Hi everyone! This is Top 3D Shop, and in this article, we will tell you about one of the flagship products by Creatbot — the F1000 3D printer that boasts not only a huge build volume but a number of cutting-edge features to offer high performance. Read on to learn more about the device.

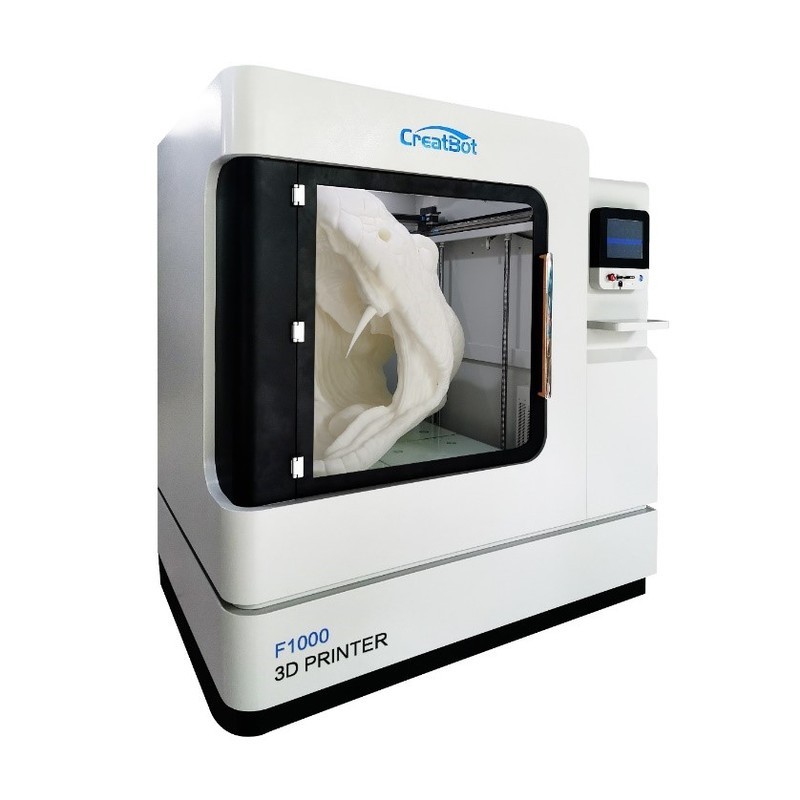

To begin with, the Creatbot F1000 industrial 3D printer has vast dimensions of 1,740 x 1,300 x 1,920 mm and weighs 600 kg. The main distinguishing feature of the device is its build volume — 1 x 1 x 1 m. Compared to its predecessor Creatbot D600, it is twice as large.

The same is true of other features of the product — the F1000 takes the advantages from the previous models and literally increases them in size. Even the heaters of the build chamber are two or even three times larger than those of their counterparts.

