There are not so many companies in the additive manufacturing market that offer such a vast range of industrial 3D printing equipment as Chinese-based E-Plus 3D. Focused on metal powder bed fusion technology, E-Plus 3D also produces SLS and SLA-based machines, alongside 3D printing materials and dedicated software to provide customers with one-stop solutions for various industries and applications.

This is Top 3D Shop, and in this article, we will talk about E-Plus 3D industrial machines and their applications in different fields.

Founded in 2014 by Mr. Feng Tao who presided over the development of China’s first SLS equipment in 1993 and cooperated with South China University of Technology to develop China’s first SLM equipment in 2002, the E-Plus 3D core technical team has more than 25 years of experience in additive manufacturing technologies, including metal powder bed fusion (MPBF), polymer powder bed fusion (PPBF), and stereolithography. The company used to be a subsidiary of Shining 3D, a well-known Chinese 3D scanner manufacturer, and was selling its 3D printers under the Shining 3D brand. In 2021, the two companies signed a joint declaration and now, E-Plus 3D is an independent company with two Chinese-based facilities in Beijing and Hangzhou and one in Stuttgart, Germany, opened in 2021.

Today, the company supplies industrial 3D printing equipment to over 40 countries and regions in Europe, America, Japan, South Korea, Southeast Asia, and others. E-Plus 3D invests more than 20% of its annual revenue into scientific research, which allows it to produce safe and reliable competitive machines meeting the quality standards for industrial equipment.

E-Plus 3D provides complete industrial additive manufacturing solutions including 3D printers based on different AM technologies and having various chamber sizes, from compact machines for dentistry to large-scale systems capable of manufacturing huge parts for the aerospace industry. Apart from that, the company has an extensive portfolio of metal and polymer powders and photosensitive resins. For all of them the company engineers have developed optimal parameter settings to achieve the best compatibility with E-Plus 3D machines. Yet, customers are not limited to only proprietary materials, since the open material system of E-Plus 3D machines allows using third-party powders and resins.

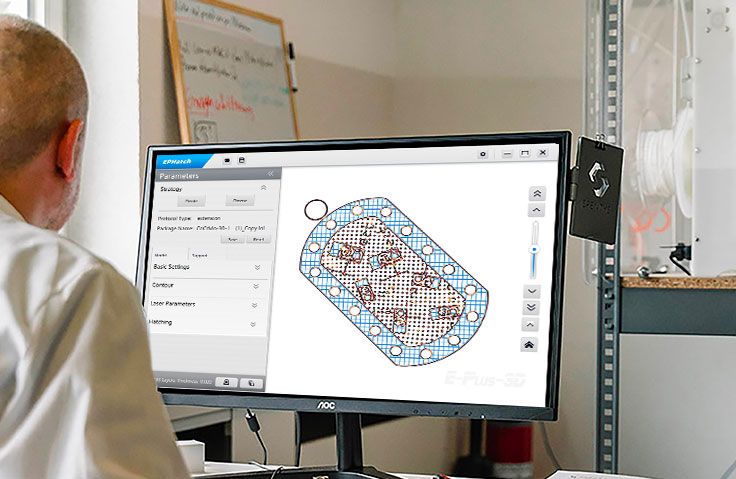

Another important part of the E-Plus 3D ecosystem is self-developed software that covers every step of the 3D printing process, from data preparation to printing control and monitoring. There are three types of software designed by E-Plus 3D, the first one is EP Hatch, data preparation software, providing various scanning methods and ensuring efficient optimization of printing parameters for the best result in each particular case. The software allows for independent parameter settings for different areas, provides the ability to vary layer thickness within a project, and is seamlessly integrated with a number of AM software solutions from other companies, such as Siemens, VoxelDance, Materialise, Oqton, and CADS Additive.

The EP Control software comes with every E-Plus 3D printer, has a convenient touchscreen UI, and allows for one-click printing function, estimation of print time and powder consumption, real-time parameter adjustment, printing report generation, and other smart features.

