The AON M2+ is the next generation of 3D printers capable of processing high-temperature materials. Developed by the Canadian company AON3D, this is the fifth iteration of the device. With each upgrade, the developer improves reliability, performance, and compatibility with a wider variety of materials.

Read on to learn more.

The new generation of the AON3D equipment features an array of significant upgrades that take the performance to a completely new level.

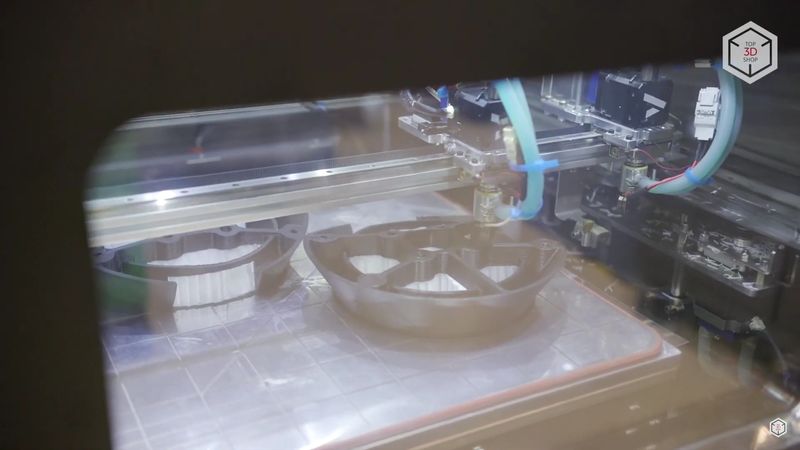

The heating temperature of the extruders has reached new highs and now exceeds 500 °C. The drives and extruders adopt liquid cooling, while the positioning system is based on the IDEX kinematics with independent movement of the printheads along the X-axis.

The machine is equipped with an active convection heated chamber capable of reaching up to 135 degrees, and the print area of the AON M2+ is one of the largest in its segment — 450 x 450 x 565 millimeters.

In turn, the print bed temperature can exceed 200 °C while the machine also supports automatic compensation of the working surface irregularities during operation.

The manufacturer recommends Simplify3D slicing software for rendering 3D models for printing, while the finished files can be sent to the machine via Wi-Fi or Ethernet.

The printer's operating modes and settings can also be managed using the touchscreen or remotely via the web interface.

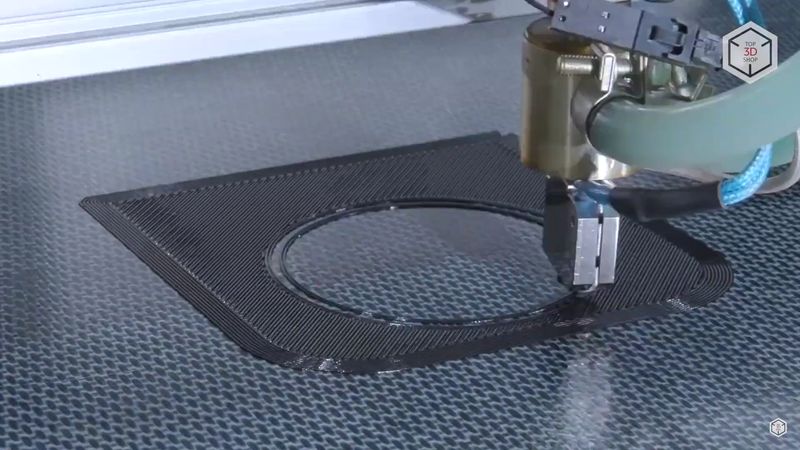

AON M2+ is capable of printing with a wide range of filaments and is an open-source platform ready to work with both branded materials as well as third-party consumables. The high-temperature extruders and the active heated chamber ensure stable processing of plastics with a high melting temperature such as PEEK, PEEK, PEI and Ultem.

The printer is a powerful tool for prototyping and mass production of finished parts with a wide range of materials, including thermoplastics with special physical and chemical properties.

Craniofacial implant

Material: biocompatible implant-grade PEEK

Aerospace Y-duct

Material: heat-resistant high-strength Ultem 9085

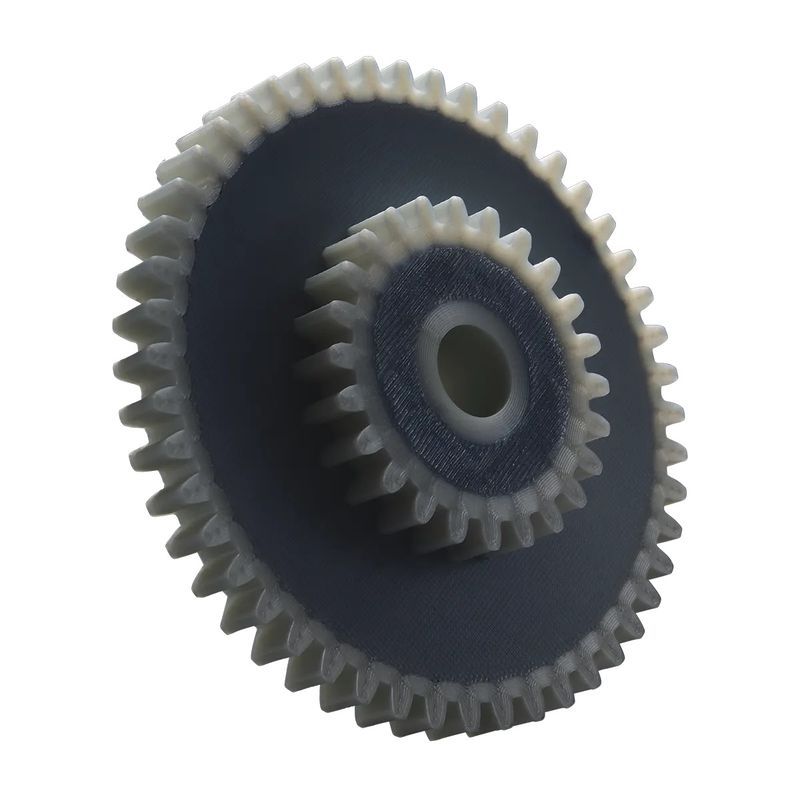

Gear

Material: wear-resistant PA

The AON3D AON M2+ is a truly industrial 3D printer that sports an impressive build chamber with large volume and active heating, outstanding material compatibility, and exceptional print quality.

Numerous smart features along with quality hardware ensure high performance and stability, while the dual extrusion setup allows doubling the output. Moreover, AON3D offers a completely open material system with configurable printing parameters and ready-to-use manufacturer’s profiles both for proprietary and third-party filaments. All that makes the 3D printer a real game-changer for a variety of industries, which can benefit from the machine not only for prototyping purposes but the production of end-use parts.

Update your browser to view this website correctly. Update my browser now

Write a comment