In this article, we will introduce you to the Israeli company Massivit 3D, one of the most innovative manufacturers in the 3D printing industry. Read more about the establishment of the company and its products.

Credit: @massivit3dprinting / Facebook

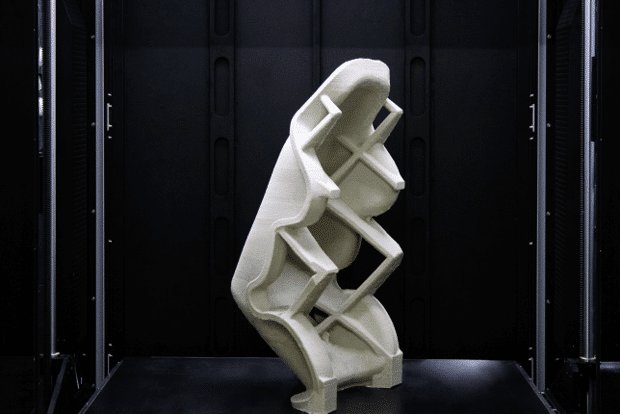

Massivit 3D Printing Technologies Ltd. is a pioneering company in large-format 3D printing headquartered in Lod, Israel. Their major accomplishment is the patented GDP (Gel Dispensing Printing) technology delivering enormous benefits for various spheres including engineering, visual communications, entertainment, education, design, and architecture. The company’s advanced solutions enable time- and cost-effective production of large-scale models, props, and functional parts.

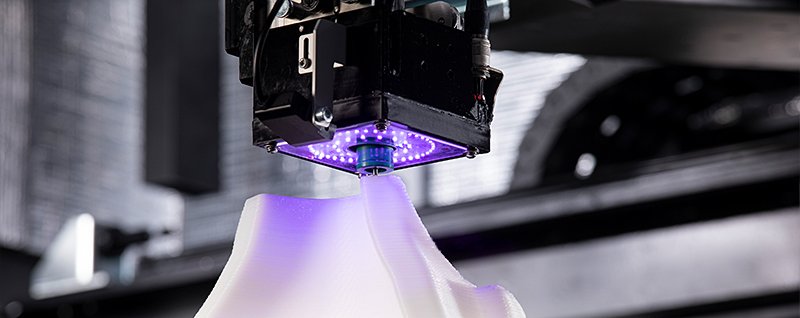

GDP is a cutting-edge technology in 3D printing. Using a special half-baked gel, which is simultaneously polymerized as it is extruded, one can greatly reduce costs and production timelines. The Massivit signature machines, such as the Massivit 1800 series and the Massivit 5000, are devised to print only the closed contours of the part, so it remains empty inside. This ensures rapid and beneficial manufacture of industrial-grade prototypes and objects.

Massivit 3D defines its main values as innovation in manufacturing, passion about their products, simplicity in use, and comprehensive partnership for their customers.

Credit: @massivit3dprinting / Facebook

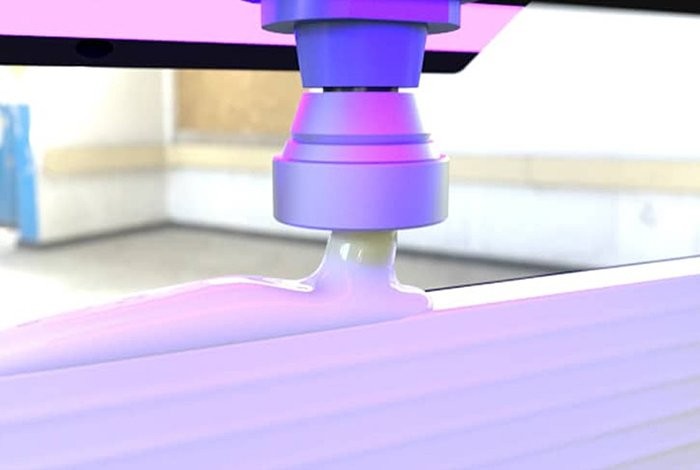

So, Massivit 3D specializes in the production of 3D printers based on GDP technology — Gel Dispensing Printing. It allows producing desired parts ultra-fast and with no support structures. This method employs acrylic-based material with good mechanical properties which is instantaneously cured in the process of printing by a UV LED lamp mounted into the printhead. Thanks to the two independent printing engines in some models, it is possible to make two different objects with varying geometries simultaneously.

