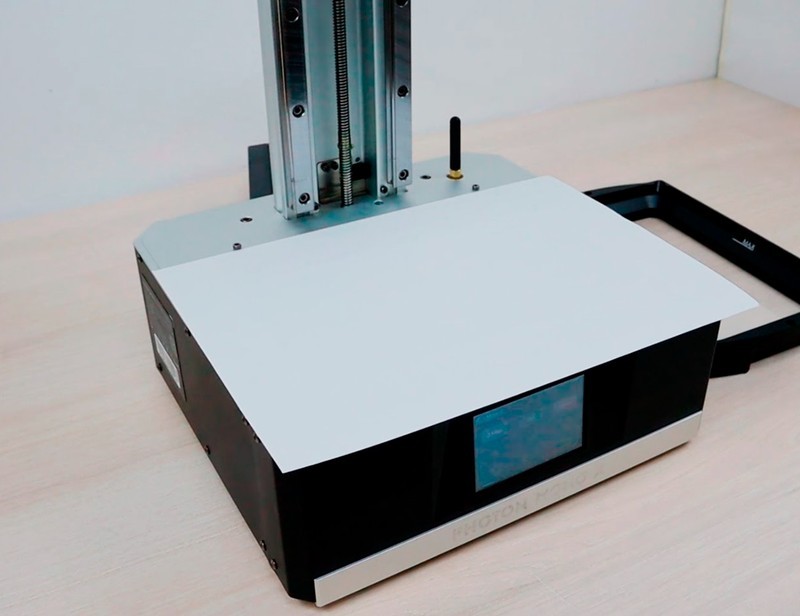

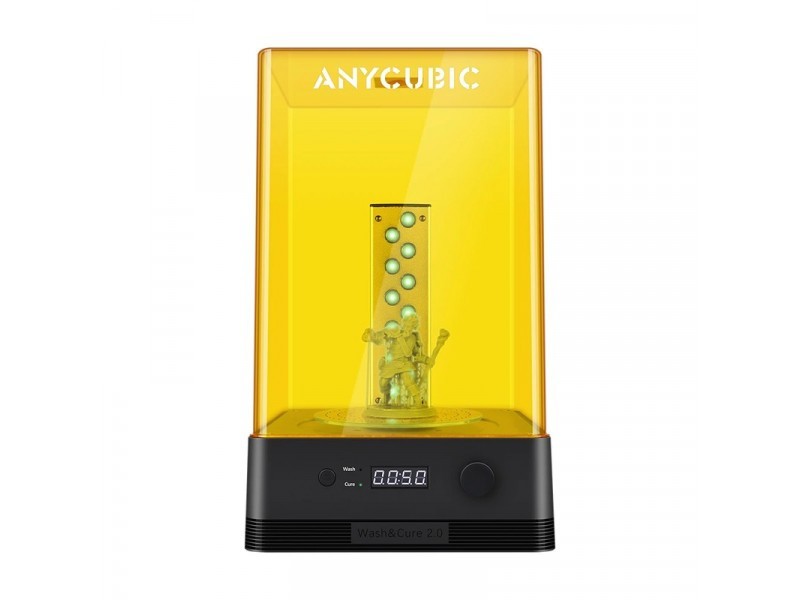

Hi everyone! This is Top 3D Shop, and in this joint review, we will tell you about the Photon Mono X 3D printer and the Wash & Cure 2.0 machine. The former device demonstrates the implementation of the company’s fresh approach to the design and capabilities of resin 3D printers: a new frame, 4K resolution matrix, Wi-Fi connectivity, and more. The upgraded Wash & Cure, too, boasts some pleasant modifications (though not so considerable) that make the machine even more convenient and effective. Read on to find out the features of these devices.

The printer comes fully assembled. Apart from the device itself, the package includes the following items:

For working with resins, the set includes a face mask, a couple of gloves, and five resin filters.

