Nexa3D is the manufacturer of one of the world's fastest 3D printers. The proprietary LSPc technology delivers high-quality printing at unseen speeds. The unique combination of speed and quality makes Nexa3D printers full-fledged industrial equipment suitable not only for the manufacture of single models and small batches but also for large-scale production.

Source: newtechnologyreview.com

The California-based company Nexa3D Inc was created as a startup to develop and manufacture high-speed 3D printers. It was founded in 2014 on the initiative of Avi Reichental, one of the 3D printing pioneers, who was then CEO at 3D Systems.

Today, Nexa3D remains a small business with a turnover of $3 million. However, it has managed to achieve worldwide fame as the manufacturer of the fastest printer in 2020. The company's website notes:

“We make the world’s fastest polymer 3D printers affordable for professionals and businesses of all sizes. Our groundbreaking technology is shattering traditional 3D printing productivity barriers and opening the aperture of additive materials. Our printers take current additive manufacturing speeds from ‘dialup internet’ to ‘broadband’ printing and are capable of continuously printing at speeds of up to 8 liters per hour. This represents some 20X productivity gains compared to all of current state additive products and is comparable only to injection molding economics.”

The key feature of Nexa3D printers is the LSPc technology, which stands for Lubricant Sublayer Photo-curing.

The technology is based on the process of photocuring: the liquid resin is exposed to ultraviolet light, which causes polymerization, leading to curing. The resin is poured into a vat, the bottom of which is made of a material permeable to ultraviolet radiation. Underneath is a UV matrix. The bottom of the vat is covered with a self-lubricating membrane that prevents the formed model from sticking. The membrane also contributes to print quality, ensuring that the resin is delivered to all printing areas, whether the model is solid or hollow.

The formation of the model begins on the surface of the platform, which lies in the resin at a distance of several tens of microns above the membrane. UV light is focused on the gap between the platform and the membrane; the resin begins to harden, adhering to the platform. The platform rises, and, following its movement, the “pattern” of ultraviolet illumination changes, forming the structure of the printed model.

The technology makes it possible to print an object without taking a break to lift it (for the next portion of resin to have access to the printing area), which is the case with other stereolithography technologies. The absence of intermediate lifts results in a rapid increase in the speed and accuracy of printing. The surface of the model becomes perfectly smooth thanks to the absence of visible boundaries between the layers.

Source: https://www.3ders.org/

The NXE 400 seems to be the world's fastest 3D printer to date: it prints at speeds up to 10 mm per minute. In addition to high speed, the device enables immensely high print accuracy. The surfaces of products printed on the NXE 400 are characterized by low roughness previously seen only in molded products.

With its large build chamber, this printer is an ideal tool for solving a wide variety of technical problems — from prototyping to serial production.

Source: nexa3d.com

The xCure smart device is designed to wash and cure parts printed on Nexa3D printers. It provides fast and high-quality cleaning as well as increases the durability of created 3D prints without changing their mechanical characteristics.

The xCure is equipped with high-power LEDs generating two wavelengths of light and is capable of operating in three curing modes:

The internal volume of the chamber is 16 liters, it can hold up to three plates simultaneously. Printed models can be processed directly on the build plate or placed in special baskets.

The pre-installed software includes modes for working with all existing Nexa3D materials, and can be easily expanded when new ones become available.

The manufacturer's website currently contains nine photopolymer materials, which are called photoplastics. These are developed for various tasks — their mechanical properties significantly differ from each other. Moreover, their number is expected to increase.

|

Materials |

Properties |

|||

|

Tensile strength |

Young’s modulus |

Elongation at break |

Shore hardness |

|

|

xCast |

6~13 MPa |

0.12~0.29 GPa |

6~11 % |

56~63 D |

|

xPRO410 |

41.6 MPa |

2.37 GPa |

5.5 % |

79 D |

|

xMED412 |

38 ± 1.4 MPa |

1.24± 0.04 GPa |

141 ± 4% |

70 D |

|

xCE-White |

69 ± 2 MPa |

2.84 ± 0.13 Gpa |

8.0 ± 0.4 % |

89 D |

|

xCE-Black |

69 ± 2 MPa |

2.84 ± 0.13 GPa |

8.0 ± 0.4 % |

89 D |

|

3843-xABS Black |

60 ± 1 MPa |

1.89 ± 0.52 GPa |

47 ± 8 % |

86 D |

|

xGPP-Translucent |

60 MPa |

2.3 GPa |

5.5 % |

88 D |

|

xGPP-Gray |

30 MPa |

2.1 GPa |

2 % |

84 D |

|

xGPP-Blue |

32.4 MPa |

2.2 GPa |

3.15 % |

80 D |

Source: facebook.com

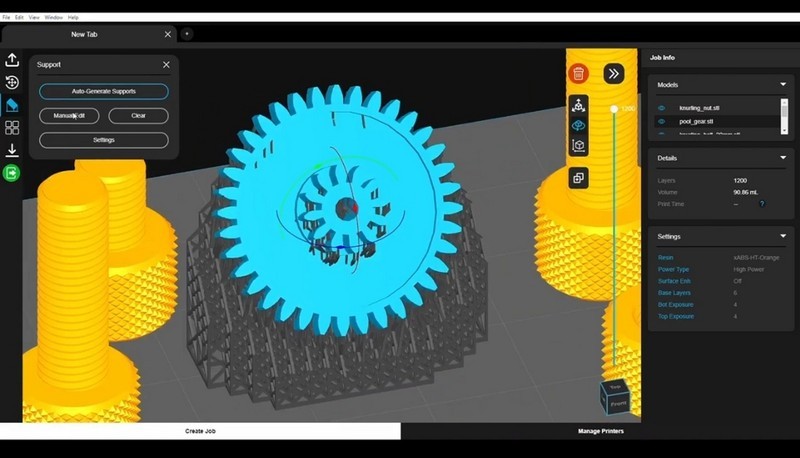

The NexaX Digital Twin Printing software (DTP) optimizes the entire print cycle using algorithms that speed up the process, minimize material consumption, and provide the following:

intuitive file preparation;

full control of the printer settings;

selection of the print options: time, resin, task, etc.;

visual cues — the necessary supports, overlaps, etc.;

best mechanical characteristics of each model.

