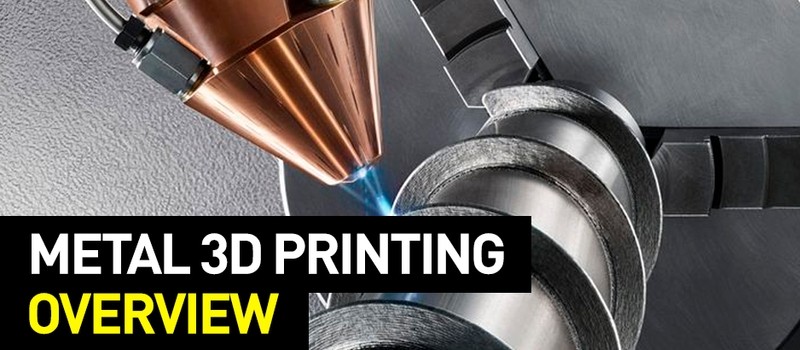

Metal 3D printing is on the rise. In this overview, we will cover everything connected with metal 3D printing: from most common technologies and 3D printers to features and ways of application.

"A 3D printer that prints with metal" - even twenty years ago, such a phrase would have been considered science fiction. Today, Audi and Porsche, SpaceX and NASA are implementing additive manufacturing of metal powder products in their production.

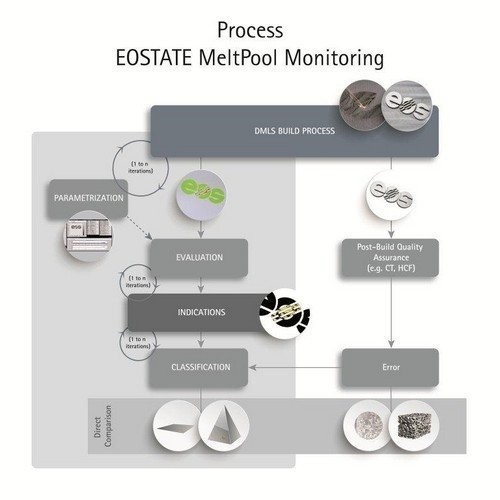

Selective laser melting (SLM) and direct metal laser sintering (DMLS) are the two most common additive manufacturing processes which use metal powders for printing.

Less common technologies for 3D printing with metals include laser or high-power electron beam additive manufacturing, as well as binder jetting where the process of 3D printing is implemented by applying and binding of the metal powder layer by layer.

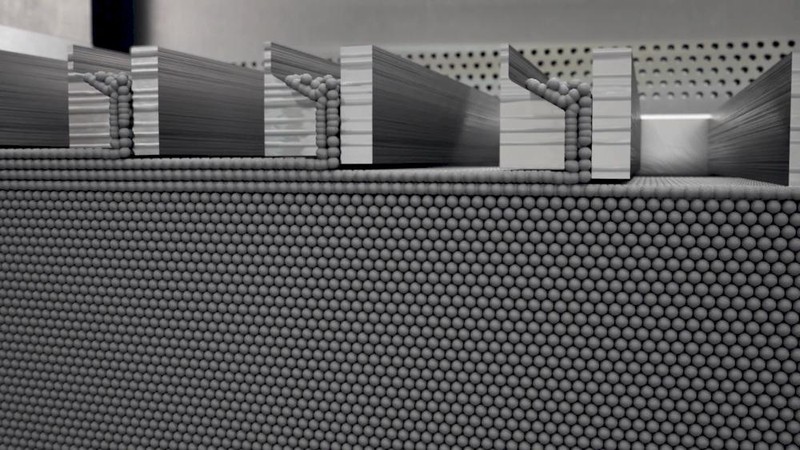

The differences between SLM and DMLS amount to the method of binding the particles: in SLM, the metal powder is melted by a laser beam, while in DMLS, the powder particles are heated in a lesser degree, which allows them to be sintered together avoiding solid-liquid transition.

DMLS printers allow to create objects without residual internal stresses, which can significantly compromise the quality of metal components manufactured by more traditional methods, such as casting and molding. This is crucial for parts manufactured for the automotive and aerospace industries, as it can increase part strength and durability.

On the other hand, SLM printers melt metal powder layer after layer. The rapid change of temperature can lead to internal stresses in the part, which can potentially affect its quality, although to a lesser extent than in casting, for example.

Another point worth mentioning is that parts manufactured using DMLS technology are inferior in solidity and safety margin to parts printed using the SLM method.