Look through the following table to get acquainted with the main characteristics of the company’s 3D printers:

|

Parameter |

Massivit 1500 |

Massivit 1800 |

Massivit 1800 Pro |

Massivit 5000 |

|

No. of printing heads |

1 (not upgradable) |

1 (not upgradable) |

1 or 2, with option to upgrade |

2 printing heads |

|

Print speed |

300 mm/sec linear speed. 35 cm / 13.7" on Z axis per hour (printing speed for 1-meter diameter cylinder) |

|||

|

Layer thickness |

|

|

|

|

|

Special printing modes |

Mega-Quality — rapid, high quality printing of large objects allowing gel cost efficiency

Variable Resolution — predefine multiple resolutions per model according to required strength and quality |

Mega-Quality — rapid, high quality printing of large objects allowing gel cost efficiency

Variable Resolution — predefine multiple resolutions per model according to required strength and quality

Mold Mode — produce architectural elements, restorations, street furniture with concrete or plaster casting |

||

|

Max. printing volume |

147 cm x 116 cm x 137 cm |

145 cm x 111 cm x 180 cm or 57" x 44" x 70" |

||

|

Supported materials |

|

|

|

|

|

Material system |

Single |

Double |

||

|

Cleaning mechanism |

Auto cleaning (time-based) |

Print head camera with image recognition provides automated, efficient cleaning as required |

||

|

Slicing |

Integrated user-friendly software plus one Massivit SMART Slicer license (purchased separately). Sophisticated algorithms for easy file preparation. |

Integrated user-friendly software plus one Massivit SMART Slicer license (purchased separately). Sophisticated algorithms for easy file preparation. Includes instant EstimatorTool. |

Integrated user-friendly software plus advanced Massivit SMART Pro Slicer with one complimentary license (purchased separately). Sophisticated algorithms for easy file preparation. Includes Estimator Tool plus additional features and modes such as Variable Resolution and Mega-Quality. |

Integrated user-friendly software plus advanced Massivit SMART Pro Slicer with two complimentary licenses. Sophisticated algorithms for easy file preparation. Includes Estimator Tool plus additional features and modes such as Mold Mode, Variable Resolution, and Mega-Quality. Additional automation features to increase workflow efficiency. |

|

Advanced monitoring |

Camera on printing head tip for monitoring. |

Camera on printing head tip for monitoring. |

Camera on printing head tip for monitoring. |

Camera on printing head tip for monitoring. Additional 40" flat panel screen displays live output from three internal cameras (recording capability for marketing purposes included). |

|

Remote control |

Not available |

Remote monitoring, operations and support available via a range of computers, tablets, and phones. |

Complimentary 9.6” tablet provided for convenient remote monitoring, operations, and support. |

Remote monitoring, operations and support available via a range of computers, tablets, and phones. |

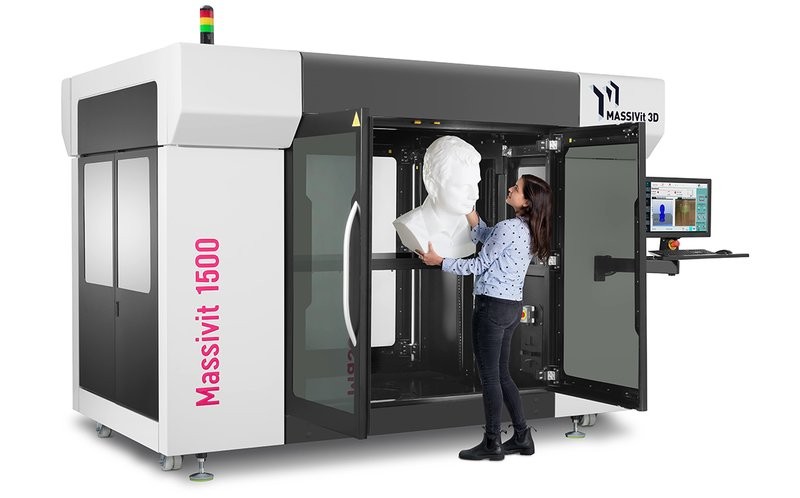

The Massivit 1500 is an exploration 3D printer which is designed as an introduction to the world of rapid large-scale printing. This simple and user-friendly machine provides orientation functionality at an affordable price and slightly reduced height.

