Released in September, 2022, the Einstar 3D scanner is the latest model in the EinScan series of Shining 3D digitizing solutions including handheld and desktop devices for both professional and consumer use. With its Einstar model, the company promises to make industrial-grade 3D scanning available to everyone.

This is Top 3D Shop, and today we are going to review the Shining 3D Einstar, the company’s most affordable handheld 3D scanner providing professional quality.

Shining 3D is a Chinese-based company founded in 2004. Headquartered in Hangzhou, China, the company employs a global team of over 700 specialists providing cutting-edge 3D digitizing solutions and support to the customers all over the world.

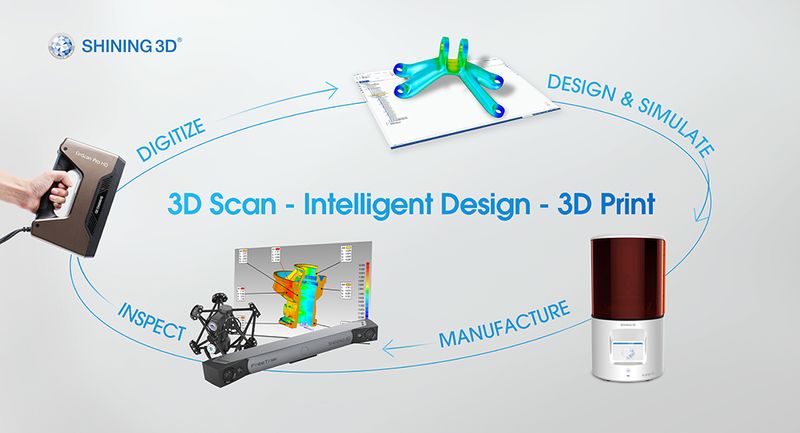

Focused on research and development of innovative 3D scanning and 3D printing technologies, Shining 3D develops three business segments, namely EinScan, metrology, and digital dentistry. Being the pioneer in the field of additive manufacturing, the company owns more than 360 patents and 140 software copyrights and offers the customers complete digitizing solutions, including high-quality 3D scanning equipment, resin 3D printers, and professional software.

The Shining 3D Einstar is a compact and lightweight handheld 3D scanner featuring versatile functionality and ease of use. Due to its high performance under various lighting conditions as well as the object and portrait scanning modes, the device is equally good for scanning people and physical objects of different sizes and textures. The scope of possible applications for the Einstar include 3D printing, design, digital archiving, education, culture and art, VR and AR, and more.

Below is the list of the Shining 3D Einstar key features.

You can see the unboxing of the Einstar in the video below.

The scanner comes with a convenient carrying case containing the Einstar 3D scanner, the calibration board, markers, and the cables. Here is the full list of items you will find in the box:

For some items, package content may change. In case of any questions, please get in touch.

Before you get started with the calibration process, you need to install the EXStar software to your computer and connect the Einstar. The power cord plugs into the USB cable connecting the scanner and the PC, so it's a convenient two-in-one solution to get rid of redundant cables.

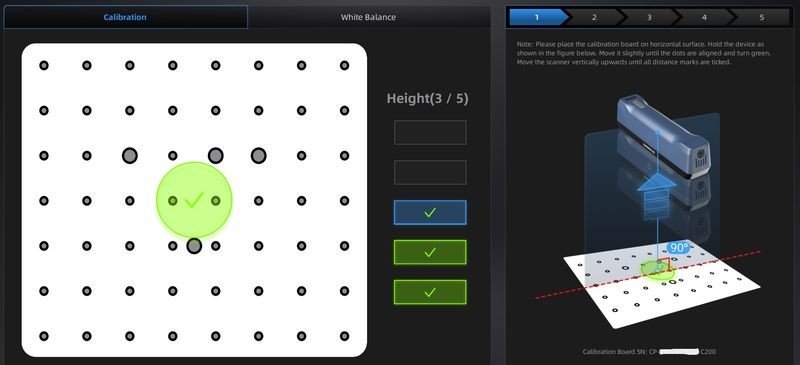

The calibration ensures the scan accuracy and is required before the first scan or if the scanner has not been used for more than a week or two. It is also advisable to calibrate the scanner in case you experience serious accuracy reduction or lack of scanning data, which can be the result of a shake.

To perform the calibration, you need to put the calibration board on a flat surface with the marker-covered side up and follow the prompts of the EXStar software, moving and tilting the scanner as shown.

Once it is done, you need to turn the calibration board the white side up and complete the calibration process by adjusting the white balance for true-to-life color capturing.

The calibration does not usually take long. You can watch the video tutorial from Shining 3D.

Before starting to scan, you need to create a new project group. While scanning large items or multiple objects at a time that require different align modes, you may need to perform several scans. Each of them will be saved as a single project in the project group folder and then aligned either manually or automatically.

