Hi everyone! Today, we are going to review the Phrozen Sonic XL 4K 3D printer, which was created specifically for the dental industry. It differs from most models in this segment by its high-resolution matrix (772 PPI) that allows printing highly accurate models with a layer thickness of 35 µm. Compared to its "little brother", the Phrozen Sonic 4K, the XL has a 45% larger build volume. The device also features a decent print speed — up to 90 mm per hour. The Phrozen Sonic XL 4K is compatible with various types of photopolymer resins, including those designed for DLP/SLA printers.

This article will look at the features of the Phrozen Sonic XL 4K, its applications, and some use cases.

Phrozen was founded by a group of Taiwanese engineers in 2016. After a successful campaign on Kickstarter.com, they managed to create a product that is now in demand all over the world.

The Phrozen team is enthusiasts and experimenters, but the manufacturer is not trying to change the market or invent a revolutionary device — they adapt to demand and offer printers that the target audience is ready to purchase. In order to interest consumers, the company creates a unique competitive advantage for each device. It can be both the price and an item in the specifications.

Phrozen was founded by engineers passionate about additive manufacturing using photopolymer resins. The history of the company began with the formation of a community of 3D printing professionals and enthusiasts from Southeast Asia.

Knowing all the details about printers by Phrozen, the community supports its projects on crowdfunding sites, collecting amounts for launching a next model that immensely exceeds the requested ones.

By 2016, the company created its first device, the Phrozen One DLP 3D Printer. As the name implies, the printer is based on the DLP technology.

In April 2017, the manufacturer announced the launch of its first LCD printer — the Phrozen Make. The Taiwanese startup launched a $30,000 Kickstarter crowdfunding campaign to find out the target audience's interest in the proposed printer. In 4 minutes, a total of $375,000 was raised.

Phrozen then began to develop a line of desktop LCD printers. Currently, the devices are presented for various target audiences: the compact budget Sonic Mini and the large productive Transform, the funds for which were also raised through Kickstarter.

The Phrozen Sonic XL 4K is a professional large-format resin 3D printer. This is the third and largest model in the Sonic lineup. But, even with its impressive build volume, it is quite compact and fits on a table in a workshop or office and, thanks to its laconic design, will also perfectly fit into the interior. This printer is meant for professionals in the dental industry but will also be useful in jewelry production, prototyping, and other areas where ultra-precise 3D printing is required. In addition to the impressive size of the build platform (190 x 120 x 200 mm), the printer features a monochrome matrix with a resolution of 3840 x 2160, which allows printing models with high accuracy and speed.

One of the key benefits of Phrozen printers is the support of resins by different manufacturers. The Sonic XL 4K is capable of printing with biocompatible, flexible, and high-strength resins, as well as those designed for DLP or SLA printers. Thus, the user gets a versatile 3D printer while saving on consumables.

The printer runs on an English-language operating system with an intuitive interface. Print-ready models are uploaded via a USB stick, Wi-Fi connection, or Ethernet cable.

The printer is delivered assembled in a foam-lined carton. To start working with the device, the user only needs to level the build plate and attach the resin vat.

