Massivit 3D Printing Technologies Ltd. has always positioned itself as a pioneering provider in large-format 3D printing. The company owns a unique proprietary technology known as GDP (Gel Dispensing Printing) which ensures time- and cost-effective production of large-scale prototypes, props, and functional parts.

The Massivit 1800 is a flagship 3D printer from the Israeli company released in 2016. Years later, it still remains one of the best industrial-size machines for fast and quality printing in engineering, visual communications, entertainment, education, design, and architecture.

This is Top 3D Shop with a detailed review of the Massivit 1800 3D printer which is renowned for its efficient GDP-printing as well as many other advanced features. Check out the specs of the device and read on for a complete overview of its highlights.

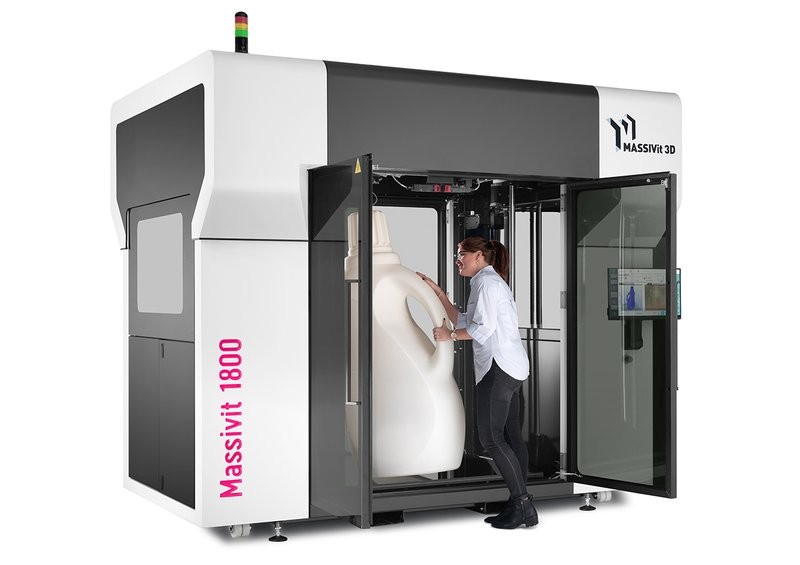

The first thing that amazes about the Massivit 1800 is its size. The printer dimensions are 10.2 x 7.3 x 9.2 ft (3.1 x 2.2 x 2.8 m), and it weighs 5511 lb (2500 kg). As for the color scheme, it is white with gray inserts. This stylish look will make it perfect for achieving new heights in additive manufacture.

The machine is controlled via specialized software from an ultra-large high-resolution touchscreen. Massivit SMART works with STL-files and is totally compatible with Windows.

Due to the built-in camera on the printhead tip it is also possible to control the machine remotely via smartphone or tablet. The whole printing process can be fully monitored through default means.

And now let’s take a closer look at the most prominent features.

