The possibilities of modern 3D printers and CNC machining centers are truly infinite. However, the fabrication of this or that 3D-printed detail always starts with creating an appropriate 3D model. There are two different ways of how engineers can get the required detail from a workpiece or manufacture it on a 3D printer: to develop a model from scratch using some three-dimensional simulator or to take advantage of 3D scanning and obtain a model of an already existing object in order to edit it and use in a desired way.

In this article, we will tell you about 3D scanning as well as devices and software through which you can get quality 3D models.

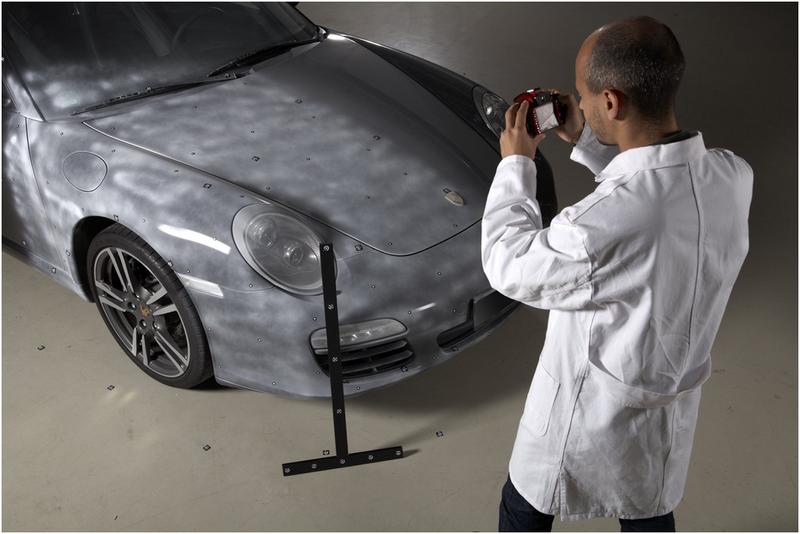

So, 3D scanners allow for getting a three-dimensional model of this or that object. Quite often, 3D scanning proves to be the quickest and easiest way to obtain a model, and sometimes – it’s the only possible way. For instance, there is no more reliable way to develop a model of some work of art other than applying 3D scanning. And if you need a more weighty argument and a real-life example, then here it is: 3D scanning is used for the defect finding automation and the parts dimension control in the automotive and aviation industries.

Interested to know about a more common, everyday use of 3D scanning? Alright, just think about 3D printing of customized footwear that allows for creating shoes based on the foot anatomic features of each specific customer.

In order to convert the spatial characteristics of some object to a three-dimensional model, it makes sense using one of the available technologies for 3D scanning. There are the following types of 3D scanning:

This 3D scanning technology allows you to design models of objects based on multiple pictures taken at different angles. The more pictures are taken – the more detailed and precise the resulting 3D model will be. Since the given method is founded on the mathematical algorithm that calculates the position of points in space by evaluating their mutual disposition depending on the illumination and the depth of field in different pictures, the best results are achieved by using cameras with fixed-focus lens and provided that there is equal distance to the object, when shooting pictures in motion, circle-wise.

The main allure behind this method is that it provides for obtaining fairly good results even when there is only a standard smartphone camera at hand. Learn more about 3D scanning with the help of a smartphone camera in this comprehensive review.

