Hey everyone! Today, we will talk about a large-format industrial-grade machine by the renowned Chinese company Creatbot — the D600 Pro 3D printer, which takes professional additive manufacturing technologies to a new level. The article will look at both the standard version and its upgraded Pro iteration. Read on to get acquainted with the features and capabilities of the device as well as discover an interesting use case.

Living up to its name, the Creatbot D600 Pro boasts an impressive build volume of 600 x 600 x 600 mm. Another important advantage of the device is a dual print unit with two separate extruders, which allows printing objects with soluble supports. These features make it possible to produce large, complex models; coupled with the ability to use a wide range of materials, they entitle the device to be regarded as a prime example of high-end professional 3D equipment.

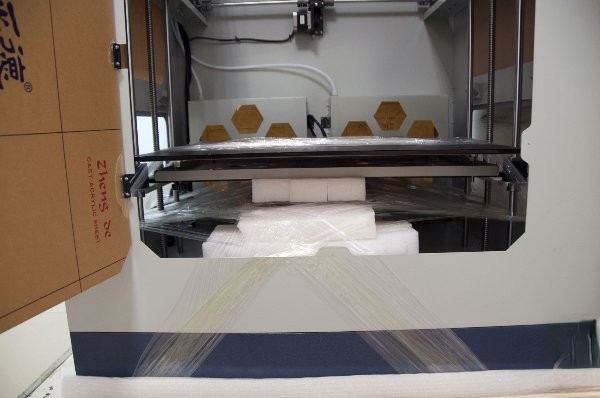

The printer comes in a wooden box that contains the following items:

The Creatbot D600 Pro has an all-metal structure with overall dimensions of 915 x 845 x 1085 mm and a weight of 125 kg. The device sports quite impressive rigidity, which reduces vibrations during the print process.

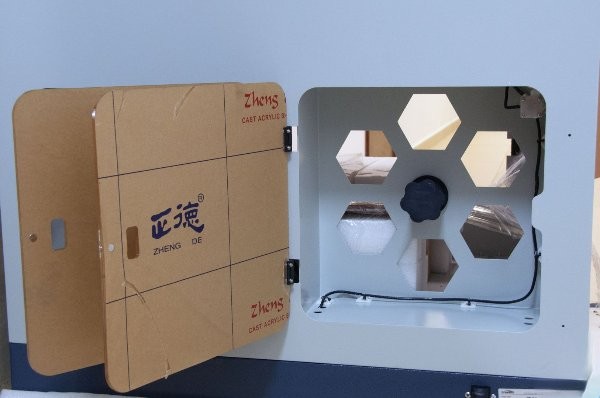

The frame has many doors and windows allowing access to the printed model from any side. Filament spool holders are located at the back of the body. Thanks to the completely enclosed chamber, there is no external interference during operation, the noise level is reduced, and the temperature inside is maintained so that the product does not deform during printing. Thus, the device can easily print plastics characterized by high shrinkage, for example, ABS derivatives or nylon.

The Pro version boasts a few extra features that add to the functionality of the device. First, it has a filament drying chamber with the possibility for the user to set the temperature of 45 or 65 °C. Secondly, the build chamber is equipped with a heater. Last but not least, the Creatbot D600 Pro sports an auto leveling system using a BLTouch sensor. Watch the following video to check out the upgrades of the enhanced version.