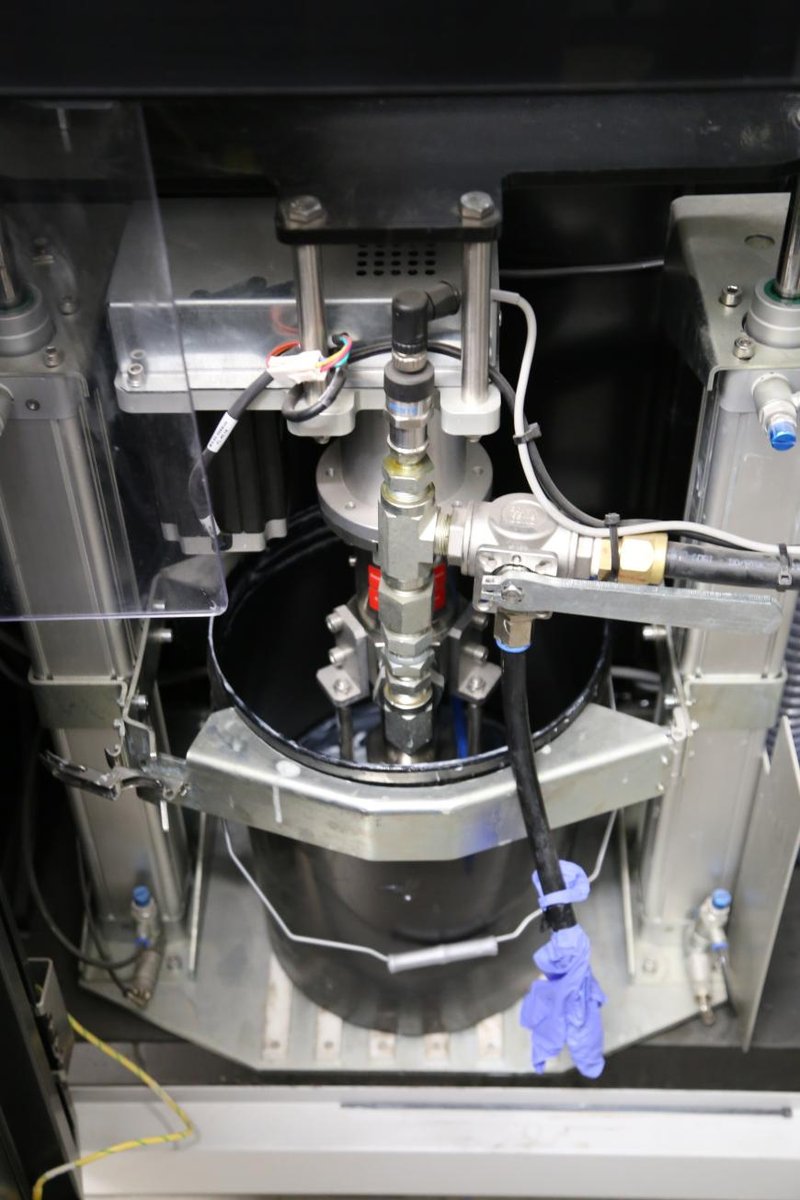

The Massivit 1800 uses a proprietary Massivit 3D technology called GDP — Gel Dispensing Printing. It involves a special photopolymer acrylic gel (Dimengel) that possesses valuable properties and can be rapidly cured under UV rays. The gel is distributed in 19 kg buckets as printing with the machine requires a corresponding amount of material.

The bucket of Dimengel is installed directly into the printer. Here you can see the feed system, vacuum pump, and other essential elements of the entire mechanism.

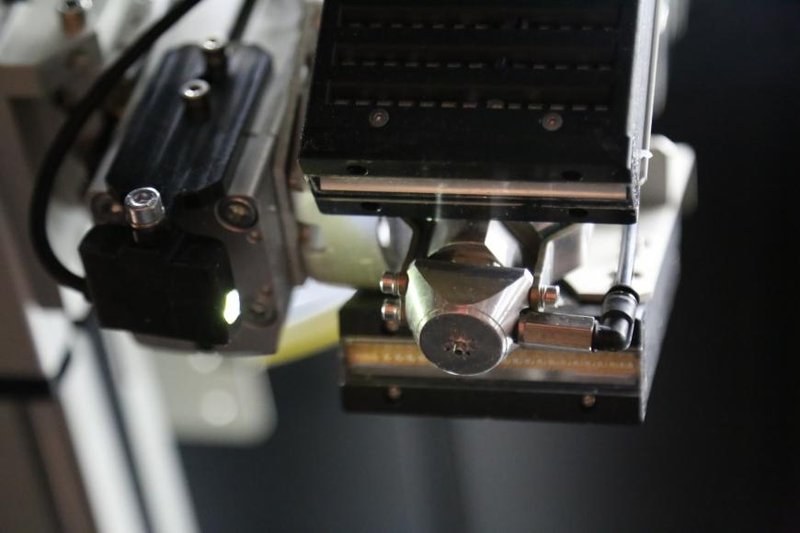

The device has two movable printheads equipped with UV lamps on both sides of the nozzle. They activate starting with the second level. This is how Dimengel is cured right in the middle of printing which saves a lot of time in the long run.