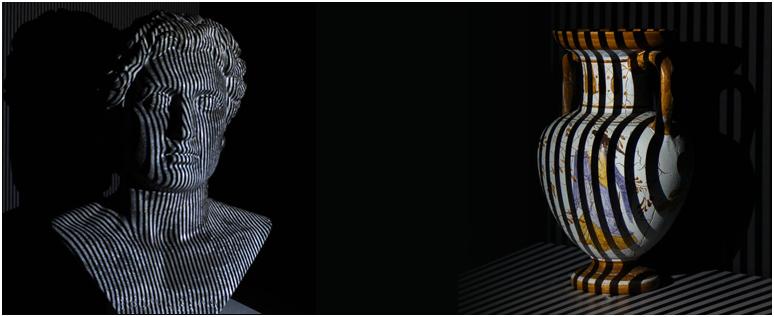

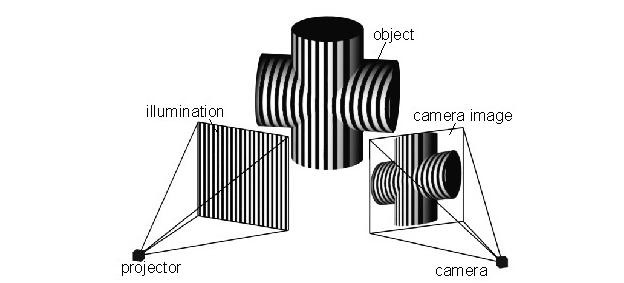

This 3D scanning approach is based on the power of reflected structured light. This method requires special equipment that is designed on the principle of projecting the light net onto the object to be scanned. Then a special camera scans the distortion of the light net on the object, which ultimately allows for getting a highly accurate representation of the object’s form.

What is more, this method provides for getting 3D models very quickly because only a few camera images are required to get initial information about the object’s surface. An alternative variant involves the use of a light beam with a variable wavelength – in this case, it becomes possible to completely exclude the impact of the existing illumination and get a holistic presentation about the shape of the scanned object.

This 3D scanning method is a bit slower compared to the one mentioned above, though in some cases, it proves to be the most adequate way to get the necessary information about an object under scanning. This approach is generally used in defectoscopy, since it allows for getting data about the presence and structure even of the tiniest pores, which is dramatically important in the production of the high-load structural components or complicated moldings such as engine cylinder heads. There are several variations of this method.

Trigonometric laser scanners measure the shifting of a reflected beam that passed through a special lens while time-of-flight cameras concoct the surface of the scanned detail based on the alteration of the return delay of the reflected laser pulse.

Mechanical 3D scanning is considered extremely slow, yet the most precise. It is the first of the existing methods for checking linear dimensions, and it is implemented in mass production in the form of CMM — coordinate measurement machines.

Mechanical scanning is accomplished by a probe that literary touches the detail in all directions. This method is not suitable for working with soft, porous, elastic, and insufficiently hard objects.

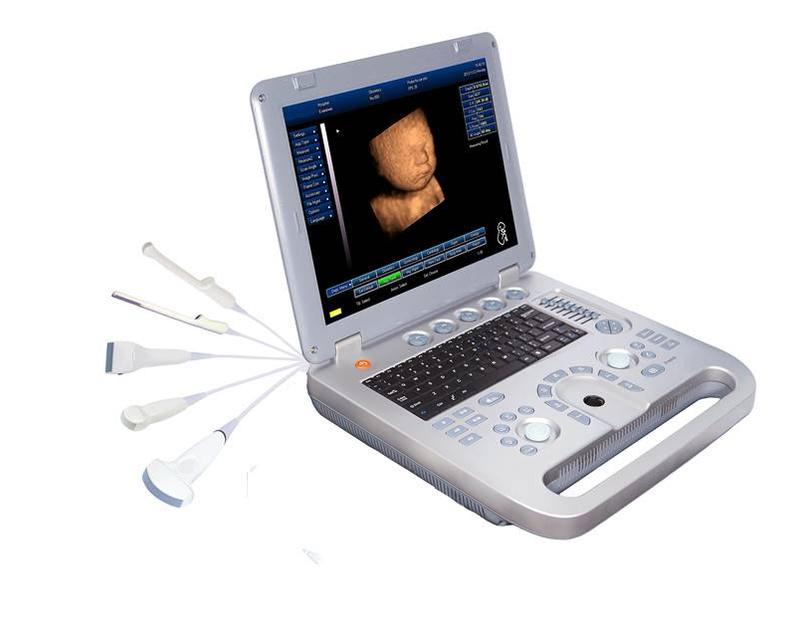

Ultrasonic scanning is widely used in medicine, namely, in ultrasound machines as well as in the river and sea businesses, precisely, in the fishery. Both modern echo depth sounders and ultrasound investigation devices present a particular case of a sound 3D scanner – a device that sends out ultrasound to the environment being studied; the device’s microphones then catch the reflected signal while a computer creates a three-dimensional model based on the received data.