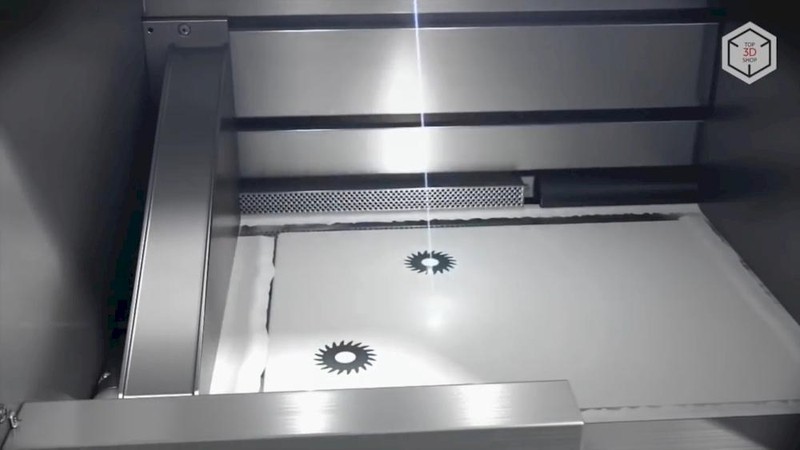

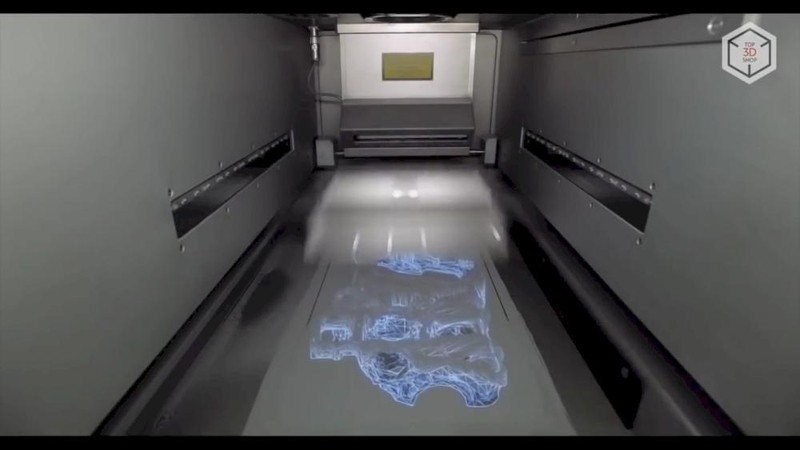

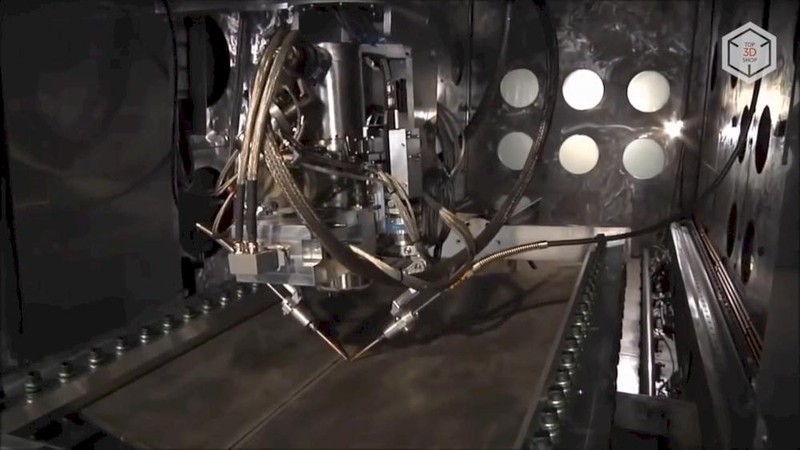

The processes of parts manufacturing implemented by SLM and DMLS technologies are very similar. The build chamber is first filled with an inert gas, and then heated.