The printer serves as the acquaintance with the GDP technology and can be successfully used in prototyping and testing Massivit technical capabilities.

Specifications:

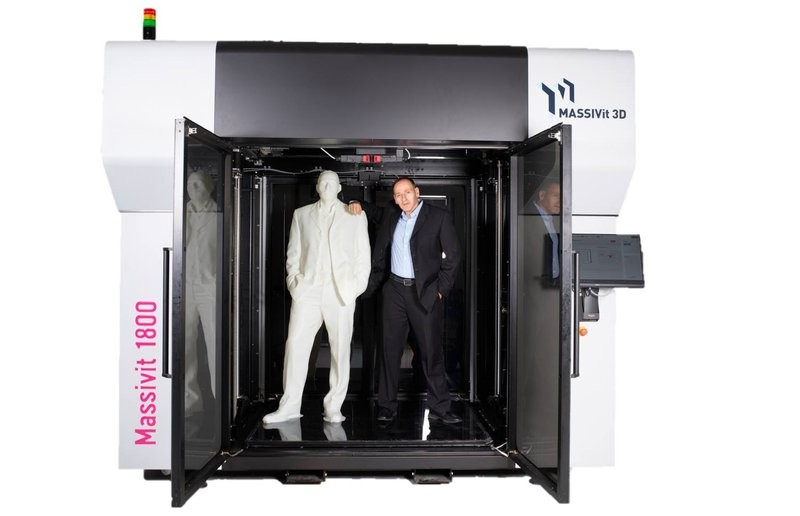

The Massivit 1800 is an industrial-grade 3D printer implementing the company’s core technology. The machine became known for its enormous build volume and unprecedented speed of 300 mm/sec in making super-size quality prints with multiple patterns.

The printer is equipped with a high-resolution touchscreen, built-in cameras, and remote control tools that provide convenient monitoring of the process. Intuitive integrated software will facilitate the manufacture and make it even faster. A variety of print modes allows adjusting layer thickness to your current needs — from 1.3 to 0.8 mm.

Credit: @dwl_studios / Instagram

The printer can be successfully used in preparing displays, props, and advertising models 30x faster than other technologies.

