Initially, the technicians were focused on milling to produce dental appliances. Currently, the Izmir-based laboratory has a fleet of Roland five-axis milling units and machine tools manufactured by the Turkish company Redon Teknoloji.

Modern dental production relies heavily on advanced additive manufacturing, especially selective laser melting of metals.

Izmir, Turkey, is a global hub for dental outsourcing, serving Europe and the Middle East with dental and orthodontic appliance production.

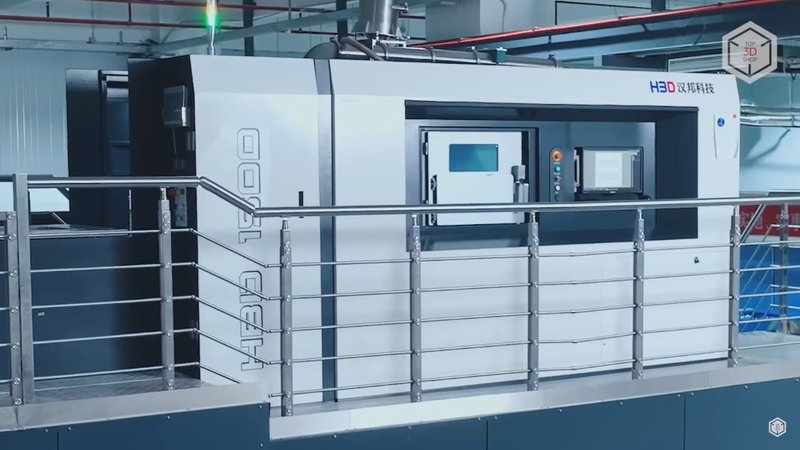

In the past two years, Izmir dental labs have bought over 80 HBD3D LPBF 3D printers. Top3DShop spoke with lab managers about the growing interest in this technology.

In 2023, Dentarium celebrates 40 years since its founding by dentist Şenol Gürbüz, who started the renowned Izmir lab in 1983.

Since 1989, Dentarium has produced dental and orthodontic products for clinics in Germany and France. It moved to central Izmir in 2000 and now ranks among the city’s largest labs, employing 70 specialists and operating in a 600 m² facility with advanced equipment.

Dentarium has a large fleet of modern equipment, which is constantly expanding. On the backdrop of increasing orders, the laboratory management started gradually abandoning traditional methods such as casting and switched to digital methods for manufacturing dental structures.

Initially, the technicians were focused on milling to produce dental appliances. Currently, the Izmir-based laboratory has a fleet of Roland five-axis milling units and machine tools manufactured by the Turkish company Redon Teknoloji.