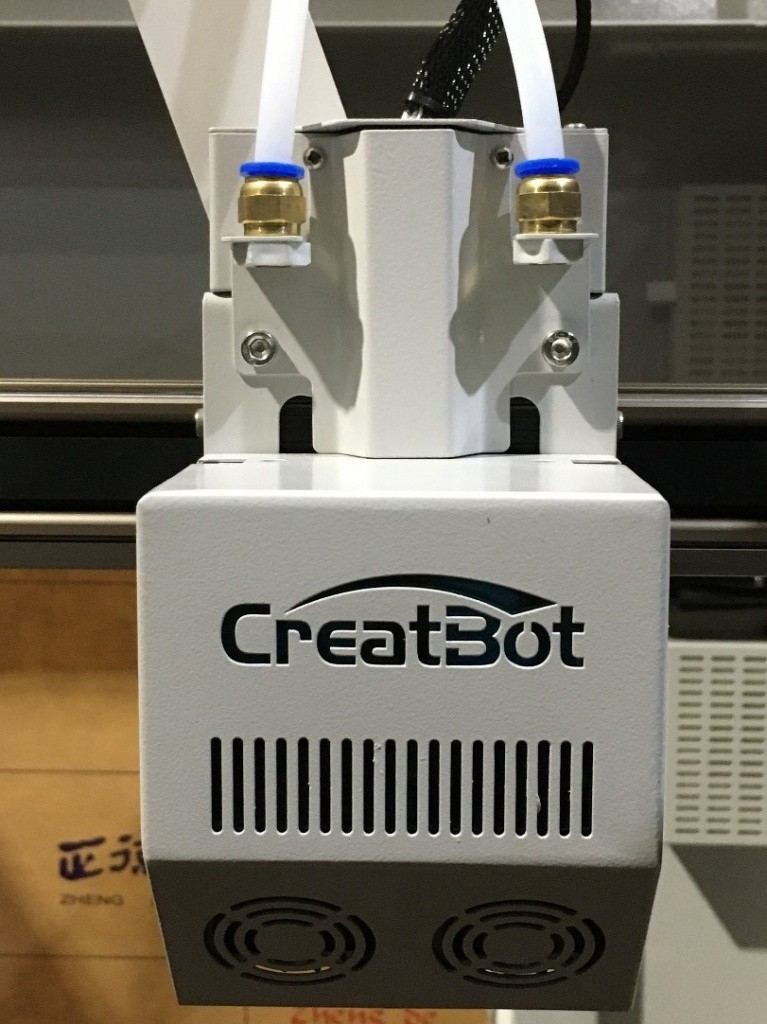

The device uses four heating platforms, the maximum temperature is 100–120 degrees. The printing unit is equipped with two nozzles and extrusion mechanisms and can heat up to 420 degrees. The nozzle options range from 0.4 to 1.5 mm. Brass, steel, ruby, and martensite nozzles can be employed for various purposes.

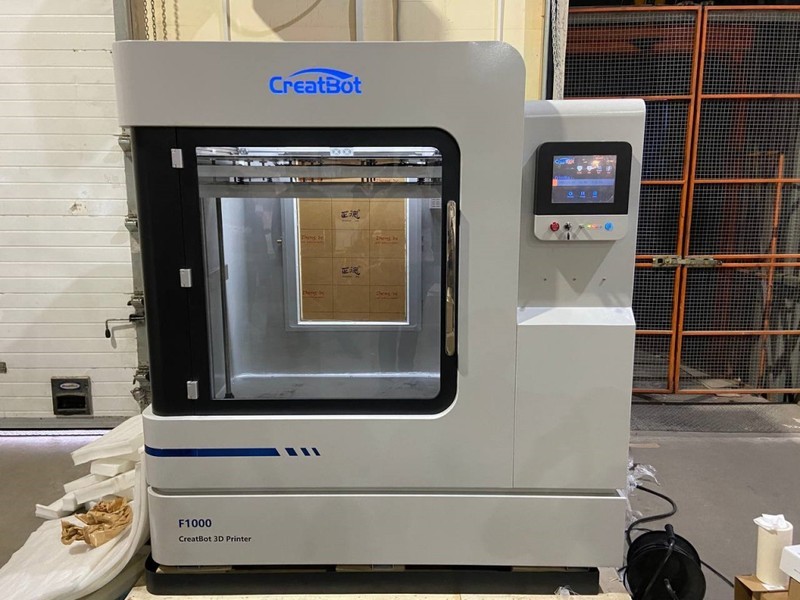

The appearance of the printer resembles that of multi-axis CNC machines. As is seen from the photo, the design is simple, laconic, and ergonomic.

The glass is transparent on all sides, there is lighting inside the chamber, so the view of the internal volume is clear.