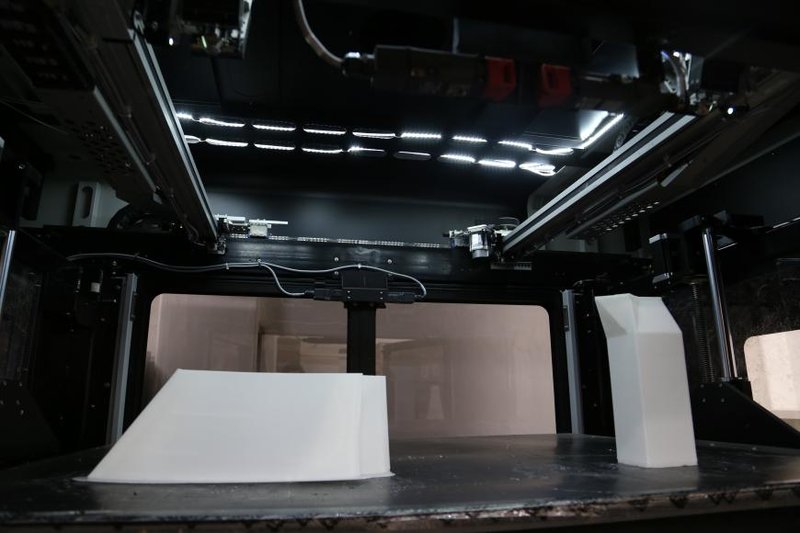

The Massivit 1800 is an industrial-grade printer, so it is only natural for it to have a large build camera.The maximum printing size for this model is 145 cm x 111 cm x 180 cm. Moreover, the machine holds two independent printheads, which enables you to print two objects simultaneously regardless of their height within 10 cm — that is the maximum distance one of the printheads can descend relative to the other.

Printing with one printhead is not a problem either. In this case, the second gear will take the initial position against the wall.

In the photo below, the right printhead is lowered by 10 cm:

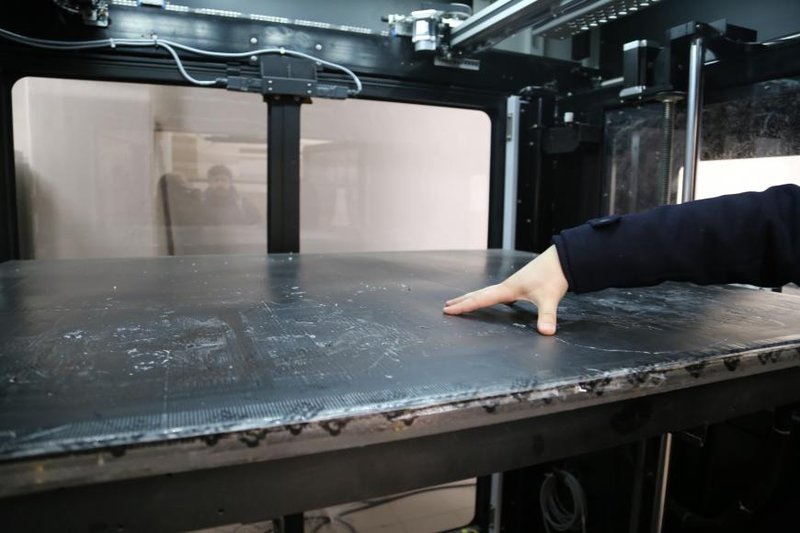

As for the printing bed, it has a rubberized cover that is pressurized by a vacuum pump when printing starts. This ensures a more even surface and adds to the quality of your future prints.

The vacuum system can be observed from the bottom of the bed.

