TPM3D is currently one of the leading manufacturers of industrial-grade SLS 3D printers capable of producing high-quality products for various applications. The company also offers auxiliary devices and polymer powders for selective laser sintering 3D printing.

This is Top 3D Shop, and from this article you will learn more about TPM3D’s range of equipment and materials. (To find out more about the company and its projects, read the brand review.)

The TPM3D S260 is the second smallest AM system from the company’s flagship S series. It comes with a build chamber of 260 x 260 x 450 mm and a single 30W CO2 laser. Despite its decreased dimensions and laser power compared to other TPM3D units, the machine boasts a high scanning speed of 8000 mm/s and a three-axis galvo system with dynamic focusing. Due to its decent capabilities and fairly compact building size, the S260 is ideal for educational purposes as well as professional use in manifold industrial areas.

The S360 model is a comprehensive SLS machine that meets all relevant industrial requirements with appropriate certifications. With a build chamber of 360 x 360 x 600 mm, potent 60W CO2 laser, and scanning speed of 15000 mm/s, it is perfect for application in various demanding spheres, from aviation and automotive to scientific research and education. Furthermore, it is capable of maintaining the build chamber temperature of up to 160 ℃ in combination with the 230 ℃ powder bed, like the majority of TPM3D devices.

The S480 is the golden mean of the S series. It is engineered with a fairly capacious build chamber of 480 x 480 x 600 mm, which lets you print large items as a whole or smaller objects in batches. This makes for significant improvements in terms of production speed and material usage. In addition, the device features a powerful 100W CO2 laser and increased scanning speed of 21000 mm/s. The machine can efficiently produce top-quality small and large R&D prototypes, models, functional parts, household appliances, and more for such industries as automotive, aviation, medical treatment, electronics, scientific research, education, art, etc.

The S600DL (Double Lasers) represents a separate segment of TPM3D’s equipment. It is a powerful AM solution designed with two 140W CO2 lasers enabling an impressive scanning speed of 25000 mm/s. Moreover, the machine comes with a huge build chamber of 600 x 600 x 800 mm, which lets you print really large industrial parts and increase production volume for smaller items. Due to the open system inherent to all the company’s devices, the S600DL model can work with a remarkable selection of powders with different properties, including PA11, PA12, PA12 GF, and TPU, that suit various purposes.

The S800QL (Quad Lasers) is a new step for the company’s SLS 3D printers. In contrast to its series counterparts, the model provides even more powerful sintering with four 500W CO2 lasers supporting 25000 mm/s scanning speed and 10–25 mm/h build speed. Despite its outstanding sintering capabilities and expanded build volume of 800 x 800 x 600 mm, the device offers traditionally smooth and user-friendly controls due to the company’s flexible multi-purpose software. Similar to other TPM3D solutions, the machine is recommended to both proficient and aspiring users for making top-quality large items of reliable structure.

The S320HT model is a high-temperature version of the industrial SLS AM system from TPM3D. The printer is equipped with a sufficient build chamber (320 x 320 x 380 mm) capable of maintaining the heat of up to 300 ℃ with the 350 ℃ powder bed. Due to its enhanced thermal capabilities, the machine is able to work with a wider range of demanding engineering powders and efficiently produce high-quality functional parts with great mechanical properties. It is equipped with a potent 60W CO2 laser and enables scanning speed of 13000 mm/s.

The S150HT is a lite version of the previously described machine. They share the majority of technical characteristics, except for the build chamber dimensions, which for the smaller model are 150 x 150 x 250 mm. As with its counterparts from the series, the machine is supplied with a built-in filtering system, oxygen detector, cooling module, dual blade recoater for efficient feeding, dynamic focusing for the scanning mechanism, integrated Nitrogen generator, PL-e dual channel security control, and more smart features that distinguish these devices from SLS 3D printers of other brands.

The Parts & Powder Processing Station is an innovative solution for clean production that allows to completely eliminate the impact of powder leakage on the environment and makes the part cleaning and powder treatment as easy, fast, and effective as possible. The device is able to mix, feed, collect, and recycle powder with increased efficiency and certified safety.

The Lifting Trolley is used to move the powder hopper and the build chamber; for example, when transferring the printed part to the post-processing unit.

The Open Breakout Unit is applied to clean batches of small items and collect the powder for future use. For some TPM3D printer models, it serves as an analogue of the PPS.

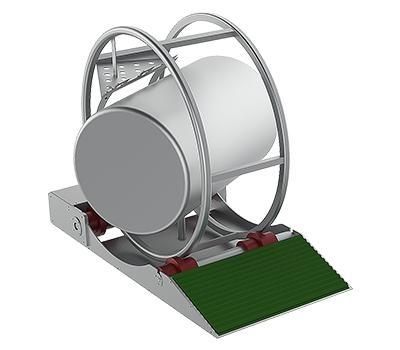

The Powder Mixer is developed for mixing powders into a homogeneous mass, for example, used and fresh powder or consumables of different brands. The enclosed design prevents powder from getting into the environment, while the tightly closed replaceable reel allows you to store the powder in the device. In addition, the Mixer boasts a large volume.

The device represents a container for collecting dust generated during part extraction and sandblasting. It helps purify the room air of powder, material particles, and other contaminants.

