Founded in 2004, Chinese-based Shining 3D company focuses on developing high-precision digital solutions, having become a recognized leader in 3D scanning equipment production. Shining 3D owns over 300 patents and 100 copyrights; the company manufactures 3D products on a large scale, offering powerful technologies and providing solid support around the world.

In this article, we will tell you about some of the most prominent Shining 3D solutions, including the EinScan lineup and other products for 3D digitization.

Shining 3D is constantly increasing the efficiency of high-quality 3D modeling, providing flexible production of complex design parts, and making 3D digitization and additive manufacturing technologies available to everyone — from transnational corporations to consumers.

Headquartered in Hangzhou (China), Shining 3D has gained a significant presence in North America and Europe, owns and manages subsidiaries in Stuttgart (Germany) and San Francisco (USA), demonstrates its influence in more than 70 countries in Asia and the Pacific, North and South America, Europe, the Middle East and Africa.

One of the official partners and integrators of Shining 3D is Top 3D Shop. For many years of fruitful and successful work, we won the Marketing Pioneer Award.

Top 3D Shop was awarded the Marketing Pioneer Award at the Shining 3D annual ceremony

Shining 3D factories located in the cities of Hangzhou, Beijing and Tianjin are engaged in mass production of 3D scanners and 3D printers of various types. The facilities equipped with advanced production and control systems offer customers innovative equipment of high quality and reliability.

Digitizing solutions represented by the EinScan series is one of the three business segments developed by the company, the other two being Metrology and Digital Dentistry solutions.

EinScan products are widely used for a variety of applications, such as Reverse Engineering, Product Development, Computer Graphics, Virtual Display, VR/AR, 3D Data Archiving, Digital Diagnosis, and others. The number of industries taking advantage of EinScan technologies include but are not limited to Aerospace, Automotive, Industrial Manufacturing, Art & Architecture, Healthcare, and Education.

The EinScan H is a hybrid color 3D scanner designed for professional use in healthcare, education, design, virtual reality, and engineering. The texture tracking and three different modes allow applying it for standard, body, and face scanning. Thanks to such devices combining high-resolution, fast acquisition speed and large operating volume, 3D scanning technology becomes easy to use, less expensive and, most importantly, capable of capturing top-quality 3D images.

The EinsScan HX is a hybrid device from Shining 3D equipped with both laser and structured light modules. Its lightweight and ergonomic design provides a comfortable application for complex and remote areas. The state-of-the-art laser technology enables one to capture dark-colored models and objects with reflective surfaces without additional equipment. Thanks to the integrated color camera, the device efficiently works with colors and textures. The listed highlights make the EinScan HX a perfect tool for the active use in architecture, art and generative design, heritage preservation, artifact restoration, healthcare, and more.

Below you can find the technical specs comparison of the EinScan H and EinScan HX models.

|

Shining 3D EinScan H |

Shining 3D EinScan HX |

|

|

Accuracy |

up to 0.05 mm |

up to 0.04 mm |

|

Connectivity |

USB 3.0 |

USB 3.0 |

|

Display |

no |

no |

|

Technology |

White light, Infrared light |

Blue LED, Laser |

|

Acquisition speed |

up to 1,200,000 points/s (Standard, Body modes); up to 720,000 points/s (Face mode) |

up to 1,200,000 points/s (Rapid scan mode); up to 480,000 points/s (Laser scan mode) |

|

Camera frame rate |

55 FPS |

55 FPS |

|

System requirements |

OS: Win10, 64 bit; Graphics card: NVIDIA GTX1080 and higher; Video memory: ≥4GB; Processor: I7-8700; Memory: ≥32GB |

OS: Win10, 64 bit; Graphics card: NVIDIA GTX1080 and higher; Video memory: ≥4Gb; Processor: I7-8700; Memory: ≥32GB |

|

Depth of field |

200–700 mm (Standard, Body modes); 200–1500 mm (Face mode) |

200–700 mm (Rapid scan mode); 350–610 mm (Laser scan mode) |

|

Output formats |

OBJ; STL; ASC; PLY; P3; 3MF |

OBJ; STL; ASC; PLY; P3; 3MF |

|

Point distance |

0.25–3mm (Standard mode); 0.5–3mm (Body, Face modes) |

0.25–3 mm (Rapid scan mode); 0.05–3mm (Laser scan mode) |

|

Rotating table |

no |

no |

|

Max. scan volume |

420 x 440 mm (Standard, Body modes); 780 x 900 mm (Face mode) |

420 x 440 mm (Rapid scan mode); 380 x 400 mm (Laser scan mode) |

|

Texture / Color |

yes |

yes |

|

Price |

$4,999.00 |

$9,999.00 |

|

Applications |

Art and heritage (digital sculpture design); Forensics (evidence analysis and archiving); Virtual display (VR/AR display); Customization (consumer goods customization); Healthcare (orthotics & prosthetics, plastic surgery, digital diagnosis and treatment); Digital entertainment (animation and games) |