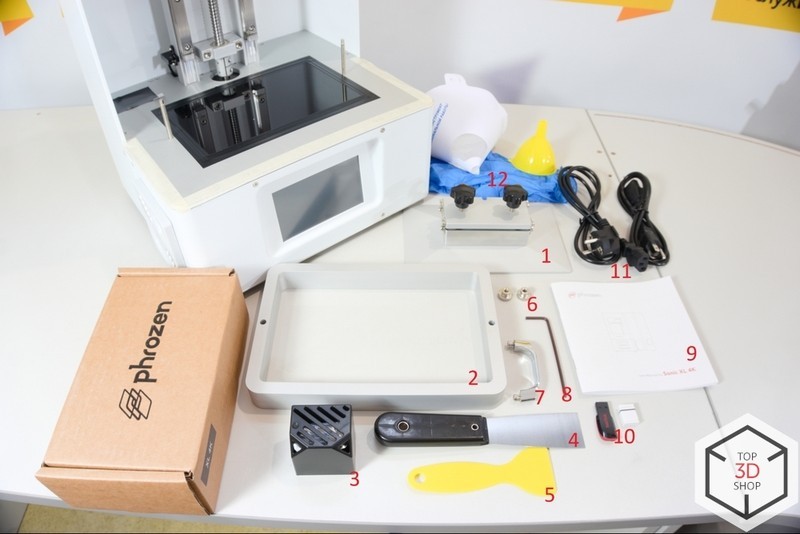

The package includes:

The package contains everything you need to work with the printer.

The most interesting part of the device is the 3840 x 2160 pixel screen. The Phrozen Sonic XL 4K uses a monochrome liquid crystal matrix — an illumination module that features high light transmittance, reducing the exposure time required to cure the resin. There is no RGB filter in the monochrome screen, which allows more light to be transmitted from the LEDs to the polymer. The monochrome matrix is designed to last longer than conventional color ones. Its lifetime exceeds two thousand hours under normal operating conditions. The LCD screen is also reinforced for strength and additional pressure resistance.

To ensure uniform illumination of the monochrome matrix, the optical system has also been improved. This printer has a more powerful ParaLED® 3.0 module. LEDs create an even stream of light, resulting in the same degree of polymerization over the entire area of the plate, which provides a uniform layer thickness and strength.

The platform moves along the Z-axis on two linear guides and a 12 mm ball screw. Compared to conventional ones, ball screws have increased wear resistance due to low friction coefficient. Ball screws are also characterized by high load capacity and transmission accuracy. During operation, they are distinguished by smoothness, noiselessness, and relatively low heating. Ball screws are capable of continuous operation while not requiring much power from the engine.

The printer is equipped with an air filtration system — when the body is closed, there is virtually no odor of resin, which allows working even in an office space.

To work with the Phrozen Sonic XL 4K printer, you can use either the proprietary Phrozen 3D software (the key can be obtained upon request from the service department after purchase) or the popular third-party Chitubox slicer distributed free of charge.