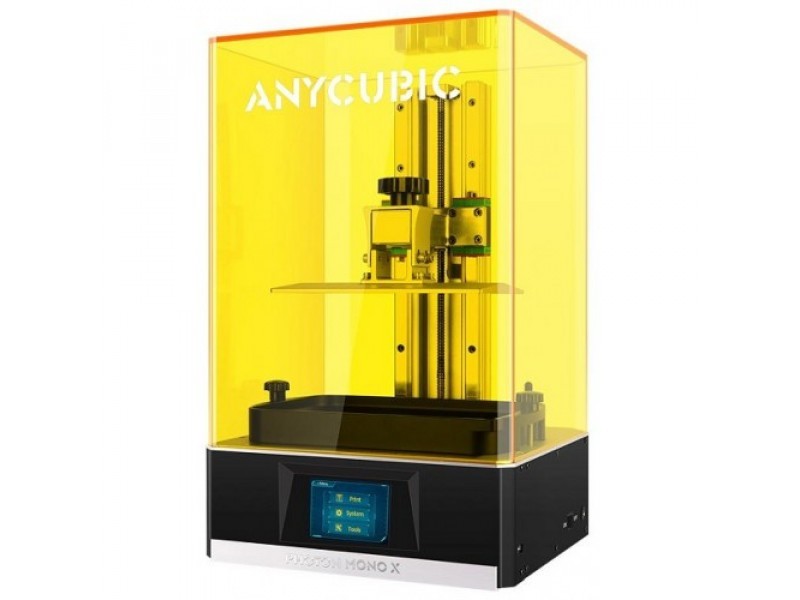

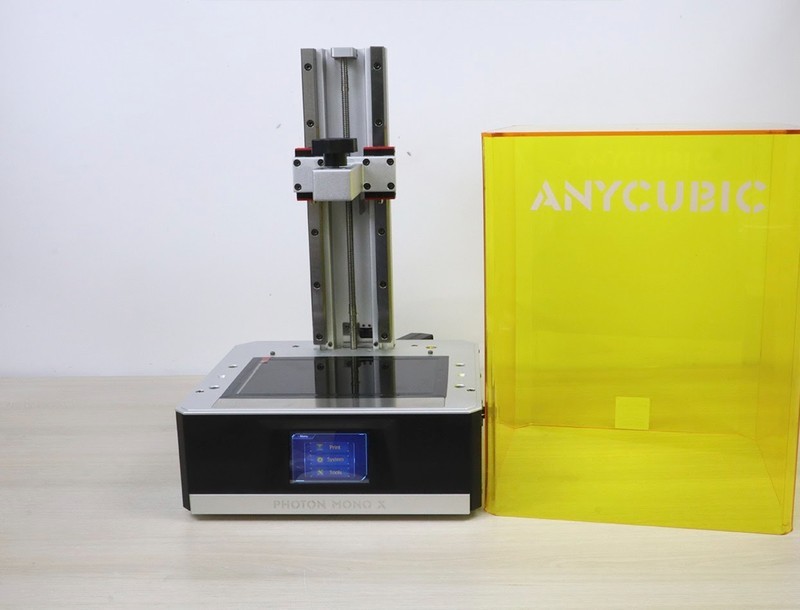

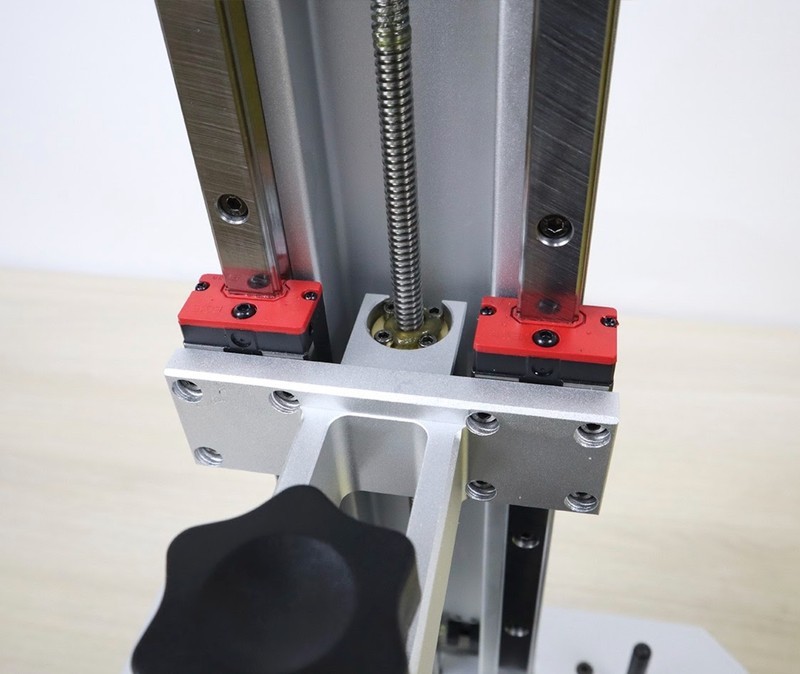

This printer may seem to be inspired by another model of the no less famous company Phrozen: Shuffle XL Lite. However, this is a big step forward for Anycubic. The plastic base was replaced by an all-metal one. On the right, there is a USB port, power input, and switch. On the top side is a Wi-Fi antenna input. The column of the printer is made of thick aluminum, which testifies to its reliability. The print bed driven by a T8 lead screw moves along two massive linear guides.