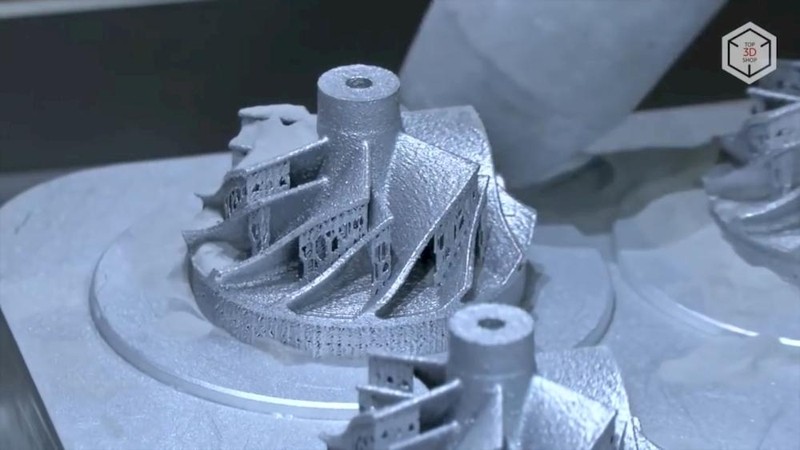

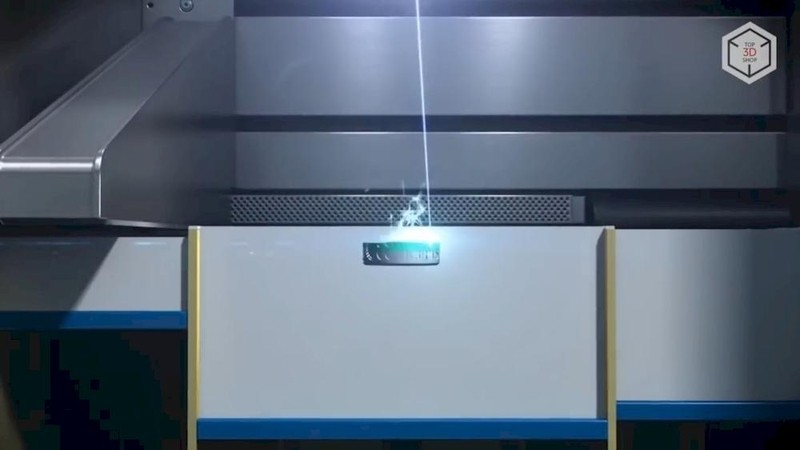

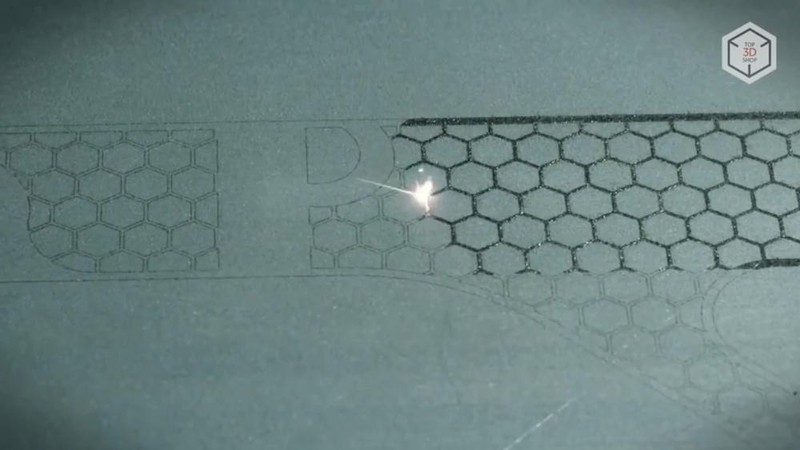

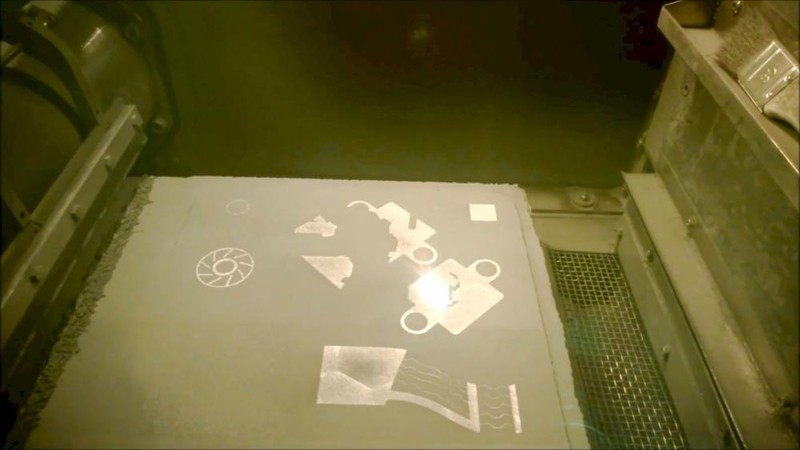

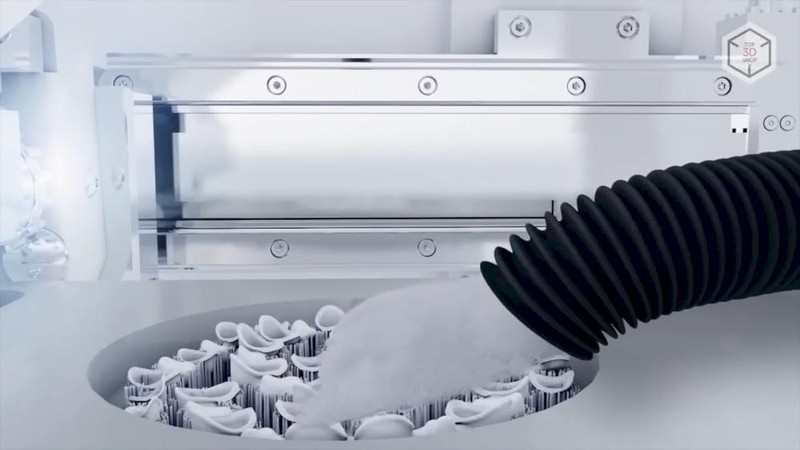

A thin layer of metal powder is distributed across the build platform. Then, a high-power laser draws a 2D cross-section of the component, melting or sintering metal particles together.

Once the layer is complete, the build platform is lowered just enough to make room for the next layer. Then, the next layer of powder is applied.

The process is repeated until the entire part is completed. During the process of printing, parts are attached to the build platform with the help of supports structures, which are created from the same material as the part itself. These structures must be added to avoid deformation and distortion that can occur due to high temperatures.

At the end of the printing process, the build chamber is cooled to room temperature. The surrounding loose metal powder is then removed from the printer. The support structures, which are no longer useful, are removed as well. The last step is to separate the part from the platform, which is now ready for further processing.

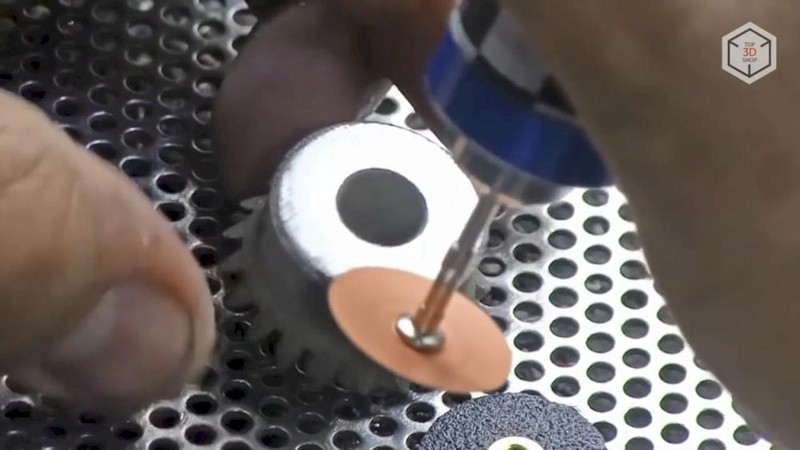

Various methods can be used to improve the mechanical properties, accuracy, and appearance of finished parts. Mandatory processing steps include the removal of the residual metal powder and support structures. Heat treatment usually helps to remove residual stresses and improve the mechanical properties of the part.

Other post-processing methods, such as pressure treatment, metallization, machining as well as CNC or manual polishing, can be implemented, depending on the purpose of a particular part.

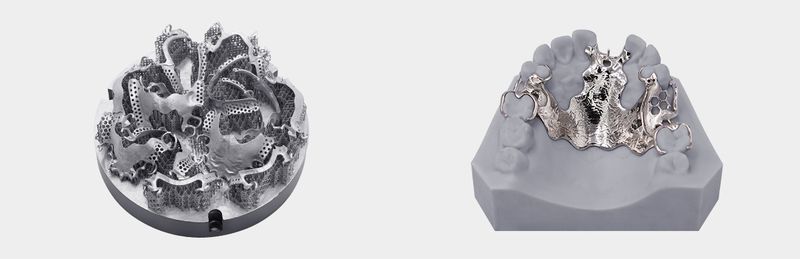

SLM and DMLS printers work with a great variety of metals and metal alloys, including aluminum, stainless steel, titanium, cobalt-chrome, and nickel-chrome. These materials can be utilised to cover the needs of the vast majority of industries, including medical, dental and aerospace sectors.

