In today’s article we are going to cover the main features and technical peculiarities of the new Funmat Pro 610 HT FDM 3D printer from the popular Intamsys Funmat line-up, which includes the Funmat Pro, the Funmat HT, and the Funmat Pro 410 models. So, what to expect from this highly professional device?

Intamsys is a well-known manufacturer of professional and industrial FDM 3D printers capable of processing high-temperature thermoplastic polymers, such as PEEK, PEKK, Ultem, etc. The company’s lineup includes machines of various sizes, from desktop devices to large industrial equipment.

The 610 HT is the flagship model in the Funmat Pro series. This industrial high-performance printer is designed for manufacturing functional parts for testing and small-scale production.

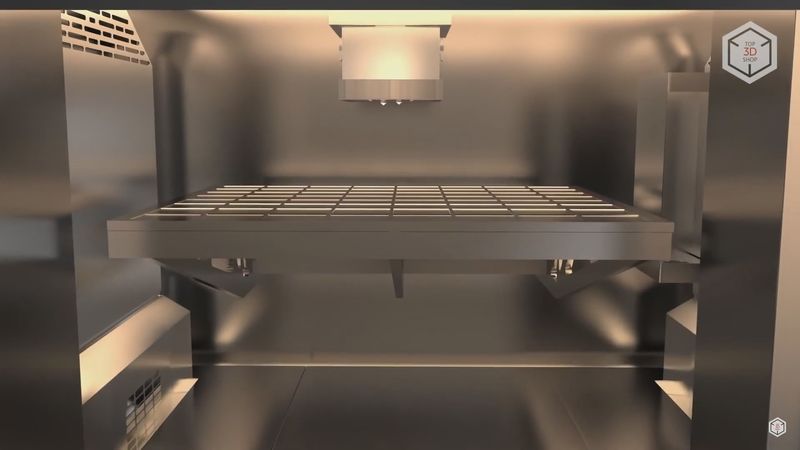

Due to the effective thermal system, the Funmat Pro 610 HT is capable of processing engineering-grade consumables with the access to ultra-high heating modes for the print bed and build chamber, the temperatures of which reach up to 300 °C. As for the machine’s dual extruder, it is able to print high-performance polymers with a melting point of up to 500 °C.

The build volume of the machine is 610 x 508 x 508 mm, while a minimum height achieves 50 microns with a position resolution of 12.5 (XY) and 1.25 micron (Z). This precision is combined with a decent travel speed of 500 mm/s on the XY-axes and 50 mm/s on the Z-axis.

The printer’s extruder is equipped with dual nozzles, which means that the new Funmat Pro is ready to print with two high-temperature plastics simultaneously, for instance, a basic filament and fitting support material. The same goes for time-effective multi-color 3D printing.

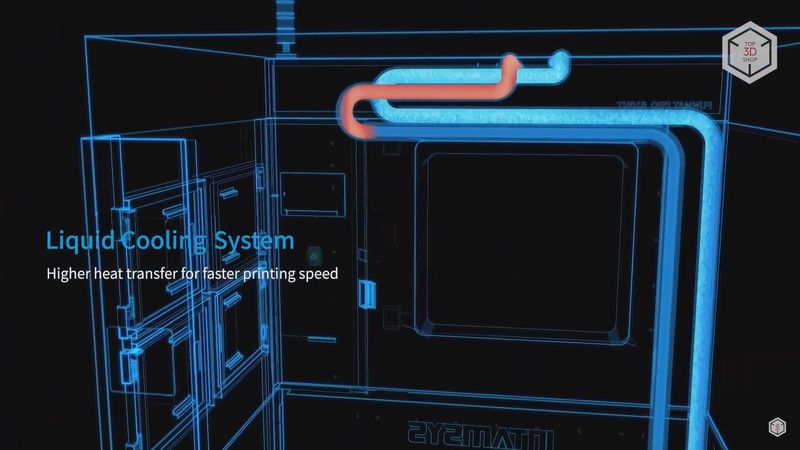

A handy auto-cleaning function takes care of nozzle cleaning, making for more accurate and neat prints. Apart from that, the extruder carries an effective liquid cooling system, which reduces the risk of overheating and warping as well as keeps nozzles from clogging, which is especially important when dealing with demanding filaments.