Unlike the above-mentioned methods, ultrasonic 3D scanning is not widely used in the manufacturing industry. However, it is put to good use in defectoscopy to detect cavities and hollows inside manufactured objects. But it is a large and complicated topic, so we will not speak much about this 3D scanning method in this review.

The most popular 3D scanning method ever

From all the techniques mentioned earlier, photogrammetric mapping is the most popular and widely-spread method of 3D scanning because it allows you to turn your Android smartphone into a real 3D scanner, provided your mobile device is equipped with a decent camera.

When using non-professional equipment such as a smartphone camera, 3D scanning with photogrammetric mapping is generally carried out for entertainment purposes. However, if one uses a professional camera when scanning through photogrammetry, the obtained results can suit well for practical implementation, for instance, for the creation of top-quality 3D models for movies and computer games, for the restoration of antique items or the reproduction of pieces of art.

Also (and it was its initial application), photogrammetric mapping is heavily used in cartography, geodesy, construction, and architecture.

Various methods of laser scanning, along with structured light scanning, are also quite popular in different branches of science and manufacturing industry.

Mechanical and ultrasonic scanning methods are also used, but they don’t boast the same popularity as photogrammetric mapping.

There is a rich selection of specialized 3D scanner programs – from non-professional ones designed for smartphones and amateur cameras to sophisticated, industry-scale and universal solutions that allow for the creation of extremely precise 3D models. Below you will see an overview of the most functional programs for 3D scanners.

In this section, we will speak only about professional software for 3d scanners by different developers. The possibilities of these software solutions are striking, but the price of these programs is impressive, too.

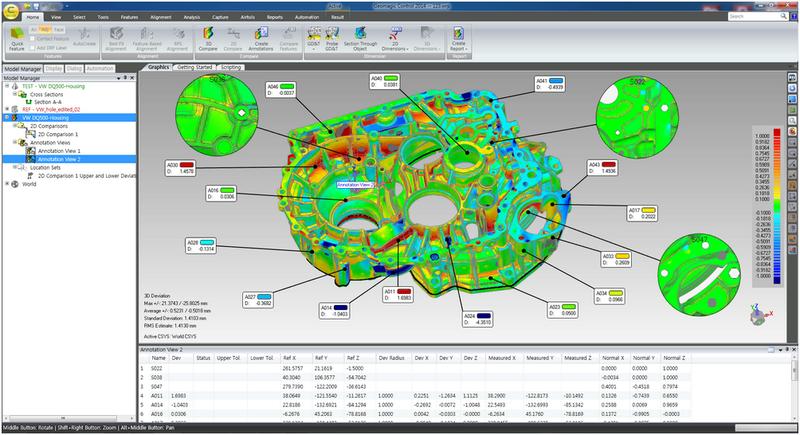

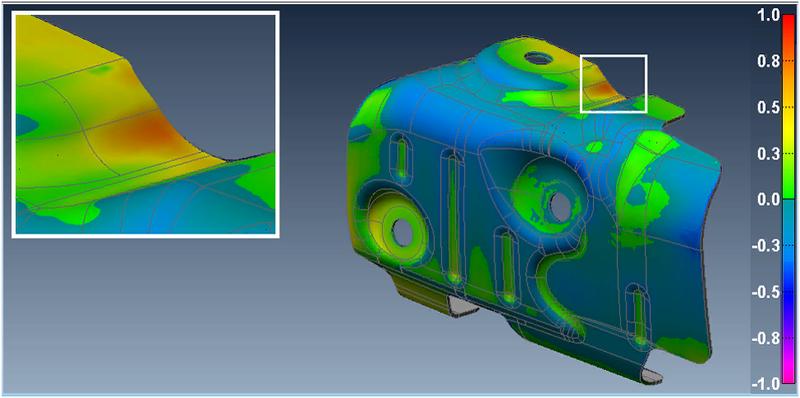

This software product is claimed by developers to be the most optimal solution to carry out surface defectoscopy and control the linear dimensions of various parts.