Precious metals, such as gold, platinum, palladium, and silver can also be used for 3D printing, but they are mostly used in jewelry making.

Main Characteristics

The HBD-150 (also available in the 150D version featuring increased laser power) is an affordable SLM machine with enhanced customization and a number of auxiliaries enabling cost-effective and conveniently automated production. It is particularly great for digital dentistry due to a compact circular build volume, impressive scanning speed of 10000 mm/s, user-friendly operation, and easy access to the printing area.

A set of thoughtful safety functions, such as a door opening detection system, atmosphere purification, and automated monitoring of oxygen content, contributes to a safe and pleasant working environment.

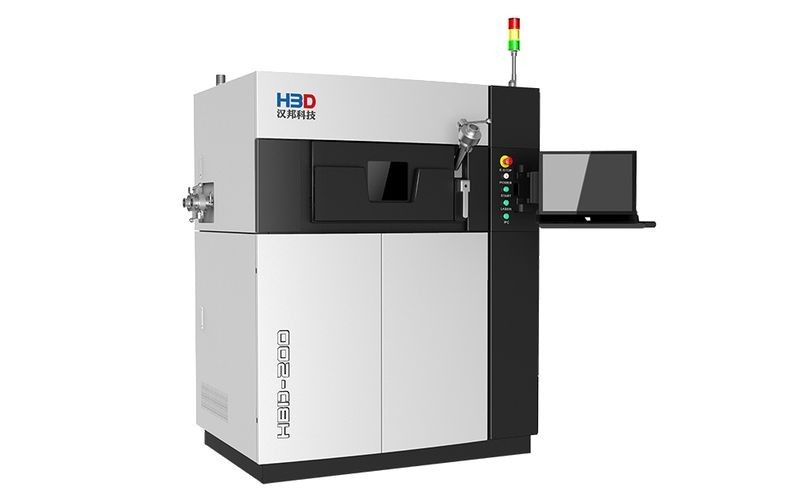

If the previous model seems insufficient for your needs, the enhanced HBD-200 will cover more tasks with increased build volume of 270 x 170 x 120 mm and two 200W lasers. The powerful SCANLAB galvo system ensures high accuracy up to 0.05 mm, which is perfect for products of various industries, including engineering, medical, jewelry, scientific research, etc.

To provide a safe and stable titanium printing environment, the machine is equipped with an independent atmosphere purification system, sealed glove structure, and handy interface for powder management without opening the chamber.

The HBD-350 is another comprehensive, customizable solution for most demanding metal 3D printing needs in a number of intense industries, such as mold, aerospace, aviation, automotive, medical equipment and functional parts production, jewelry, prototyping, and more.

As a standard model from the HBD lineup, the machine offers a large build volume of 325 x 325 x 400 mm, which makes for sufficient production speed and effective material usage. There is also a dual-laser version of the printer with increased productivity — HBD-350T.

Due to advanced production capabilities, the HBD-E500 model is recommended for aerospace, automotive, and medical applications. With a build area of 430 x 520 x 520 mm and minimum layer height of 30 microns, this industrial machine can be used to continuously produce top-quality end-use parts and large-scale prototypes in small batch production runs.

The system is compatible with various metals and alloys, such as stainless and tool steel, cobalt-chrome alloy, titanium alloy, aluminum alloy, and some refractory metals like Tungsten and Tantalum. Depending on the modification, the HBD-E500 can be equipped with two or three 500W lasers.

Similar to the aforementioned systems, the HBD-1000 meets most demanding metal 3D printing needs while still being an affordable entry point for SLM technology.

Considering an impressively large build volume of 600 x 600 x 1000 mm, the machine can print the majority of items as a whole. In terms of power, the solution is available in two versions — with four 500W or 1000W lasers that provide outstanding sintering capacity. Thanks to the brand scanning speed and flexible multi-purpose software with rich functionality, the machine offers smooth operation and elevated productivity alongside numerous safety features.

Speaking of the largest SLM devices in the market, it is hard not to mention the HBD-1200 boasting an impressive build volume of 460 x 460 x 1200 mm. The machine comes in two versions — with dual 500W or 1000W laser configuration.

Like the rest of the company’s systems, the HBD-1200 is noted for its precision, high scanning speed, automated functionality, and thoughtful safety features.

Main Characteristics

SLM 500 from SLM Solutions is an industrial-scale plant, used for additive manufacturing of metal products. The printing technology used in SLM 500 is selective laser melting, hence the name of the printer. The generous dimensions of the chamber make it possible to create large-sized models.

The melting process is implemented by four lasers with a power of either 400 or 700 watts each. The minimum thickness of the applied layer is 20 microns. This printer uses a wide range of materials, including titanium, aluminum, steel powders, as well as powders made of other metals and alloys.

Main Characteristics

Markforged Metal X is a 3D printer for metal printing that offers a full-rate production decision. The company claims that its 3D printer is ten times cheaper than products with similar qualities from its competitors.

The construction of parts is completed layer by layer, from metal powder that is contained within a plastic binder.

After printing, the part is heated in a special chamber to remove the binder, and the powder particles are fused together. This way, the integrity of the crystal lattice can be restores, which ensures the solidity of the part.

Metal X has a build volume of 250x220x200 mm and a layer height of 50 microns.