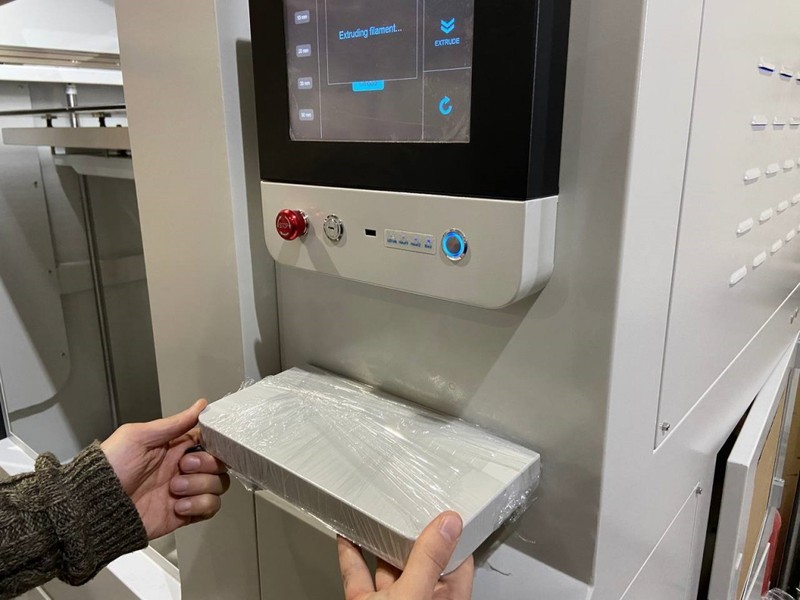

To the right of the front door, there is a control panel, with a shelf from the supply package to be installed below. The controls include a touchscreen itself, emergency stop button, standard power button, and status indicators, as well as the USB connector and a master keyed lock for the power button.

On top is another door for easy access to print units and the motion system.

The left side of the printer houses a panel enclosing the electronics unit, as well as a filament chamber. Buttons for two modes of heating the chamber are located next to it.

The most noteworthy element in the Creatbot F1000 is its build volume and print bed in particular. The 1 x 1 x 1 m chamber allows printing really large objects in a single pass, and the bed heated to 120 degrees makes it possible to use not only PLA, unlike the analogs of the device. However, with such dimensions, printing ABS and plastics with high shrinkage over the entire volume will still require serious skills from the operator.

The surface of the bed is covered with a sticker similar to the BuildTak, which provides remarkable adhesion, the materials sticking very well even without the use of glue. However, if necessary, a glue stick can be found in the supply package.

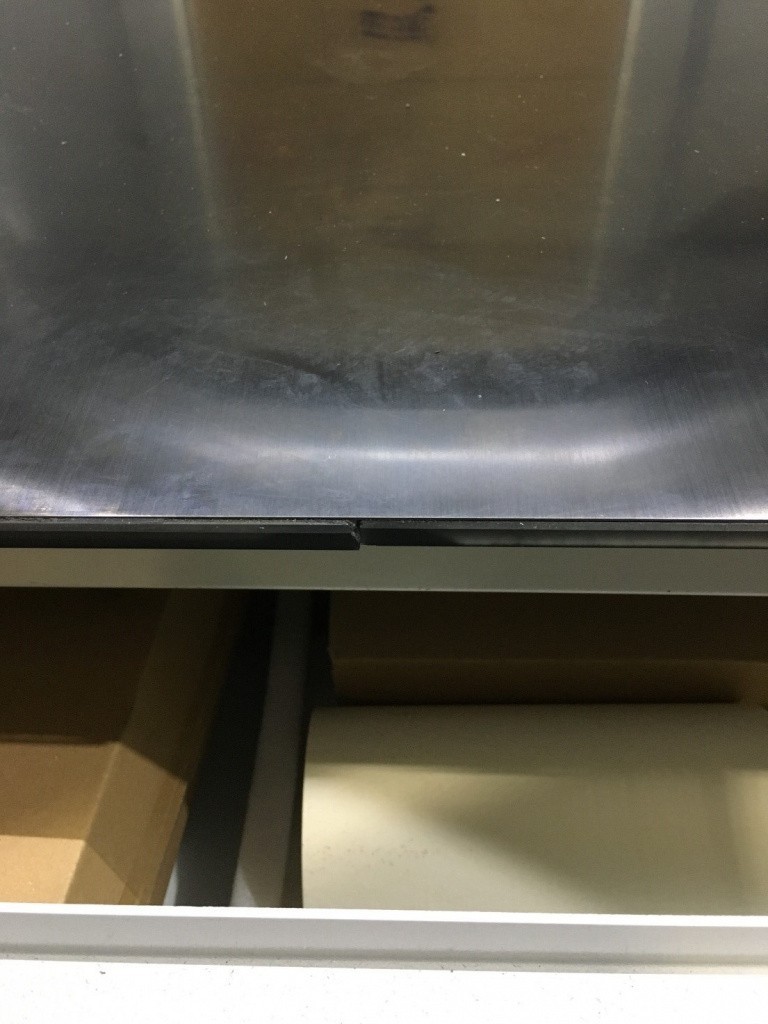

It is noteworthy that the print bed of the Creatbot F1000 is composite — it consists of four glasses from the D600 connected together. That is why the entire surface is covered with a continuous adhesive sheet.

