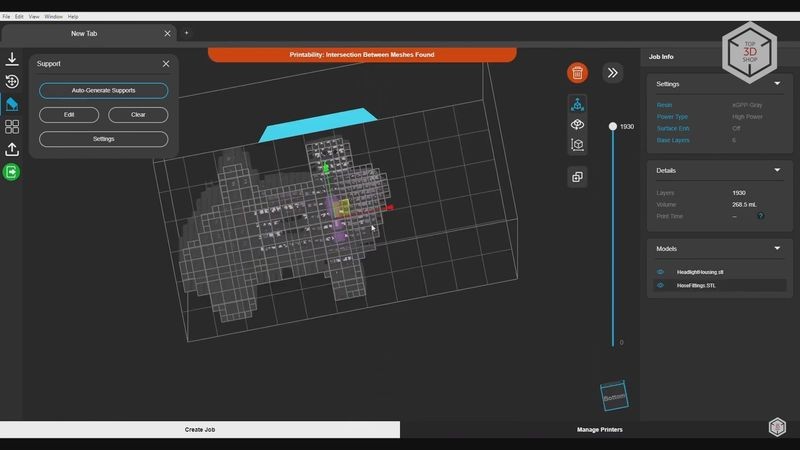

Both NXE 200 and NXE 400 3D printers use the NexaX proprietary software, supporting such file formats as STL and 3MF and running on Windows. File transfer to the printer’s memory is carried out via a wireless connection or an Ethernet local area network.

A color touchscreen located above the build chamber of the device is used to control the operating modes of the machine.

The Nexa3D lineup also includes two devices for post-processing the finished parts: the xWash and the xCure stations. Both devices operate in automatic mode.

Both NXE models serve as perfect machines for professional applications in manifold industries, including automotive, medical, engineering, consumer goods, education, and more. The printers can be effectively used for rapid prototyping, reverse engineering, dental 3D printing, and more.

The Nexa3D NXE 400 and NXE 200 are state-of-the-art industrial devices for highly professional use that combine the company’s successful LSPc technology, patented structured light matrix, high performance, reliable hardware platform capable of days of uninterrupted printing, intelligent software, and top-quality materials to greatly accelerate additive manufacturing process. Due to all these benefits, the machines will be a valuable tool for production of complex and strong models, functional prototypes, engineering builds, jigs, and fixtures.

Update your browser to view this website correctly. Update my browser now

Write a comment