Main Characteristics

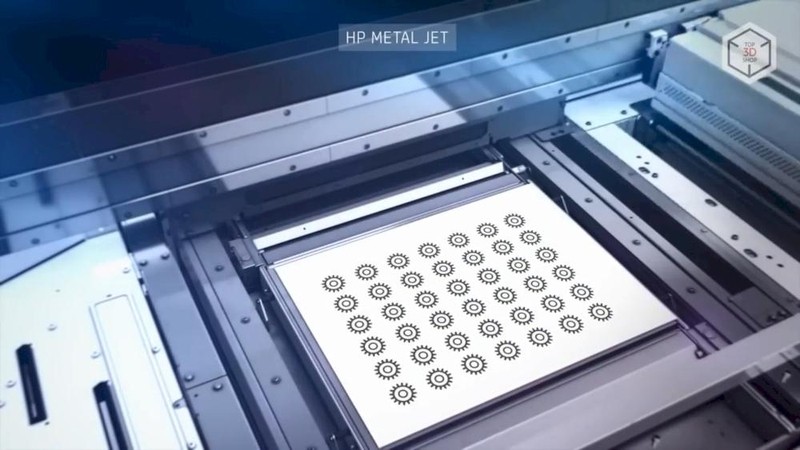

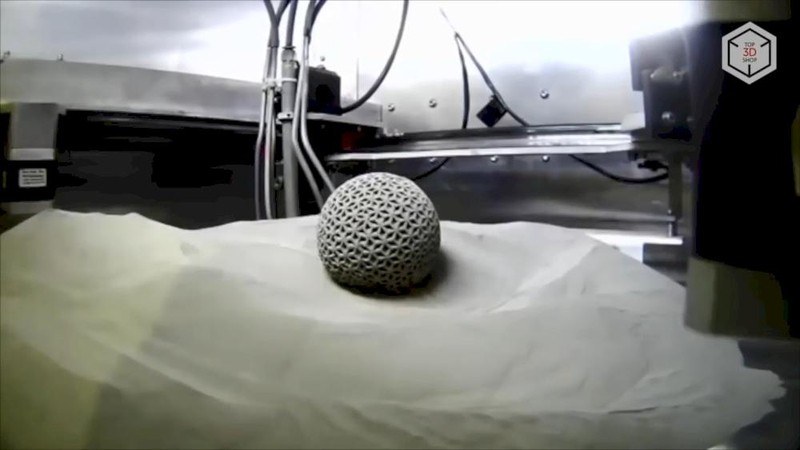

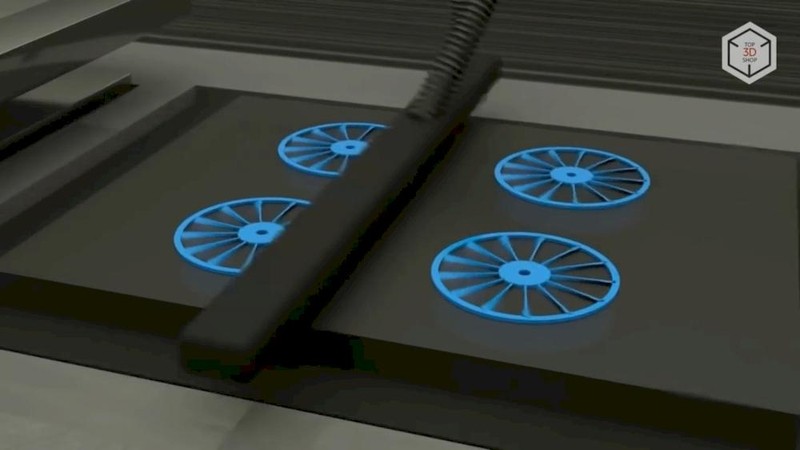

At the 2018 International Manufacturing Technology Show (IMTS), HP launched HP Metal Jet - a 3D printer, which uses a technology similar to Binder Jetting.

HP Metal Jet uses layer-by-layer printing with the application of a binder to a powder basecoat - the process is similar to how a conventional inkjet printer applies ink to a sheets of paper. Then, after which the product exposed to the heat treatment.

Parts can be freely placed in the powder layer in several levels, in order to optimize the use of the build volume, increase productivity and reduce production costs.

Implementation video:

Main Characteristics

Aurora Labs, an Australian-based manufacturer, is a newcomer in the field of additive technologies. In September 2018, the company announced that it had made great progress in developing metal printing technologies.

Aurora Labs has launched S-Titanium Pro, an open source 3D printer. Users will be able to create their own software and metal powders.

The printing speed of the S-Titanium Pro is 662 grams per hour, which is eight times faster than the speed of similar models on the market.

At Formtext 2019, the company introduced their MP-1 Beta - a 3D printer, which uses the Aurora Labs Multi-layer Concurrent Printing (MCP) technology. The manufacturer managed to exceed all available printing speeds on the market manifold. According to the latest trials, the printer is capable of working at a speed of 350 kilograms of material per day.

This result can be achieved thanks to technology of concurrent powder pouring. Several lasers simultaneously kiln a section of the metal part in their individual chambers.

Main Characteristics

Digital Metal, a subsidiary of a Swedish metal powder manufacturer Höganäs, has recently presented a new high-precision method for layer-by-layer bonding of metal particles.