Calibration is carried out with a probe on the printing unit and manually, by adjusting the screws under the bed.

The build chamber is equipped with filters on the exhaust fans as well as heating elements, as is the case with all Creatbot industrial models. More than that, the F1000 uses dual heaters. Both the build chamber and the spool compartment sport full-size versions. It is possible to set the temperature for heating up the air inside the chamber at 45 or 60 degrees. Due to thermal inertia, there is no way to heat such a gigantic volume to a higher temperature.

Also, the build chamber is equipped with a webcam that allows you to connect via a smartphone.

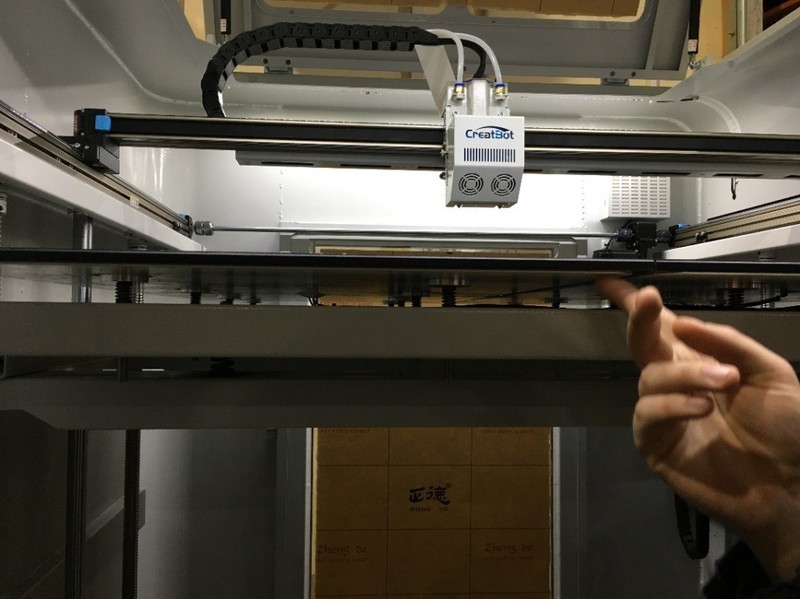

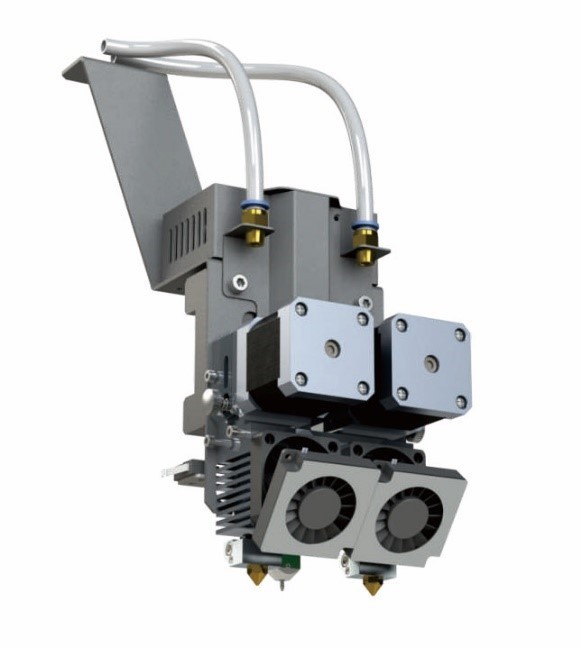

The print unit has undergone significant changes from previous versions, but it still features a BLTouch sensor located on the back of the bracket.

As usual, the extruder is equipped with two sets of hotends — a high-temp one, with the ability of heating up to 420 degrees, and an ordinary hotend that can heat up to 250 degrees. It is also possible to use different nozzle sizes: from classic 0.4 mm to high-performance 1.5 mm.

The printing unit itself is extremely lightweight compared to the first iterations on previous brand models. It boasts motorized hotends for raising/lowering during the print process, as well as a redesigned cooling system due to which it became more stable when printing with low-temperature filaments and more productive when using large nozzle sizes.

