In the following article, we would like to take a closer look at the ARGO and PRO lineups of industrial FDM 3D printers suited for complex and fast high-temperature tasks. Made by the Italian-based company Roboze, both series include several machines varying in terms of build volume, maximum extruder temperature, and price.

Below, you will find information on their main features, technical parameters, and potential applications.

The current range of 3D equipment by Roboze comprises two lineups — ARGO and PRO. Let’s discuss their main peculiarities.

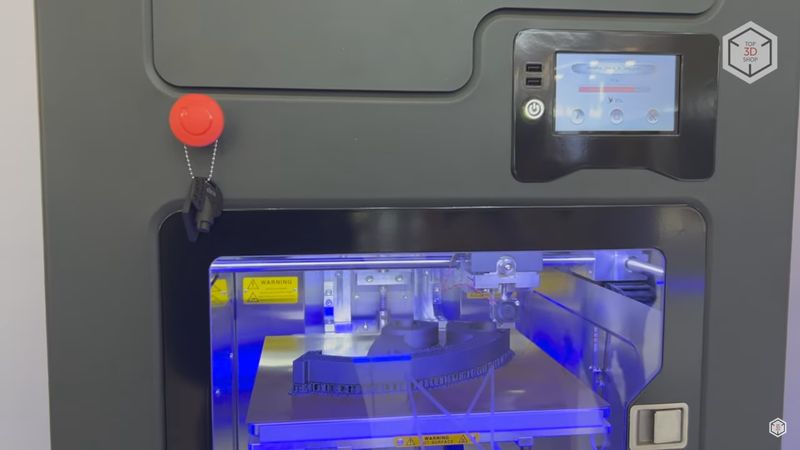

The industrial series ARGO includes three models — 350, 500, and 1000. These machines are designed for large-scale printing and mass production in medium volumes.

Capable of heating up to 450 °C, the extruder of the ARGO 500 model allows printing with such materials as conventional and carbon fiber-reinforced PEEK, PEI, and other high-temp plastics and composites.

With the build volume being a cube with the edge of 500 mm, the capacious print chamber can maintain a temperature of up to 180 °C, which minimizes product deformation.