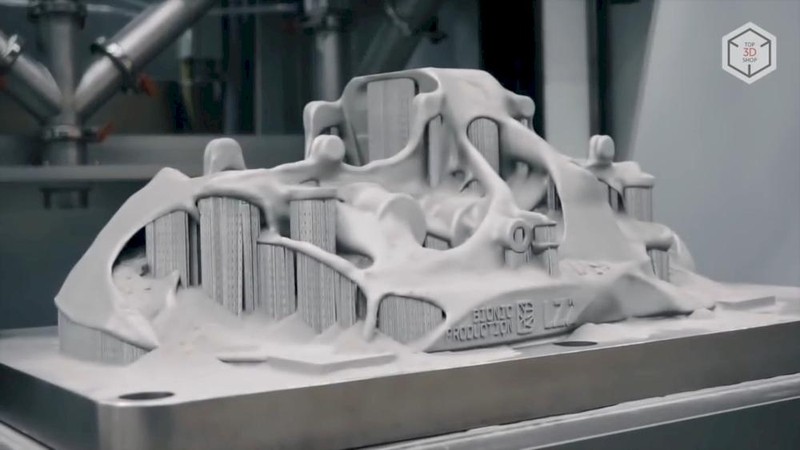

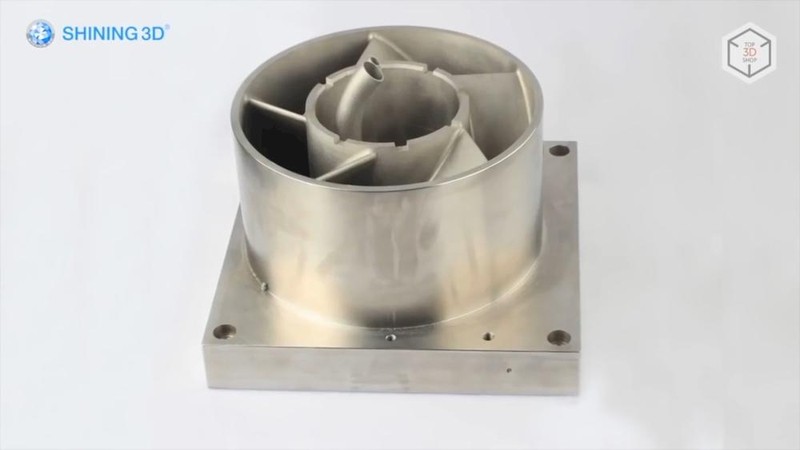

The 3D metal printer, called the DMX 2500, produces small and exceptionally complex metal parts. The company’s proprietary technology makes it possible to manufacture parts without support structures.

Digital Metal has a print volume of 2500 cubic centimeters and a print speed of 100 cubic centimeters per hour.

Main Characteristics

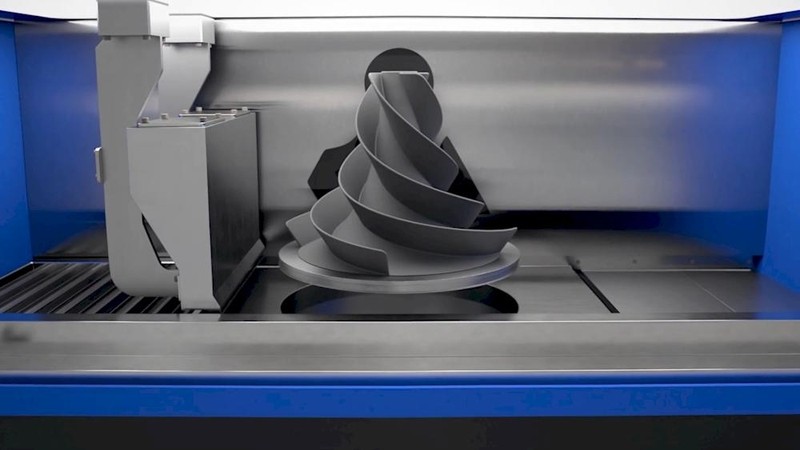

The Shining 3D EP-M250 is the latest version of a 3D printer, which uses metal powder material for printing. This printer is capable of creating objects with free structures of any complexity and can provide virtually total density of the part.

The material utilization rate for printing exceeds 90%, which makes it possible to efficiently use such expensive materials, as titanium or nickel powders, which helps to reduce material expenses.

The EP-M250 is widely used in the aerospace, medical, automotive, and home appliance industries.

At the 2018 Formtext exhibition, Stratasys announced a completely new additive technology, Layered Powder Metallurgy. According to Stratasys’ representatives, this technology will revolutionize 3D printing with metals.

LPM was designed to become the fastest and most cost-effective direction in additive manufacturing — the company claims that the system will be able to print nine times faster than it is possible using other 3D metal printing technologies.

Main Characteristics

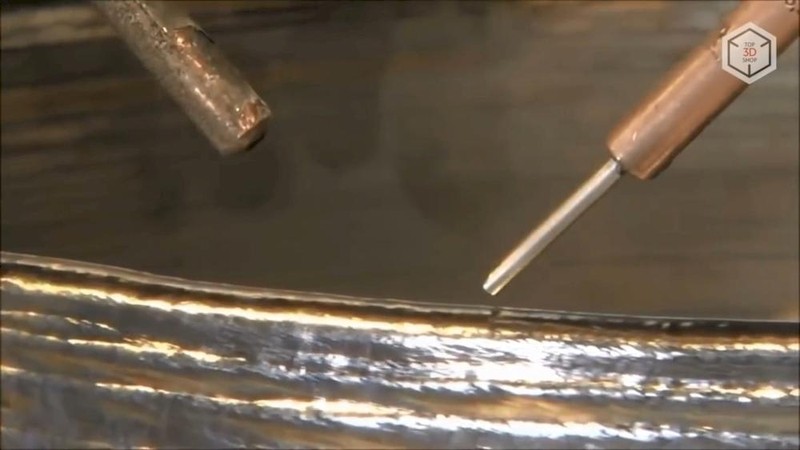

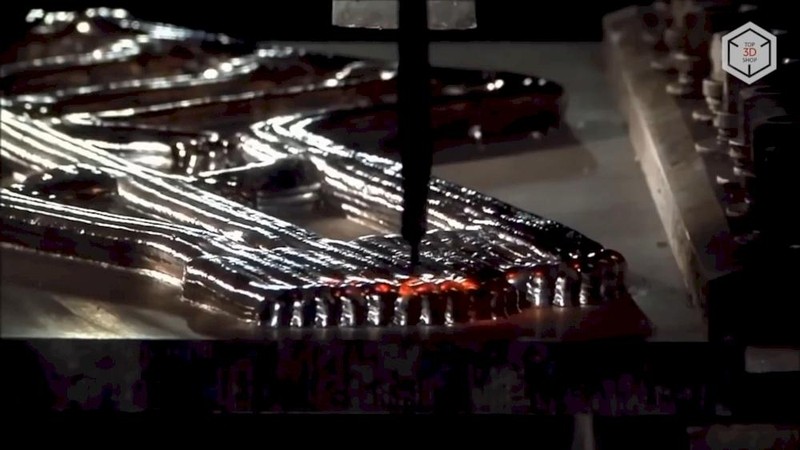

Fabrisonic offers an alternative method for 3D printing of large metal parts - ultrasonic additive manufacturing technology. Fabrisnic’s machines are equipped with a device for metal tape delivery and cutting, a milling machine and a sonotrode - a tool for ultrasonic welding of metal.