Material is fed from a special chamber on the side of the printer. It can accommodate two 3 kg spools. The compartment is equipped with a heating system and an additional filament extrusion mechanism, because with such an enormous volume, the print head alone would not be able to extrude the entire amount of plastic through the feeder.

By the way, the print unit is equipped with a filament control sensor — if the filament runs out, the printing will pause.

A temperature sensor is also located on the top of the filament chamber.

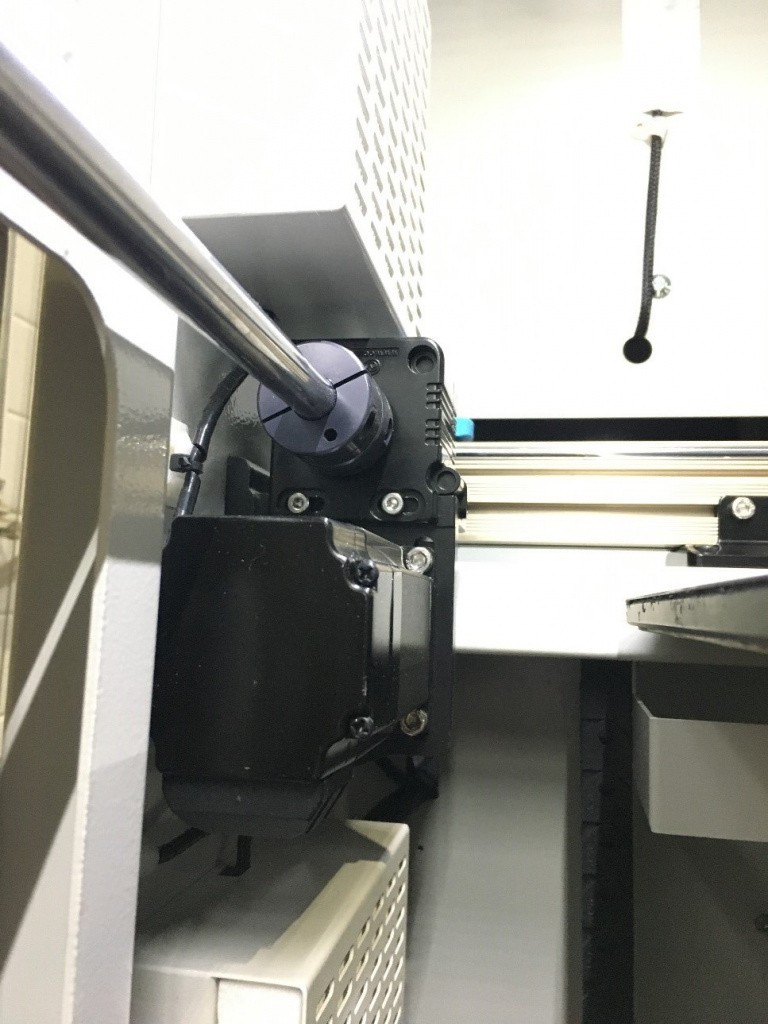

As with all Creatbot industrial models, the F1000 has block modules along the X/Y axes. Such a module was engineered on the basis of a structural profile, it contains extrusion rollers, a belt, and a carriage on a linear guide.

The kinematic scheme of the printer is classic, one motor per axis. The X-axis guides are connected by a solid rod on a coupling and rest on a heavy-duty welded base.

The Z-axis guides are cylindrical, one per side, with the movement carried out by four ball screws — one stepper motor per pair.

The Y-axis uses one stepper motor and a rod.

On the X-axis, momentum is transmitted by a motor with additional cooling and a gearbox.

The belt is approximately 2 cm wide, and the Z-axis ball screws are about 3 centimeters.

In general, the kinematics is very similar to that of the D600 but significantly larger in size and power.

