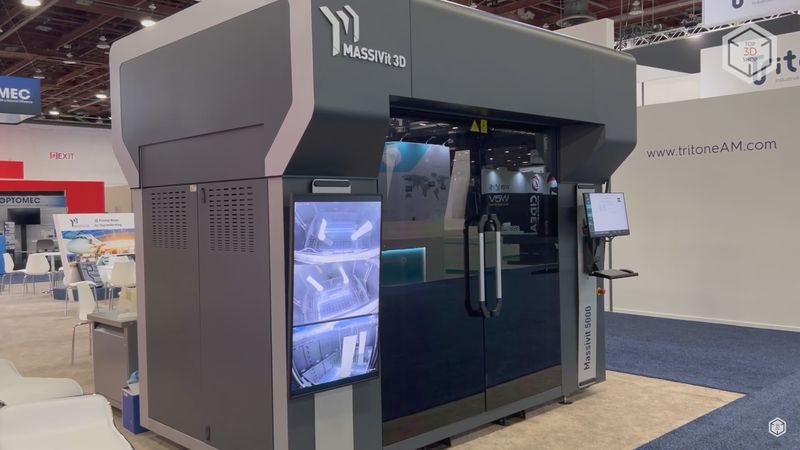

Today, we are going to tell you about one of the fastest industrial-grade machines — the Massivit 5000 3D printer. It stands out from the rest of the models in the line due to a wider range of materials and print modes, which will be of great use for numerous applications. Let’s now look at its main peculiarities and technical specifications.

Massivit 3D printers are large-format additive manufacturing machines designed and produced by the namesake Israeli company. The new Massivit 5000 is an improved version of the flagship 1800 model that ensures rapid and high-quality production.

These large-format 3D printers are indispensable in a wide array of industries requiring fast, reliable, and massive printing, such as automotive, rail, marine, mechanical engineering, education, etc.

Alongside some staple applications, the printer greatly facilitates the manufacturing process in the architecture sphere by working with plaster and concrete castings in the brand new Mold Mode.

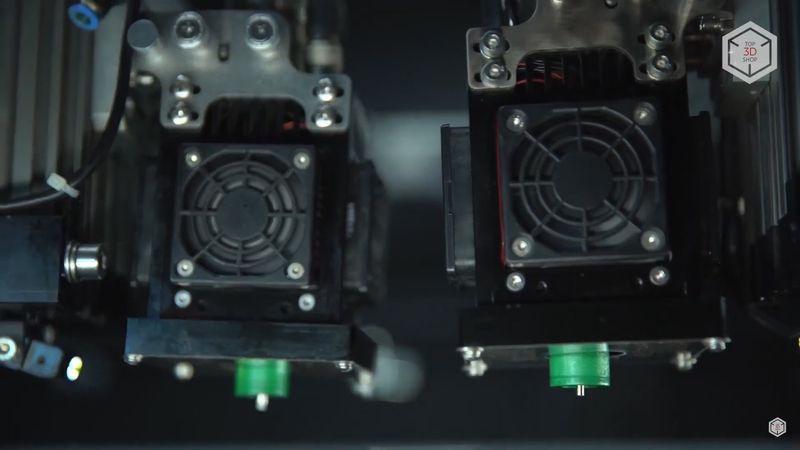

The Massivit 5000 is primarily aimed at improved performance and resolution. It is equipped with two independent print heads that allow you to quickly print-out two objects up to 180 cm in size at once, utilizing relatively affordable materials with different properties and ensuring admirable workflow flexibility.

