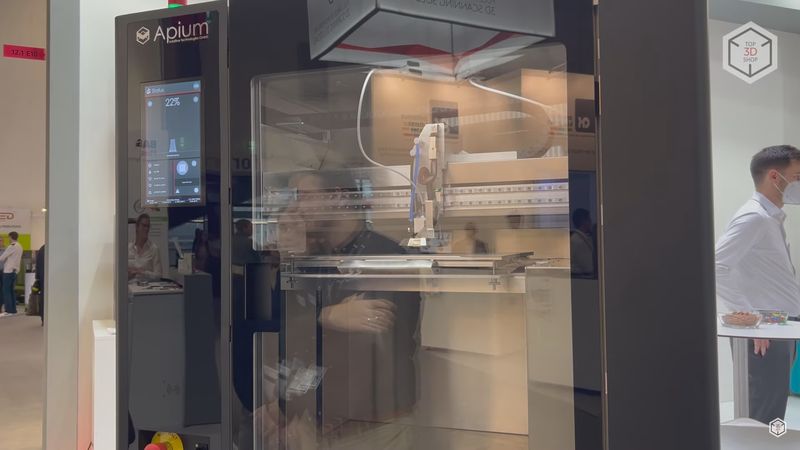

Hi everyone! This is Top 3D Shop, and in the following article we are going to introduce you to industrial-grade 3D printers by Apium.

The current range of Apium 3D equipment includes three industrial-grade models — P220, P400, and M220. All of them are designed for high-precision printing with such materials as regular and carbon fiber-reinforced PEEK, PEI, and other high-temp plastics and composites. So, let’s find out more about their technical characteristics, main features, and spheres of application.

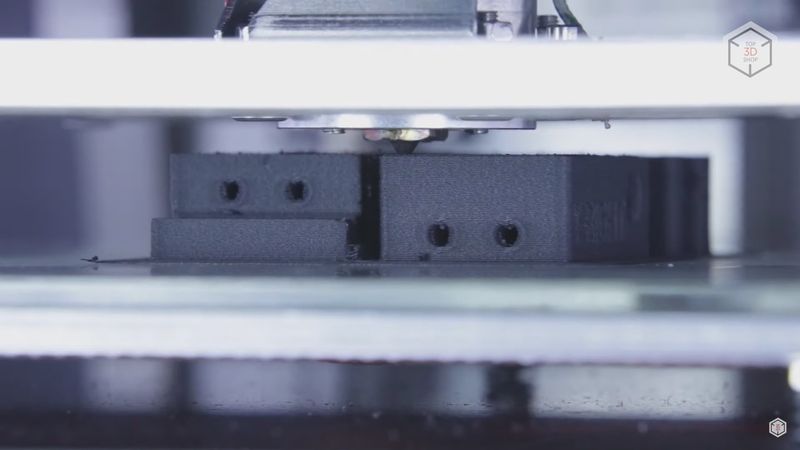

The P220 model is a unique 3D printer capable of processing pure PEEK with high crystallinity or carbon fiber-reinforced PEEK with up to 30% fiber content. Due to an innovative adaptive zone heating system, the printer ensures time and energy saving as well as optimal printing conditions for highly demanding industrial filaments.

The main specs of the device are as follows: maximum extruder temperature — 540 °C; platform heating — up to 160 °C; build volume — 205 x 155 x 150 mm; and the layer thickness from 50 to 600 microns.

The advanced extruder with 4x higher feeding allows printing with composite materials as well as metal-filled filaments with further debinding and sintering to get ready-to-use full-metal parts.

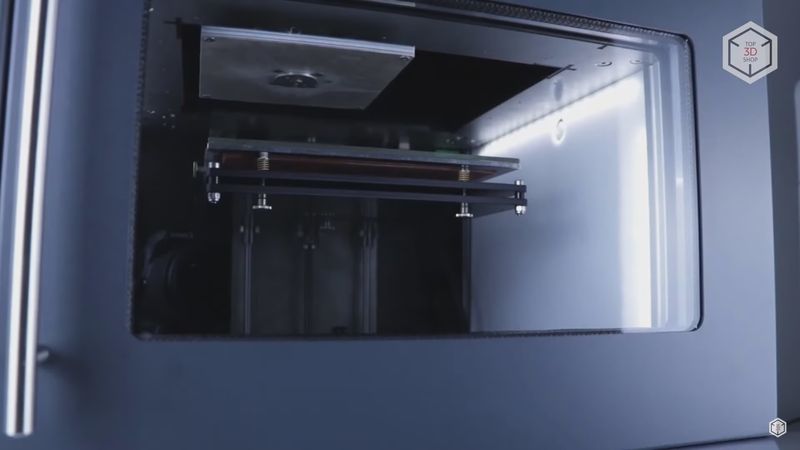

Apium P400 is a device for printing with two materials, equipped with a system of independent dual extrusion called IDEX.

The design of the flagship model uses premium components. The model is equipped with an optical calibration system and includes an integrated module for filament drying.

The printer features the maximum extruder temperature of 540 °C, a print bed heated up to 200 °C, print chamber of 400 x 300 x 300 mm, and layer thickness from 50 to 600 microns.