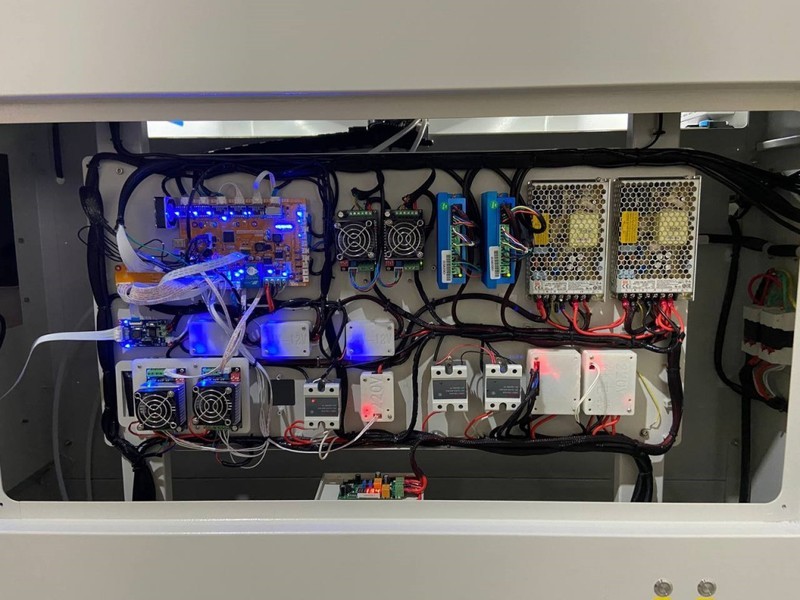

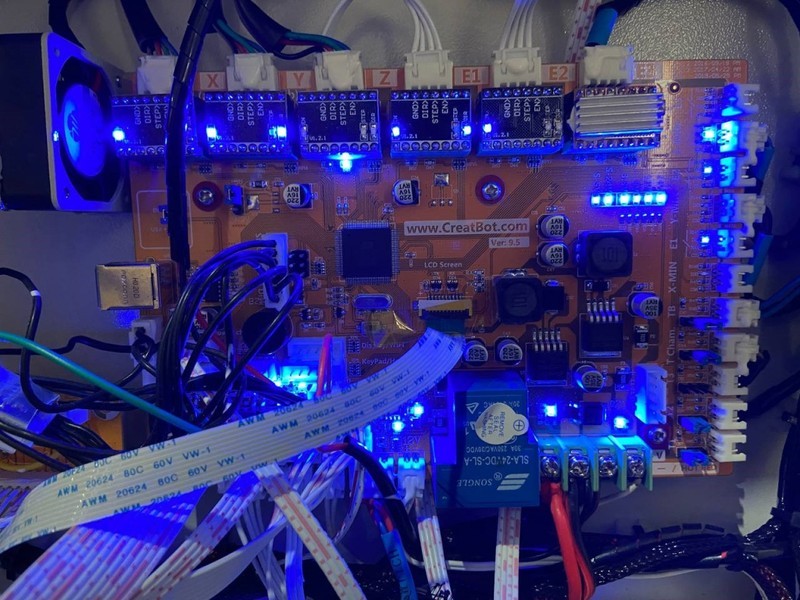

The electronics compartment of the F1000 houses two power supply units, industrial stepper motor drivers, a series of relays, and a motherboard.

The display module of the device is manufactured by Beijing DWIN Technology Co., Ltd and has an independent operating system. The screen boasts a 12-inch diagonal, the backlight life is ≥ 30,000 hours.

The motherboard is unified on the entire device platform. Also, this model features quieter drivers.

Next are two more industrial Z-axis drivers, two power supplies, and packet switches on the back wall.

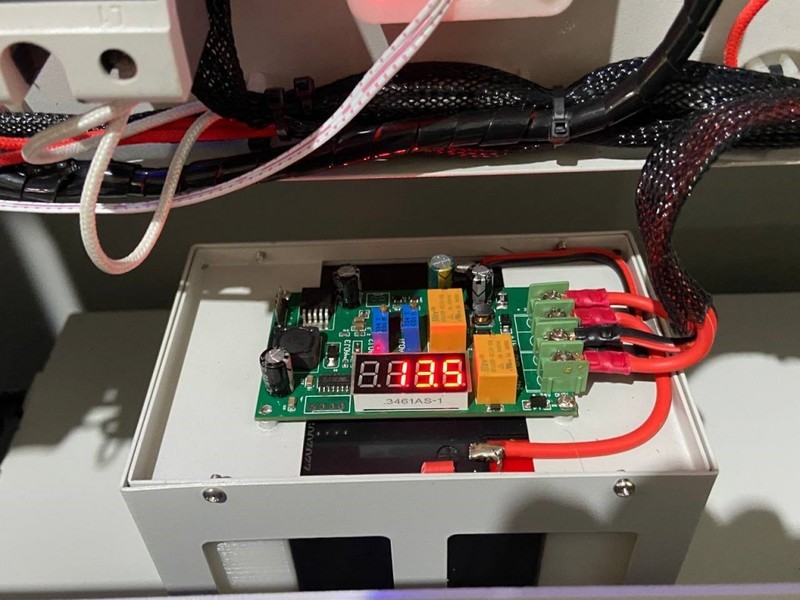

Below is an array of solid-state relays and step-down boards. They are mainly needed to connect the bed and extruder heaters.