The E-Plus 3D Monitoring and Quality assurance software designed specifically for metal 3D printing allows for real-time monitoring of powder bed, laser power, and molten pool. The video below shows how it works.

Metal powder bed fusion (MPBF) is the core technology for E-Plus 3D. Since the launch of the first SLM machine EP-M250 in 2016, the company has developed an extensive range of SLM 3D printers that can handle titanium, aluminum, and nickel-based alloys, maraging steel, stainless steel, chrome cobalt alloys, and other metal powders to produce precise, high-quality parts for various industries.

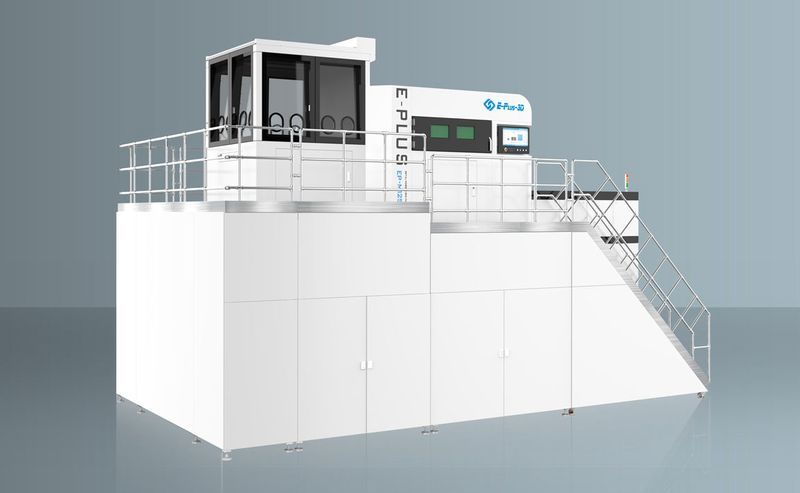

The flagship of E-Plus 3D SLM 3D printer lineup is the EP-M1250 model equipped with nine fiber lasers, each of them covering a separate area for maximum productivity. The machine features a huge build volume of 1258 x 1258 x 1350 mm allowing printing sizable parts for aerospace, automotive, oil and gas, and other industries, or batches of smaller models.

The EP-M150 Dental 3D printer, the most compact of E-Plus 3D SLM machines, is designed specifically for digital dentistry. Due to its improved powder feeding system and optimized gas consumption, the device ensures low operation cost. The EP-M150 can print a full plate of dental crowns (approximately 220 pieces) for only about 5.5 hours, being an efficient tool for series manufacturing of high-quality small-sized objects.

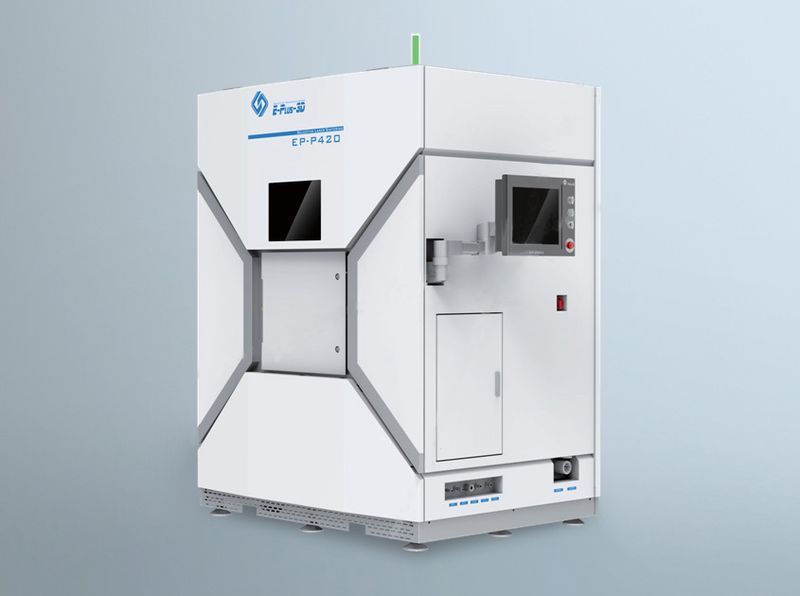

There are two types of E-Plus 3D SLS 3D printers. The EP-P420 and EP-P3850 are compatible with various polymer powders, such as PA12, PA12GF, PA11, PA11CF, TPU, and others, and capable of producing industrial-quality plastic parts both for functional prototyping and end-use product manufacturing.