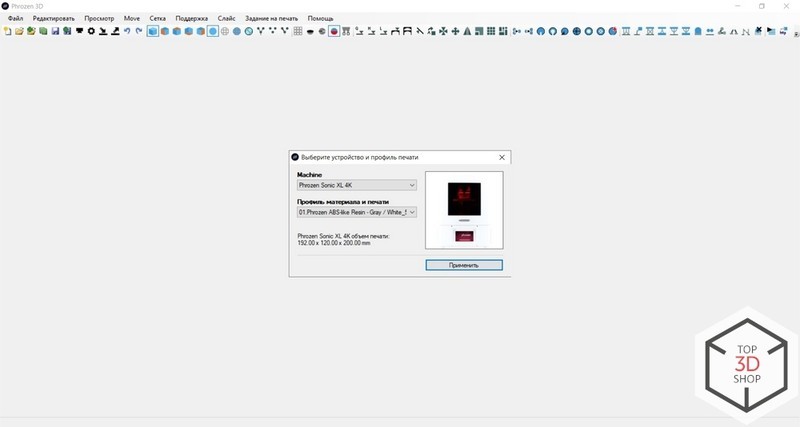

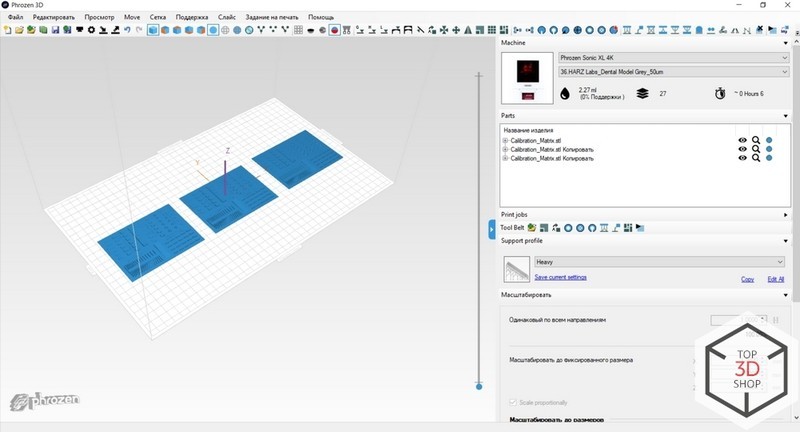

Phrozen 3D is an analog and almost a copy of the well-known Formware 3D software — a very convenient and functional program. After a quick registration, all that remains is to set up the slicer to work with the Sonic XL 4K — just select a model in the corresponding menu. All printer parameters are set automatically.

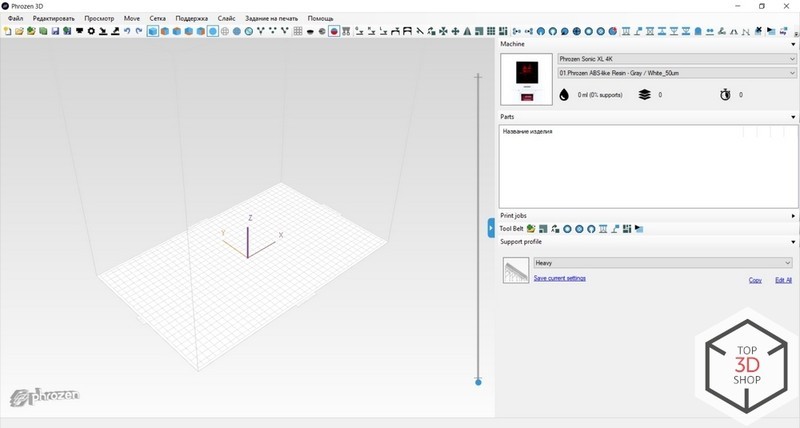

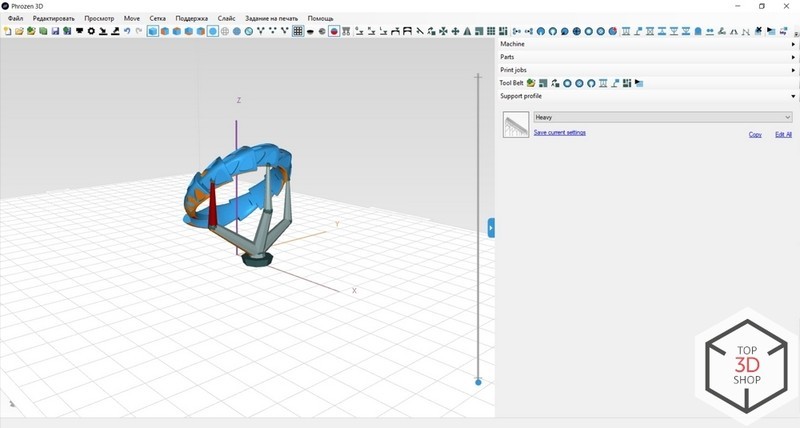

After choosing the printer, you will see the basic interface of the program.

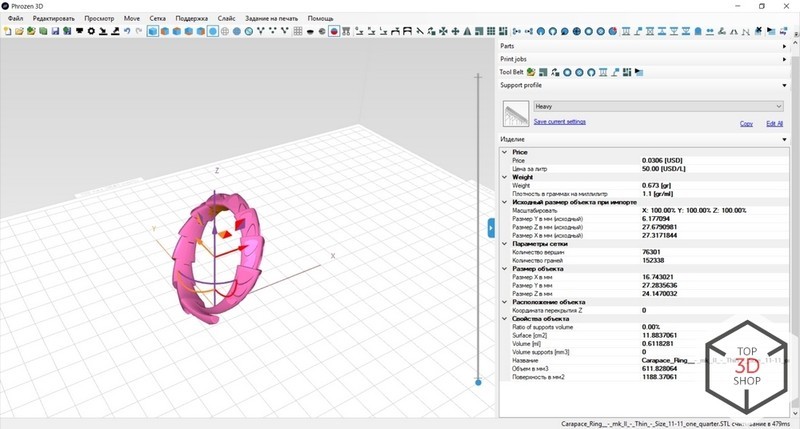

Here are some of the noteworthy functions:

1 . Convenient tools for working with a model, namely: changing the position and size, various types of displaying the model on the platform.

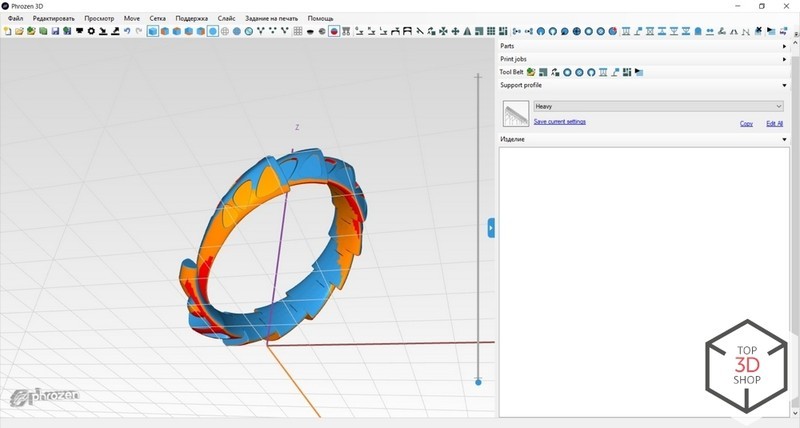

2. The software automatically displays surfaces on the model that require supports for correct printing. It shows them in the form of separate zones, where an area hangs too much over the platform.

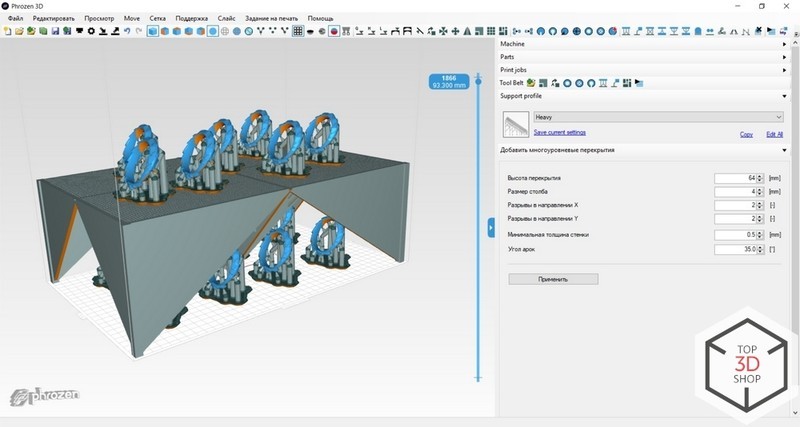

3. The program also provides the ability to create multilevel overlays, which enables you to print several models at the same time, with one support system.

