In this review, we will examine professional wax 3D printers and cover equipment from two industrial giants: 3D Systems and FlashForge. With a deeper dive into the differences, similarities, pros and cons of both brands, let’s explore what wax 3D printing has to offer to contemporary industries.

Additive manufacturing technologies allow 3D printing with an array of completely different materials, including wax. In 3D printing, what is commonly referred to as “wax” is not in fact a natural material, rather a wax-like filament, which has the same characteristics as its natural counterpart.

Wax models are used in various industries, for example, for metal casting in jewelry and medicine. And thanks to 3D printing, making stencils for the subsequent production of jewelry or medical parts has become incredibly simple, fast and accurate.

Different types of materials are used to create wax objects, depending on the utilized technology. You can print wax-like materials even on desktop FDM or SLA printers. But the highest quality is obtained using MJP or the MultiJet Printing technology. Similar to a conventional inkjet printer, this technology allows you to create three-dimensional objects from wax.

Learn more about MJP 3D printers in this article.

3D Systems is a pioneer in the additive manufacturing industry based in the USA. In-house R&D in the field of 3D equipment and materials allowed 3D Systems to secure a leading position in the global market.

The company has been crafting wax 3D printing solutions for over 20 years. 3D Systems wax modeling equipment meets all the requirements of modern production and easily adapts to the user’s needs.

Each of the 3D printers in the ProJet series is designed to meet specific industry needs: jewelry, medical or casting. All ProJet printers are capable of large-scale and small-scale production with high precision and detail.

Credit: 3dsystems.com

This powerful and high-performance 3D printer is capable of producing durable and high-quality models from 100% wax. Designed specifically for jewelry making, it can create highly detailed wax models for casting precious metals and alloys.

The ProJet MJP 2500W prints 10 times faster than 3D printers of the same class, has a print volume 3.7 times larger than counterparts by other manufacturers, and is efficient in creating models with sharp edges and many intricate details.

The 3D printer is designed for different production scenarios, both for manufacturing large batches in an enhanced mode of operation, and for creating smaller batches several times a day.

The ProJet MJP 2500W 3D printer is compatible with proprietary original VisiJet materials. The melting qualities of these filaments are similar to natural waxes, they have zero ash content and come in contrast colors. These materials allow to preserve the smallest details and provide for high-quality casting eliminating defects in downstream processing.

The manufacturer offers a soluble material for support structures that can be completely removed after printing, without deforming or damaging the printed part.

These print examples clearly show the capabilities of the ProJet MJP 2500W in producing complex shapes.

Credit: 3dsystems.com

Print technology: MJP

Print material: Wax

Build volume: 295 x 211 x 142 mm

Print modes: XHD (Extreme High Definition)

Layer thickness: 16 microns

Resolution: XY — 1200 dpi; Z — 1600 dpi

Compatible materials: VisiJet M2 CAST, VisiJet M2 SUW

Credit: 3dsystems.com

The ProJet MJP 2500IC is another machine by 3D Systems that boasts flawless wax printing results. It is designed for fast and high-quality production of wax models for casting. A build volume of 9,000 cubic centimeters allows you to print out batches of smaller parts or create large objects with a maximum length of 29.4 cm on one of the sides.

The ProJet MJP 2500IC enables you to enjoy all the benefits of 3D printing for metal fabrication: weight reduction through the creation of hollow areas or lattice internal structures, printing several parts in one cycle and their efficient positioning on the printing platform.

3D Systems offers a proprietary lineup of printing materials dubbed VisiJet, which shares the same properties with natural wax. The M2 ICast filament provides for unparalleled precision and is ideal for creating parts with small fine details.

3D Systems’ equipment can be tuned to meet specific production needs. For example, these complex parts with blades and smooth objects were produced using the ProJet MJP 2500IC 3D printer for subsequent metal casting.

Credit: 3dsystems.com

Print technology: MJP

Print material: Wax

Build volume: 295 x 211 x 142 mm

Layer thickness: 0.042 mm

Resolution: X. Y, Z — 600 dpi

Compatible materials: VisiJet M2 ICast, VisiJet M2 IC SUW

FlashForge is a Chinese-based company founded in 2011 that has already managed to become one of the industry leaders. The manufacturer has proprietary R&D and production know-how in the field of 3D printing, as well as a lineup of original materials for wax models.

