Chinese-based Shining 3D company provides unique solutions in 3D digitization, intellectual design, and additive technologies for industrial production, healthcare and biological sciences, the creation of personalized products and training. The company offers comprehensive, easy-to-use, and profitable products contributing to the development of 3D technologies.

This article focuses on Shining 3D metrology-grade equipment. Read on to learn about the best products designed for these purposes.

Shining 3D production systems are based on the strict standards of ISO 9001, ISO 14001, ISO 13485, OHSAS 18001. Most products are certified by CE, FDA, UL, FCC, and RoHS, which guarantees consistency in standard and large-scale production, a safeguards system, stable quality, and efficiency of production. Applying the criteria for performance excellence (GB/T 19580-2012), the company received the Hangzhou Quality Award, Xiaoshan District, in 2018.

Shining 3D develops, manufactures and commercializes a wide range of 3D technologies, including 3D scanners for different industries and applications, professional software, and 3D control systems.

The metrology solutions offered by Shining 3D are based on the company's numerous patented technologies and prove indispensable when it comes to 3D inspection of complex objects. They are also widely used for simulation, reverse engineering, product development, and other applications in such industries as aerospace, automotive and transportation, power generation, industrial manufacturing, and more.

The Shining 3D FreeScan UE Pro is a laser handheld professional scanner featuring high accuracy and ergonomic design. The scanner has a built-in photogrammetric module that increases volumetric accuracy. Moreover, it boasts an outstanding acquisition speed of 1,850,000 points/s and three advanced modes of scanning fit for various purposes. For example, 26 crossed blue lasers can be used to get the general outline of an object; the 5 laser lines mode is perfect for scanning fine details, and the single line mode captures the most difficult surfaces. The precision of the device is ideal for 3D inspection, reverse design, additive manufacturing, and other applications.

The Shining 3D FreeScan UE is a blue laser handheld 3D scanner that provides metrology-grade, high-accuracy inspection solutions for various industries, including automotive, transportation, aerospace, energy generation, molding inspection, machinery manufacturing, and others. There are two modifications of the FreeScan UE, namely FreeScan UE7 and FreeScan UE11, the latter featuring higher scan speed of 1,020,000 points/s (650,000 points/s for the UE7) and the light source of 22 lines + 1 line blue laser ray, compared to UE7’s 14 lines + 1 line blue laser ray. With scanning accuracy of 0.02 mm, the FreeScan UE features remarkable repeatability of the final result, which makes it a perfect tool for 3D inspection. The device supports scanning of black and reflective surfaces and weighs only 750 grams. The operating system with simple software setup is user-friendly and intuitive.

The FreeScan Trak is a professional optical tracker system with a high-precision 3D scanner. The optical tracker captures the spatial position of the scanner structure in real time thus allowing the user not to use markers which helps save time. Due to its impressive accuracy of up to 30 microns, large scanning area of 3000 x 2500 mm, and convenient wireless design, the FreeScan Trak is a perfect tool for static and dynamic inspection of medium and large objects, deformation analysis, 3D modeling, maintenance, repair, overhaul, and design.

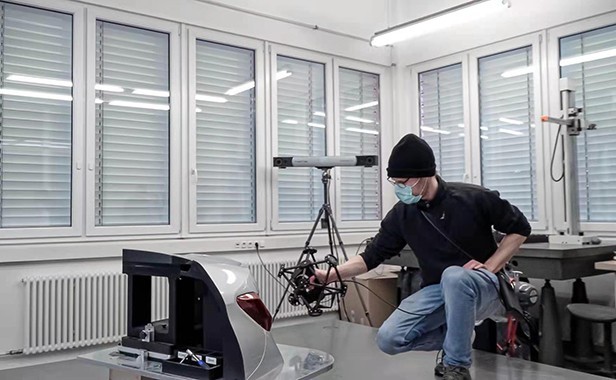

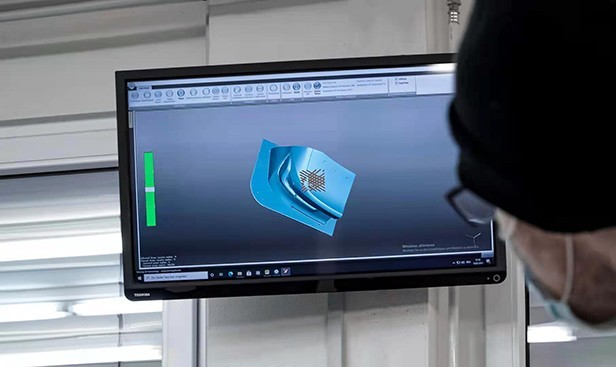

The use of high-precision 3D scanners takes the measurement standards to a new level allowing for a perfect replication of the object to be inspected and providing considerable time saving. The German ATD Automobil-Technik-Design GmbH company appreciated the advantages of digital measurement technology and digitalized the entire inspection process for automotive parts. ATD GmbH specializes in engineering services, model technology, and small series production.

Among others, ATD produces test cubings for its customers. These are highly accurate replicas of car body parts used for quality control.

The perfect solution for large-scale 3D inspection is the portable wireless CMM scanning system FreeScan Trak.

The scanning process can be viewed in real time in the scan software.