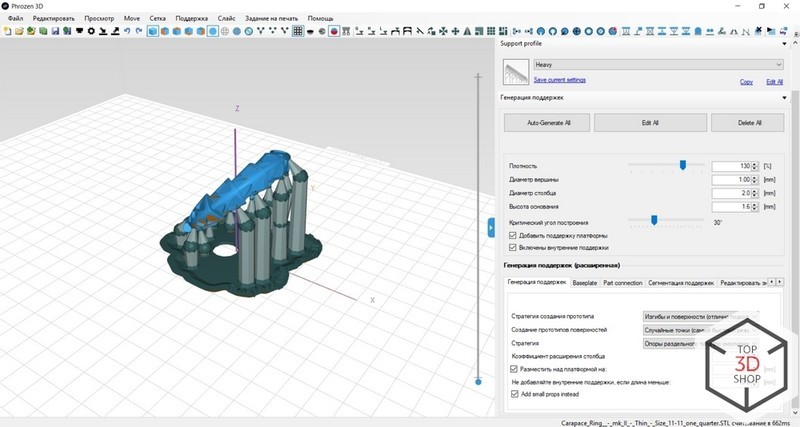

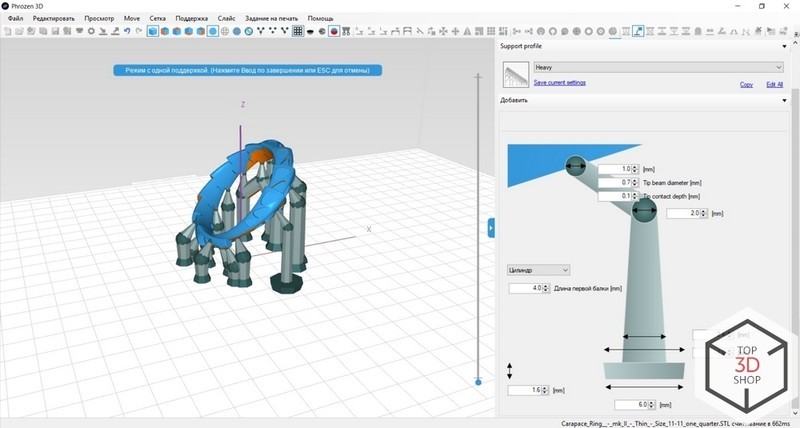

4. A very flexible system for building and configuring supports. Automatic generation with manual adjustment allows you to configure each element.

It is possible to manage each element separately, add your custom supports at any point.

There are also various forms of supports for specific tasks.

The Phrozen 3D slicer is an excellent choice for professionals who are familiar with resin 3D printing and those just getting started with it. Thanks to its advanced functionality, it unleashes the full potential of Phrozen printers. For beginners, the software provides a simplified version of the interface — it disables some of the functions that might confuse a new user. Several Formware 3D tutorial videos are available online, you can watch them to get acquainted with Phrozen 3D as well.