Automotive; Shipbuilding; Machining; Education and research |

Will Huff, a Hollywood make-up effects artist, designed fantastic face masks to make exactly fitting, customized cosplay and Halloween costumes for his children. Everything he needed was the 3D scan to 3D print workflow and his skills from the motion picture industry.

The costume: a skull mask made by means of 3D scanning, Zbrush, and 3D printing.

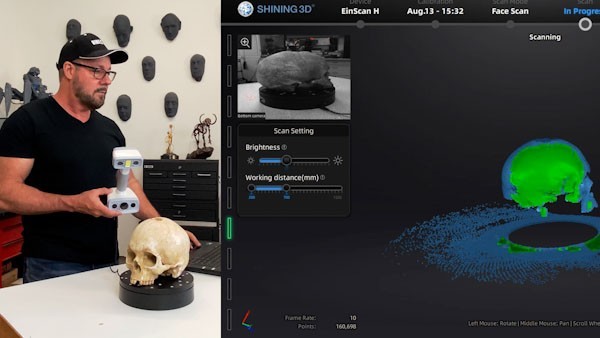

The design process started by scanning a skull with the EinScan H.

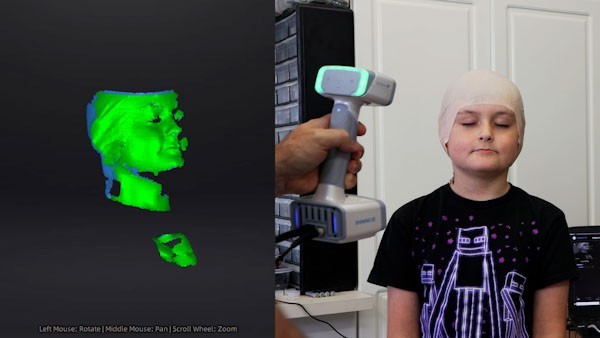

Scanning his children, Will placed a rubber cap over their heads to flatten down their hair, and scanned their heads in Face scan mode.

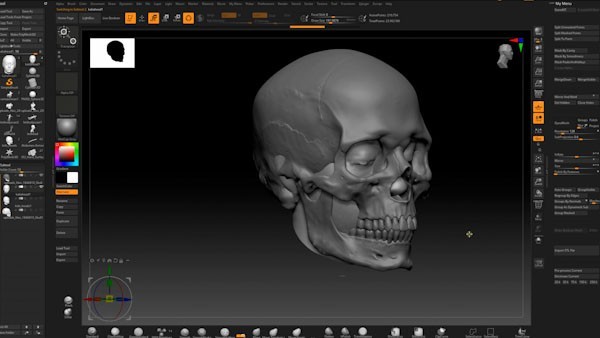

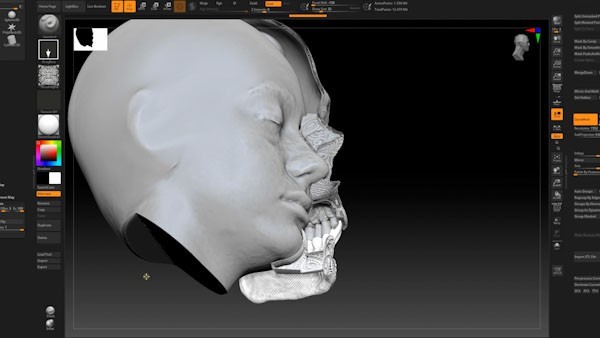

When scanning was done, Will imported the scan data into Zbrush.

He sized the scan data of the skull to perfectly fit the scan data of the head.