In this printer, the layers are formed by a metal foil - the device cuts it from a tape reel. The added metal is pressed against the previous layer and is exposed to ultrasound, making it possible to fuse the layers with the help of accelerated diffusion.

After fusion, the cutter removes excess material, forming another layer. This method of metal printing provides fewer opportunities for the formation of complex shapes and internal structures, but is best suited for batch printing of large products.

Main Characteristics

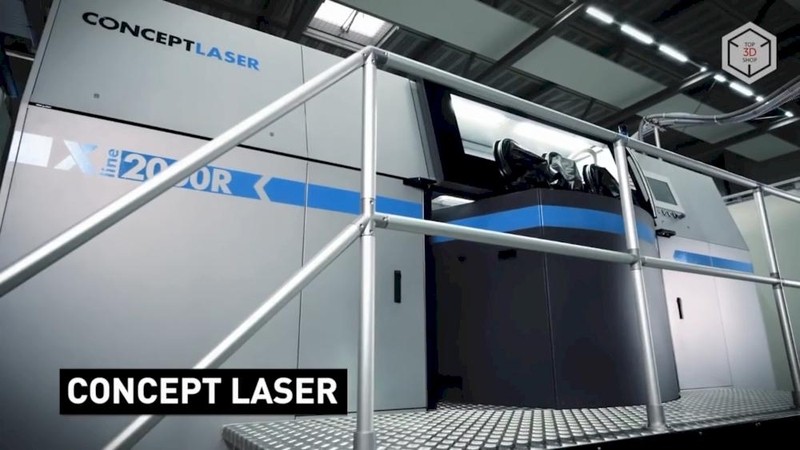

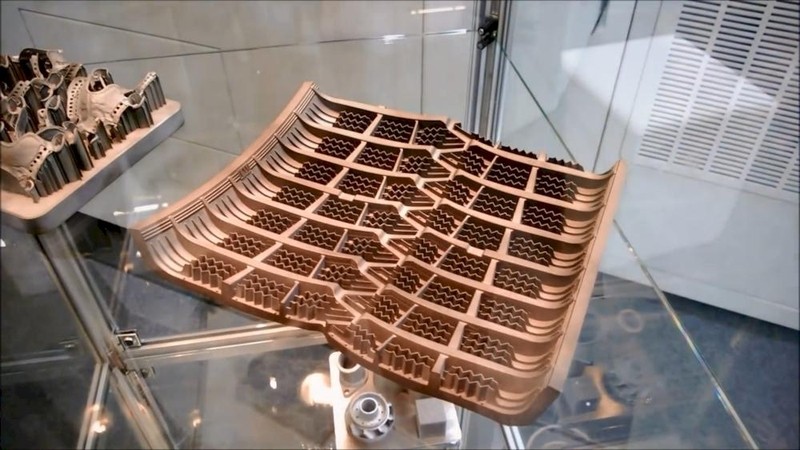

Concept Laser X Line 2000R is one of the largest 3D printers which print using metal powders on the market. The manufacturer is a supplier of 3D printers to aerospace corporate giants, such as Airbus.

The X Line 2000R is equipped with two lasers and has a build volume. The printer uses a type of selective laser melting to manufacture parts - the patented LaserCUSING technology.

It is possible to manufacture objects made of steel, aluminum alloys, nickel, titanium, and precious metals.

Application example:

Main Characteristics

It’s safe to say, that the best choice for printing of really large metal structures is EBAM from Sciaky. This company's printers are used primarily in the aerospace and defense industries of the United States.

Structural elements of aircrafts, which could take up to six months to produce using traditional technologies, can now be printed within 48 hours.

The unique Sciaky technology uses a high-power electron beam projector to melt a 3 mm thick titanium filament, with a standard deposition rate of 3 to 9 kilograms per hour.

Example of application by Lockheed Martin aircraft company:

Source: youtube.com

Main Characteristics

3D systems Proxy DMP 320 is a new generation printer, which uses DMLS technology in the printing process. This printer can work non-stop 24 hours a day, 7 days a week, and is able to provide the highest rates of model building speed and productive capacity. Another rather noteworthy feature of the printer is its impressive build volume, which amounts to 275x275x420 mm.

Source: youtube.com

The production process is fully automated - from setting parameters for construction to removing and disposing of waste and excess material. With this printer, it is possible to print using various alloys of titanium, nickel, and steel. Products, which are manufactured using the ProX DMP 320, are characterized by high strength, durability and light weight, thanks to the reduced presence of oxygen in the build chamber.

Source: youtube.com

Example of application in motorsport:

Main Characteristics

ProX DMP 300 from 3D Systems is another popular equipment for 3D metal printing. This printer stands out from its competitors thanks to its convenience - it is equipped with an automated system for material loading and recycling.

Source: youtube.com

Thanks to the proprietary fusing system, the ProX DMP 300 can print at an angle of up to 20° without the help of support structures. As a result, improved printed surface quality and elimination of support structures lead to fewer post-processing procedures and significantly cut down on the use of material, hence saving time and money.

Source: youtube.com

Main Characteristics

EOS M 100 is a 3D metal printing system from a German manufacturer. This printer implements direct metal laser sintering technology — DMLS. The printer is equipped with a 200-watt fiber laser. This equipment makes it possible to produce parts with complex geometries.

The M 100 is optimized to reduce post-processing and cleaning time. Another great feature of this printer is its modular inner structure, which makes it possible to initiate and stop the printing process in virtually no time.