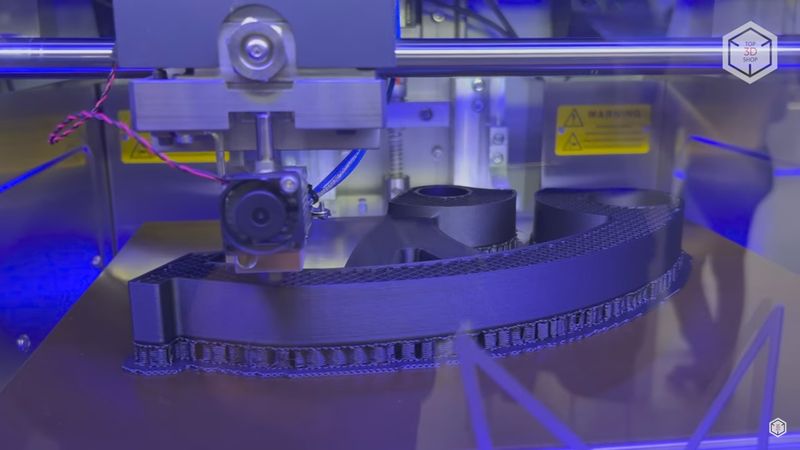

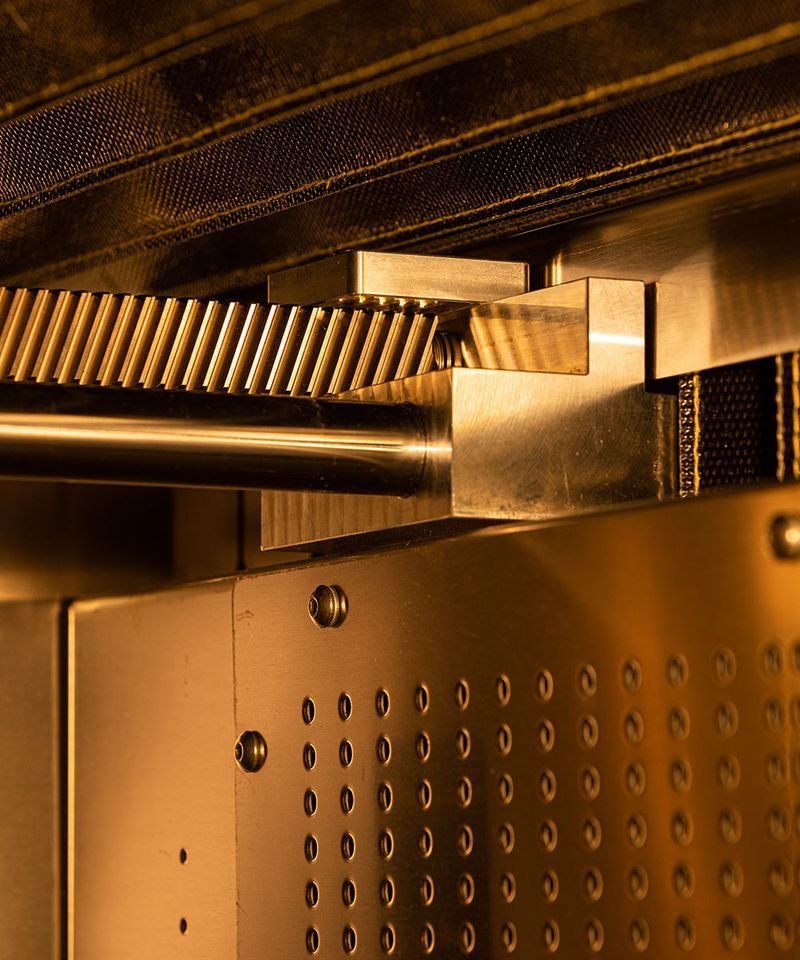

Interestingly, ARGO 3D printers are engineered without using any belts, which results in high accuracy of printing — 10 microns in X/Y axes and 25 microns in Z axis.

The Roboze One PRO and Plus PRO belong to the series recommended for fast, high-precision printing.

The Roboze Plus PRO 3D printer is equipped with an extruder that can reach 500 °C. The list of compatible materials includes regular and carbon fiber-reinforced PEEK, PEKK, PEI, other high-temp plastics and composites with special physical and chemical properties developed in-house.

The build volume of the device is 300 x 250 x 220 mm. The machine features a print bed heating up to 150 °C, with a vacuum fixation system.

Like in the ARGO lineup, PRO 3D printers do not use belts, so the printing accuracy reaches 15 microns in X/Y axes and 25 microns in Z axis.

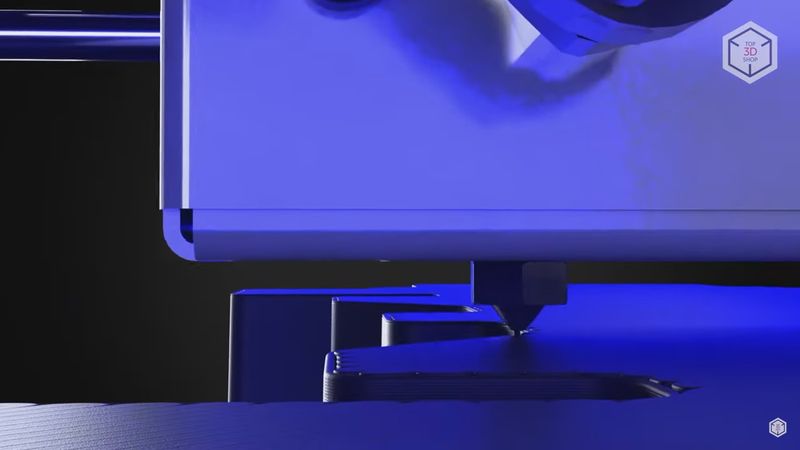

Based on the patented Beltless System, which uses mechatronic movement of the X and Y axes with C5 hardened helical rack and pinion gears instead of conventional rubber belts, the Roboze 3D printers provide high accuracy and repeatable printing results. Plus, stepper motors with high resolution encoders provide smooth movement and allow for high print precision.

The high-temperature extruders of the ARGO and PRO series provide continuous flow and allow printing with high-viscosity polymers. To prevent model deformation and shrinkage, the build chamber of ARGO devices is engineered with homogeneous heating in mind. Furthermore, each Roboze model comes with removable polymer build sheets based on vacuum technology that are used to improve first layer adhesion.

