Polyether ether ketone (or simply PEEK) is a very durable polymer that has been used in industrial-level additive manufacturing for some years. Impressive mechanical properties and weight-to-strength ratio make it a great choice to use instead of metals and other materials. Printing with PEEK has never been an easy task: this polymer is demanding but its properties make up for that. It’s widely used in the aerospace and automotive fields, as well as across the medical sector (a lot of prosthetics available on the market are made of PEEK). Lately, the devices that are able to work with this material have become more affordable, so the days of PEEK-printing being available only on expensive 3D printers solely for industrial purposes are gone.

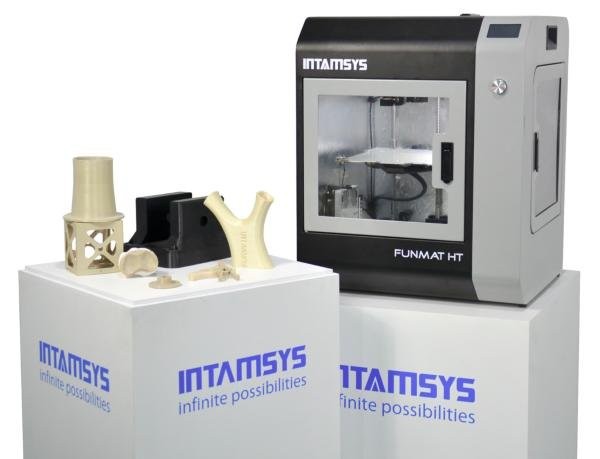

Intamsys Funman HT is one of such devices. This 3D printer is affordable and designed to work with PEEK (as well as other ‘exotic’ materials’).

Source: youtube.com

Intamsys (Intelligent Additive Manufacturing Systems) is a China-based 3D printing manufacturer. The headquarters are located in Shanghai. The company focuses on producing FFF/FDM 3D printers that can handle working with exotic materials.

The Funmat series of 3D printers by Intamsys are professional machines that provide industrial-level quality at affordable prices. These devices feature enclosed chambers that allow them to work with high temperatures making it possible to handle demanding materials such as PEEK.

The Intamsys Funmat HT is one of the most affordable machines in the series, making working with high-performance materials cheaper than ever.

The Funmat HT is a professional FFF/FDM printer designed to work with demanding materials such as PEEK and ULTEM (but it’s not limited to these filaments). The machine is sturdily built and features a fully enclosed insulated print chamber that helps to keep high temperatures stable. This design also reduces the levels of noise, so the machine is pretty quiet, operating at just 55-59 dB The extruder (with an all-metal hot end) can reach a temperature of 400 °C. The build plate is heated, removable and magnetic. This significantly streamlines the printing process.

Other features include a filament runout sensor, an open material system (meaning that the machine isn’t limited to proprietary filaments) and the ability to print at an impressive speed of 300 mm/s.

Source: youtube.com

The device comes in a large box, the contents of the package include:

The machine comes fully assembled. Some accessories are located inside the print chamber protected by foam plastic. To remove them you should lower the print bed manually.

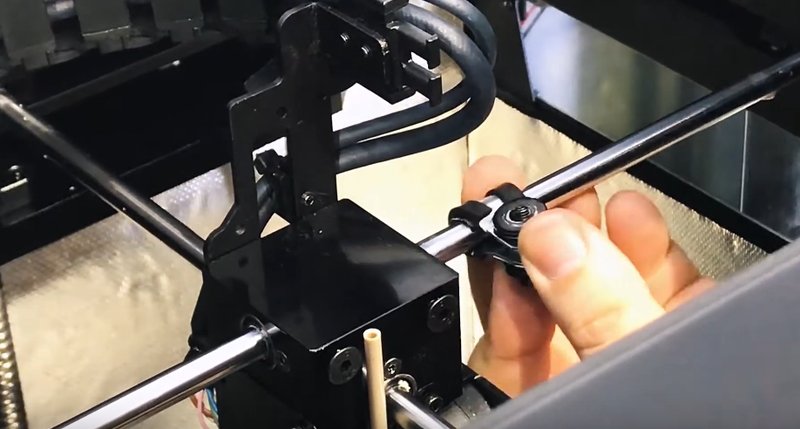

After extracting those parts, the first thing one should do is to remove the clamps that hold the print head (they protect it from damage during the transportation).

Source: youtube.com

Source: youtube.com

Then you should install the extruder onto the print head. It comes together with a motor in a small block.

Source: youtube.com

Source: youtube.com

Connect a feeding tube to it.

Source: youtube.com

Plug the power cord in and turn the machine on.