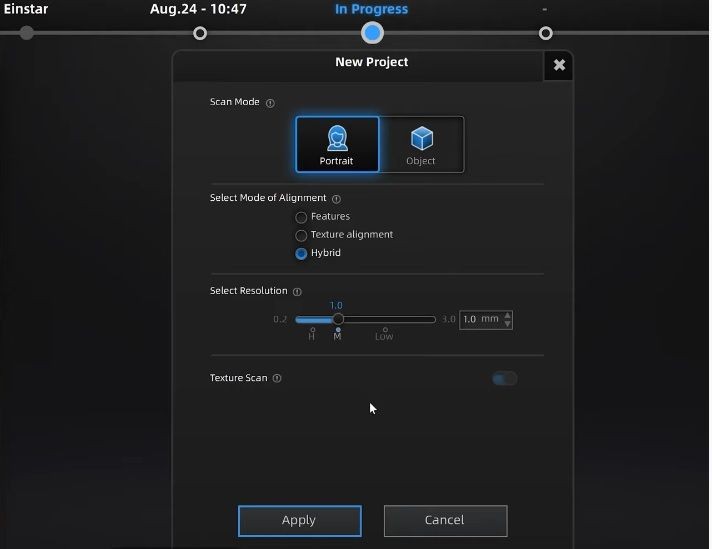

Now we proceed to scan settings. First you choose one of the two supported scan modes, namely the object or portrait scan. Other settings to adjust here are resolution, alignment mode, and texture.

|

Scan mode |

Options |

Alignment mode |

Resolution |

Texture |

|

Object |

Small object (for object dimensions from 50 x 50 x 50 mm to 200 x 200 x 200 mm) |

Features |

0.2–3.0 mm |

on / off |

|

Portrait |

Hair mode (for better hair capturing) |

Features |

0.2–3.0 mm |

on / off |

The Einstar is capable of creating point clouds with a minimum point distance of 0.1 mm in the small object mode. The higher the resolution, the more details you can get, but the file size and processing time will increase correspondingly.

The choice of the alignment mode depends on the object to be scanned. Feature alignment better works for the objects with different geometries but it may fail dealing with flat surfaces or objects with repeating geometric patterns. For such models the hybrid mode is the best choice. Select the texture alignment mode for objects with rich textures or of different colors.

If the texture switch is turned off, the scanner will not capture texture data, so turn it on if you want a full-color scan.

Now you are ready to start scanning by pressing the button on the back of the Einstar. First you will see the preview allowing you to adjust brightness and set the working distance. The Einstar’s effective working distance is 160–1400 mm for the portrait mode, and 160–600 mm for the object mode (160–250 for small items).

By pressing the button again, you finally start actual scanning. The built-in distance indicator will let you know if you are too close or too far from the object.

Another useful feature is the data quality indicator which provides you with the real-time view of the areas that do not have sufficient scanning data yet.

When the point cloud becomes mostly green which means the scanner has captured enough data, you can stop scanning and generate a point cloud. If more scans of the object are required, be sure to start a new project in the same project group for each new scan.

The EXStar software provides a set of useful tools for scan data editing. You can delete scanning artifacts using various selection tools, or remove the base where your object rested while being scanned, using the cutting plane function.

The final step before obtaining a 3D mesh is aligning multiple projects within the project group. The software can do it automatically or you can choose manual alignment if necessary.

The video from Shining 3D provides a complete guide on scanning with the Einstar.

With EXStar, you do not have to install additional software for mesh editing, as it provides all the functions you need, such as mesh optimization, auto and manual hole filling, texture remapping, and more.

Before you get to mesh optimization, you should select the mesh type — unwatertight, semi-watertight, when only small holes are filled automatically, or watertight with all the holes automatically filled. Watertight models are the longest to process but they are the only ones to be used directly for 3D printing or for volume measurements.

This video shows the use of the Einstar for virtual / augmented reality creation. Will Huff demonstrates how to make your digital avatar for the Metaverse.

Ken Coleman, a digital artist, shares his experience with the Einstar in his work.

David Miao, also known as 3D DIY Dave, is a maker and content creator. He has started an open-source project called the Maker Scan Project which is a collection of scan portraits of makers all over the world. In the video, David speaks about the advantages of the Einstar for people scanning.

Will Co, the co-founder of CoKreeate and Replikeate3D, created a customized Samurai mask for Halloween.

The Shining 3D Einstar is a compact, easy-to-use handheld 3D scanner with powerful capabilities. With its incredible performance under different lighting conditions, wide functionality, and affordable price, the Einstar is an unrivaled choice both for beginners and advanced users. The scanner features a number of professional-grade functions and is incredibly versatile in its application. The dedicated EXStar software provides a comprehensive solution for the entire 3D scanning process including mesh editing tools.

Update your browser to view this website correctly. Update my browser now

Write a comment