Hello, dear reader. This time, we are going to tell you everything you need to know about CreatBot F160 PEEK (also known as CreatBot F160) ― one of the most cost-efficient printers designed to print with refractory materials. The device is compatible with engineering polymers, including the ones reinforced with carbon fiber, and with high-performance materials like ULTEM. Besides, there are no limitations applied to filament brands whatsoever, so you are free to use those that suit you best.

Continue reading to know more about the main peculiarities of this excellent desktop FDM 3D printer.

Source: facebook.com

Henan Suwei Electronic Technology Co., LTD was established in 2011 and, as of now, is a quite prominent manufacturer of 3D printers. Located in China, the company began the production of their own industrial FDM 3D printing machines under the proprietary brand named CreatBot. The main advantages of CreatBot products are affordability and a truly wide range of filaments compatible with the device. Another distinctive feature is reliability — all of the models feature enclosed high-temperature chambers with robust, steel-made bodies. By the way, first batches of the printers have already been up and running for 9 years (more than 30 000 hours of operation time), which is another fact that highlights their reliability.

The current lineup consists of seven different models, and the company produces and sells as much as 3000 printers annually. Such reasonable demand is explained by the above-mentioned advantages, and the brisk manner, in which the manufacturer continues to conquest the global market. The company’s firm grasp can be traced back to January 2013, when CreatBot printers first appeared on the digital market and got certified by the EU in November the same year. Just a couple of years later, they also received the USA certification.

Source: facebook.com

The company’s clientele can be divided into two main groups. The first group consists of private clients, educational institutions, and small facilities that prefer standard devices, such as CreatBot F160 PEEK. Another group (health facilities in particular) opts for more advanced devices, such as new CreatBot PEEK-300.

Source: creatbot.com

Specifications

Source: creatbot.com

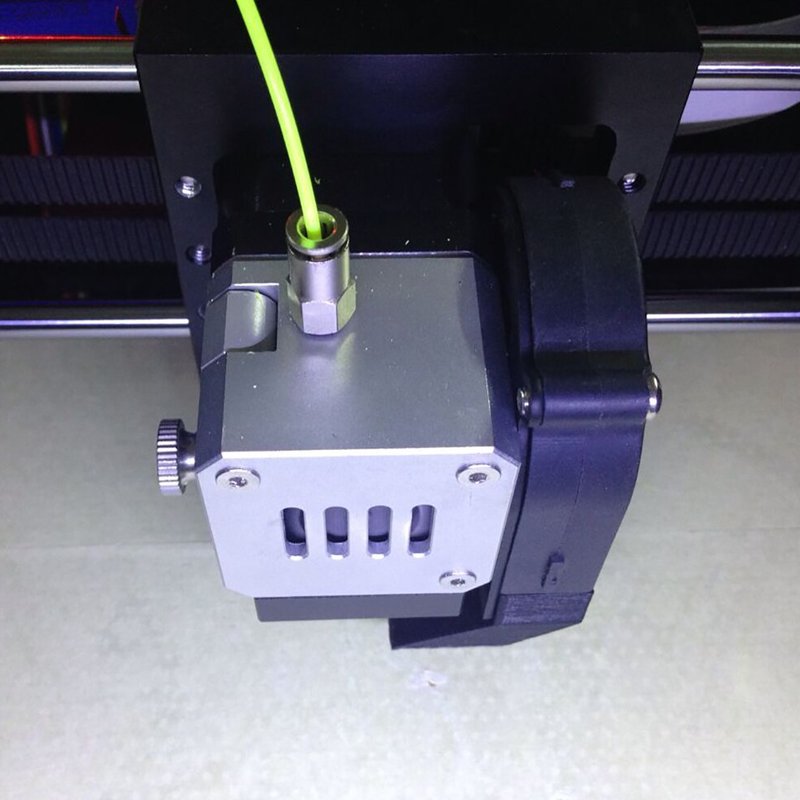

CreatBot F160 PEEK is a desktop printer designed to fulfill the needs of both manufacturers and educational institutions. The main feature of this particular model is that the nozzle can be heated up to 420 °C, which makes printing with high-performance polymers like PEEK, or carbon fiber reinforced ones available. In order to see the process of printing with carbon fibers, please refer to the video below:

The printer is compatible with both hard and soft polymers, requiring a filament diameter of 1,75 mm. The maximum dimensions of a printed model will be 160 x 160 x 200 mm, which is quite good for such a device. Moreover, a horizontal resolution of 40 µm ensures that the products are manufactured in a precise fashion, taking away the need for post-processing duties such as polishing.