The given software allows you to set dimensions and permissible tolerance for literally every plane, which means that in mass production, quality control will take considerably less time: it is just enough to set up the measurement algorithm once only. In assembly plants, Geomagic Control X can be used to identify defects in details delivered by the suppliers.

But the abilities of this software are not limited to just control. Geomagic Control X works in conjunction with CAD and can be used to calculate thermal alterations, to estimate dimensional changes after casting and in other manufacturing processes. Thanks to such functionality, it is possible to adjust the initial model, reducing possible defect costs before the part goes into production.

And finally, this software product for 3D scanning can be used to evaluate wear and tear as surely as to identify defects in already exploited parts. Algorithms of Geomagic Control X allow for tracking changes in the object’s geometry that inevitably occur over time, which allows you to detect a number of unforeseen issues and promptly take corrective measures. Conducting a trend analysis and compilation of detailed reports in the program itself allows for predicting the malfunction of the investigated detail or tool.

Learn more about the essential features of the Geomagic Control X software for 3D scanning in this video:

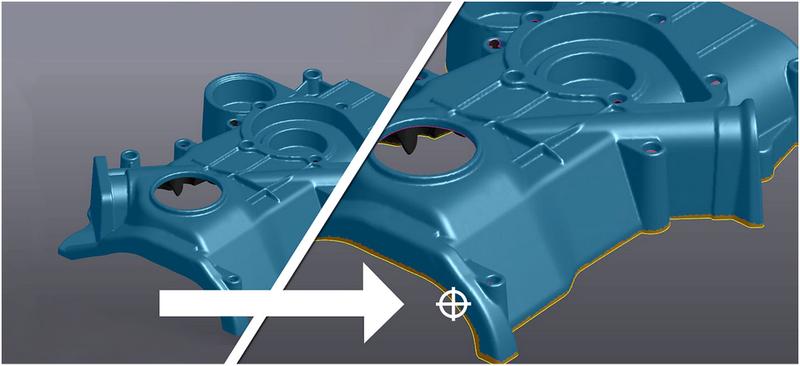

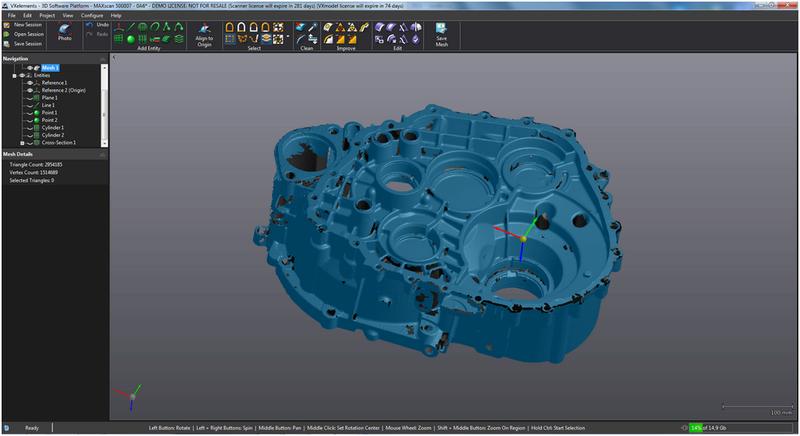

The Creaform Company offers a comprehensive software package that includes several programs for 3D scanning and working with models, each having different functionality and field of application. Most users will be especially interested in VXmodel software, which offers a galore of great capabilities for scanning and transferring the processed results to CAD systems.

The software itself ensures the elimination of most scanning defects and allows you to align and combine the edges of the model, fill hollows and reduce the grid density, removing unnecessary points. Moreover, VXmodel provides for compiling multiple scan results into one model, which is very useful when scanning large objects.