At the bottom is a capacitor with a charge indicator as an emergency shutdown system.

Although optical limit switches are already adopted in other models of the manufacturer, the F1000 uses mechanical ones. Apparently, this approach was considered more reliable.

The visual design of the interface and its functions have not changed. As in previous models, the screen displays the temperatures of the extruder, print bed, and build chamber.

The Preheat Filament Move and Settings menus have not changed either and correspond to those of the Creatbot PEEK 300, for example.

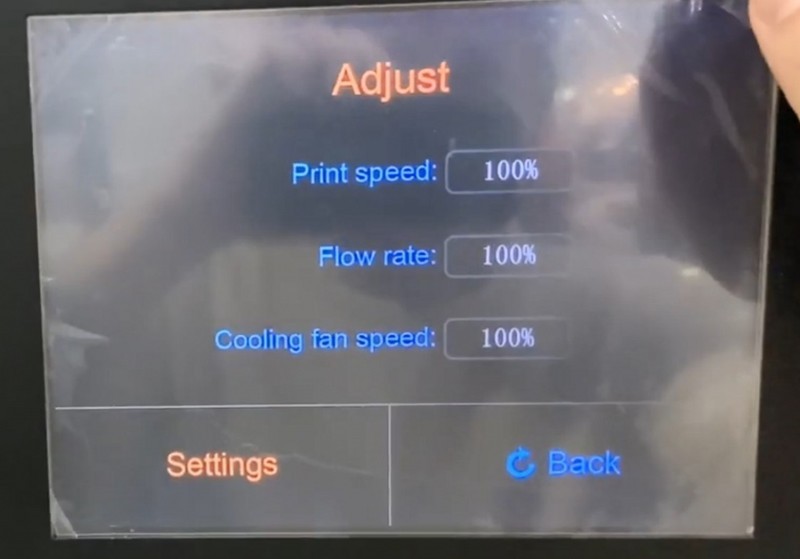

The display of the print process has been slightly modified. Now we can adjust the parameters or open the print settings by pressing the Adjust button in the upper right corner.

Here we have access to print speed, filament flow rate, and cooling fan speed.

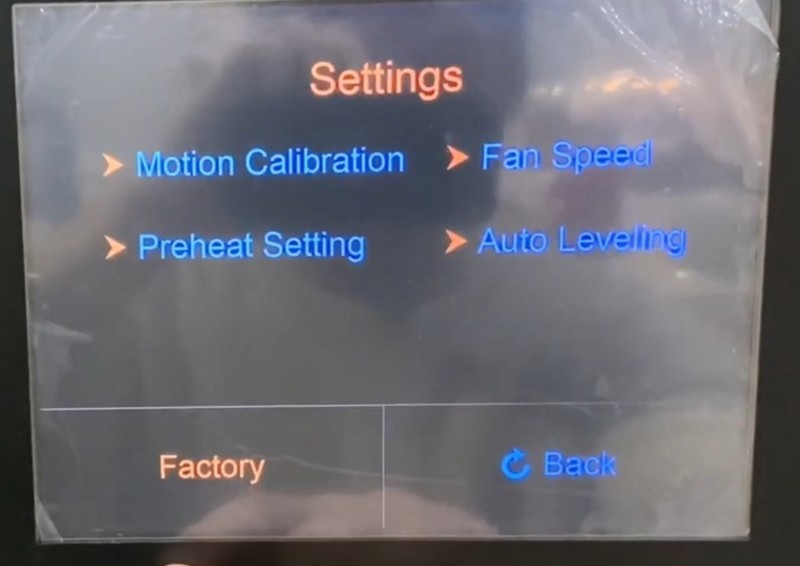

By tapping the Settings menu, we can calibrate the motion, set the fan speed, adjust the preheat, or trigger the auto leveling using BLTouch.