The other SLS 3D printer type handles polystyrene, powdered wax, or resin sand and is used mostly for mold manufacturing for a conventional casting process. Integrating additive manufacturing technology into a traditional production cycle provides a number of benefits, such as lower mold cost, shorter delivery time, and improved mold quality, especially when it comes to complex and thin-wall parts. The EP-C7250 and EP-C5050 models are also efficiently used for rapid prototyping.

E-Plus 3D resin 3D printers differ in build volume sizes, with the largest EP-A800 featuring an enormous chamber of 800 x 800 x 450 mm. The machines ensure industrial-grade performance in terms of both part quality and efficiency, and are ideal for the applications where exceptional surface quality is required. The company offers a selection of proprietary resins with different properties, including casting, transparent, heat-resistant, and other materials.

The introduction of additive manufacturing provides a number of technical and economical benefits for the aerospace industry. 3D printed parts more and more often replace traditionally manufactured elements in this field. Let us look at the key advantages of using metal 3D printing for the aerospace and aviation industry.

Metal materials most often used in the aerospace industry are titanium, aluminum, and nickel-based alloys, and stainless steel.

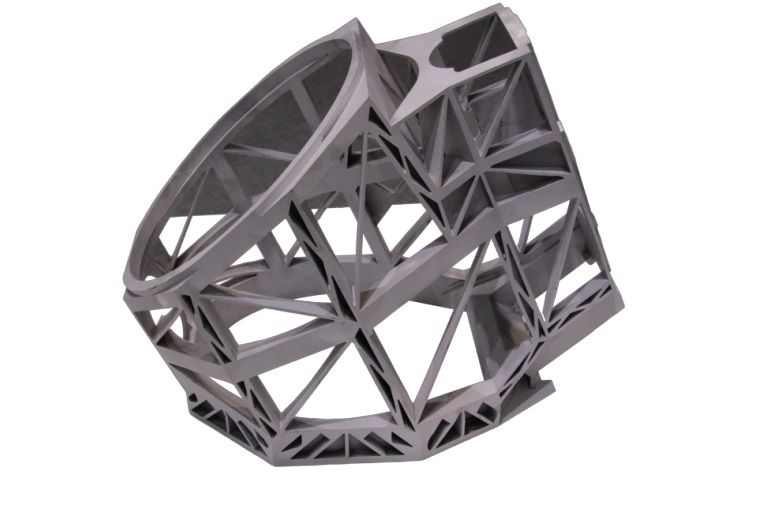

Frame

Machine: EP-M650

Material: aluminum alloy

Size: 470 x 400 x 499 mm

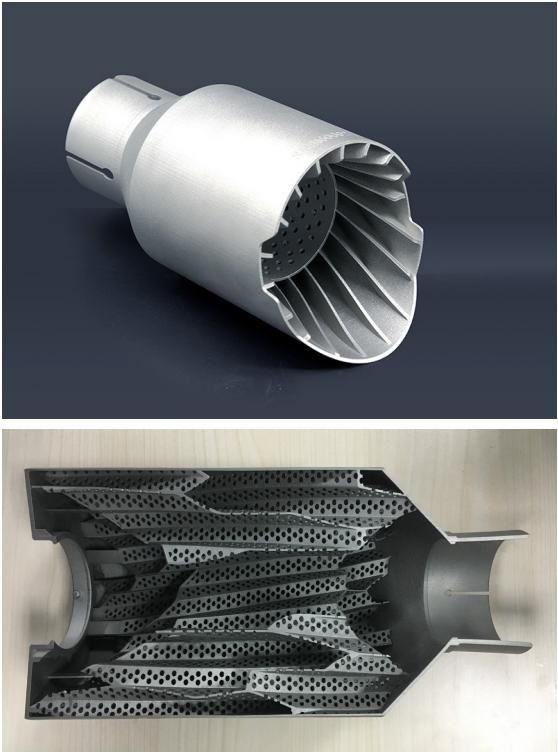