Advanced features of automatic and manual creation of curves and surfaces, as well as easy export of work results to Solid Works and Autodesk Inventor, make this software almost indispensable for those who have to scan much and simultaneously clear models of errors.

Here is a short video describing the main features of the VXmodel program for 3d scanning:

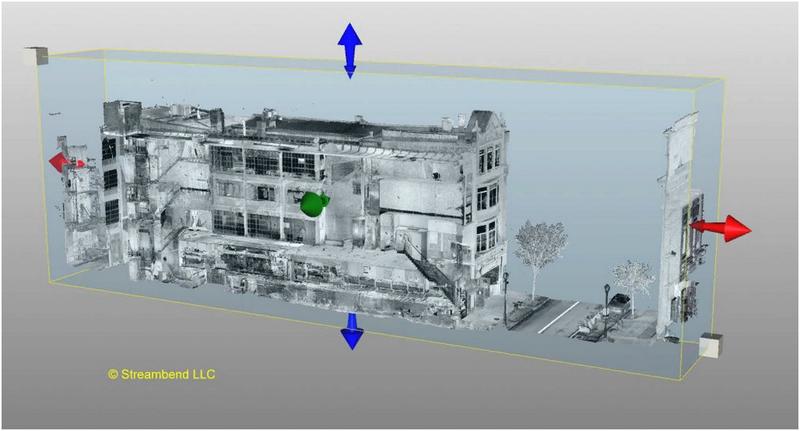

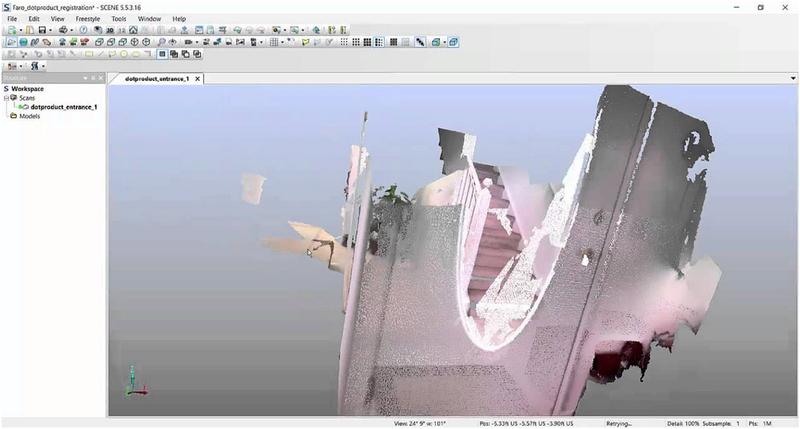

FARO® is a top-tier manufacturer of 3D scanners that offers proprietary solutions for processing point clouds collected with the help of the given devices. The application is compatible both with the brand-name devices and the majority of third-party 3D scanners.

The most remarkable feature of this program for 3D scanners is an extremely high level of visualization, as well as the opportunity to view results in the VR environment. On top of that, the ability to automatically overlay a photo image on the resulting model provides for obtaining scans that contain information about the color of the object.

While scanning, the user receives information about the already collected points as well as about the progress of the model construction in a real-time mode. This solution allows you to save a lot of time: the scanning process can be paused in any moment, if something goes wrong, and easily resumed.

From this video, you can learn about the principle of using Faro 3D scanner and SCENE program for creating 3D plans of premises and facades in architecture:

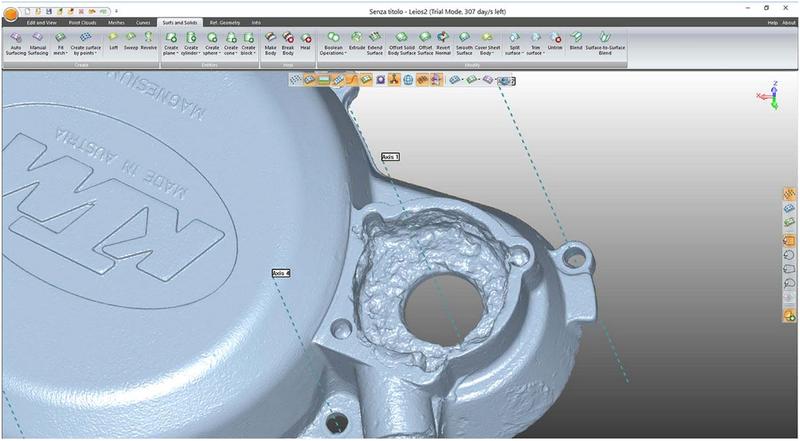

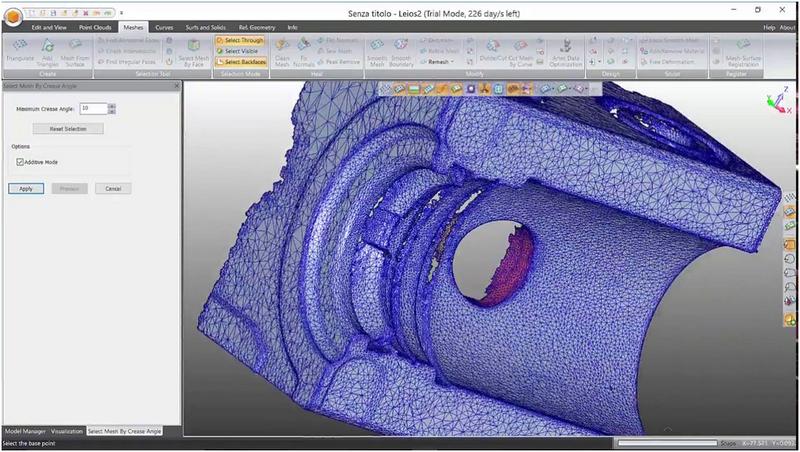

Yet another comprehensive 3D scanning software for a wide variety of industries is offered by EG Solutions. The program for 3D scanning called Leios 2 got three modifications: For Makers – for experienced makers, Premium – comes with advanced functionality and Professional – for industrial application. The program’s functionality allows you to receive a point cloud from scanners, compile three-dimensional models based on the provided data and make corrections, including the use of automatic algorithms for processing curves and surfaces.

Leios 2 for Makers allows you to perform a full range of works with three-dimensional models, such as to smooth uneven areas, to carry out deformation in relation to control points, as well as to conduct optimization and restoration of the damaged edges on the net which is crucially important when modeling different details and equipment.

There is also a library package for scanning and post-processing of three-dimensional models. This program product can also be partially or completely integrated into the software of other manufacturers. The company supplies a full software package that comprises:

SFLib: a library to work with surfaces. It allows you to automate the process of identification of associated uncut surfaces. This library automatically accomplishes surface fitting, distributes NURBS patches and adjusts them to the net.

LEOS helps you recognize ribs and objects. The main features include the automation of work with curves on a triangular grid, their segmentation, and automatic rearrangement.

LMModel is designed to work with models. This component allows you to combine several scanning results and even different models into one document.

LMPython can be used to access the functionality of any supplied library and write your own procedures in the Python programming language.

LMViewGL: a visualization library that is supplied both in the form of a ready-to-integrate component and as an individual application.

Additionally, the developers of this software pay great attention to the issues of compatibility with various models of 3d scanners while a simplified, user-friendly interface allows you to focus on a prototyping process without being distracted by the routine chores of corrections.