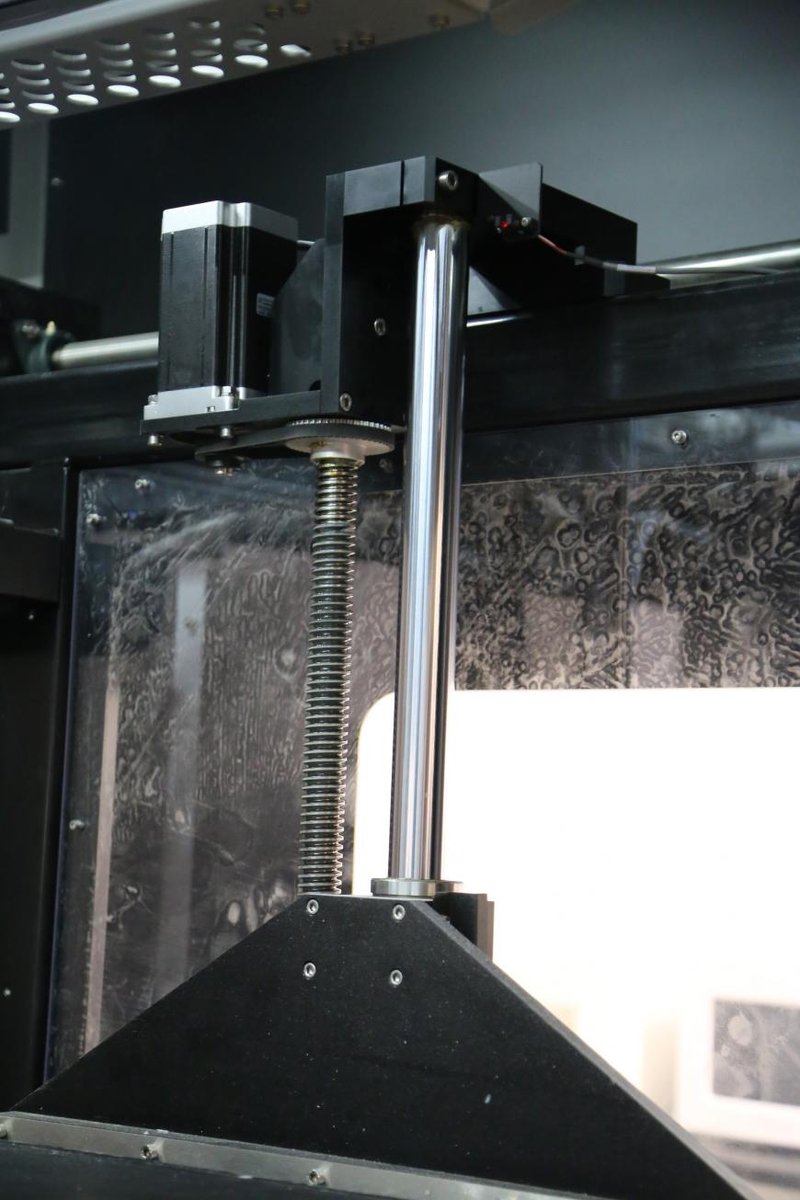

The print speed by the Massivit 1800 is most impressive. It comprises 300 mm/sec (with linear printing) or 35 cm (13.7") on the Z axis per hour. Such a brilliant result is achieved due to the machine’s advanced mechanics.

With the well-coordinated parts, the operation runs smoothly, especially along the Z-axis that is particularly important.

This allows the printheads to do their job with no delays. Speed won’t be an issue even for big projects and strict deadlines.

The Massivit 1800 is a perfect solution for time- and cost-effective production. The GDP technology offers one more benefit – printing with practically no supports. Among other things, it provides great material savings.

The key to that is the manner of printing with the Massivit devices. The printhead distributes the gel in layers, and the mounted UV lamps cure it almost instantly. Therefore, it creates a safe base for the next layer.

The final product looks like this:

You can choose between three print modes with differing layer thickness: Normal (1.3 mm), Quality (1 mm), or High Resolution (0.8 mm). Obviously, these parameters define speed and quality of your printing. In this case, the layer height is 0.8 mm.