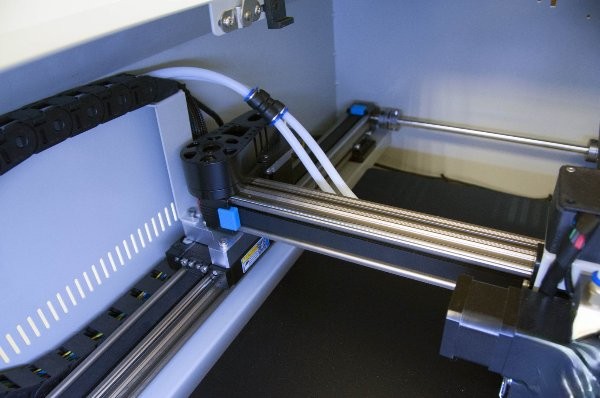

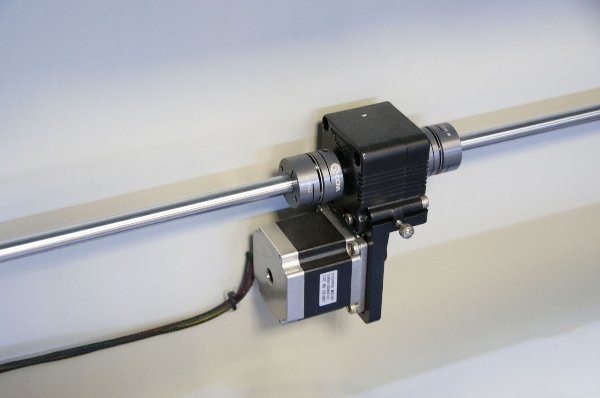

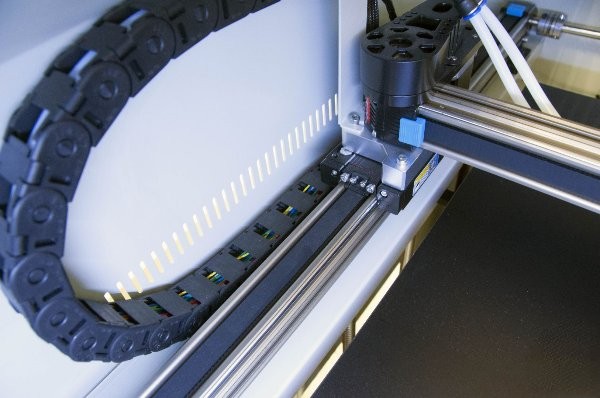

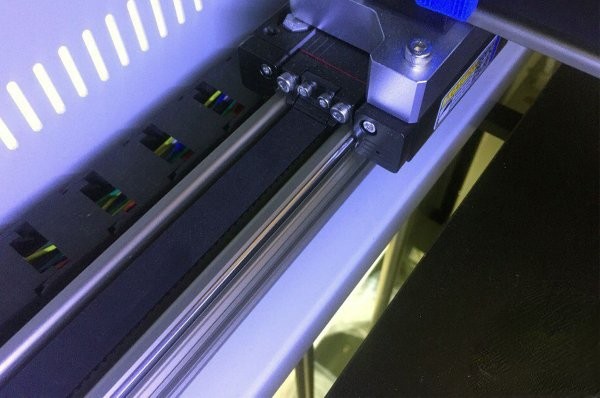

Made in the form of a single unit with a belt, linear rail guides ensure high positioning accuracy — higher than not only that of their counterparts but even of some optical printers available on the mass market. Albeit a little slower than analogs on the H-Bot and Core-XY systems, the classic kinematic scheme provides much more reliable printing due to the direct drive of the motor. By the way, along the Y-axis, the printing unit moves using two belts (one per rail).

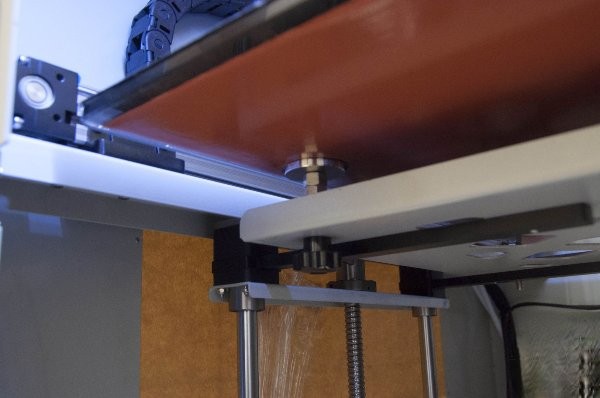

Along the Z-axis, the heated bed is moved by means of two ball screws installed at the side walls. Four cold-rolled shafts with a diameter of 16 mm serve as guides for the print bed.

Block rails with an integrated belt are installed on the X and Y axes.

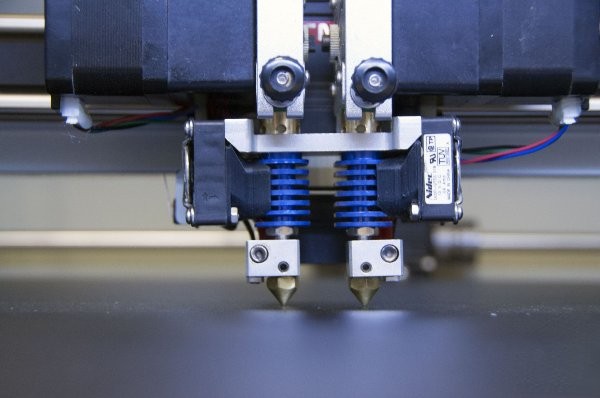

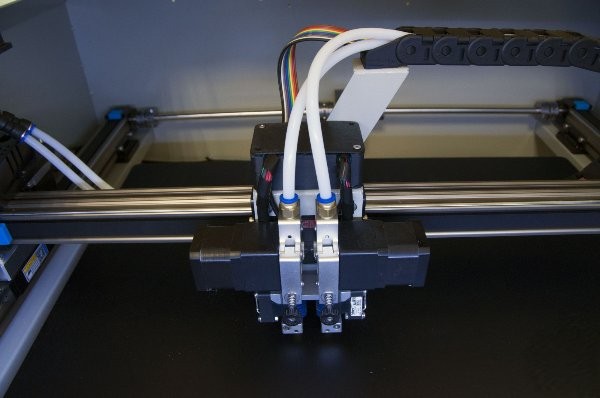

The printer comes standard with a dual print unit with two extruders. It is also possible to install an optional third. The extruders are equipped with a gearbox, the reduction ratio standing at 1:10.

The all-metal feeding mechanism allows printing a wide array of materials, which is also ensured by the nozzle heating up to 400 °C. The print unit itself is made according to the classic scheme (direct extruder). Two small fans with adjustable speed blow on the cold end.