Tail spray

Machine: EP-M450

Material: Ti6Al4V

Turbine

Machine: EP-M650

Material: nickel-based alloy

Size: 620 x 150 mm

Blade

Machine: EP-M260

Material: stainless steel

SLS 3D printing technology also finds its use in the aerospace and aviation industry, mainly for printing aircraft cabin interior elements, but also for manufacturing functional components.

The advantages of additive manufacturing over traditional methods have already been appreciated by many players in this market. Today, more than 30 automotive companies employ E-Plus 3D equipment in their production cycle. Car manufacturers benefit from 3D printing technologies in the following ways:

Exhaust pipe for Ford Mustang

Machine: EP-M260

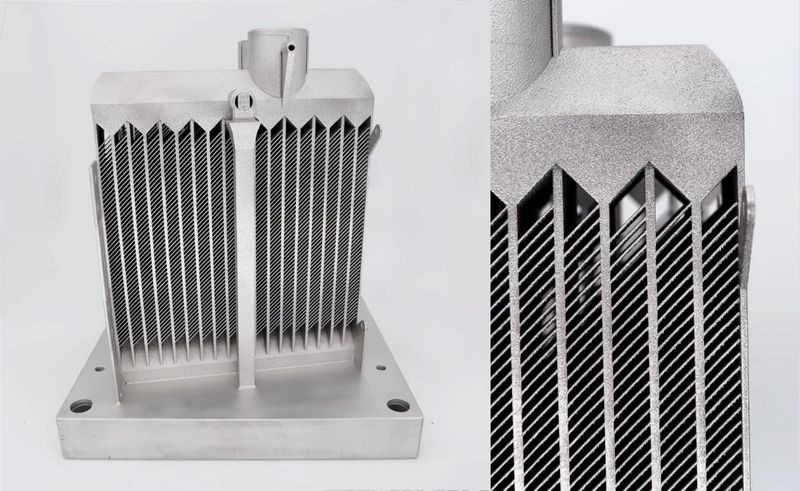

Racing car condenser

Machine: EP-M250

Material: aluminum alloy

Racing car wheel carriers

Machine: EP-M250Pro

Material: aluminum alloy

Oil and gas industry has not been as fast as the aerospace or automotive sectors to adopt additive manufacturing, but the share of 3D printed components in this field is growing constantly. The main benefits, such as faster product development, reduced costs, and design flexibility are greatly demanded in the energy sector. Besides, the use of additively manufactured spare parts simplifies supply chains and minimizes downtime, which is crucially important when the equipment is used in remote offshore regions. Production on demand eliminates the need for warehouse space and cuts transportation costs as the required components can be manufactured on site.