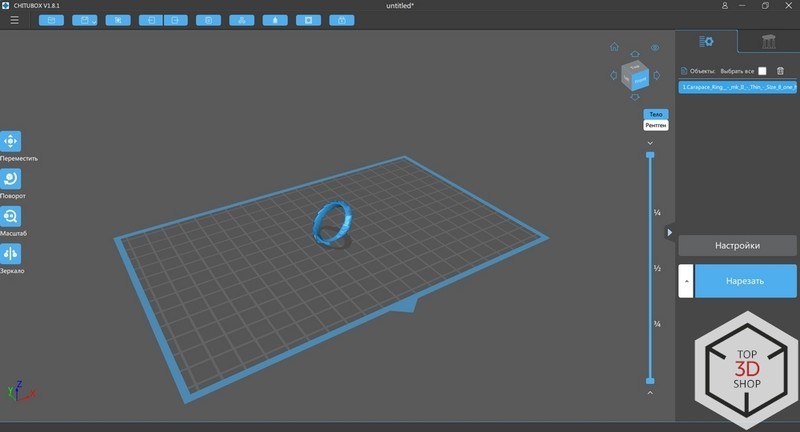

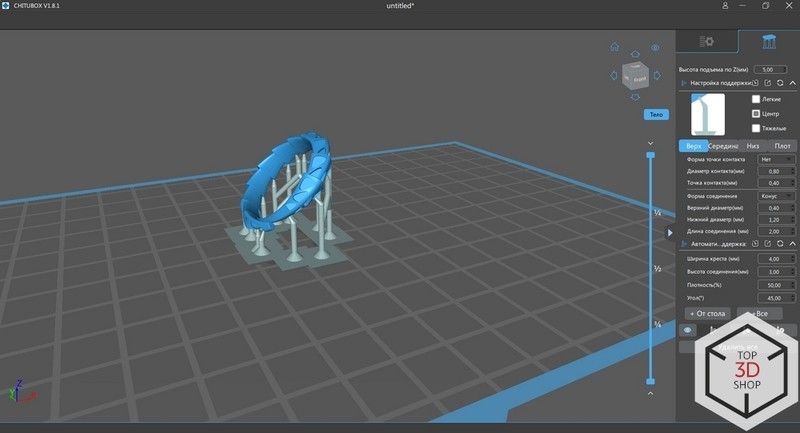

One of the alternative programs is Chitubox. Well known to those who have worked a lot with resin printers, this popular slicer is provided with a good deal of educational material from 3D printing enthusiasts — tips, guides, and instructions, which can be found on forums on the Internet and YouTube channels.

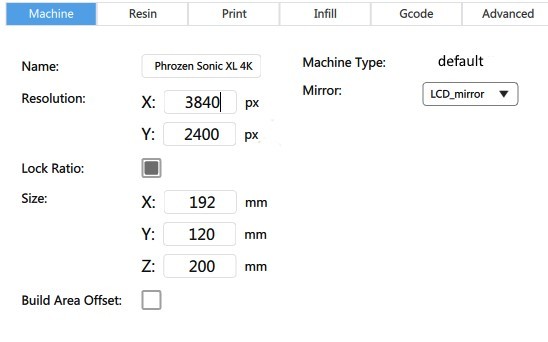

To work with the Phrozen Sonic XL 4K in Chitubox, you first need to specify the correct printer settings. Look at the example in the picture below.

The following functions are of particular use:

1. Convenient interface. Compared to Phrozen 3D, there are fewer features, which makes Chitubox a little easier for a beginner to understand.

2. It is possible to make a model hollow, make holes to drain the resin, and repair the model.

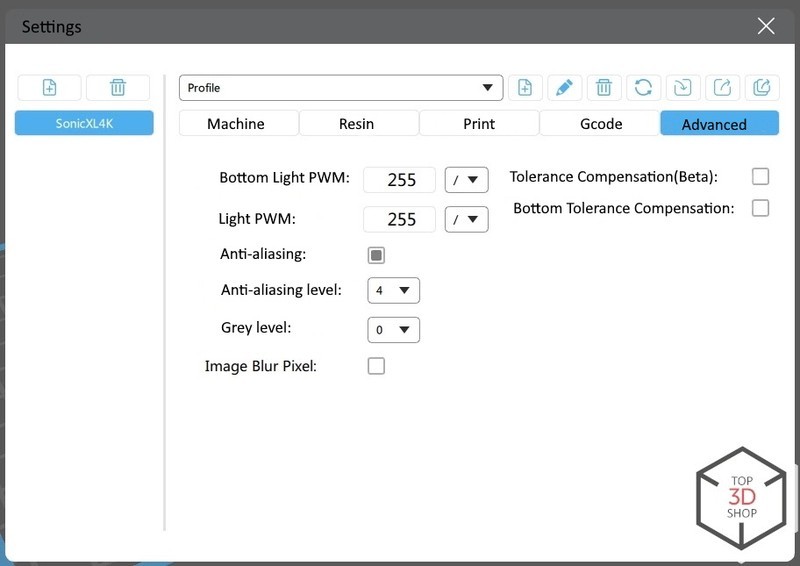

3. The slicer has the function of Anti-aliasing for smoothing the gradient and pixels to achieve maximum print quality. You can read more about these settings and check out some tests in this article on the Chitubox website.

The program offers fairly detailed support settings, although not as detailed as in Phrozen 3D.

On first turning on, the user is greeted with a pleasant English-language interface.

