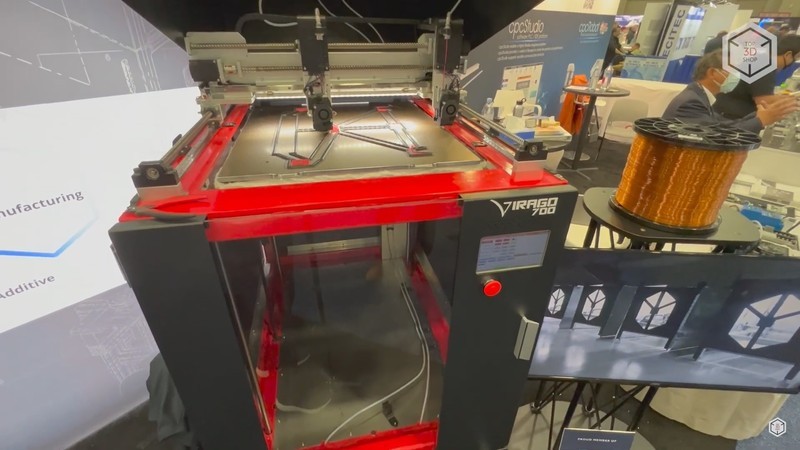

American company IC3D specializes in complex projects execution in the field of additive manufacturing — from consumables and software creation to custom-built 3D printing equipment and products manufacturing using in-house designed FDM printers. The IC3D Virago 700 is the company’s first commercial 3D printer. From this overview, you will learn its main peculiarities and specs.

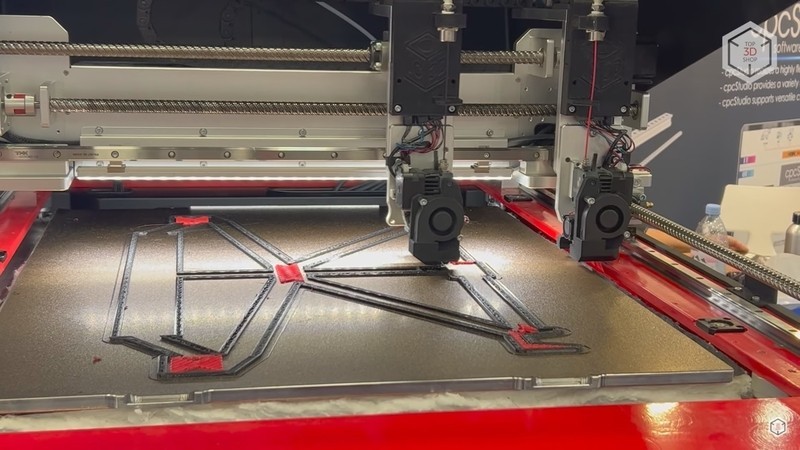

The Virago 700 model features a fully enclosed build chamber and is equipped with an independent dual extruder that supports simultaneous printing with different materials in the Duplication, Parallel, and Mirrored modes. Moreover, the machine supports various IDEX-based print modes, including Dual material, Color, and Soluble support printing.

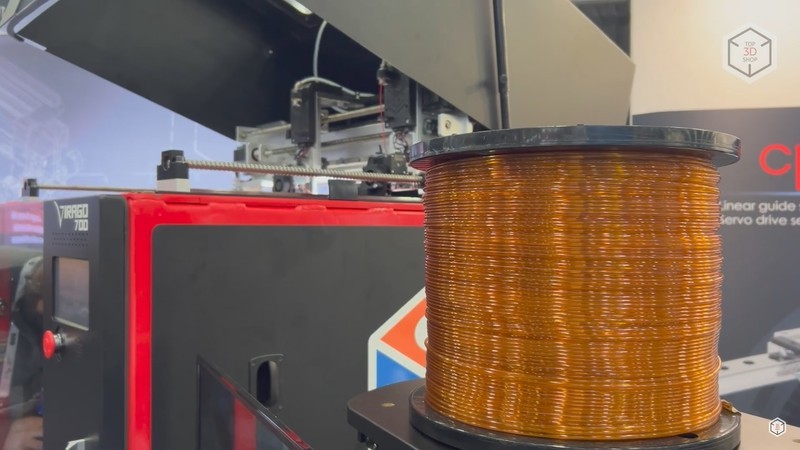

The maximum heating temperature of the dual gear drive extruder is 500 °C. This allows working with a wide range of refractory and special engineering-grade materials, including polycarbonate, polypropylene, nylon, thermoplastic polyurethane, and fiber-reinforced composites.

Available nozzle diameters range from 0.4 to 2.5 mm. The company also provides optional tool heads for printing with demanding industrial, flexible, and abrasive materials.

The build volume of the IC3D Virago 700 is 600 x 700 x 785 mm. A 340-kilos welded steel frame and precision kinematics components ensure consistent 24/7 printing and significant speed-up in production. Optional features include a heated build chamber and uninterruptible power supply system.

The build platform is equipped with a removable magnetic plate and can heat up to 125 °C. The PEX print surface ensures exceptional adhesion for higher quality outputs.

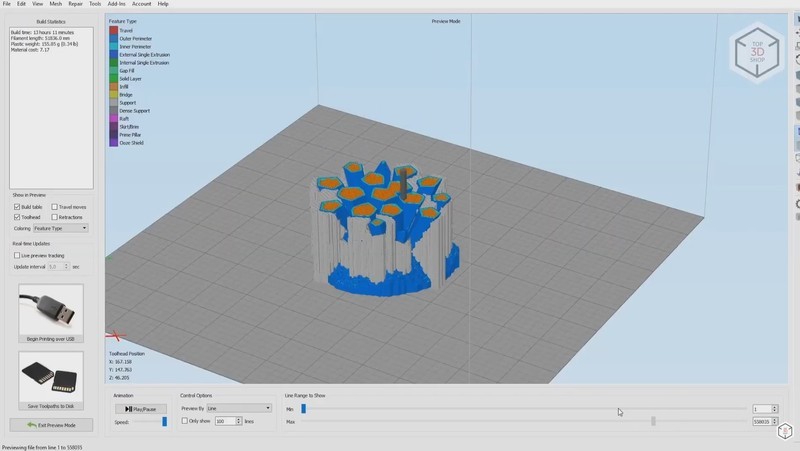

To prepare digital models for printing, the manufacturer recommends applying the Simplify3D slicer. This professional yet user-friendly program is capable of processing and analyzing 3D models with impressive speed as well as providing overall monitoring tools and realistic pre-print simulations.

The IC3D Virago 700 can be controlled via a sensitive color touchscreen. Besides, the printer supports Ethernet connectivity making for a convenient remote operation.

With the mentioned features, such as robust mechanisms, cost-effective performance, and great material flexibility, the IC3D Virago 700 perfectly fits the demands of functional prototyping, industrial part design, small-scale production, and much more.

As is seen, the Virago 700 3D printer from the IC3D company is a well-done debut worth the attention of professional manufacturers, which seems ready to deal with complex tasks in manifold industries.

Update your browser to view this website correctly. Update my browser now

Write a comment