The Massivit 1800 has established itself as a perfect device for industrial prototyping, advertising, architecture and design, making props, signage, and decorating exhibitions.

Now, let’s go over the models we’ve made with the Massivit 1800 3D printer and see how good it can really be.

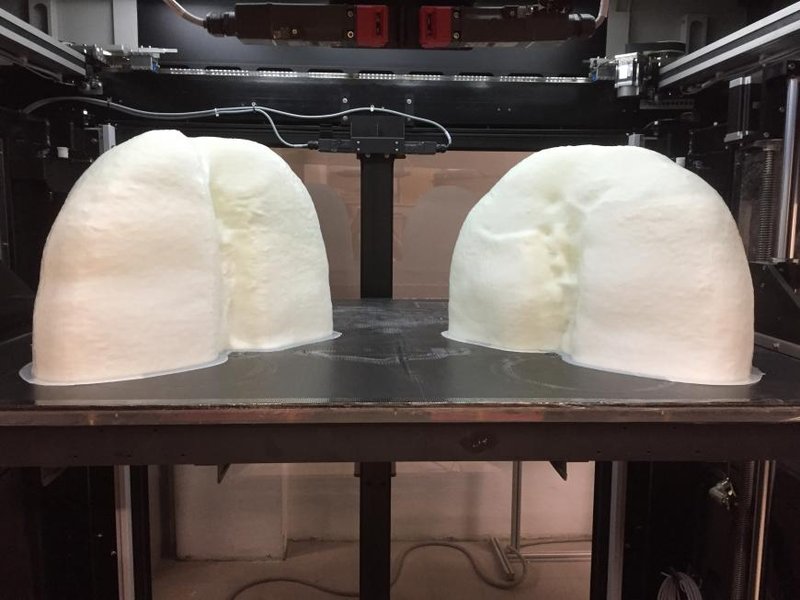

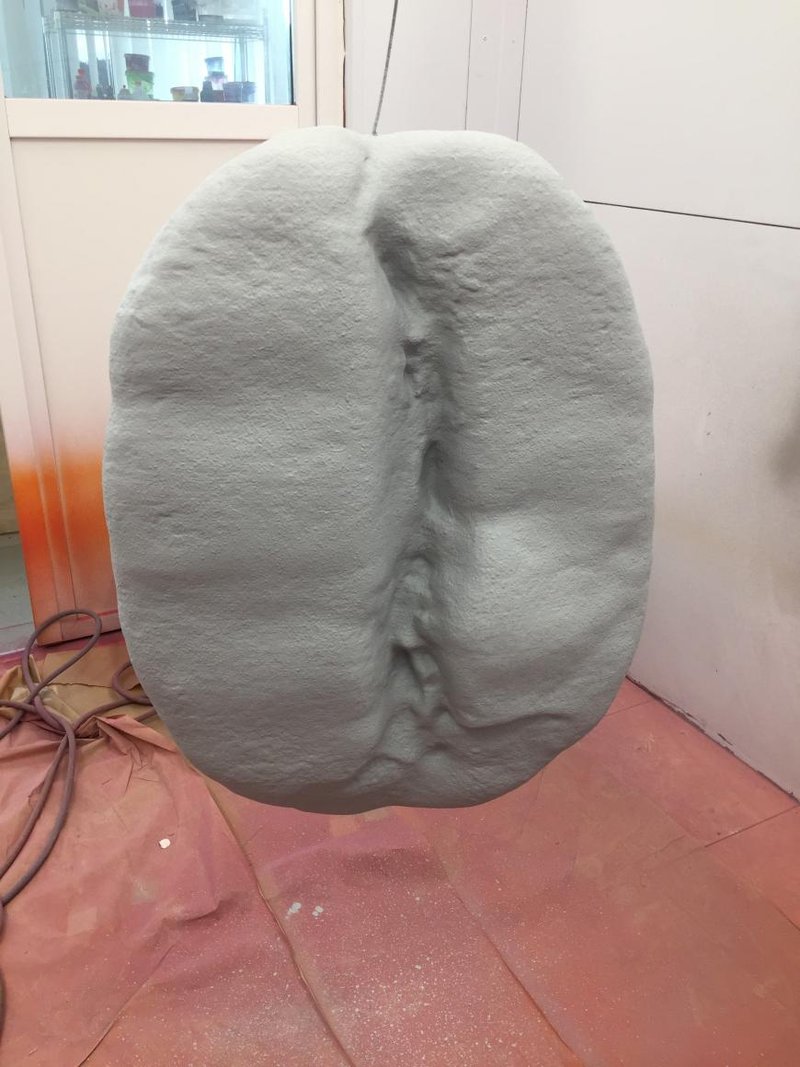

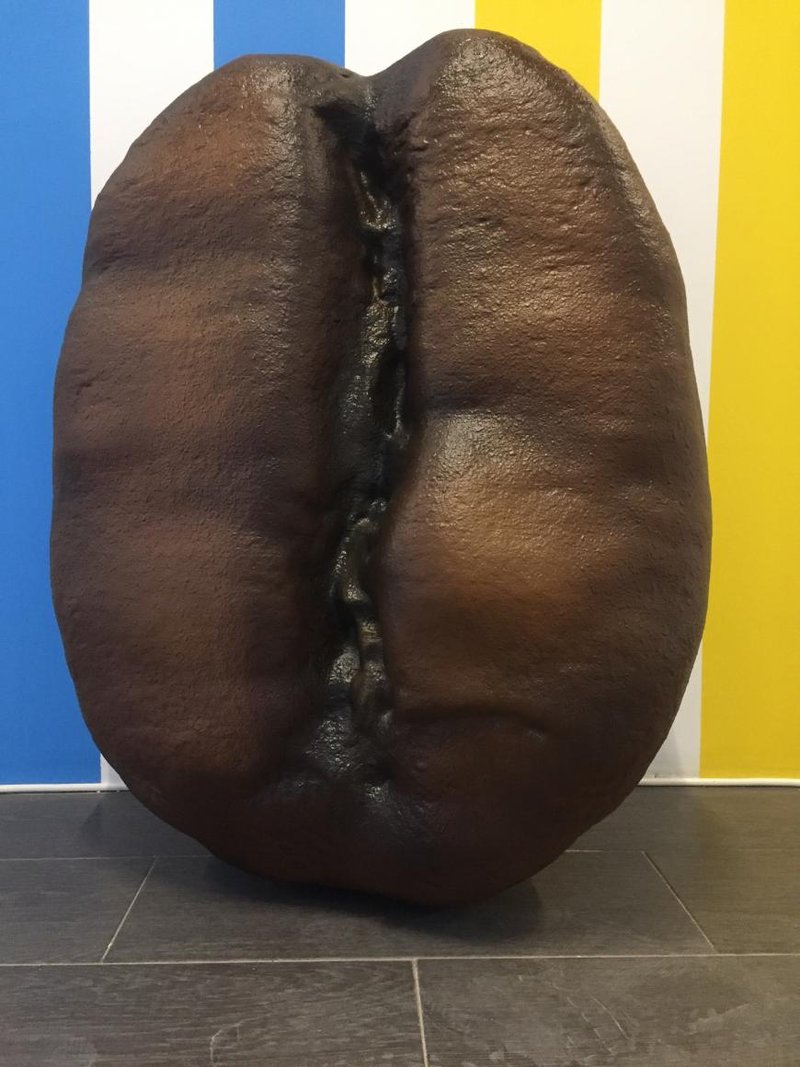

First of all, we decided to print a giant coffee bean. To try out independent printing with both printheads, we divided the model into two parts that were printed simultaneously.

Later on, the coffee bean parts were glued together and painted.

You can see its final form in the next picture.

Height: 0.8 m

Printing time: 2 h 30 min

Weight: 3.5 kg

For the second test we made a model of a giant KFC chicken leg. Due to the same size, it had to be printed in two parts, too. Although, the production took twice as long as the previous project.