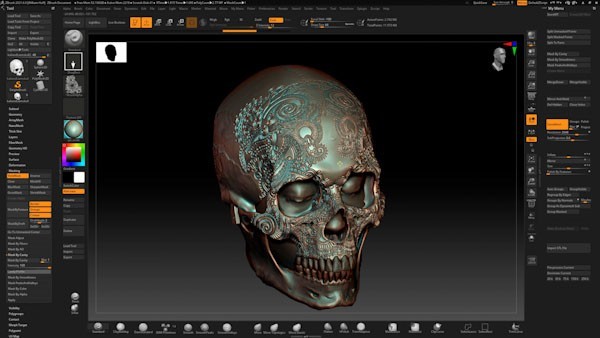

Then Will added some surface design to the skull.

Will wanted to make an articulated skull his kids could wear, for example, for Halloween. So, he designed tabs for the jaws, so that the skull could open its “mouth”.

Final skull design in Zbrush.

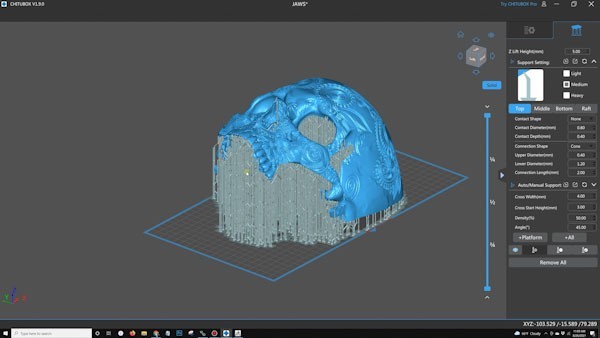

The 3D model was prepared for printing.

Some final decoration…

And the fantastic result!

“I have to say this is an astounding piece of technology. It really is. If you are an artist that has a budget to buy something like this I would highly recommend it, if you do a lot of virtual stuff inside the computer. This thing is an incredible tool,” Will says.

The EinScan Pro HD is a professional handheld structured-light 3D scanner of a new generation. Like the other models of the Pro series, it features high resolution and incredible performance based on a rapid capture and large scan volume. Getting complex, dark, and casting metal surfaces is not a problem for the EinScan Pro HD due to its optimized algorithms and four different modes. With the necessary add-ons, such as a tripod or turntable, the device can meet real industrial challenges in a very convenient way.

The EinScan Pro 2X 2020 is an improved version of the EinScan Pro 2X handheld scanner. It adopts structured light scanning technology with better HD accuracy and speed. Moreover, the device offers new alignment modes based on markers and features. With a compact and easy-to-handle design, this high-precision 3D scanner provides top-quality renders of even the most intricate and highly detailed objects. The model can be upgraded with two additional modules to complete a wide range of tasks in various environments.

Let’s compare the technical specs of the two devices:

|

Shining EinScan Pro HD |

Shining EinScan Pro 2X 2020 |

|

|

Weight, kg |

1.25 |

1.13 |

|

File formats |

OBJ, STL, ASC, PLY, P3, 3MF |

OBJ, STL, ASC, PLY, P3, 3MF |

|

Color scanning |

yes (with Color Pack add-on) |

yes (with Color Pack add-on) |

|

Minimum system requirements |

NVIDIA Quadro P1000 and above or NVIDIA GTX660 and higher; CPU: Intel (R) Xeon E3-1230, Intel (R) I5-3470, Intel (R) I7-3770; RAM: 8GB |

NVIDIA Quadro P1000 or NVIDIA GTX660 or higher; CPU: Intel (R) Xeon E3-1230, Intel (R) 15-3470, Intel (R) 17-3770; RAM: 8 GB |

|

Connectivity |

high-speed USB 3.0 |

high-speed USB 3.0 |

|

Scanning area |

209 x 160 mm — 310 x 240 mm |

150 x 120 mm — 250 x 200 mm |

|

Scan accuracy |

up to 0.045 mm (Handheld HD scan mode); up to 0.1 mm (Handheld Rapid scan mode) |

up to 0.045 mm (Handheld HD scan mode); up to 0.1 mm (Handheld Rapid scan mode) |

|

Working distance, mm |

510 |

400 |

|

Acquisition speed |

up to 3,000,000 points/s (Handheld HD scan mode); up to 1,500,000 points/s (Handheld Rapid scan mode) |

up to 3,000,000 points/s (Handheld HD scan mode); up to 1,500,000 points/s (Handheld Rapid scan mode) |

|

Align Mode |

Marker Alignment; Texture Alignment (with Color Pack); Feature Alignment; Hybrid Alignment |