To control the webcam, it is necessary to install a corresponding app on your smartphone.

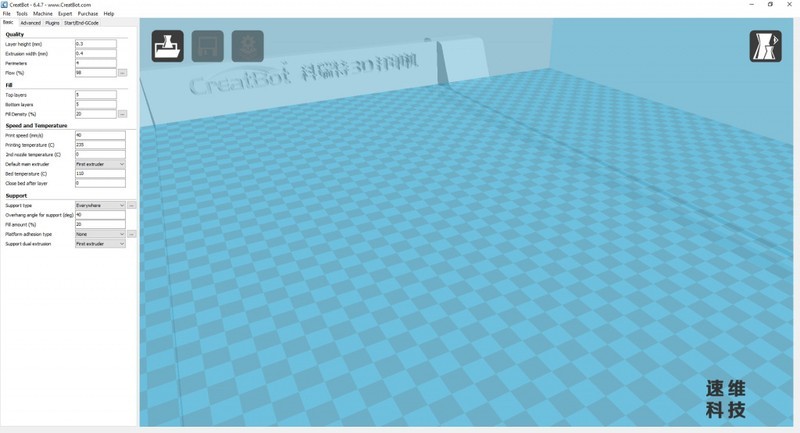

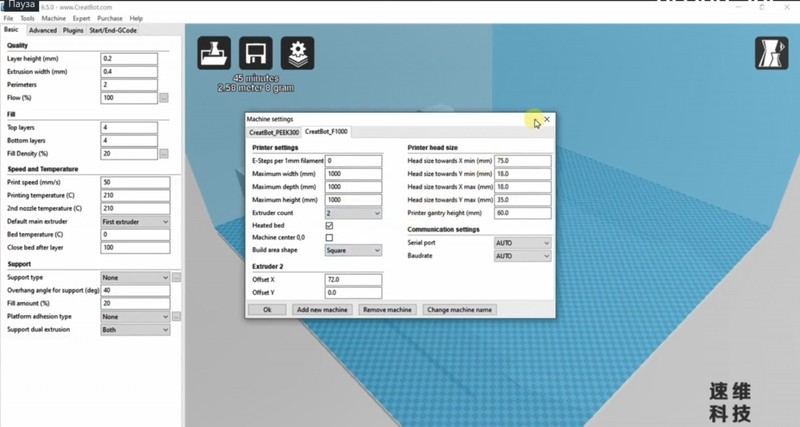

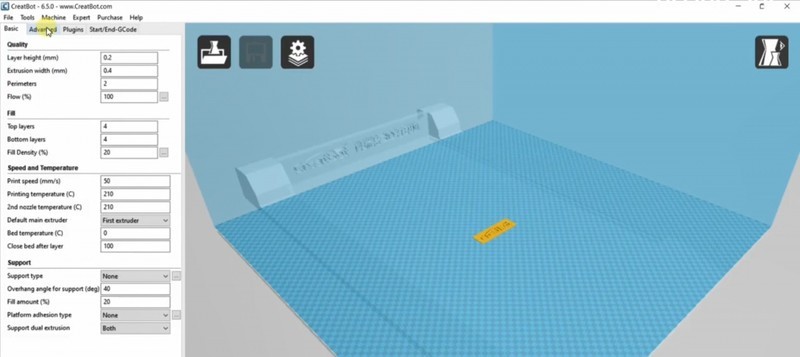

So far as the slicer is concerned, the Creatbot F1000 uses the classic Creatware based on Cura 1.5.6. However, it is possible to use any other software, for example, Simplify3D.

Printer settings are available on installing the program. There is no need for any configurations provided the original version is used.

Check the following short video to see what the Creatbot F1000 is capable of.

Creatbot offers a convenient and complete solution for printing PLA and ABS plastics, as well as PETG and SBS in the large-scale printing segment. The heated bed and the powerful extruders coupled with a large nozzle size ensure high performance. If necessary, it is possible to set another nozzle diameter and print small items with virtually no loss in quality. The F1000 3D printer is a perfect tool for industrial enterprises that aim at expanding their production. Adopting the strengths of the company's previous products, the device substantially enhances them, which brings large-format 3D printing to a new level.

Update your browser to view this website correctly. Update my browser now

Write a comment