Credit: flashforge.com

The WaxJet 3D printer series uses multi-jet technology — the professional machinery in this lineup is designed to create precise and smooth wax models applied in conventional casting methods.

WaxJet 3D printers became powerful tools for industries ranging from jewelry and watchmaking to precision casting and aerospace.

Credit: flashforge.com

The WaxJet 410 is a versatile wax 3D printer capable of both jewelry making and creating high-precision and detailed parts for casting with different metals. A fairly impressive print area allows the user to start mass production or manufacture large wax models.

FlashForge WaxJet 410 works with proprietary materials based on pure FFWJ1100 wax. This contrasting purple material allows for enhanced visualization of all the part’s elements and high resolution printing, stirring up demand in both the jewelry and metal casting industries.

The white, wax-like FFMS3100 support material has a lower melting point than the base material. It can be partially removed manually and automatically, allowing to preserve fragile elements and save time and money on dissolving supports.

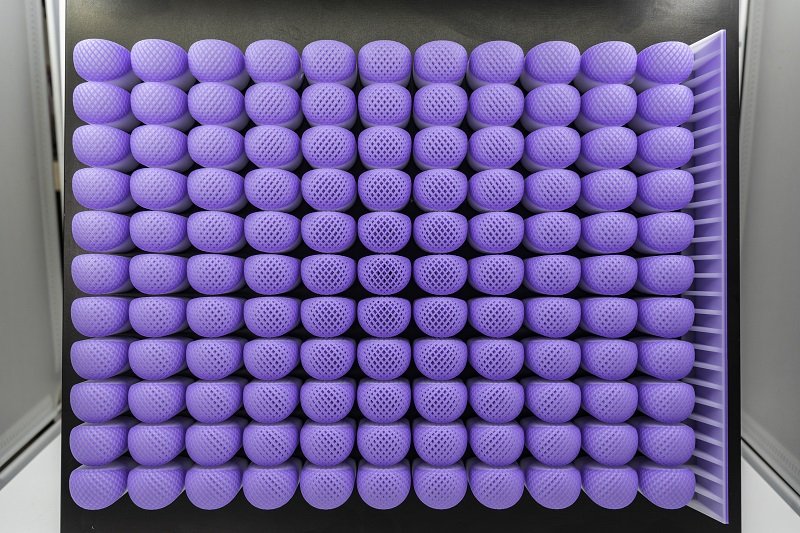

These high-quality blanks for ring casting were made on the WaxJet 410.

Credit: flashforge.com

The universal machine can also print complex objects for metal casting. For example, such parts with blades as in the photo below.

Credit: flashforge.com

Print technology: MJP

Print material: Wax

Build volume: 289 x 218 x 150 mm

Layer thickness: 16 microns

Compatible materials: FFWJ1100, FFMS3100

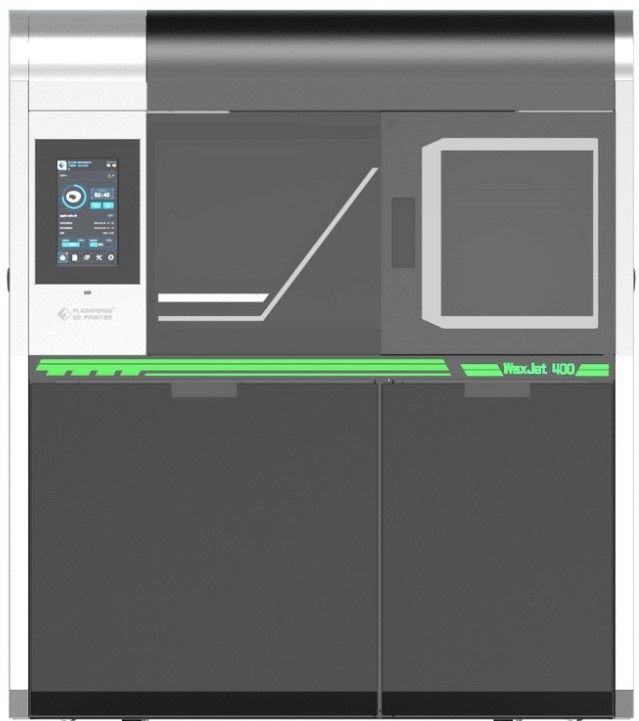

Credit: flashforge.com

This 3D printer was designed specifically for the jewelry industry. Utilizing MJP technology, it can produce intricate wax models with smooth surfaces.