Source: creatbot.com

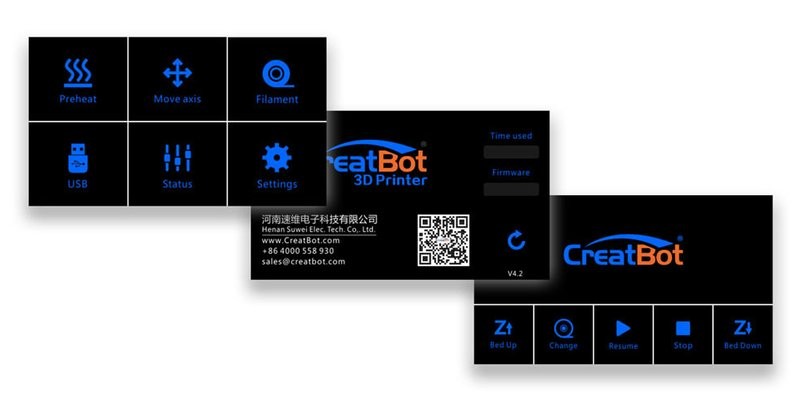

CreatBot F160 PEEK features a fully enclosed high-temperature chamber and a steel-made body with 4 acrylic glass doors. The filament spool holder is located inside the printer, on its back wall. The files can be uploaded to the printer via a USB flash drive. You can control the printing process via a 4.3" touch screen located on the front side of the printer.

Source: creatbot.com

Before printing, you’ll have to set up temperature parameters for the hotend and build plate. The optimal values can always be found inside the device manual. For more useful features, CreatBot F160 also has ‘Outage Restored’ and ‘Filament Detection’ functions, which help to prevent any misprints related to a sudden power outage or lack of filament. In such situations, the printing process will stop automatically. Then, it can be resumed manually, after the problem is resolved. Moreover, you are free to stop the process yourself at any time needed.

Source: creatbot.com

Inside the box, there is a fully assembled CreatBot F430 that’s ready to print. There is also a USB cable, palette knife, technical documentation, USB flash drive, and masking tape.

Source: creatbot.com

Before proceeding to the actual printing process, you’ll first have to manually level the build plate. To do this, turn on the printer and select ‘All Home’ on the display’s menu. This action will bring the extruder to its minimum position. Then, make sure that the distance between the extruder and the plate is 0,2 mm (200 µm), which is roughly equal to two standard sheets of office paper that are usually used for such calibration procedures. After this, consecutively move the extruder into each of the plate’s corners. If the nozzle-plate distance is incorrect, use some screws to readjust the plate position.

In order for the printed model to stick to the plate, the platform needs to be processed with a hard glue or adhesive tape. Before inserting the filament, make sure to secure it into the extruder guide and to warm the extruder up.

Source: creatware.software.informer.com

CreatWare is a convenient go-to proprietary solution developed by the manufacturer, available on Windows and Mac OS. It is considered the best practice for designing and slicing 3D models while using CreatBot machines. Besides, you are free to use Simplify 3D, Cura, or Slic3r if you wish. CreatBot F430 works with .stl, .obj, and .amf file formats.