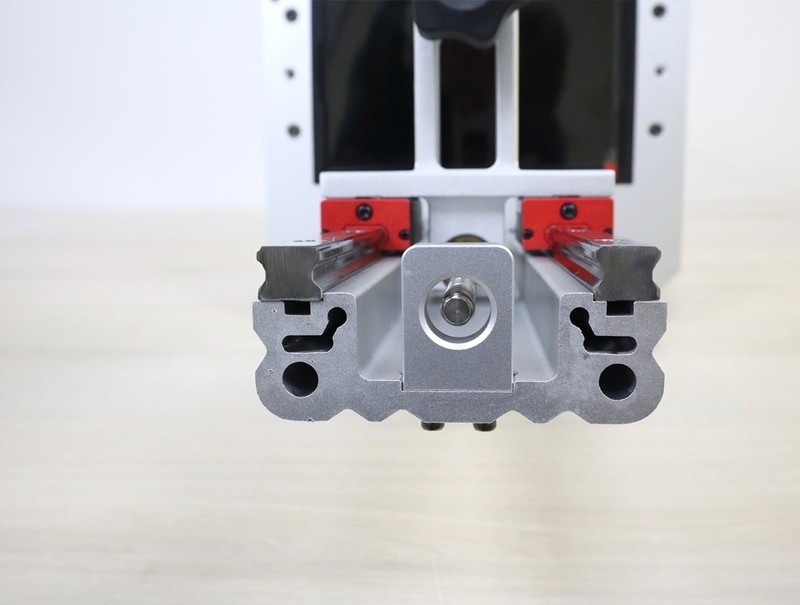

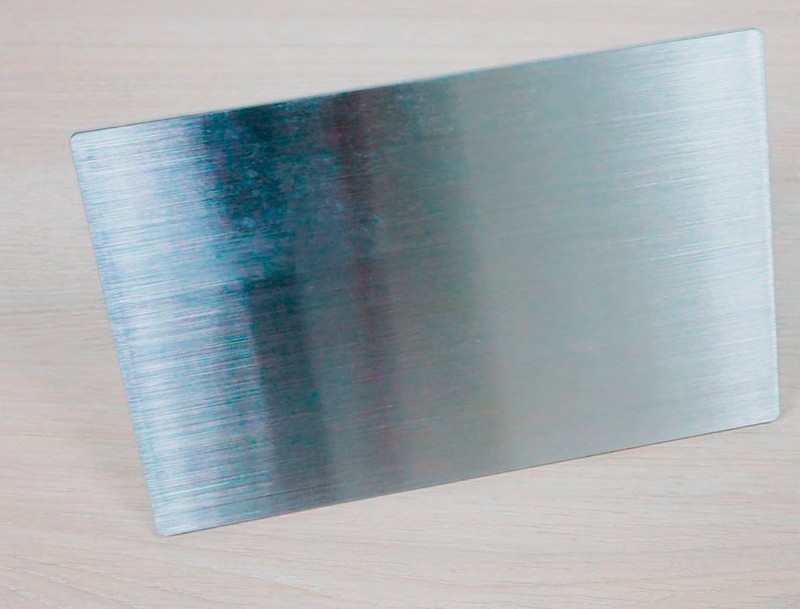

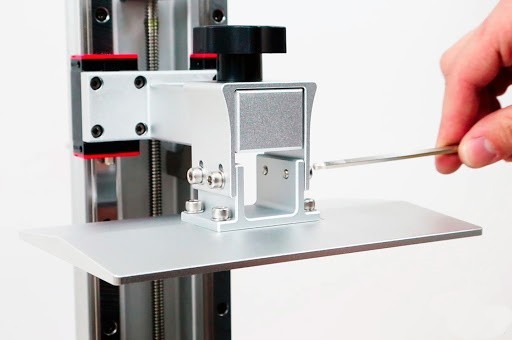

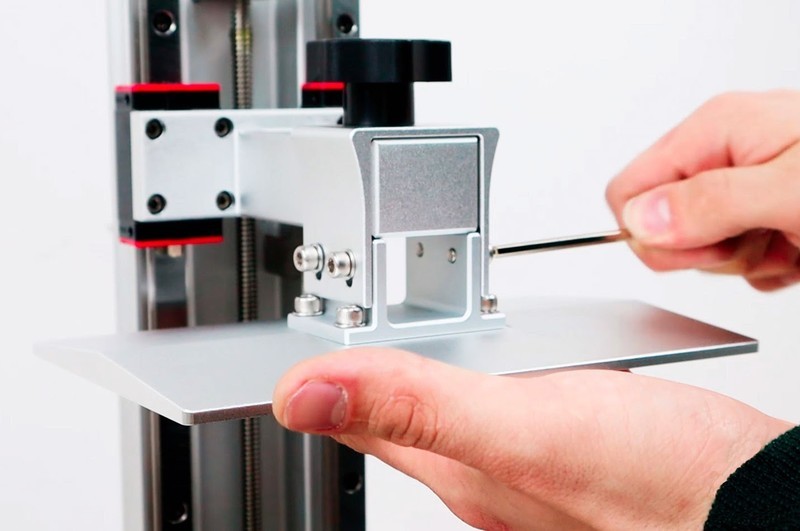

The bed itself has changed as well. As before, it is made of anodized steel, but the anode below is removed, and the surface is milled. This should contribute to good adhesion. The calibration system is now four bolts — two on each side. It is likely that the old ball head system could not handle the weight of the enlarged bed. Compared to the Anycubic Photon S, the build volume has increased threefold: now it is 192 x 120 x 245 mm.

The vat has not undergone major changes. Yet, it has become more convenient to use. The expanding shape controls the resin revel, and the special groove in the corner will make it easier to replace the material. Four legs appeared at the bottom of the vat, acting as centering pins before securing the vat with screws on the printer.