Thanks to the printer’s open material system, the range of supported consumables includes proprietary and third-party high-temp filaments, such as polyetheretherketone, polycarbonate, nylon, thermoplastic polyurethane, and carbon fiber reinforced plastics. Naturally, the machine can also handle more conventional ABS, PLA, and HIPS.

As for printing with PEEK, the particular interest of professional users is usually related to the physical properties of the material. It is lightweight, yet strong and durable at the same time. Due to these peculiarities, PEEK is used in experimental medicine to repair damaged spinal cords.

In terms of construction, the printer’s filament spools are placed separately in a compartment isolated from the build chamber.

The Intamsys Funmat Pro 610 HT can be intuitively controlled via a 10" LCD touch screen and sports a plethora of features ensuring streamlined workflow. Alongside the mentioned automatic nozzle cleaning, these include filament jam and runout sensors, auto bed leveling, and automatic material loading for continuous production.

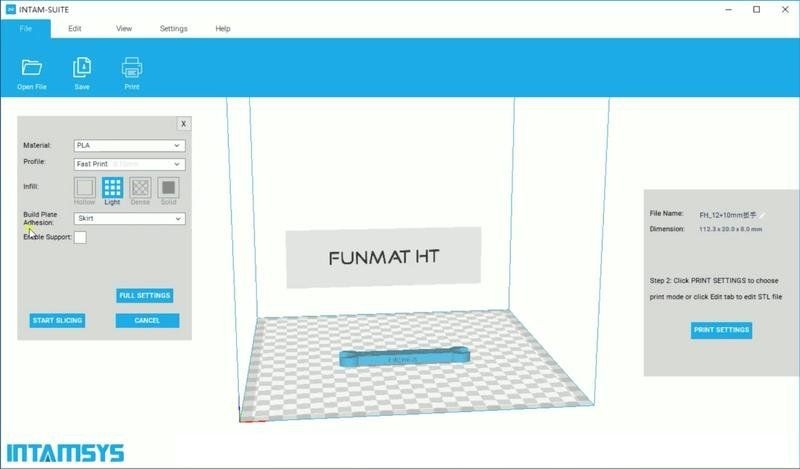

3D models are prepared in the proprietary IntamSuite slicing software included in the package. To transfer files for printing, you can use the USB port, local area network, or Wi-Fi connection.

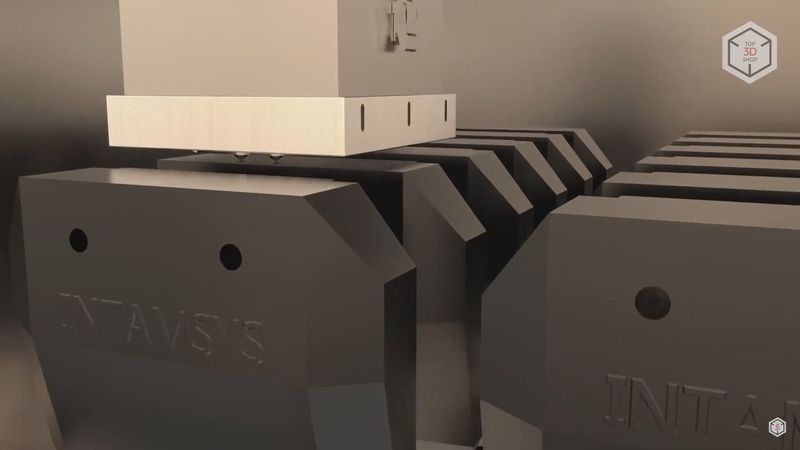

The Funmat Pro 610 HT is great for conceptual and functional prototyping as well as small-scale production covering a wide variety of applications in aerospace, automotive, medical, high-tech, and other demanding spheres. For example, here you can see some sample parts printed with PEEK filaments:

Ultimately, the Intamsys Funmat Pro 610 HT FDM 3D printer is ideal for manifold high-performance applications. This professional machine is intended for the manufacturing of full-size functional tools with critical requirements, where resolution and temperature resistance do matter. The capacious build chamber and reliable dual nozzles guarantee top-quality work with high-temperature filaments from any brand.

Update your browser to view this website correctly. Update my browser now

Write a comment