Still, the coating made it all worth it. The result looks delicious, doesn’t it?

Height: 0.8 m

Printing time: 5 h 30 min

Weight: 5.5 kg

One more thing to check out was the quality of support-less printing. We took a beer bottle with a cap and beer glass. The latter was 50 cm high and took 1 h 24 min to print.

And the bottle cap turned out great with no supporting structures involved. It was printed with the side facing down. As for the top, the machine was laying layers from the outer perimeter inward.

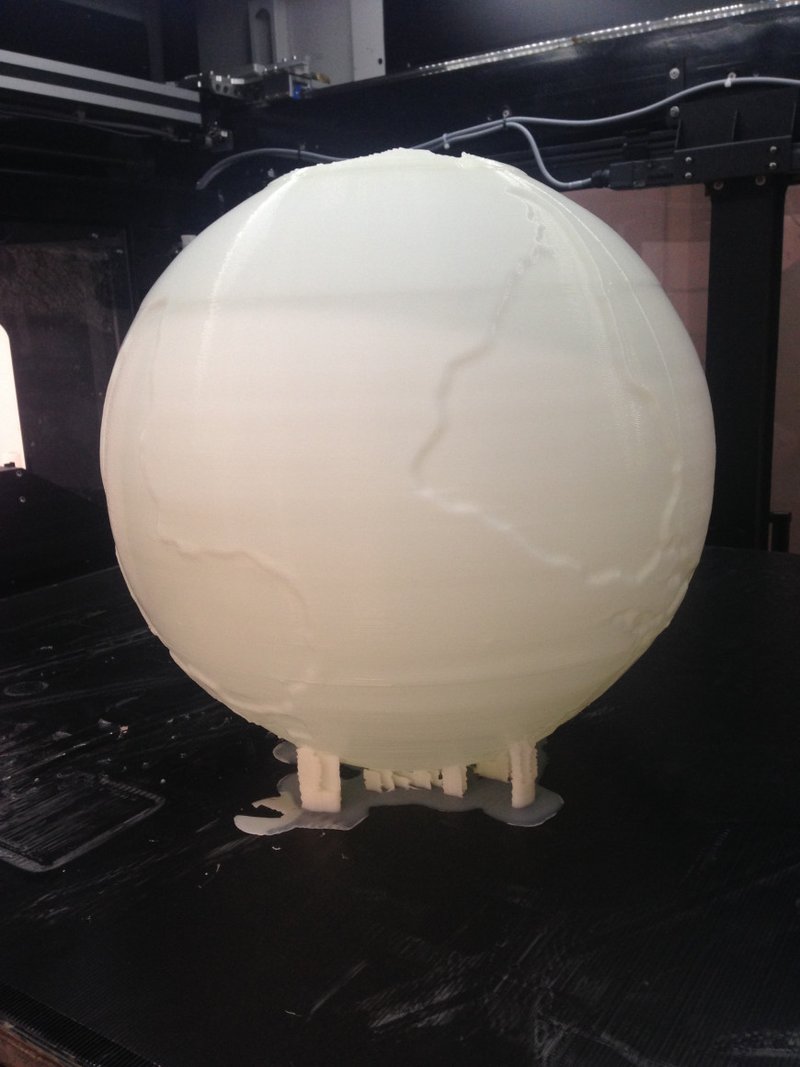

Finally, we wanted to make a real challenge and settled on the Earth model.

Ball diameter: 50 cm

Printing time: 4 min 3 sec

Layer height: 1 mm

After that, the model was complemented with the continents printed separately and coated with paint. The result can serve as a perfect scenery or presentation prop.

The Massivit 1800 3D printer is your best choice with large-scale, fast, and quality prototyping as well as design, promotional projects and advertising. With the impressive build volume, decent detailing, and high speed of production, it will be of great use to every person who appreciates their resources.

Update your browser to view this website correctly. Update my browser now

Write a comment