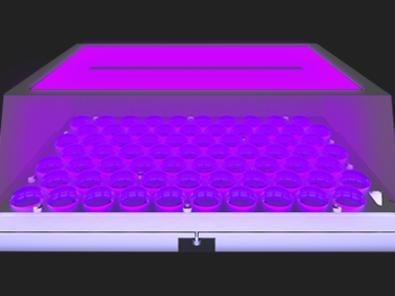

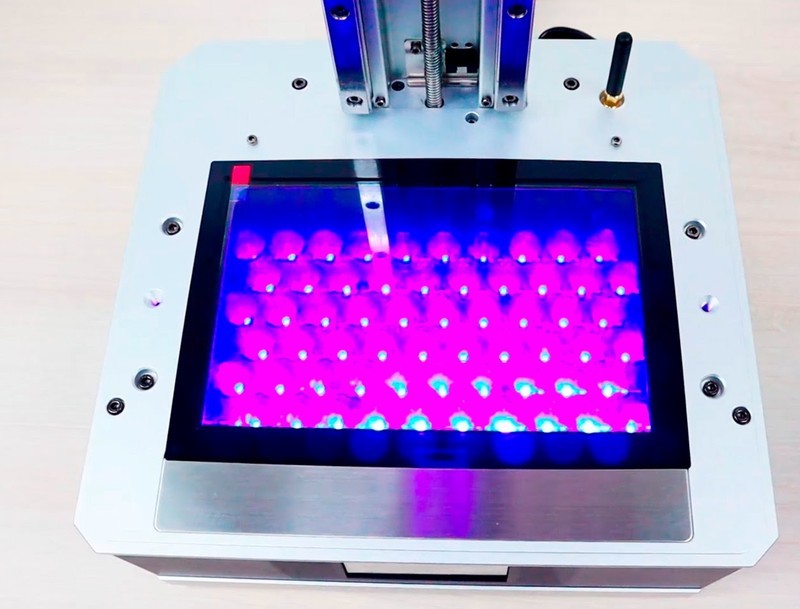

The most significant modernization in the Anycubic Photon Mono X seems to be electronics — in particular, the LCD display. It features an 8.9" monochrome matrix with a 4K resolution (3840 x 2400 pixels). Thus, the device boasts an XY accuracy of 50 microns, which is very good for a (comparatively) budget-friendly printer of this size. In addition, monochrome displays have a much higher light transmittance, contributing to fast printing.

The new projector also plays an important role. It is located right under the display in its entire size. This approach is more correct than one high-power LED in the center and a reflector: the illumination is more even and does not diminish towards the edges. The light emitted by the projector has a wavelength of 405 nm, which is suitable for most photopolymer resins, opening up a wide range of applications for this printer.

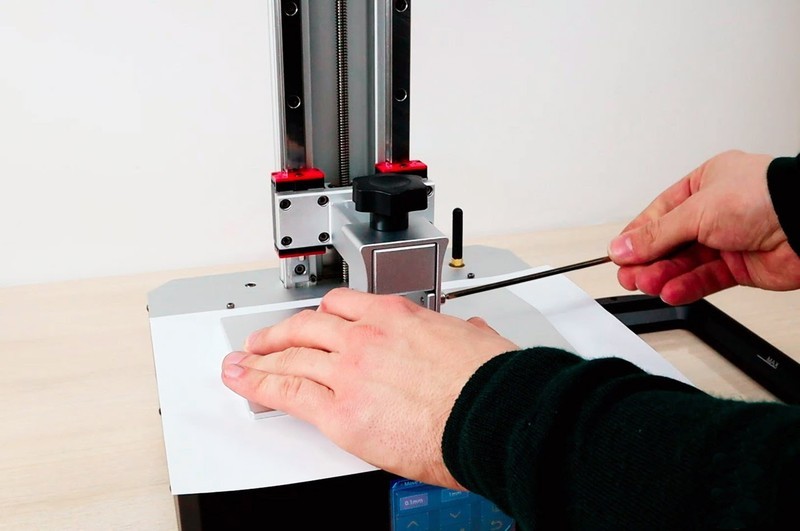

The first thing to do before starting to print is calibration — bed leveling. For those who have used the aforementioned Phrozen Shuffle XL Lite or similar printers, calibration will not cause any problems. First, we need to loosen the four screws holding the bed and raise it to the highest position. Fix the bed with at least one screw. Put a sheet of paper on the printer display, having removed the protective film. In the Tools>Move Z menu, tap the house-shaped icon. The bed will move to the lowest position. Then release the screws that secure the bed so that it presses the paper. Tighten the screws, tap the Z = 0 button, and confirm the operation. At this point, the calibration is complete.

As the name implies, the Anycubic Wash & Cure 2.0 post-processing machine is an upgraded version of the previous model — the Anycubic Wash & Cure. The first changes can be seen in the wash tank. Now you can keep it closed during the operation cycle, preventing odors and splashes. There are nets fixed directly to its inner walls.