Marker Alignment; Texture Alignment (with Color Pack); Feature Alignment; Hybrid Alignment |

|

Price |

$7,699 |

$5,999 |

|

Applications |

Manufacturing & reverse engineering; 3D Modeling for customized products; Digital medical analysis; Orthotics & prosthetics; Art & heritage; Design; Virtual Display |

Manufacturing & reverse engineering; 3D Modeling for customized products; Healthcare; Art & heritage; Design; Virtual Display; Research and education |

Reverse engineering is the most commonly used application of 3D scanning and 3D printing in many industries. The ability to 3D scan an object and create an individual product is an invaluable opportunity. 3D scanners allow digitizing both inanimate objects and living beings, which makes them an ideal tool in industries related to traditional CAD design methods. One of these industries is prosthetics and the creation of supporting devices.

Functionality is the main criterion for evaluating an artificial limb, but the fit and shape of the prosthesis are no less important for the patient. A correctly selected prosthesis adds confidence and provides comfort. 3D scanners paved the way for the individualization of the shape of these products, and personalized prostheses have become a reality for many disabled people. EinScan portable 3D scanners make reverse engineering more available for healthcare.

The EinScan Pro 2X 3D scanner is a multifunctional device. The portable capabilities make it easy to scan large objects, a human body, or its parts. The flagship scanner of the company scans a person’s leg, and the received data can be processed, customized and printed in 3D very quickly.

Using the Handheld Rapid Scan mode, scanning is literally instant. The data collected is accurate enough for reverse engineering, which helps create individual prostheses.

A 3D scan of the patient’s healthy leg is taken as a pattern, which is then mirrored in the software and used as a model to make the prosthesis as close as possible to a real leg.

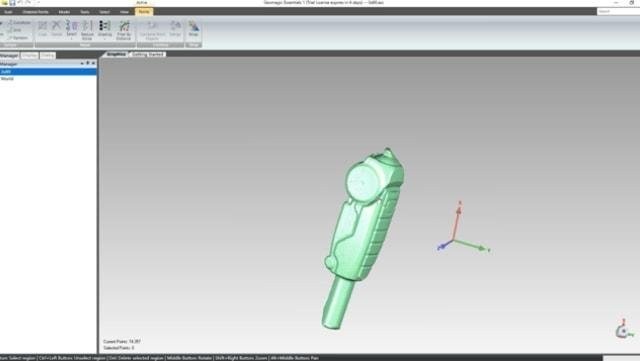

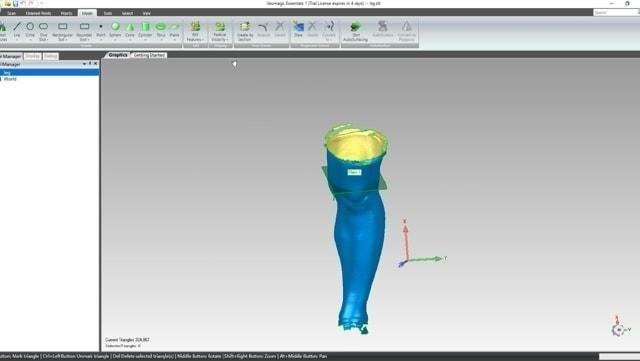

After collecting the data and completing the scan, the file is exported to the Geomagic Essentials software.

Working with organic forms in the context of CAD can be a difficult task even for the most experienced professionals, but the Essentials tools provide a smooth transformation of 3D scans into a CAD model.

Coordinates are assigned to 3D models, which simplifies reverse engineering. The contours, general shape, and geometry of the product are extracted and determined using available tools.

The second dataset of the patient’s leg scanning is imported into the Essentials. The process repeats, and the 3D model is prepared for reverse engineering.