0.4 mm nozzles are installed by default. If necessary, the user can replace them with other diameters for a specific task (0.3, 0.5, 0.6, 0.8, 1.0 mm).

In case of a power outage, the printer will automatically memorize the current position and save the print data, lower the build platform, and retract the nozzle.

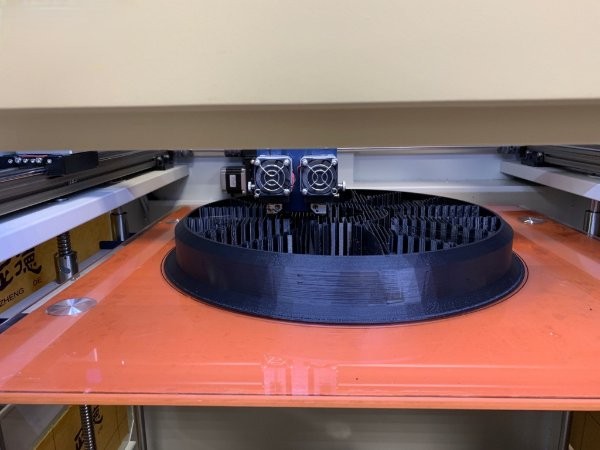

The build plate of the device is made of glass ceramics and can be heated up to 100–110 °C. A surface similar to BuildTak acts as an adhesive, holding even very large objects made from materials with high shrinkage.

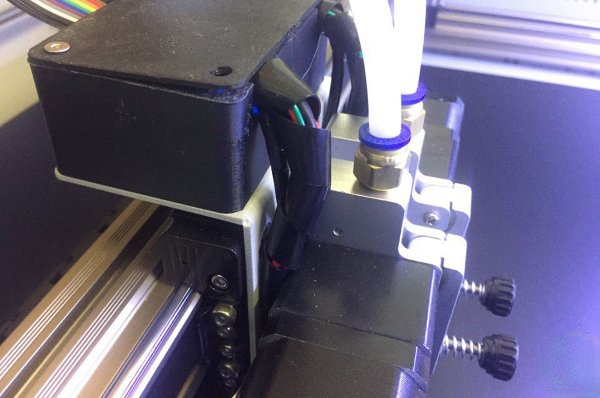

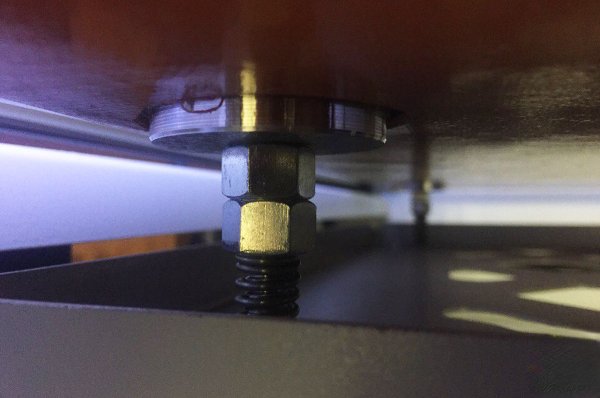

Leveling screws are located at the bottom of the print bed.

The Creatbot D600 is equipped with a 4.3-inch touchscreen. There are separate menus for preheating and movement along axes. The interface contains intuitive icons allowing you to quickly understand the toolkit and operate the printer with maximum convenience.

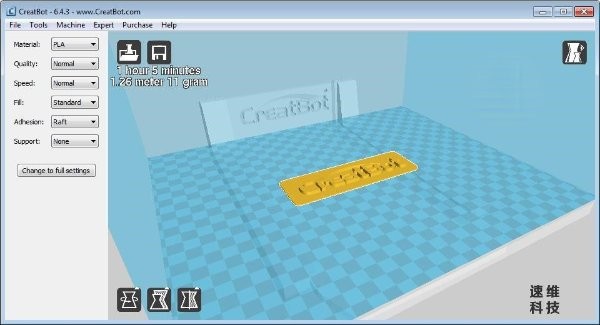

The printer comes with a free, easy-to-learn CreatWare slicer based on the popular Cura 1.5.4. The user can download the program from the manufacturer's website. Third-party software is also compatible with the device.

To assess the scope and quality of printing that the machine is capable of, let’s take a model of a wheel rim for BMW vehicles and print it with the D600 Pro.

In order to avoid wasted use of expensive filament (as we don’t know what the output is going to be), we employ ABS, so the resulting object cannot be utilized — it is made for demonstration’s sake. Single extrusion is used for the same reason, with no additional support material taking part in the process.

For this task, a 0.6 mm nozzle is applied. Layer height: 300 microns. Infill: 20%; overlap: 30%.

The rim has a diameter of 431 mm and a height of 120 mm. It was post-processed with acetone to smooth the surface. As is seen from the photo, the result is outstanding.

The Creatbot D600 Pro 3D printer is designed to solve serious tasks of printing large-sized objects. Significant advantages of the device include reliable and accurate kinematics, the ability to heat the extruder up to 400 degrees, dual extrusion print head, high build quality. These and other features make the D600 series a perfect solution for professional 3D printing studios.

Update your browser to view this website correctly. Update my browser now

Write a comment