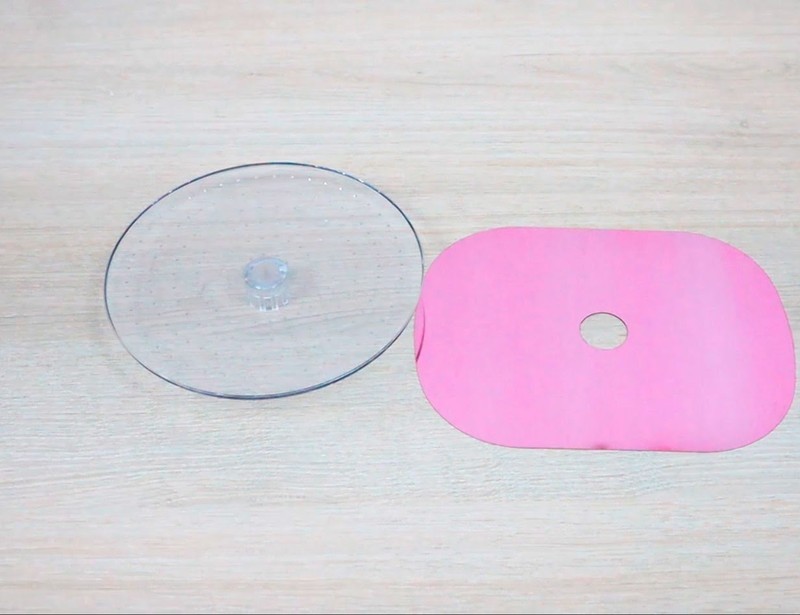

The rotating plate became transparent, there being a reflector added. Changes are also noticeable in the diode area, with a reflector in the front and an emitter in the back. The emitter part does not heat up too much, which indicates the high efficiency of the installed diodes.

The device comes with a 36W power supply, which is less than in the previous model. Hopefully, this does not affect the intensity of the light.

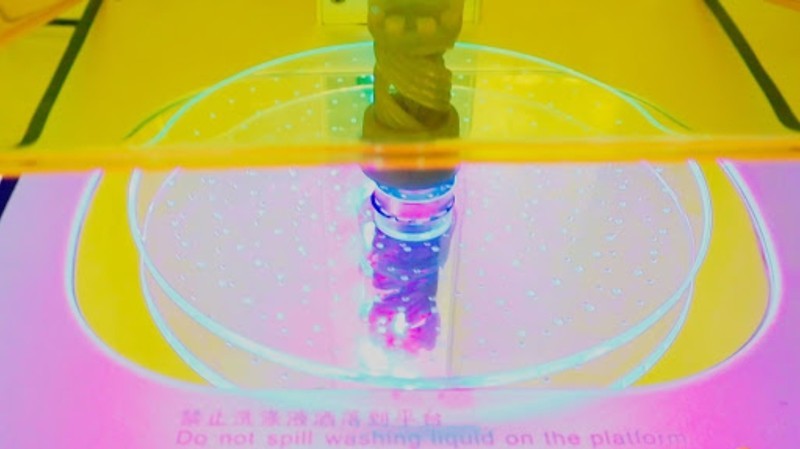

To process a model, install the tank and fill in isopropyl alcohol. Next, install the net basket with the model inside, turn on the Wash mode, choose the time you need, and start the process of washing.

Every minute the motor will change the direction of rotation to flush all the excess material.

When the washing is over, it is necessary to dry the model to avoid the appearance of white streaks when cured.

Set up the plate with the reflector, put the model inside, cover it, and start curing.

Check some models printed on the Anycubic Photon Mono X 3D printer and processed with the Wash & Cure 2.0 machine.

This model was printed with the eSun Standard Grey resin. The letters both on the top and at the bottom look clear, the surface finish is smooth. Even the spiral in the center turned out neat, despite the high printing speed. There are some vertical lines visible on the walls — they are caused by a large fraction of the material. It is not possible to catch them with a fingernail, which means that their thickness does not exceed the claimed 50 microns.