Due to the printers’ efficient thermal management, the users can work with any high-performance engineering filaments and create parts with outstanding chemical, mechanical, and thermal properties.

Serving as reliable industrial tools, the Roboze machines feature a high level of automation of the printing process, including auto bed leveling and extruder calibration, automatic material loading, and filament runout detection. Moreover, all operation and monitoring functions can be performed remotely to minimize downtime.

Due to the integrated B&R PLC system, the printers save all the information and parameters during each print and create a data log helping certify every printed part.

Thanks to the integrated HT filament dryer, the printers ensure optimal material treatment and guarantee the consistent quality of the printed models.

The Roboze 3D printers are operated via a convenient color touchscreen. They provide USB, Wi-Fi, and Ethernet connectivity options. Also, due to automated operation and remote control functions, the machines allow for a highly efficient end-to-end manufacturing cycle.

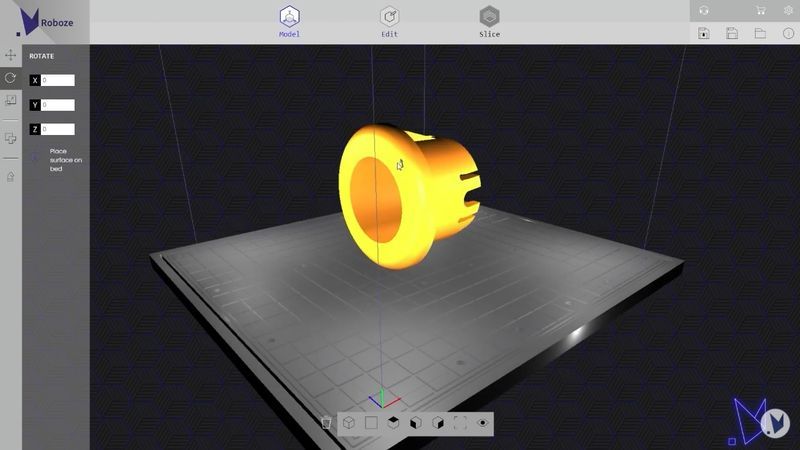

The proprietary Prometheus slicer is used to prepare files for printing in an extremely effective and streamlined way. With a set of ready-made profiles for working with the recommended thermoplastics, the program ensures seamless workflow and intuitive user experience.

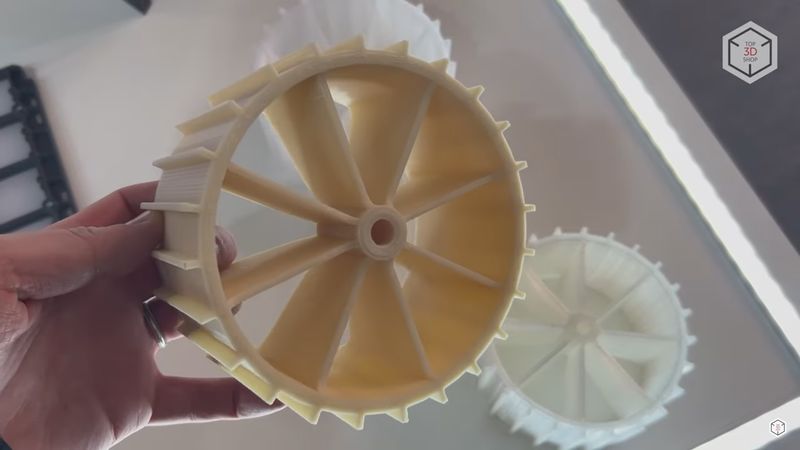

The following items clearly demonstrate the enhanced printing capabilities of the Roboze FDM machines that will find applications in different spheres:

Considering all the mentioned properties, technical characteristics, and unique technologies of the Roboze industrial printers, both ARGO and PRO series might serve as perfect machines for high-quality industrial uses in workshops, design studios, educational centers, and other establishments aimed at accurate, fast, and reliable production.

Primarily, they will be ideal for functional prototyping and tooling production. Furthermore, printed models can be used as a lightweight yet durable substitute for metal parts in aerospace, automotive, energy, oil and gas, and other industries.

Update your browser to view this website correctly. Update my browser now

Write a comment