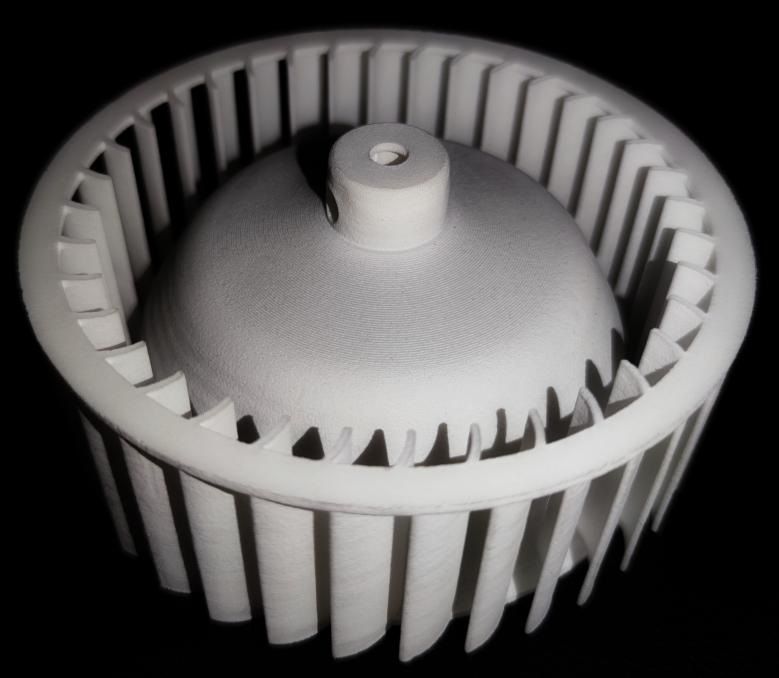

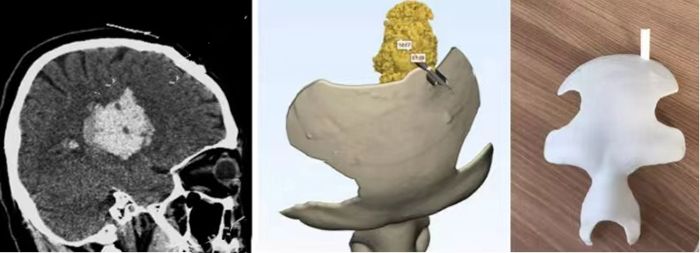

Impeller

Control valve plug

In healthcare, 3D printing is widely used for various applications, providing benefits for both doctors and patients. 3D printed customized medical models are a great help in surgical planning and education. The variety of biocompatible materials allow for creation of patient-specific implants and prosthetics that reduce the risk of post-op complications and speed up the rehabilitation process, due to their perfect fit and low risk of rejection. Customized medical instruments and surgical guides make for doctors’ convenience and flexibility during medical manipulations. Besides, most materials used for medical tools withstand various sterilization methods and feature wear, corrosion, and heat resistance.