Composite materials are a great choice for 3D printing, since they offer high strength and durability while being significantly more lightweight than metal products while being stronger than regular polymers.

The majority of composites consist of a core polymer material (such as ABS, PLA, Nylon) reinforced with either chopped or continuous fiber of a stronger material. Carbon fiber is predominantly the most popular choice. Some combinations (eg. PETG + Continuous Carbon Fiber) can achieve an ultimate tensile strength of 860 MPa in the fiber direction. In contrast, some aluminum alloys such as Aluminum 6061-T6 have an ultimate tensile strength of only 310 MPa.

Apart from being an alternative to metal 3D printing, composite printing is a great counterpart to traditional composite manufacturing: it significantly streamlines the process and makes it less expensive. It’s also much less resource-intensive compared to traditional manufacturing.

There are various technologies for composites 3D printing available on the market. They are usually modified FFF/FDM solutions. For example, a Luxembourg-based startup Anisoprint uses their patented proprietary Composite Filament Coextrusion (CFC) technology in their desktop 3D printer named Anisoprint Composer A4 and its larger sibling Composer A3. This technology differs from other composite 3D printing solutions by reinforcing fibers directly during the printing process, making the method more versatile and offering wider material choice to an end user. For example, some manufacturers limit your choice of thermoplastics to only Nylon, while with Anisoprint, one can print with any thermoplastic with a processing temperature up to 270 C (PLA, PETG, PA, ABS, TPU, PC, etc.)

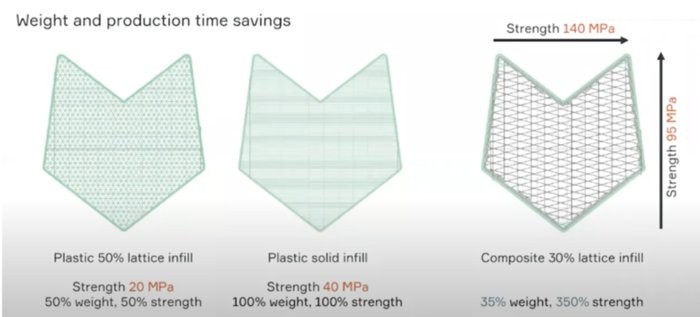

In addition, Anisoprint allows printing with not only reinforced perimeters and solid infills, but also with lattice composite infills that enable achieving optimal strength with minimal material.

Source: anisoprint.com

40% weight reduction compared to the original aluminum-made part means saving a lot of money, since in the aerospace field every kilogram matters.

Source: anisoprint.com

The composite 3D printing technology made it possible to get the needed chemical properties for the part: it’s very resistant to peroxide hydrogen. This in turn means increased lifespan.

Thermoplastics are a popular choice for FDM 3D printing, many common materials such as ABS and PLA belong to the group. High-performance thermoplastics provide great levels of strength while being significantly lighter (up to 80% in some cases) than metal. Such materials include PEEK, PEI and various types of Nylon. Apart from superior weight-to-strength ratio (which is very important for end-use products), printing with high-performance thermoplastics offers more flexibility and versatility. The drawbacks include being less cost-efficient for mass production and some problems with printing very large parts.

Intamsys Funmat HT is among the examples of 3D printers capable of working with high-performance thermoplastics. It features an all-metal hot-end that extrudes filament at the temperature of up to 450 °C, resulting in an impressive range of supported materials, including high-performance thermoplastics such as Carbon Fiber, PEEK and ULTEM.

The device was used to 3D print the parts of a race car. This helped to reduce weight and provide impressive mechanical properties of car’s parts.

The majority of 3D printers that use High-Performance Thermoplastics utilize either FFF/FDM or SLS (Selective Laser Sintering) technology.

Thermoplastics can be a core material for composites: reinforced nylon and PEEK are popular solutions.

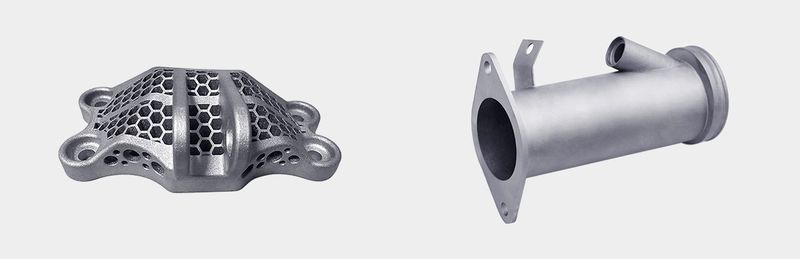

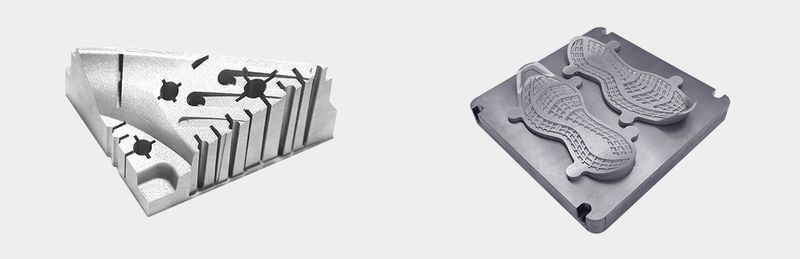

3D printing with metals allows to effectively create prototypes in product development. On top of that, it makes it possible to manufacture ready-for-assembly parts in low-circulation and single-run production. Often, 3D printed metal parts can even outmatch those, manufactured by traditional methods. This advantage is expressed not only in the reduced production time and costs, but also in the improved accuracy and functionality. Even nowadays, it is already possible to create 3D printed metal objects of much higher complexity than those manufactured by casting and molding.

You can reach out to Top 3D Shop to upgrade your production line with top-notch metal 3D printers. Our team of engineers and managers will select and offer the most suitable options for your requirements and provide technical and service support.

Update your browser to view this website correctly. Update my browser now

Write a comment