The main advantages of Nexa3D printers are:

extremely high print speed combined with high quality;

large build volume, making it possible to print products in large batches;

a wide range of resins with very different characteristics;

low power consumption;

convenience and safe operation.

The strategic partnership between Nexa3D and the Henkel chemical company should also be mentioned as a significant advantage. Thanks to their close cooperation, it became possible to develop new materials that completely meet both the technical requirements of the 3D printer manufacturer and the needs of customers.

The disadvantages include:

big overall dimensions of the equipment and its weight;

the high cost of the printer, software, and consumables.

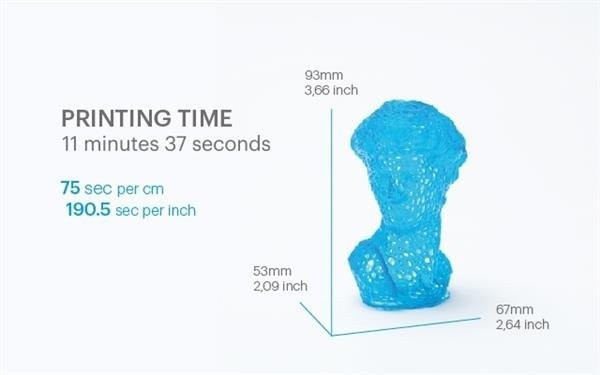

With the capabilities of LSPc technology, the NXE400 dramatically increases print speed, reducing the time required to produce objects from hours and days to minutes. It allows you to quickly manufacture hundreds of parts on one plate and significantly shorten the design cycle.

Source: nexa3d.com

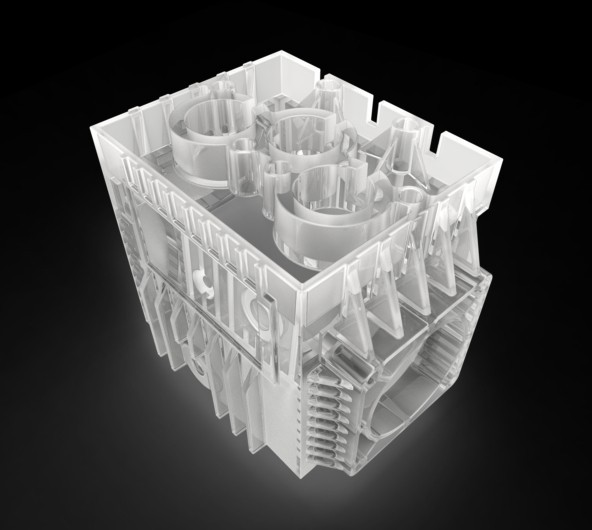

The NXE400 is indispensable for preparing complex geometry parts. The ability to print materials with very different properties ensures ample opportunities for rapid prototyping and subsequent refinement.

Source: nexa3d.com

With its fast and high-quality printing, the NXE400 is great not only for prototyping but also for batch production.

Source: nexa3d.com

The closest alternative to the NXE400 is the Carbon M1 3D printer. This device uses the CLIP technology (Continuous Liquid Interface Production) which differs from the LSPc in that instead of a membrane it uses a special "window", transparent to light and permeable to oxygen. The oxygen flux forms in the liquid polymer a "dead zone" only tens of micrometers wide, where polymerization is impossible. Other than that, there is no fundamental difference.

The printing speed of the Carbon M1, is claimed to outperform competitors by 20–100 times.

The Carbon M1 demonstrates a considerably lesser layer thickness: 10 microns versus 50 microns. But the NXE400 is almost five times larger than the Carbon M1 in the build chamber size: 280 x 165 x 400 mm versus 144 x 81 x 330 mm. One more significant advantage of the NXE400 is the greater number of printable resins: there are currently nine of them, versus seven for the Carbon M1. Furthermore, this gap is expected to widen, thanks to the partnership between Nexa3D and Henkel.

Another important advantage of the Nexa3D printer is that it’s available for purchase while Carbon printers are supplied only by subscription (something like a lease, with software and technical support, included in the price). Not only does it cost $40.000 per year, plus $10.000 for installation, with a minimum contract of three years — it is also unavailable in several regions.

Traditional technologies have limitations in the complexity of the shape and structure of manufactured products. Besides, the production of single models and small batches is nearly always economically impractical due to the high tooling cost.

3D printing allows producing objects of any shape and internal structure, and the price of a print is virtually independent of the batch size. Yet, until recently, the use of 3D printers in industries has been limited by low print speeds.

The NXE400 breaks all the print speed records, making it possible to produce objects almost as quickly as using conventional methods. The possibilities for its application are boundless in terms of any process related to the manufacture of plastic parts, accessories, and finished products.

Update your browser to view this website correctly. Update my browser now

Write a comment