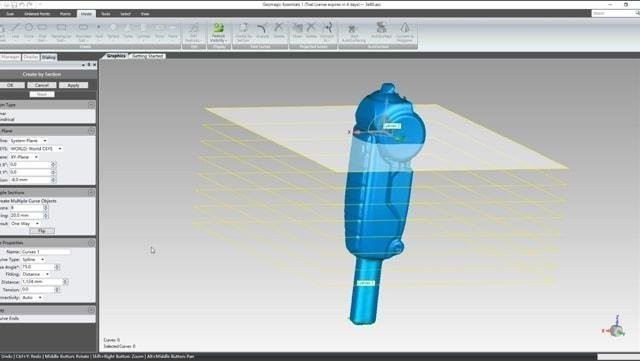

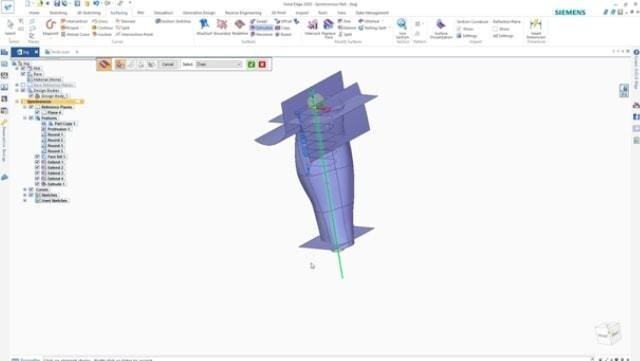

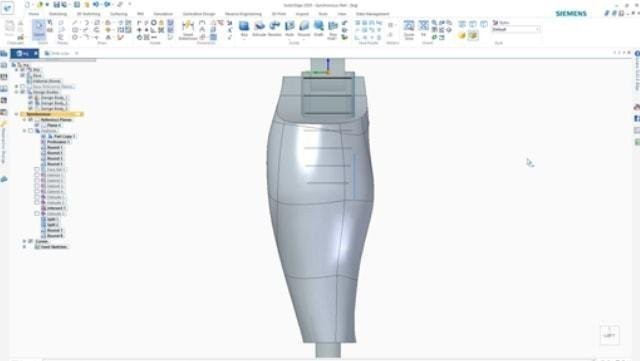

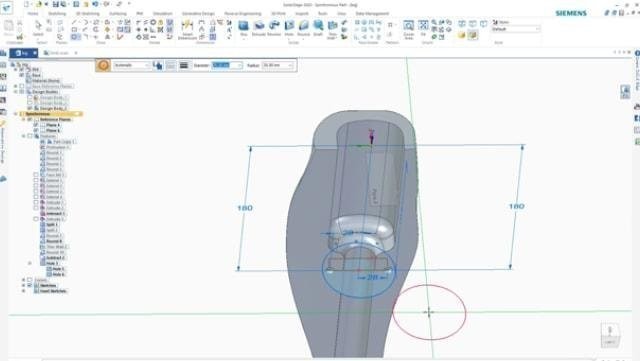

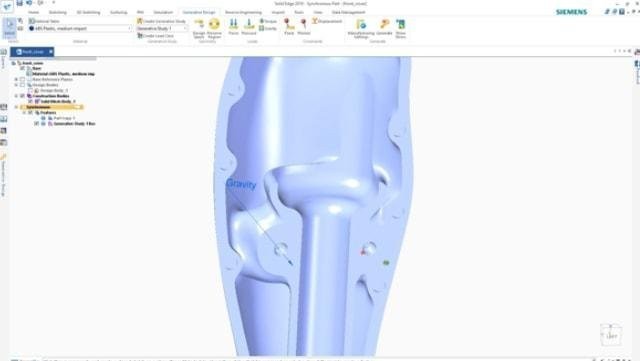

Once both datasets are processed, they are exported to the Solid Edge Shining 3D Edition. Solid Edge is a professional piece of CAD software that allows reverse engineering based on 3D scans.

The software imports both scans directly. Two models are developed individually. The prosthesis is used as the mechanical part of the CAD model, while the scan of the healthy leg is employed as a form to shape its appearance.

As soon as the overall design is complete, the Generative Design function is applied. The result is an absolutely functional prosthesis that takes into account the patient’s weight and the loads exerted on him when running, walking, and exercising.

The 3D model is saved and printed on the Shining 3D EP-P3850 SLS 3D printer. The finished print is post-processed and prepared for the patient.

The EinScan Pro scanners have made 3D scanning in the medical sector more available than ever.

Shining 3D offers everything required for “3D Scan to Design” concept solutions, and industrial 3D printers bring projects to life with amazing accuracy.

Shining 3D EinScan-SE

The best 3D scanner of 2019, the EinScan-SE is the “Elite” version of the Einscan desktop scanners. This product is followed by the “Platinum” version — EinScan-SP. Both models scan three-dimensional objects in color or black-and-white. They are equipped with the easy-to-use EinScan software, which acts as a simplified editing program for 3D scans, being able to export them as well.