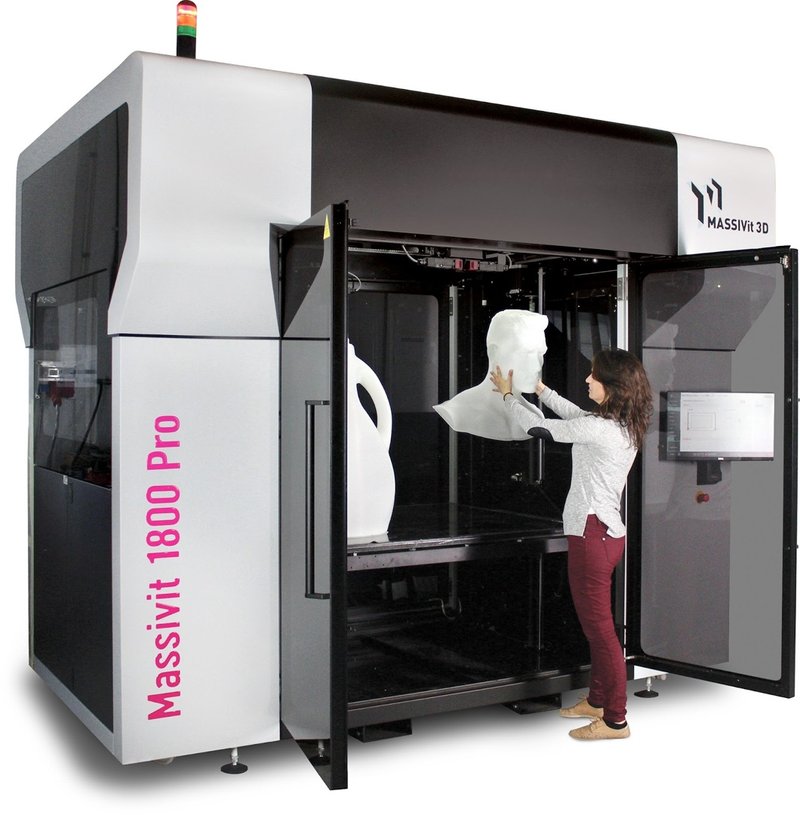

The Massivit 1800 Pro is an industrial-grade 3D printer for massive manufacture. Compared to its predecessor, the machine boasts a wider range of print modes, such as Variable Resolution and Mega Quality, as well as two independent printheads ready to be used at the same time.

Due to the advanced monitoring system via complimentary 9.6" tablet, the Pro version ensures brilliant workflow flexibility with almost no manual labor. Its smart features and enormous capacity allow creating large, complex objects in ultra-fast and highly detailed manner. It is even possible to set multiple resolutions for a single model in the Variable Resolution mode.

Credit: @massivit3d / Instagram

The Massivit 1800 Pro is great for industrial application, advertising and marketing purposes. It produces functional parts, props, and elements of interior design with great speed and outstanding quality.

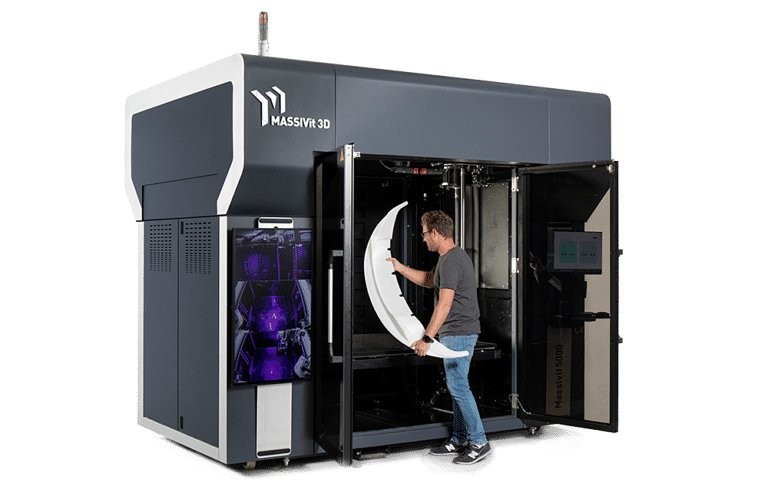

The Massivit 5000 is an industrial-grade 3D printer for mass quality production. Thanks to the unique GDP technology, it allows high-resolution printing at the 300 mm/sec speed. Also, this model boasts multiple print modes such as High Definition, Variable Resolution, Mega-Quality, as well as Mold Mode. With all the smart features, it can print layers from 1.5 to 0.5 mm.

In addition to the two independent printheads, the Massivit 5000 introduces the dual material system that enables impressive workflow flexibility and time-effective manufacture. The intuitive UI and automated functions of the signature software provide full control over the printing process.

Credit: @figureplant / Instagram

Due to its grand scale and high speed of production, the printer is perfectly suited for numerous industrial applications, particularly automotive, rail, and marine areas.

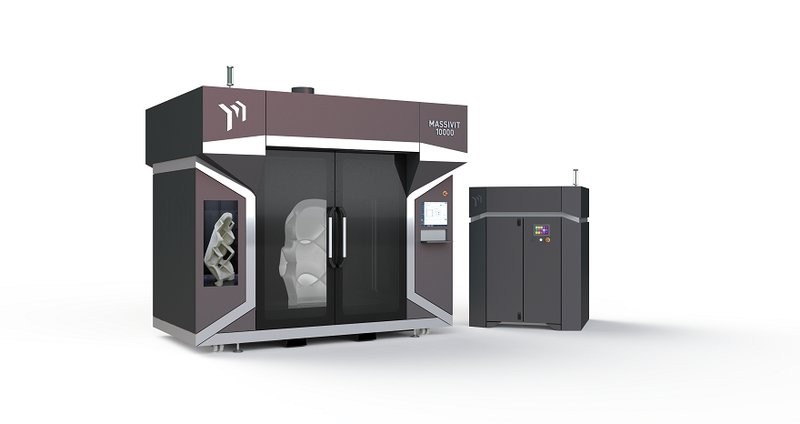

The Massivit 10000 is another high-performance industrial-grade 3D printer with a hybrid technology. It introduces a new Cast-in-Motion (CIM) method in combination with the patented Gel Dispensing Printing in the production of large tooling for composite manufacturing.