Source: creatbot.com

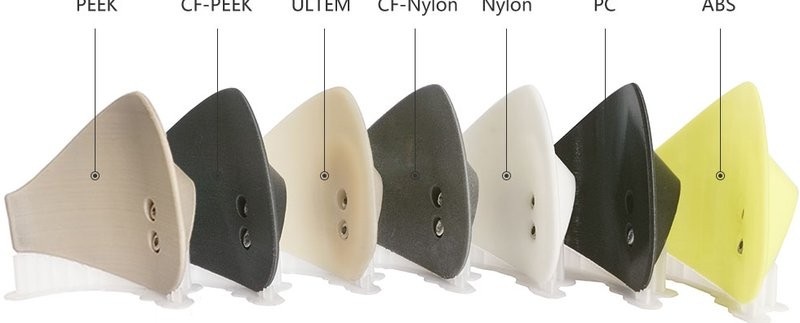

One of the most distinctive features of CreatBot F160 PEEK is the ability to print at high extruder temperature, making it compatible with high-performance polymers like PEEK (Polyetheretherketone). PEEK is a highly durable engineering polymer with a melting temperature of 343 °C. The products made from this polymer are widely used in various industries, replacing its counterparts with more lightweight ones. ULTEM (PEI, Polyetherimide) is a less durable, but more affordable analog of PEEK that can also be used with the device.

Source: creatbot.com

Carbon-reinforced filaments like CF-PEEK (Carbon fiber reinforced PEEK) and its cheaper analog PA-CF (Carbon fiber reinforced nylon) are compatible with the printer too. These are thermoplastic composite materials that consist of 30% carbon fiber, which accounts for outstanding durability and a high degree of corrosion resistance of the final product. Needless to say, CreatBot F160 is able to print with popular materials, such as PLA, ABS, and TPU.

Source: 3dprintingmedia.network

3D printing with refractory polymers is a common practice in different industries. In such cases, PEEK is the material of choice because of its outstanding durability and heat resistance that allow the manufacturing of products with a high degree of chemical and abrasion resistance. Products made from PEEK usually have thin, but truly durable walls, and, as a rule, are quite lighter than their metal analogs. Such properties are always in demand in the aerospace industry, where PEEK is used to print cable trunks. Because of its biocompatibility, PEEK is also widely used as the main material for 3D printed implants and thin catheters for health facilities.

MedCAD, a US-based company located in Texas is manufacturing implants for the purposes of craniofacial surgery on demand of health facilities. Additive manufacturing provides excellent precision, that’s why the produced implants, as a rule, are a perfect fit. Another important factor is manufacturing speed ― the implant can be received in just 5 days after completing the computed tomography.

In order to highlight all of the benefits provided by replacing metal parts with their PEEK analogs, let’s review the example of using electrical cable clamps in Boeing 787 aircraft. When using the polymer part, the installation time can be reduced by 30%. But the most important factor is that polymer clamps are 20-50% lighter than the metal ones. Each aircraft has thousands of clamps, so if all of the metal clamps are replaced with their plastic counterparts, the total weight reduction would really matter. The lighter the plane, the less fuel it burns, resulting in a prolonged operation period and reduced environmental damage.

PICASO Designer X is an FDM 3D printer developed in Russia. The device is very similar to CreatBot F160 PEEK in terms of features and functionality, but is more affordable. Designer X has a maximum nozzle temperature of 410°C, which makes printing with refractory materials available. It has a minimum layer height of 10 microns and a maximum build volume of 200 x 200 x 210 mm, which is more than that of its Chinese analog.

PICASO Designer X and CreatBot F160 PEEK are very similar - both in terms of functionality and performance. The final words will be the buyer’s.

The main pros and cons of CreatBot F430 are the following:

Pros:

Cons:

CreatBot F160 PEEK provides the opportunity to use FDM technology to its utmost potential. 3D printing with high-performance and composite materials will sure be of liking to both additive manufacturing enthusiasts and to manufacturers that build lightweight parts for the needs of various industries. Another important factor to consider is the reputation of CreatBot F160 PEEK’s manufacturing company, which is excellent.

You can purchase CreatBot F160 PEEK at Top 3D Shop. This exceptional and high-quality device comes with the manufacturer’s warranty. In addition, our team will make sure to provide the best service possible, just like we always do.

Update your browser to view this website correctly. Update my browser now

Write a comment