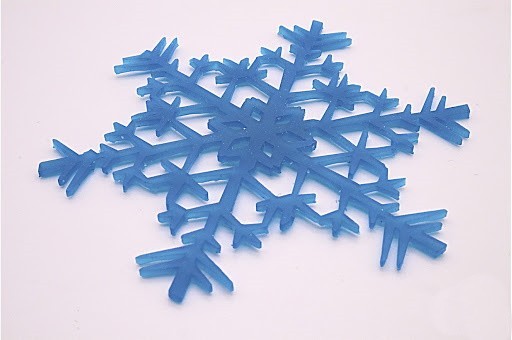

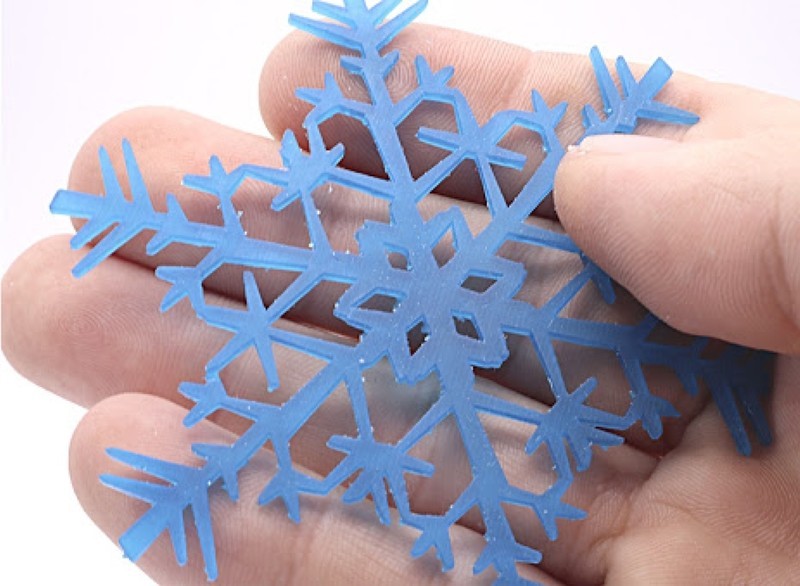

The next object is a snowflake printed with the eSun Hard Tough. This resin is perfect for high detail. The model was printed on supports, at a 20° angle — layers can be seen over its entire surface. They are not felt with a fingernail either, so we will not consider it a defect. The snowflake turned out immensely durable.

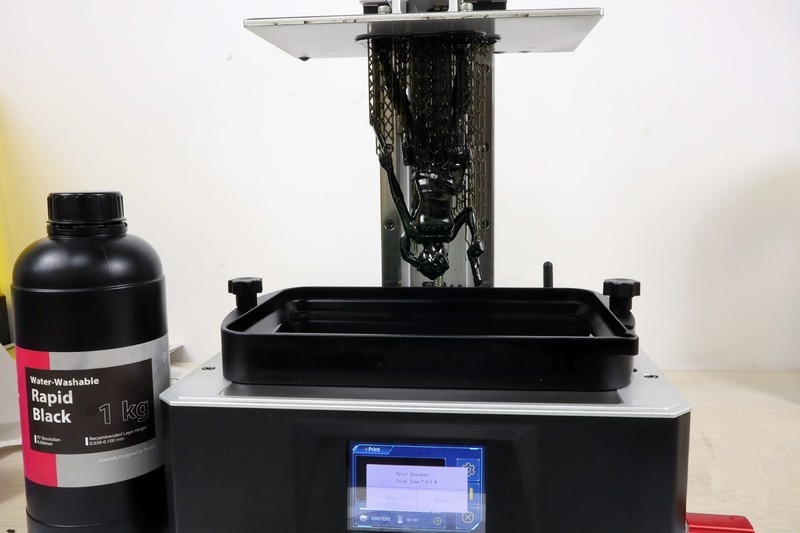

The third model is quite an intricate one. It was made of the Phrozen Rapid Black Water Washable resin. This castle, four and a half centimeters high, took about an hour and a half, with an exposure time of 1.2 seconds. The quality is perfect — especially the through windows (the roof after them had to be printed on very thin legs). The sloping surfaces are fine, too. Lamination did not occur despite the layer of 50 microns.

This figurine of Lara Croft was printed from the same Phrozen material, but it is almost three times as big as the Castle model — 16 centimeters. It took about seven hours to print it. The model looks very nice.

Anycubic has reached a new level in 3D equipment production, releasing a cutting-edge 3D printer coupled with an upgraded version of their already known post-processing device. Apart from the 4K resolution, the printer features a large build volume and high printing speed, not to mention a strong frame and smartly designed structure. This makes the Anycubic Photon Mono X a great alternative to more expensive 3D printers by other manufacturers. The Wash & Cure 2.0 machine in turn contributes to delivering a quality result with less effort and more convenience.

Update your browser to view this website correctly. Update my browser now

Write a comment