Type: Polyamide

Certified by USP (US Pharmacopeia): National Standard GB/16886 J In vitro hemolysis test; National Standard GB/T4806.7 for food safety contact materials and products

Key properties: Biocompatibility and food compatibility, dimensional accuracy, high strength, high reusability rate

Application: Medical, food industry

Type: Metal-filled polyamide

Color: Metallic gray (after polishing)

Key properties: High strength, wear resistance, reusability

Additives: 40% aluminum

Application: Automotive

Type: Glass-filled polyamide

Color: Ash-gray

Key properties: High strength, thermal deformation resistance, reusability

Additives: 40% glass

Application: Automotive, aerospace

Type: Polyamide

Color: Milky-white

Key properties: Good performance, stable color, dimensional accuracy, reusability

Application: Automotive, spare parts, functional shells and instrument housings, art and creativity, drone frames and bodies

Type: Polyamide

Color: Ash-black

Key properties: Stable color, dimensional accuracy, reusability

Application: Automotive, medical, education, aerospace

Type: Glass-filled polyamide

Color: Gray-yellow

Key properties: High strength, thermal deformation resistance, reusability

Additives: 30% glass

Application: Automotive, aerospace, impellers, propellers, tools

PA12 Precimid1172Pro GF30 BLK shares physical and mechanical properties with PA12 Precimid1172Pro GF30 and is different only in color.

Type: Polyamide

Color: White

Key properties: High impact resistance, reusability, thermal deformation resistance

Application: Household appliances and machine parts with heat resistance and high mechanical properties

Type: Polyamide

Color: Black

Key properties: High strength, reusability, thermal deformation resistance

Application: Durable parts ready for work at elevated temperatures

Type: Thermoplastic polyurethane

Color: White

Key properties: Flexibility, elasticity, impact resistance, efficient vibration damping, reusability, heat resistance, mildew and water resistance

Application: Automotive, light industry, medical, education

Type: Thermoplastic polyurethane

Color: White

Key properties: Flexibility, elasticity, impact resistance, efficient vibration damping, reusability, heat resistance, mildew and water resistance

Application: Sealing washers, vibration damping parts and buffer insulation, soft treads, sports insoles, and other uses requiring high plasticity of the material

Type: Thermoplastic polyurethane

Color: Natural, milky-white

The properties are basically similar to Precimid1130 90A and Precimid1130 92A. The key feature of Precimid1130 95A is its cooling resistance: it becomes brittle only at -25 ℃.

Product: McPherson spring suspension

Material: Precimid1180 BLK

Product: Battery holder for electric race car

Material: Precimid1171FR BLK

Product: Engine jacket water for electric race car

Material: Precimid1172Pro GF30 BLK

Product: Automotive turbine deflector

Material: TPM3D PA6X BLK

Product: Engine intake manifold

Material: TPM3D PA6X BLK

Product: Cupholder expansion module

Material: Precimid1172Pro

Product: Inner block housing for air conditioner

Material: Precimid1172Pro GF30 BLK

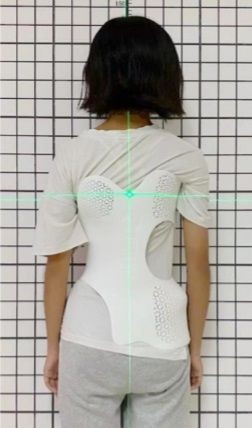

Product: Scoliosis orthosis

Material: Precimid1172Pro

The material features great mechanical properties and extensive durability. It is wear resistant, fatigue-resistant, and durable while exerting sufficient orthopedic force on a patient who can wear it for a long time.

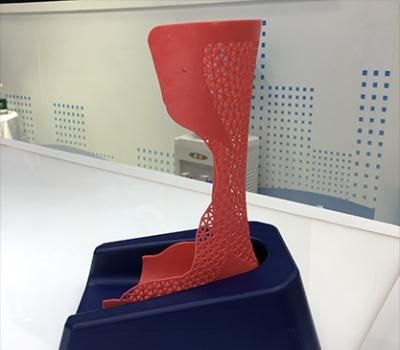

Product: External foot brace, orthosis for ankle injuries

Material: Precimid1172Pro

Product: Wrist orthosis for rehabilitation after sprains

Materials: Precimid1172Pro, Precimid1180 BLK

Product: Orthopedic pillow; relieves stress on the cervical spine

Material: Precimid1130 90A

Product: Foot model; used in the manufacture of orthopedic insoles

Material: Precimid1172Pro

Product: Surgical model of brain hemorrhage; used in surgical planning

Material: Precimid1172Pro

Product: Cervical screw guides

Materials: Precimid1172Pro, Precimid1171Pro

High biocompatibility and durability of the material makes for reliable fixation of the vertebrae for proper healing. Precimid1171Pro is certified for medical use.

Product: Hair dryer

Material: Precimid1171Pro AF40

The material is 40% aluminum powder, which provides the product with high strength, wear and thermal resistance as well as heat conductivity.

Product: Vacuum cleaner

Material: Precimid1171Pro AF40

Product: Power tool housing

Materials: Precimid1172Pro GF30 BLK

Due to its heat resistance, high strength, and capacity for chemical polishing, Precimid1172Pro GF30 is easy to work with and well suited for power tool housings.

Product: Decorative lamp

Material: Precimid1172Pro

SLS 3D printing allows one to build almost any shape, limited only by the author’s imagination.

Product: Sculpture

Material: Precimid1172Pro

Decorative items printed through SLS technology demonstrate its ability to create the most complex forms with an extraordinary degree of freedom.

Product: Integrated glasses frame

Material: Precimid1172Pro

SLS technology is perfect for making customized glasses, since the frames printed by polyamides feature great toughness, light weight, better temperature and aging resistance.

TPM3D equipment can be successfully applied in a wide range of spheres, such as industrial prototyping, consumer electronics, automotive, aviation, medicine, education, household goods, etc. The company’s products boast high quality and affordability; they are widely used for equipping development centers and effective modernization of production facilities.

The company not only produces AM systems and materials, but also conducts developments in the field of 3D printing and provides services to a large number of organizations around the world. Read more in our article about the company.

Update your browser to view this website correctly. Update my browser now

Write a comment