The FlashForge WaxJet 400 offers high performance, efficiency, and cost-savings. Unlike the WaxJet 410 model, the WaxJet 400 has 3 printheads for outstandingly high performance. If necessary, the 3D printer can be used 24/7, securing maximum output.

The WaxJet 400 allows for fast production capacity ramp-up in any industry. This accurate, fast and reliable 3D printer with automatic material loading is an excellent tool for creating high-quality models for casting.

The WaxJet series works with original FFWJ1100 and FFMS3100 materials, which are designed for printing wax parts and supports. Two compartments for the corresponding materials reduce man-hours required to operate the printer.

The high-precision WaxJet 400 is extremely productive. This wax model was completed in less than 8 hours.

Credit: flashforge.com

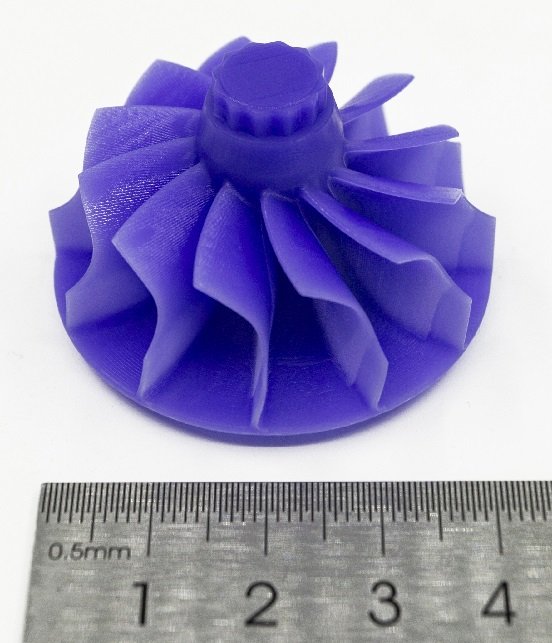

And this wheel with a diameter of 4 cm and curved blades was printed in 4 hours and 54 minutes.

Credit: flashforge.com

Both manufacturers offer advanced wax 3D printing solutions. The reviewed printers are excellent equipment capable of sustainable mass production of wax parts.

The ProJet and WaxJet series share many of the same features that affect print quality and speed. In general, these series of equipment from 3D Systems and FlashForge are very similar.

The devices are equal in terms of build volume. A few millimeter difference does not play a big role and can house approximately the same number of parts on the printing platform.

The same number of nozzles on the printhead and layer height range also make both series look quite similar.

ProJet and WaxJet are compatible exclusively with proprietary materials developed by the manufacturers. Dedicated wax materials help create smooth finishes, while fully soluble supports ensure fine details.

Despite the great similarity in terms of features and parameters, the ProJet and WaxJet series have some noticeable differences as well.

Powered by MJP technology, ProJet and WaxJet are the most suitable pieces of hardware for the casting process. The 3D printers can be easily tailored to specific production needs and have excellent performance for projects of different scales.

3D Systems ProJet series printers are great for a specific industry: medicine, jewelry, or injection molding. The relatively low maintenance and spare parts costs are a nice addition protecting your overall budget.

Versatile and affordable, the WaxJet 410 is a great solution for additive manufacturing in any industry requiring high accuracy and performance, covering the vast majority of professional needs.

If your workflow requires a powerful and productive 3D printer, then the WaxJet 400 would be the most comprehensive solution for making wax models. Thanks to its versatility, the WaxJet 400 can effectively handle projects for a variety of industrial applications.

Update your browser to view this website correctly. Update my browser now

Write a comment