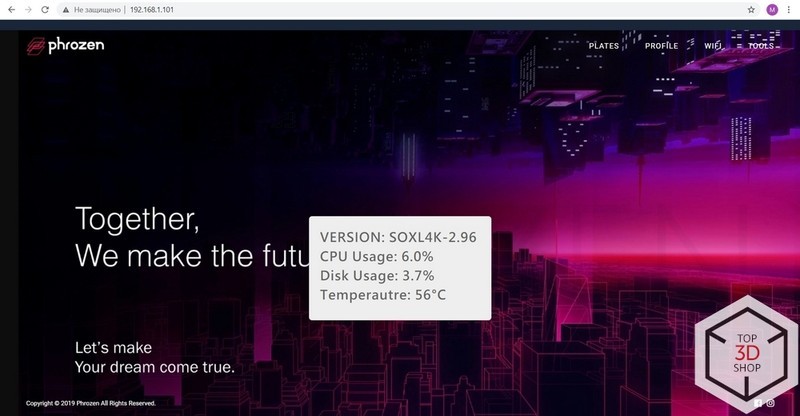

There are not so many functions in the printer itself. All basic print settings can be configured in the slicer on your PC and in a special web interface.

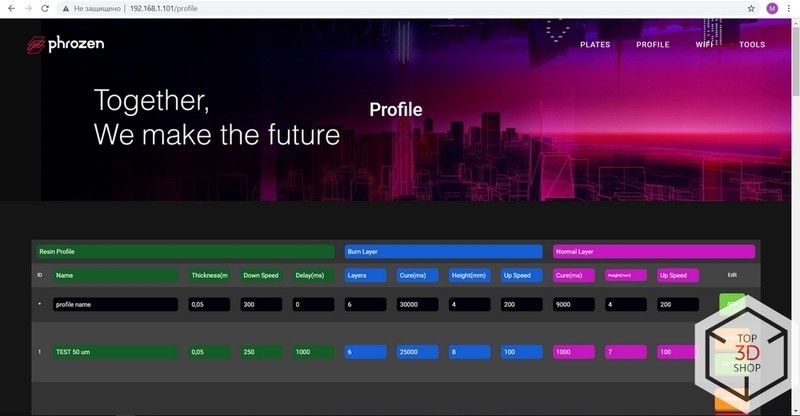

A well-tuned print profile is required for correct printing with a particular resin. You can adjust the profile for a resin both in Chitubox and in Phrozen 3D, but unfortunately, you will not be able to transfer this profile to the printer. The printer itself has several pre-configured profiles, but they are not enough for adequate work with the printer.

The first step is to print calibration models. It does not take much time, and most importantly, such models help correctly adjust the parameters for a specific resin. The Calibration_matrix.stl model is perfect for this purpose, it can be found on Thingiverse.com.

To transfer the prepared file to the printer, you can use a USB flash drive, Ethernet cable, or Wi-Fi connection. The most convenient means is Wi-Fi, but it still needs to be configured. The easiest way is to first connect the printer to your network with an Ethernet cable and then insert the Wi-Fi adapter into the printer, after which the IP for connection will appear on the printer screen. Type this IP in the address bar of the browser to open the printer's web interface, where, in the corresponding menu, you can connect to the Wi-Fi network. Then you can connect to the printer without an Ethernet cable.

From the web interface, you can upload models to the printer, create new profiles and printing tasks, control basic printer functions.

Create a new profile in the PLATES menu. A number of settings can be found in a table on the Phrozen website. These settings are quite accurate, but it is better to empirically find the optimal ones (on their basis). If the resin you need is not in the table, you will have to adjust the settings yourself.

Having created a new profile for the resin and downloaded the model, you need to prepare the device itself. The first step is printer calibration. It is rather easy to do: loosen the screws on the platform, select Z-AXIS in the menu, press the center button, and wait for the platform to lower. Tighten the screws, slightly pressing the plate against the glass. In the menu, press DONE and wait for the platform to rise back.

Attention!

