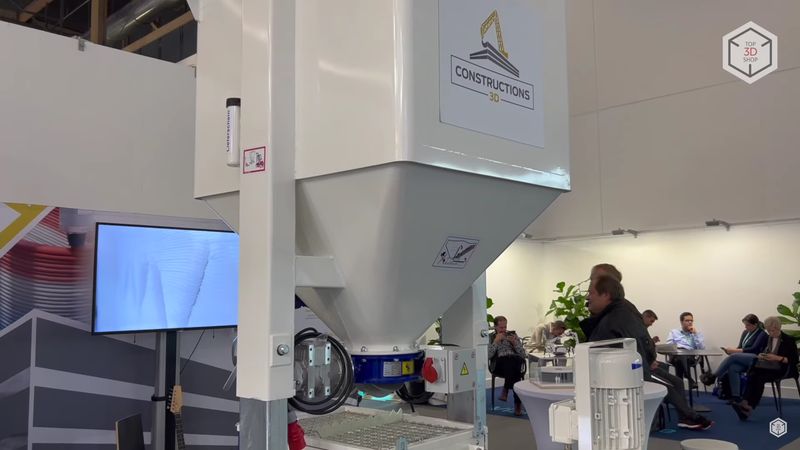

Having been on the market of additive building installations since 2017, the French company Constructions-3D offers a lineup of industrial 3D printers designed for creating large-sized objects using mortars.

The machine we are talking about today is MiniPrinter PRO — a reliable, versatile tool for professionals working in different industries such as construction, architecture, design, and scientific research.

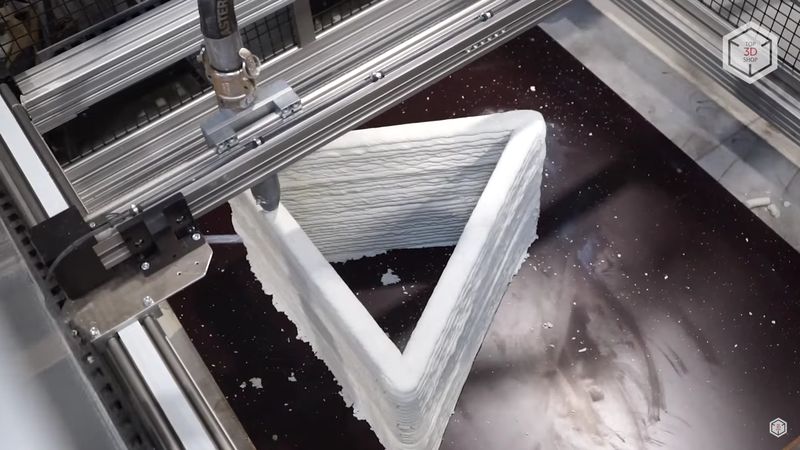

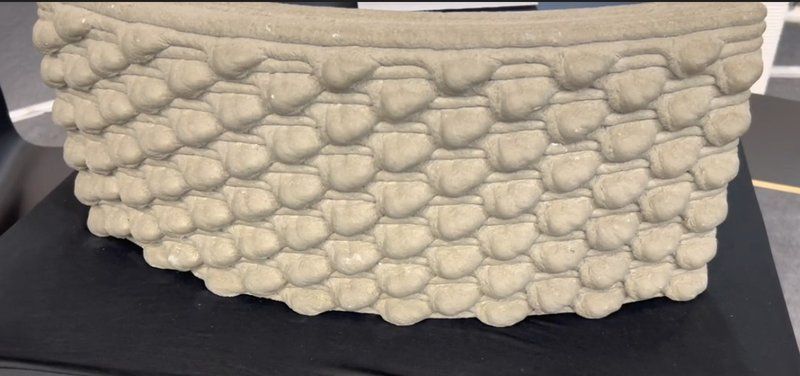

The 3D printer is characterized by a portal-type three-axis design employing mortar layer-by-layer extrusion technology, and its print volume represents a cube with a side of 120 centimeters. With a standard layer thickness of 35 millimeters, the device features repeatability of one millimeter and the Z-axis accuracy of five tenths of a millimeter.

The MiniPrinter PRO comes with a pumping system, giving customers a choice of three options depending on their printing needs and volumes.

Rendering files for printing is carried out using in-house developed slicing software that supports STL and DXF formats.

The standard package includes the installation, one of three types of pumps, proprietary slicing software with a library of three-dimensional objects, and one ton of dry mortar mix.

The machine is compatible with third-party mixtures, with all the necessary requirements for consumables set-out in the instruction manual.

Combining excellent precision and repeatability with a high degree of automation, the Constructions-3D MiniPrinter PRO is a cutting-edge machine that can dramatically transform modern construction. Indeed, the printer impresses with the high-end technologies used in its components, huge build volume, and undeniably quality hardware. The product is designed to yield consistent results with minimum effort engaged.

In addition to the MiniPrinter PRO, the Constructions-3D’s lineup of equipment also includes a version for educational institutions, the ultra-large MaxiPrinter, and a device for evaluating the properties of ready-to-print mortar mixes.

Update your browser to view this website correctly. Update my browser now

Write a comment