Source: youtube.com

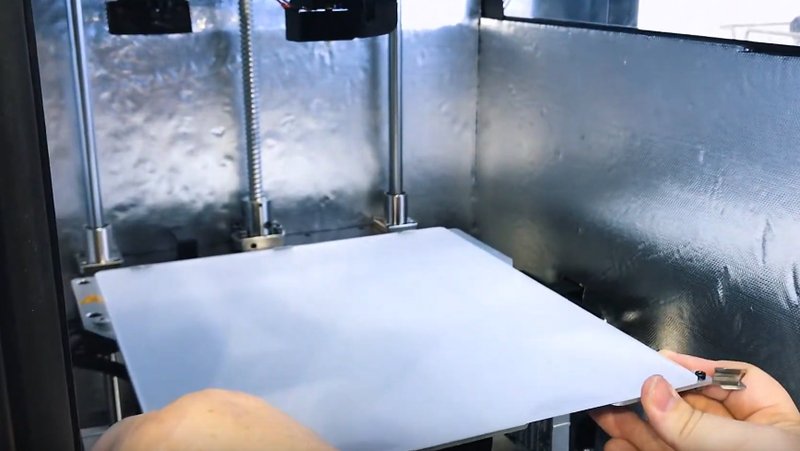

Slide the print plate in and make sure it sits there tightly.

Source: youtube.com

In the main menu on the machine’s LCD screen go to ‘Axis’.

Source: youtube.com

Press ‘Home’.

Source: youtube.com

And confirm that you want to home all axes.

Source: youtube.com

The machine will home the extruder and the print plate and is now ready for printing.

The Funmat HT can be controlled either via a built-in touchscreen or connection to a PC. The latter is achieved by various connectivity options (USB cable, USB flash drive and an SD card).

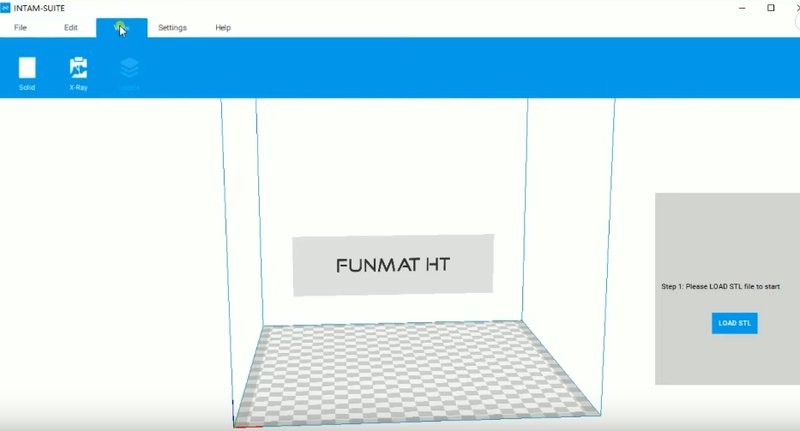

The INTAMSUITE software comes with the printer. It’s a slicing solution based on Cura. It features a clean and minimalistic interface that’s not cluttered or overly complicated.

Source: youtube.com

Source: youtube.com

The program also shows some tips to help newcomers to use this slicer.

Buttons under the ‘Edit’ tab allow users to manipulate the objects, while the menu on the left of the screen provides the means to control the properties and settings of the models.

The program supports STL and OBJ file formats and can be used with the cloud connection.

The device was used by SAIC Yanfeng, a Chinese leading automotive company, to print some essential parts for its seating inspection systems. The picture shows a size control unit of inspection QC gauge for automotive seating. Adopting Intamsys technology, the company has been able to reduce the part components from five to one single piece. In this way, it highly increased both development and production times.

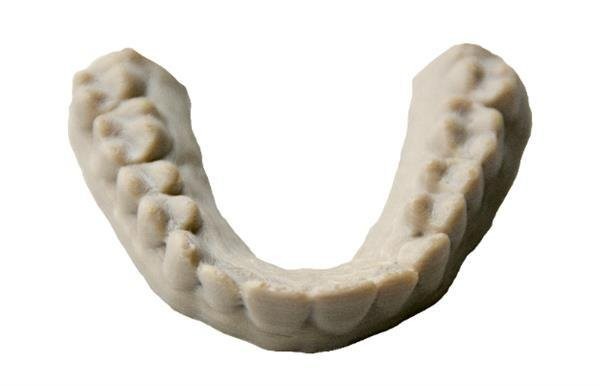

This smooth dental arch was made of PEEK and printed with impressive accuracy and surface finish.

Pros

Cons

The Funmat HT by Intamsys is a functional device that offers industrial-grade quality and commercial-grade speeds at an affordable price. It’s quiet, easy to work with and offer a great level of quality. Designed to work with high-performance demanding materials with impressive mechanical properties such as PEEK and ULTEM, the machine is a great choice for anybody willing to try their hand at working with exotic filaments without spending too much money.

Update your browser to view this website correctly. Update my browser now

Write a comment