Spinal implants

Material: titanium alloy

Hip bone implant

Material: titanium alloy

Customized surgical instruments

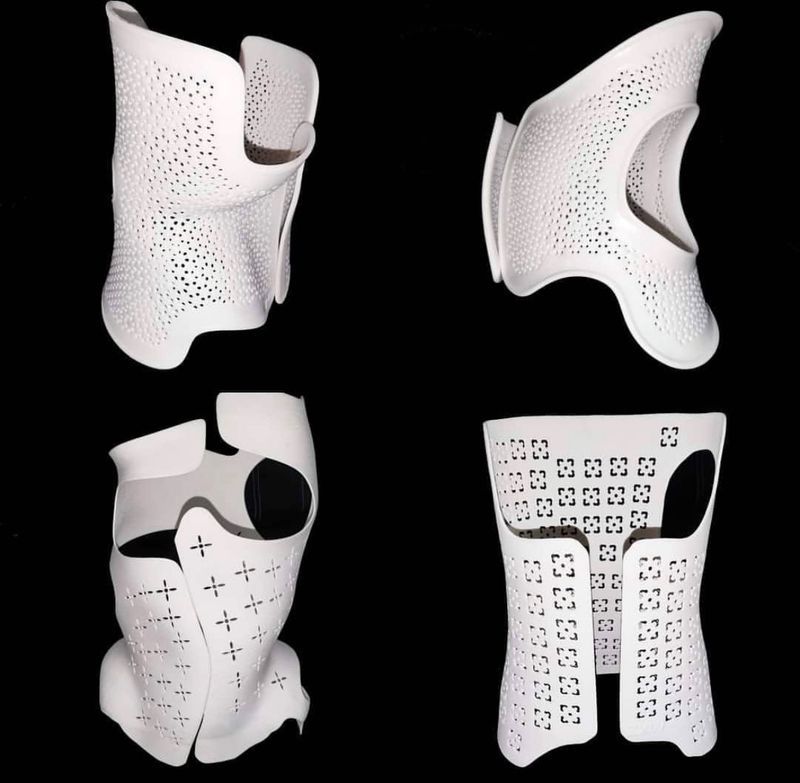

Customizes scoliosis braces

Technology: SLS

Machine: EP-P420

Skull surgical guide

Technology: SLA

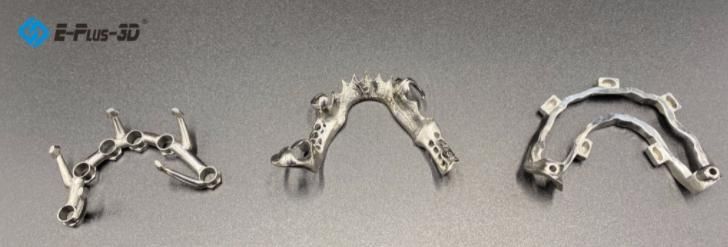

Metal powders, like titanium and cobalt chromium, are widely used in dentistry for making patient-specific appliances, such as crowns, bridges, brackets, and others. These materials are biocompatible and have excellent mechanical properties, wear and corrosion resistance, which makes them highly suitable for dental applications. The introduction of 3D scanning and 3D printing has revolutionized the dental industry, greatly reducing treatment time and cost, while increasing efficiency and precision and eliminating the risk of failure because of manual operation.

Dental crowns

Machine: EP-M150 Dental

Material: CoCrMo alloy

Dental frameworks

Machine: EP-M150

SLA 3D printing technology is also used in digital dentistry for creating dental models, dentures, aligners, and other appliances. The use of special dental resins ensures full biocompatibility and exceptional quality of printed parts.

Transparent orthodontic braces

Technology: SLA

Machine: EP-A650

Metal 3D printing greatly improves efficiency of the traditional injection molding process. While in traditional mold production, cooling channels are made by drilling and can only be straight, often being placed far from the mold surface, 3D printed molds allow for complex designs with conformal cooling channels based on the part geometry. This results in faster and more uniform heat dissipation, shortened production cycle, and better final part quality, as uniform cooling prevents possible deformation.

3D printed metal mold and the final product. Cooling channels are shown in blue.

Cooling channels are shown in red

This video shows the metal 3D printing workflow of mold creation.

In machinery, 3D printing is extensively used for prototyping, as complex elements usually require various design iterations, and 3D printing allows for it at no additional costs. Yet, comparatively low production volumes in the machinery industry are ideal for the use of 3D printing not only for making functional prototypes but for series manufacturing of final products as well. Among other benefits of 3D printing discussed above, spare part fabrication plays an important role in the machinery industry, as it allows reducing downtime and avoiding storage and transportation costs.

With the advantage of complete design freedom, unlimited customization opportunities, and variety of materials with different properties, additive manufacturing is a perfect tool not only in the industrial field, but for manufacturing various consumer products. Some typical applications of 3D printing are clothes and footwear, health and beauty, furniture and interior design, home and garden appliances, sporting goods, fashion accessories, and much more. Depending on a particular application, SLM, SLS, or SLA E-Plus 3D printers can be used for production.

Key ring bottle opener

Technology: SLM

Machine: EP-M150

Material: titanium alloy

Running shoe sole

Technology: SLS

Material: TPU

E-Plus 3D is a fast-growing company that offers an extensive range of industrial 3D printers based on SLM, SLS, and SLA technologies. The manufacturer pays a lot of attention to R&D and plans its strategic development with market demands in mind. E-Plus 3D machines incorporate innovative technologies, have various chamber sizes and laser power to meet the requirements of various industries. Producing not only 3D printing equipment, but also materials and software, as well as providing comprehensive customer support, E-Plus 3D offers reliable, convenient, and cost-effective solutions in the rapidly developing additive manufacturing market.

Update your browser to view this website correctly. Update my browser now

Write a comment