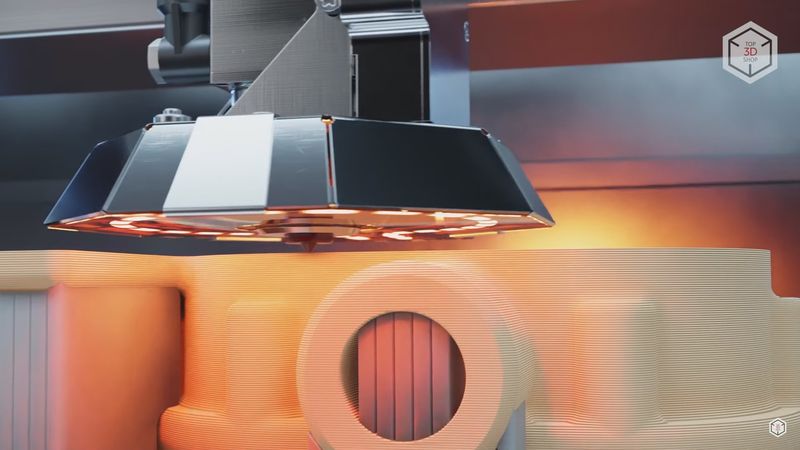

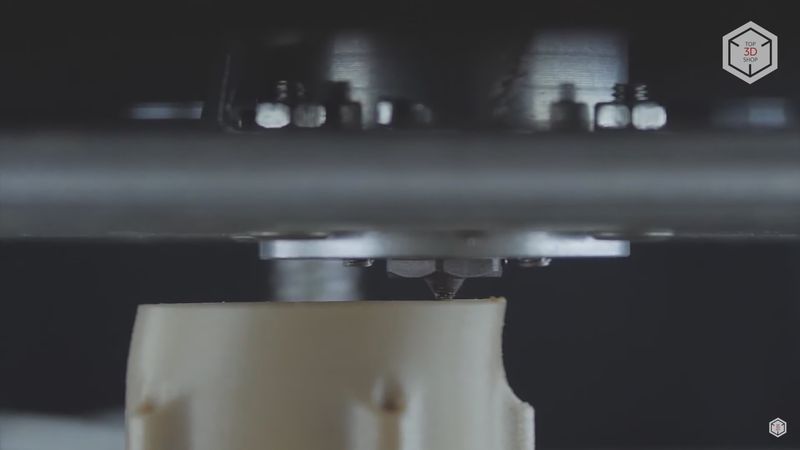

Both of the mentioned models are equipped with a patented adaptive heating system — the heat is supplied only where it is needed, in the uppermost layers. The printhead design includes a zone heater that generates a thin stream of hot air at temperatures of up to five hundred degrees directly above the print surface. This solution guarantees high-quality products printed in the most complex materials.

And the last model in the line is M220 — the first 3D printer specially designed for printing medical devices and implants made of PEEK.

The unit is equipped with a sterile build chamber, and all its working components are made of biocompatible materials. Plus, the hot-air filter system ensures a sterile printing environment essential for medical device manufacturing.

The extruder of the M220 can heat up to 540 °C, while the temperature in the print chamber can reach 280 °C.

This model has a build volume of 130 x 130 x 120 mm and is capable of printing layers at thickness from 50 to 600 microns, like the previous Apium 3D printers.

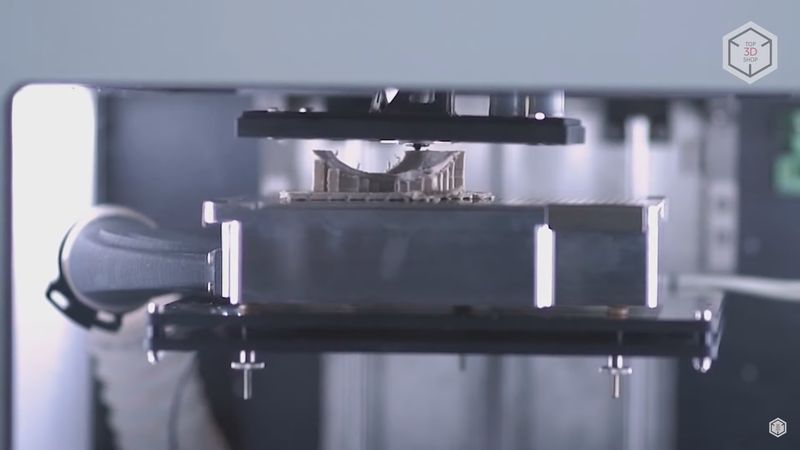

The printed models below demonstrate impressive capabilities of the highlighted Apium devices:

One of the most distinctive features of Apium 3D printers is their capability of printing with PEEK and other engineering filaments. This allows using the company’s machines for a variety of applications in different industries, including automotive, aerospace, engineering, and others. Thanks to the patented adaptive zone heating system, Apium devices provide superior interlayer adhesion that results in isotropic properties of finished parts, comparable to conventional manufacturing methods like injection molding.

Update your browser to view this website correctly. Update my browser now

Write a comment