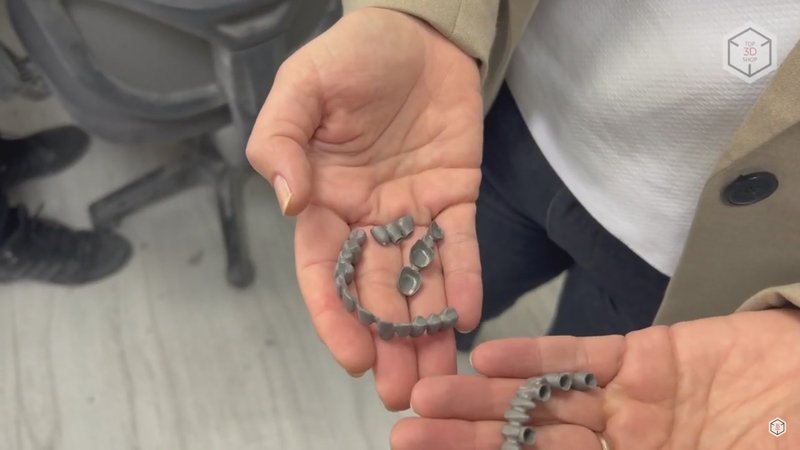

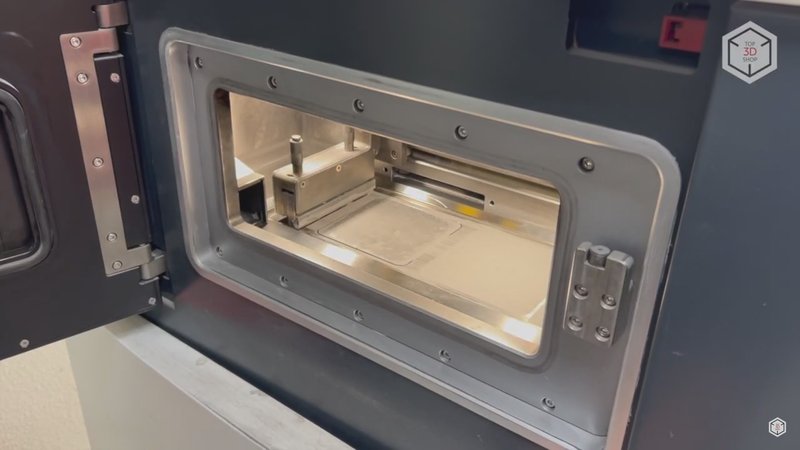

In 2020, Dentarium made the decision to purchase an HBD-100D SLM 3D printing unit manufactured by the China-based company H3D HBD metal 3D printer. This machine utilizes selective laser melting technology and is engaged primarily in printing clasps, bridges, and crowns.

HBD entered the metal 3D printing industry in 2007 and launched its first 3D printer, the HBD-150, in 2013. Since then, HBD has expanded its lineup of equipment and released over a dozen of industrial SLM printers with different build volumes: from the HBD-80 with a 120 x 80 mm cylindrical shaped chamber to the HBD-1500 with a working area of 460 x 460 x 1500 mm.

The HBD-100D 3D printer, equipped with a 100W laser, is widely used in dentistry to produce dentures, crowns, and jaw implants.

The 3D printer uses fine metal powders, including titanium, aluminum, cobalt-chrome, nickel alloys, and stainless and tool steels.

Dentarium chose HBD 3D printers for their reliability, print speed, responsive support, and strong price-performance ratio.

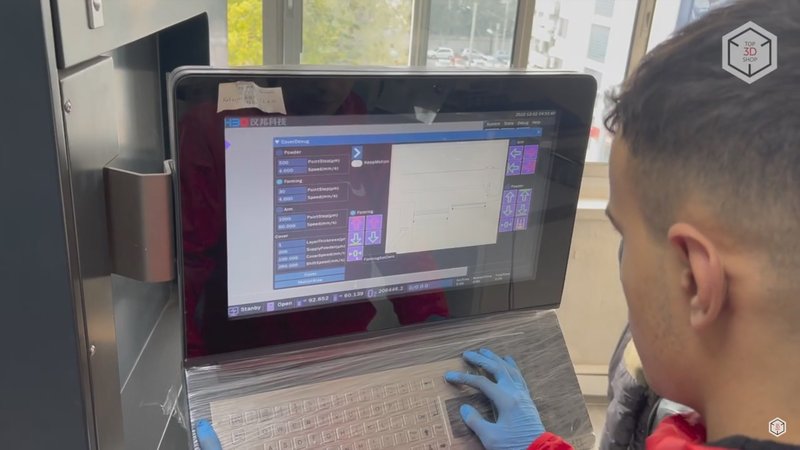

HBD machines require only one technician for maintenance and are easy to operate despite their advanced technology.

The Dentarium laboratory plans to purchase a second HBD SLM unit for making dental crowns.

With advanced printing, automation, and ease of use, HBD SLM systems are ideal for digital dentistry. They eliminate waxing, embedding, and casting, and lower costs, enabling more economical production. Their versatility also suits medical, automotive, R&D, jewelry, prototyping, and customization applications.

Update your browser to view this website correctly. Update my browser now

Write a comment