The FreeScan Trak is compatible with most of the 3D inspection software providing the flexibility and ease of use.

In this particular case, the Shining 3D measurement hardware was used together with Verisurf software to do the evaluation.

The Shining 3D OptimScan 5M features two 5 MP cameras and blue light scanning technology which make for extremely high scan speed of less than 1.5 seconds for a single scan, and accuracy within 0.08 mm/m. The device is capable of scanning dark-color or metal objects and is great for such applications as defense, aerospace, or mold production. The maximum single scan range is 400 x 300 mm² and the minimum point distance is 0.04 mm.

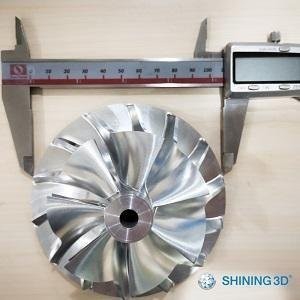

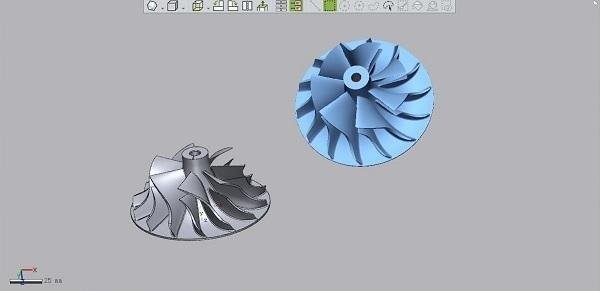

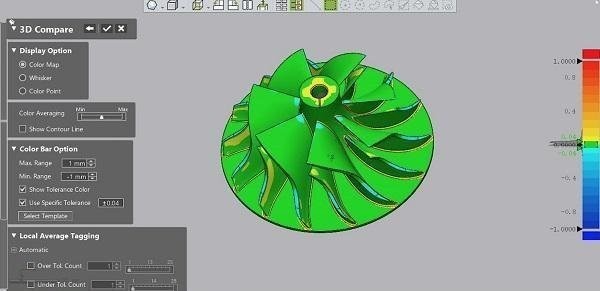

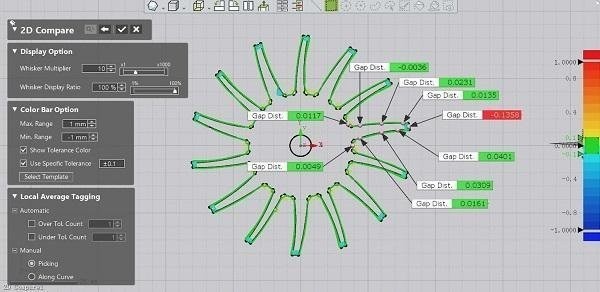

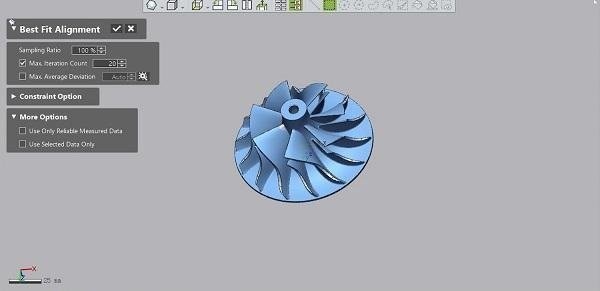

For the production of turbine blades, an aerospace company used high-temperature alloys processed with CNC machines. After the completion of the production process, it is necessary to check the finished part for compliance with the design dimensions — the deviation between the manufactured blade and the design data should not exceed 0.04 mm.

Until recently, the company used a three-coordinate measurement of certain given points of the object, which did not give a complete picture. A new measurement method was needed to inspect the entire surface. This led to the development and use of a metrology-grade 3D scanner.

Using the 3D scanner from Shining 3D, it was possible to get three-dimensional data of the part. The process only took a few minutes, and the 3D models obtained by scanning contained all the necessary information about the surfaces.

A three-dimensional scan consists of hundreds of thousands of points collected from the scanned part, which makes this form of measurement reliable when checking for deviations.

Deviations from the given dimensions are displayed with the help of a chromatographic scale. Thus, users learn about deviations, determine the source of errors, and adjust the processing method according to the results.

All of that can be done with the Geomagic Control X software, which is employed to check the collected 3D scan data.

The AutoScan Inspec is an industrial desktop 3D scanner of metrological precision. Apart from its accuracy, the device offers fully automated operation, which comes in handy for scanning small and complex parts. In contrast to other desktop 3D scanners, the AutoScan Inspec is engineered with a 3-axis system. It is able to rotate an object at many different angles to obtain all necessary data and further export it to popular CAD software, such as the Geomagic Control X, PolyWorks, etc. The scanner is perfect for quality check, non-contact measurement, reverse engineering, and product design.

The Shining 3D metrology solutions are a perfect tool that grants the industries inspection methods with unprecedented precision, accuracy, and the opportunity to evaluate the entire surface of the inspected objects however complex they appear to be. Moreover, the time and cost efficiency of 3D metrology, compared to traditional methods, is really impressive.

Update your browser to view this website correctly. Update my browser now

Write a comment