Shining 3D EinScan-SP

The key technical differences between the Shining 3D EinScan-SP and the Shining 3D EinScan-SE are shown in the table below:

|

Shining 3D EinScan-SP |

Shining 3D EinScan-SE |

|

|

Accuracy |

0.05 mm |

0.1 mm |

|

Connectivity |

USB |

USB |

|

Display |

no |

no |

|

Outer dimensions (xyz) |

570 x 210 x 210 mm |

570 x 210 x 210 mm |

|

Weight, kg |

4.2 |

2.5 |

|

Technology |

Structured light |

Structured light |

|

Camera resolution |

1.3 MP |

1.3 MP |

|

System requirements |

Nvidia GTX 660 or higher: Graphic memory > 2GB: RAM: 16GB |

Nvidia series; Graphics memory > 1GB |

|

Output formats |

ASC, OBJ, PLY, STL |

ASC, OBJ, PLY, STL |

|

Point distance |

0.17–0.2 mm |

0.17–0.2 mm |

|

Align Mode |

Fixed Scan without Turntable: Feature, Markers, Manual

Fixed Scan with Turntable: Turntable, Turntable Coded Targets, Feature, Markers, Manual |

Fixed Scan without Turntable: Feature, Manual

Fixed Scan with Turntable: Turntable, Manual, Feature |

|

Rotating table |

yes |

yes |

|

Working range |

0.29–0.48 m |

0.29–0.48 m |

|

Max. scan volume |

1200 x 1200 x 1200 mm (Fixed Scan); 200 x 200 x 200 mm (Auto Scan) |

700 x 700 x 700 mm (Fixed Scan); 200 x 200 x 200 mm (Auto Scan) |

|

Single scan capture |

4 seconds |

8 seconds |

|

Texture / Color |

yes |

yes |

|

Price |

$2,599 |

$1,199 |

|

Applications |

Education (primary, middle and high school, K12 education, training on 3D design); Design & art (high-quality 3D design, 3D printing applications, reverse engineering); Digital industry (animation, CG, VR & AR); Archiving and sharing (3D digital archiving, data sharing) |

Education (primary, middle and high school, K12 education, training on 3D design); Design & art (high-quality 3D design, 3D printing applications, reverse engineering); Digital industry (animation, CG, VR & AR); Archiving and sharing (3D digital archiving, data sharing) |

Ye Tianwei and Weng Jia, two designers from Beijing, won the first prize in the “2019 Global Additive Manufacturing Application Innovation Competition” with a series of creative derivatives made of famous white Dehua porcelain.

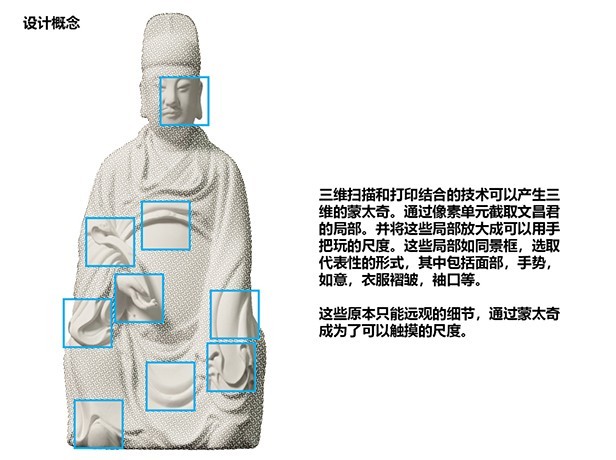

The Fujian Museum exhibited the jade-like Dehua white porcelain with the amazing “Wenchang Lord” seated statue being one of the key items of the collection. However, due to its unobtrusiveness at a first glance, not so many visitors appreciated its elegance. So the Fujian Museum invited designers to create a new approach to enjoying the unique beauty of small cultural relics.

Having designed a creative concept of exhibiting the precious piece of art, Ye Tianwei and Weng Jia chose to use the Shining 3D EinScan-SE desktop 3D scanner to implement their project.