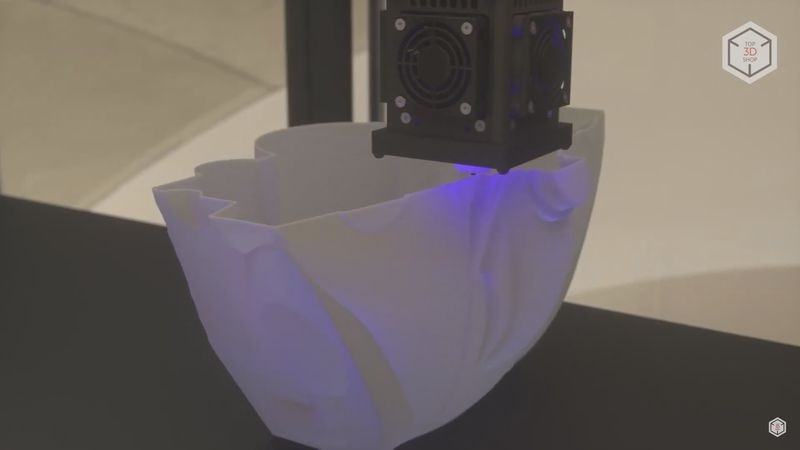

Massivit engineers have developed and patented their own Gel Dispensing Printing technology (GDP) that uses proprietary viscous acrylic-based photopolymer feedstock, immediately cured by built-in UV-light emitters.

This specific method delivers enormous benefits for time- and cost-effective production of large-scale models, props, and functional parts in various spheres, including engineering, visual communications, entertainment, design, and more.

To date, three versions of the branded photopolymer are available: the universal DIM 90, the translucent DIM 100, and the special-purpose high-precision DIM 110.

In the near future, the company plans to introduce two new types of materials: completely transparent and heat-resistant gels for even wider industrial purposes.

Overall, the Massivit 5000 features five print modes to select from. The thickness of each layer depends on the build speed and varies from 0.5 to 1.5 mm. The new High Definition mode provides the finest layer thickness for extra smooth and detailed prints, while the Mega-Quality option combines precise printing of large objects with great speed.

With a build area of 1450 x 1110 x 1800 mm, the machine can reach a speed of up to 35 cm per hour along the Z axis, making massive industrial crafting ultra-fast and efficient.

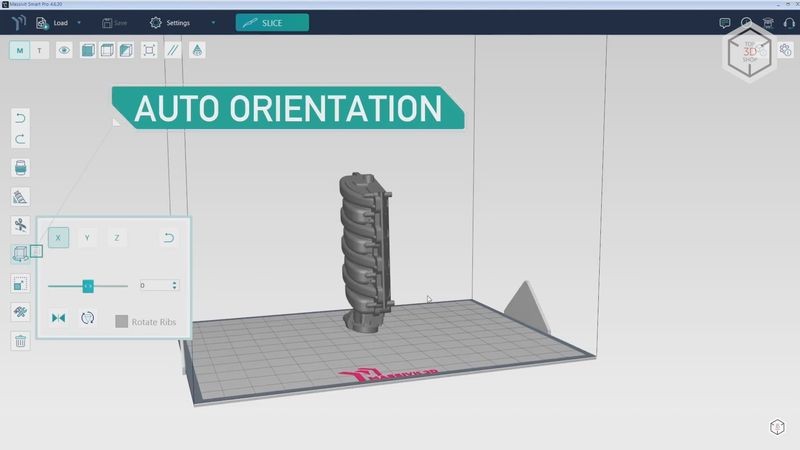

The printer can be easily controlled through Massivit Smart Pro software with intuitive UI and sophisticated functions. It is developed in-house and used to prepare 3D files for printing. The program works with data in STL format and allows you to scale, rotate, and cut digital objects, as well as track the printing process.

The Massivit 5000 3D printer is engineered with a real-time parameter correction system that utilizes integrated machine vision. The user can access the three cameras located inside the build chamber for real-time monitoring through an external 40-inch LCD screen.

Moreover, it is possible to manage the machine remotely via smartphone or tablet.

The capabilities of Massivit 3D printers are extraordinary when producing promotional materials for retail, in the process of designing equipment for exhibitions and other public events, and for making scenery for theater and concert performances.

Credit: @figureplant / Instagram

Massivit technology greatly simplifies large-sized manufacturing of any complexity without compromising quality. The use of such 3D printers speeds up the completion of large-scale projects by 2-3 times, compared to traditional methods.

As you can see, the enhanced features and impressive build volume of the Massivit 5000 are successfully combined with high resolution and great accuracy. With all the above mentioned characteristics considered, the machine is highly recommended for large-scale industrial manufacture, as it is clearly aimed at reliable performance, smooth operation, low material costs, and rapid production of high-quality items with outstanding characteristics.

Update your browser to view this website correctly. Update my browser now

Write a comment