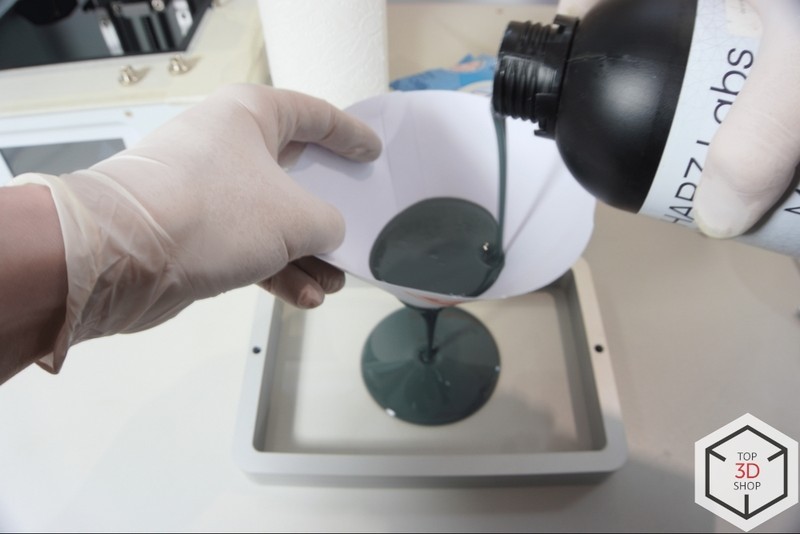

When working with resins, observe safety precautions, be sure to use gloves.

Shake the bottle of resin. If it is a new bottle, there is no necessity to use a filter. Still, it must be employed to pour the resin back into the bottle. After printing, there can be small pieces fallen off the model and left in the vat. During the next printing, they can damage the screen when the plate is lowered to its working position.

Put the vat in place, tighten it. The plate can be sanded a little so the model will stick better to it. You can start printing both via the device itself and through the web interface.

Always keep some wet and dry wipes along with isopropyl alcohol near the printer. When working with resins, wipe down all surfaces — the polymer leaves stains that cannot be removed.

First, we will take a look at some prints of dental models. The layer height is 50 microns.

We used the Harz Labs Dental Sand A3 resin. It is designed for printing demo models, temporary crowns, and bridges. The material is very durable, non-irritating, and odorless.

When printing dental models, the correct scaling of objects and the final size of the resulting products are very important. It should be borne in mind that after being washed in isopropyl alcohol and cured, any resin shrinks. Adjusting the size of an object is very simple: you need to print a 100 x 100 mm cube without filling and, after the curing procedure, measure each side of the cube. The resulting difference between the dimensions of the original model and the printed part must be calculated as a percentage, which is to be added to the dimensions in the slicer.

In addition to dental models, we also checked detail on more complex products.

For the printing, we used the Harz Labs Model Resin Gray. It is intended for models with increased requirements for physical and mechanical properties — prototypes, functional parts. Cured models are resistant to degradation and can withstand temperatures of up to 100 °C.

Check out some other nice print examples:

Thanks to its ultra-fine precision, the device can create astonishingly detailed dental impressions with incredible mechanical properties, allowing the Sonic XL 4K to print cutting-edge dental solutions.

Besides, the Phrozen Sonic XL 4K could be a fine machine for jewelry and souvenir businesses. Take a look at the models below. Printed with Phrozen ABS-LIKE Ocean Blue resin, the parts came out perfectly accurate.

Source: Instagram.com

The Sonic XL 4K provides unbelievably smooth surface finish and outputs fine and well-detailed models, allowing it to be used in a variety of other professional applications aside from the above-mentioned ones.

Source: Instagram.com

Pros

Cons

The Phrozen Sonic XL 4K is a professional resin 3D printer that boasts a large build volume coupled with excellent speed and accuracy putting it on par with more expensive models from other manufacturers. In addition, the printer is compatible with a large number of resins by different brands, which significantly expands its capabilities.

Update your browser to view this website correctly. Update my browser now

Write a comment