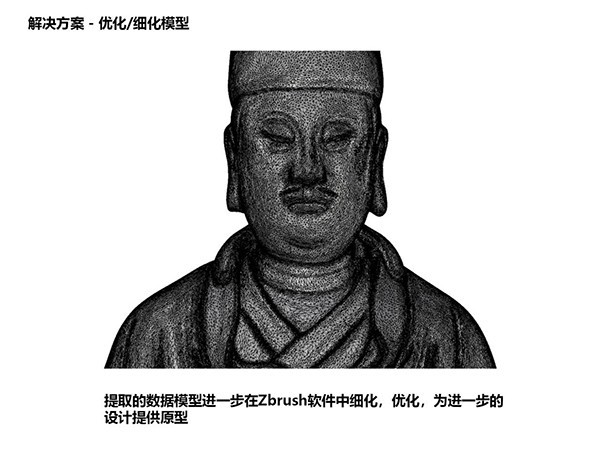

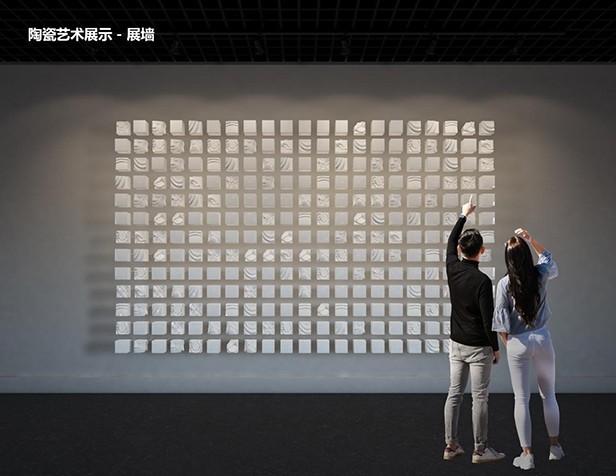

After the statue was scanned, the designers used Zbrush software. The digital model was divided into many small squares which were upscaled in size. The most representative parts, including the face, hands, parts of the clothing and extremities were replicated with the help of 3D printing technology and mounted to a wall in the museum.

For each piece of white porcelain on the wall the mold was 3D printed. After that every part went through the stages of porcelain casting, firing, and, finally, glazing. All those steps allowed for the authentic look of the installation.

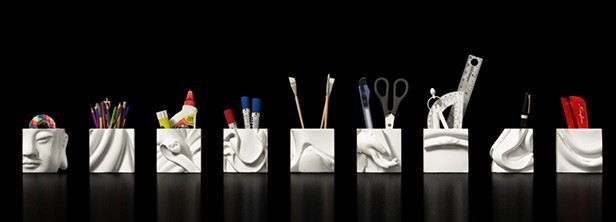

Based on this concept, the designers created several artistic, still functional derivatives.

Stationery boxes

Jewelry set

The Shining 3D Transcan C is a compact professional-grade 3D scanner with two 12 MP professional color cameras allowing the user to replicate the authentic color of the object being scanned. The scanning range of the device is easily switched between 150 x 96 mm and 300 x 190 mm due to its slide-rail design. The Multi-Resolution Fusion Algorithm is highly efficient for complex tasks as it allows shifting between high, medium and low resolution levels in one project. The Transcan C boasts high accuracy of 0.035 mm at the inner position, and of 0.05 mm at the outer one. The minimum point distance of 0.0375 mm at the inner position allows capturing the finest details of the surface.

The performance of the Shining 3D EinScan models can be further expanded with the use of add-ons offered by the manufacturer.

The EinScan Industrial Pack includes a tripod and a turntable; the add-on enables Fixed Scan mode with or without a turntable, allowing for high accuracy and level of detail of the result. Fixed Scan mode with a turntable is great for scanning small objects; the 360° scan can be completed in a few minutes.

The EinScan Industrial Pack is compatible with the EinScan Pro 2X 2020 and the EinScan Pro HD models.

The EinScan Color Pack is an additional camera module for the EinScan Pro series, which allows capturing full-color textures of the objects for highly realistic 3D models.

The EinScan HD Prime Pack module allows increasing scan speed in Handheld HD Scan mode by 30%. It also enables marker-less scanning for surfaces with enough geometries. The HD Prime Pack increases efficiency and makes the scanning process more convenient for the user. The module can be used with the EinScan Pro series scanners.

The Shining 3D EinScan solutions are a powerful versatile tool that can be successfully employed in a great number of industries from aerospace to entertainment. Due to the constant development of 3D digitizing technologies, a lot of tasks that seemed impossible not long ago can now be performed easily and efficiently, opening up new opportunities for designers and engineers.

Update your browser to view this website correctly. Update my browser now

Write a comment