The machine is primarily aimed at facilitating the traditional molding process. The mix of GDP and CIM reduces the number of necessary steps from 19 to only 4. With the build chamber of 120 х 150 х 165 cm, two printheads, and great operation speed, it is possible to significantly shorten the production time of molds as well as tool and material costs.

Credit: massivit3d.com

The Massivit 10000 provides advanced design options for large-scale mold production of functional models with intricate geometries. It is perfect for the needs of a wide range of industries including automotive, aerospace, marine, and energy.

Credit: massivit3d.com

Massivit 3D’s technology employs unique photopolymer materials that cure immediately during printing with the UV LED lamps installed on the printheads. This efficient method enables production of large parts, prototypes, and molds at an exceptional speed of 300 mm/sec and with no support structures at all. The company’s proprietary material is known as Dimengel of various subtypes:

All the mentioned materials possess the following properties:

The table below shows the compatibility of the materials with the Massivit printers.

|

Massivit 1500 |

Massivit 1800 |

Massivit 1800 Pro |

Massivit 5000 |

|

|

Dimengel 90 |

✔ |

✔ |

✔ |

✔ |

|

Dimengel 100 |

✔ |

✔ |

✔ |

✔ |

|

Dimengel 110 |

✔ |

|||

|

Dimengel 20-FR |

✔ |

|||

|

Dimengel 300 |

✔ |

✔ |

✔ |

✔ |

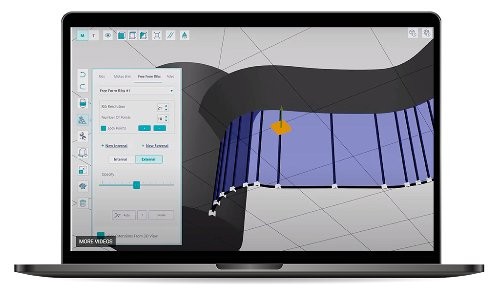

Massivit SMART is integrated proprietary software. Due to the friendly UI, it accelerates workflow and optimizes STL files for Massivit 3D printing. With the program’s advanced algorithms, you can produce hollow models with vertical angles, minimizing printing time and material waste.

Massivit SMART is capable of scaling, rotating, and slicing 3D files. It provides you with a ready-to-print file according to the chosen print mode.

The software features:

Credit: massivit3d.com

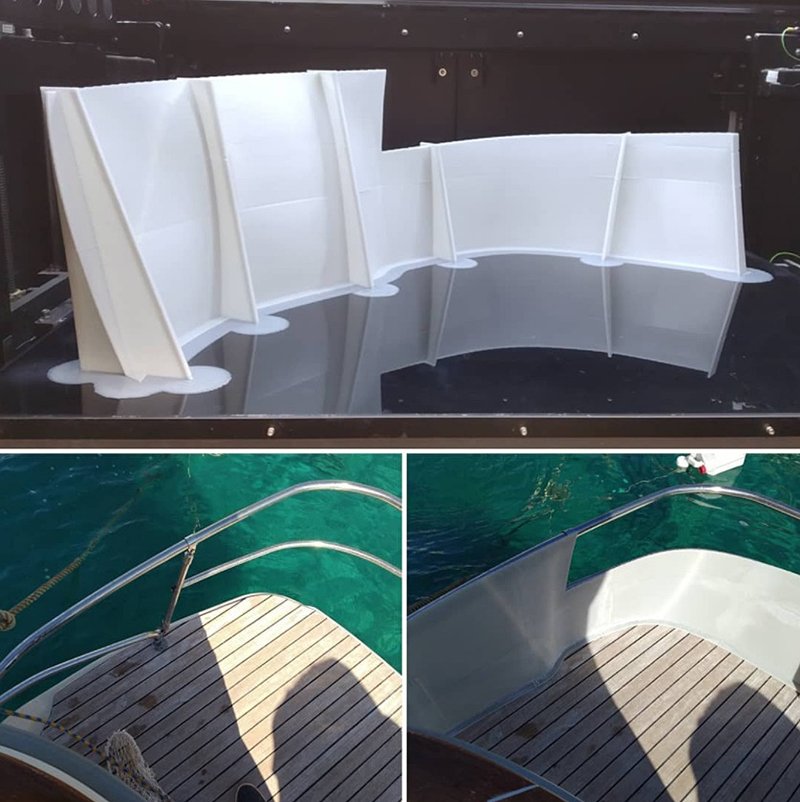

Making a single mold for marine parts requires a number of skilled craftsmen working for weeks or even months, and then the part itself is yet to be cast. Needless to say, this method is both time- and cost-consuming. That is why Velum Nautica, a leading Croatia-based company in vessel maintenance and repair since 2002, decided to use a large-scale Massivit 3D printer to produce custom marine vessel components in the most effective way possible.

Credit: @velum_nautica / Instagram

The harsh environmental conditions provide certain challenges for the maritime industry and corresponding demands. These parts should be lightweight, hermetically sealed, and strong enough to endure years of exposure to moisture, salt, wind, and sunlight. With Massivit 3D’s large-scale printers and proprietary printing materials, Velum Nautica is now able to produce custom parts with complex geometries in a matter of mere hours. Plus, their hollow nature makes the printouts perfectly suited to contain important machine devices or be filled with various strengthening materials for reinforcement purposes.

Credit: @velum_nautica / Instagram

The industrial Massivit printers ensure simplified, less labor-intensive, and more efficient manufacture of quality marine components. The integrated software with advanced functionality enables flexibility in design at the click of a button and almost autonomous production. With this machine at hand, Velum Nautica can greatly expand their activities and benefit from using the 3D printing technology.

All sports fans know that no experience is brighter than being close to your favorite players. And Chambery Savoie Mont-Blanc’s sponsor Euromedia sought to replicate this glorious feeling of interaction, only without the actual sportsmen. The task was addressed to Deko 3D by Sepia, one of the leading print shops in Europe. Using the Massivit 1800, they managed to create a 3D-printed handball player. The model took only 11 hours to print. It reached a height of 1.8 m and weighed 34 kg.

Club president Alain Poncet admired both the quality of the 3D-printed player and the hype from the fans of his team. They gladly took selfies with the model and definitely enjoyed the opportunity to embrace their connection with the team and the sport as a whole.

Credit: @deko3d_bysepia / Instagram

Thus, large format 3D printing has a unique power in helping brands to reach their audience. There is no doubt that the technology has a bright future in the publicity sphere.

To celebrate the 20th anniversary of the best-selling manga and comic series of all time, SID Installation Art 3D printed 24 large models of One Piece’s leading characters. The idea came from Remake Works Co., Ltd and One Piece Mugiwara Store Taiwan. They commissioned SID Installation Art with the Massivit 1800 Pro 3D printer to make giant versions (1.8–5 m) of the fan-favorite characters. The audience was truly impressed with the scenes of augmented reality that allowed them to dive into their favorite universe.

Credit: @massivit3dprinting / Facebook

Massivit 3D’s technology turned out to be faster than the previous method of SID Installation Art. They used to work with foam and fiberglass to produce gaming and manga-related props. Moreover, it offered a wider creative freedom and greatly reduced the amount of time needed for such an extensive work.

Hung Jui Chia, COO of SID Installation Art, noted that the Massivit solution significantly accelerated their timelines and provided new possibilities in terms of design. According to the COO, with a GDP printer, they can now make unique props and models and cut the time and material costs twice.

Credit: @massivit3dprinting / Facebook

The Massivit 1800 series, Massivit 5000, and Massivit 10000 are cutting-edge GDP 3D printers that by all means match the requirements of numerous industries, such as automotive, marine, architecture, entertainment, and signage market. The machines are great for ultra-fast and large-scale production of prototypes, advertising props, and function-oriented parts, providing significant time- and cost-effectiveness.

Update your browser to view this website correctly. Update my browser now

Write a comment