Here is a short video demonstrating the processing of a small figure through Leios 2 for Makers:

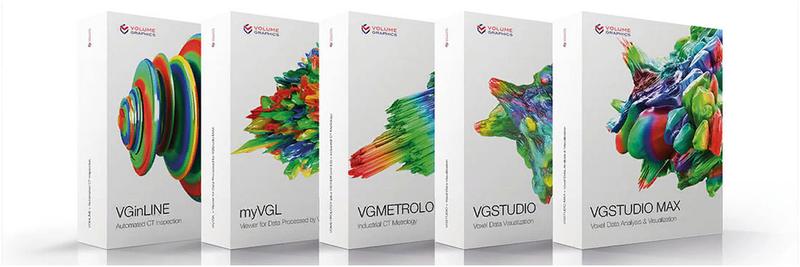

Volumegraphics Company offers a broad range of software tools for 3D scanning, which allows for accomplishing different tasks – from design to mass production. It should be noted that thanks to the implementation of the most advanced post-processing algorithms, it is possible to achieve excellent results and bring models of any scale to perfection.

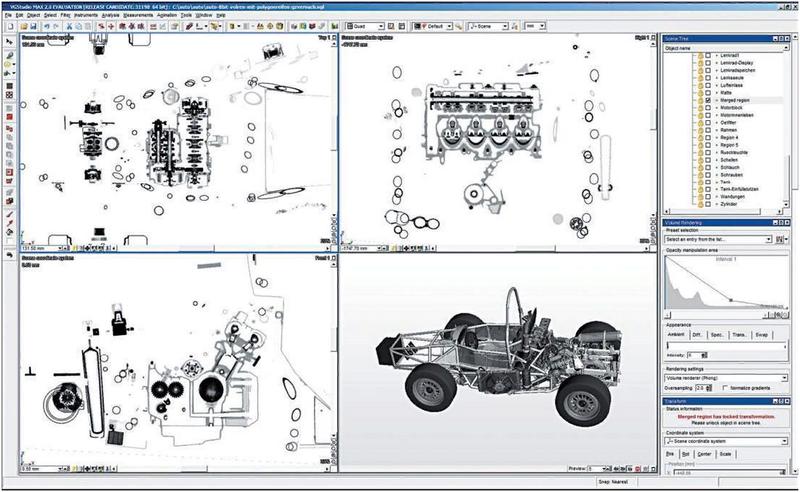

Volumegraphics offers a proprietary comprehensive design technology called CT. However, the manufacturer also supports other types of 3D data – a point cloud, grid and CAD formats. The most sophisticated software package, VGSTUDIO MAX, allows you to solve almost all existing control problems related to metrology, detection, and evaluation of defects, properties of materials or modeling.

The instruments of analysis, modeling, and visualization as well as the ability to automate control operations will be especially useful for the realization of large projects and mass production.

Even the basic version comes with modules using which, you can process the results of scanning (CT Reconstruction), analyze and correct the geometry of the model including wall thickness (Geometry Analysis group), and conduct the defect finding using modules of the Material Analysis group (support not only metals but also composites and even products from lightweight materials).

The basic version is also loaded with the Simulation module through which, you can simulate various loads – not only mechanical but also the impact of different liquids, electric current, heating and diffusion (applicable for porous materials, as well).

Watch a short video explaining the main features of the VGSTUDIO MAX 3.3 package:

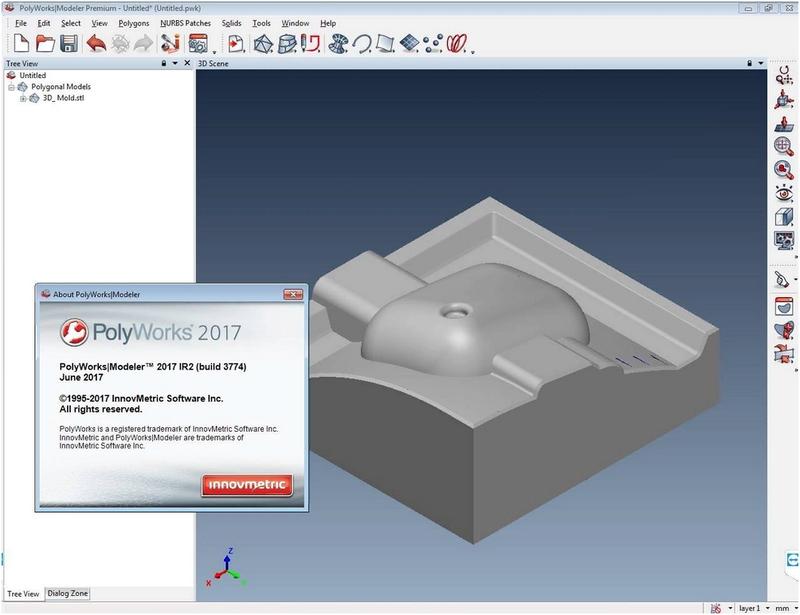

This developer also offers a decent assortment of customized solutions for designing and reverse engineering. For example, PolyWorks Modeler provides for working with any scan results even if they contain a great number of points, while PolyWorks Inspector allows you to automate quality control and flaw detection operations, as well as to significantly simplify and accelerate any other operations related to metrology in different industries with different volume of production.

If your task is obtaining models from the results of 3D scanning and editing them afterward to match your precise needs, then PolyWorks Modeler will be the best choice for you. As in other similar programs, the work in PolyWorks Modeler begins by combining multiple points into polygonal models. But the full potential of this application is unleashed when you edit NURBS surfaces obtained after processing the scan results. The used algorithms allow you to automatically arrange the curves to achieve the best results and to form a continuous smooth surface of the model consisting of many NURBS.

This software product also supports the functionality of modeling three-dimensional details from 2D drawings, which helps to considerably reduce the preparation time of 3D models. It is possible to send the result to CAD systems through the format export at any stage of the work, while drawings (and models) can easily be combined with each other based on a unified size system.

Watch a short video devoted to the PolyWorks program:

All 3D scanning programs mentioned above are designed for working with 3D scanners, however, it is also possible to concoct models using photography equipment.

The software we are going to speak about now is based on the methods of photogrammetric mapping that uses photographs to create three-dimensional digital objects. In fact, it is possible to use any camera or smartphone camera, turning your mobile device into a personal 3D scanner, which you can always take with you.

In the image above, you see an example of a complex solution for such a type of scanning - the Aicon Scanreference set, consisting of a camera, special tools for boosting the accuracy of image compilation, and the software itself. This is a professional, all-in-one solution with special software.

In this section of our review, we will also mention applications that are used for processing images and never fail to produce excellent results.

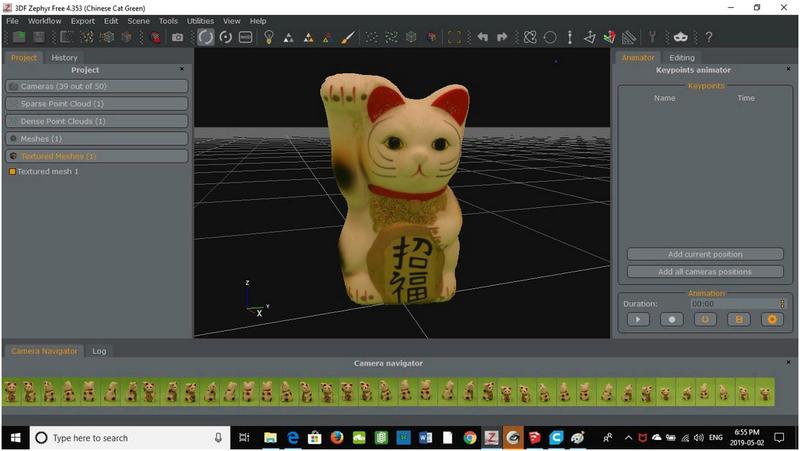

The brainchild of the 3DFlow Company is free for private use and supports the upload of up to 50 photos per project. Usually, this amount of photographs is pretty enough to get a model without a necessity to buy a paid license.

The main features supported by this program are the creation of a model based on photographs, the adjustment of edges and surfaces, the upload of the result in various formats of CAD systems. The solution also allows you to create animations, as well as record videos and automatically upload the results to Youtube. The process of editing models is maximally simplified and supports working with masks, which allows you to accelerate the processing.

Another benefit of this program is a nifty training section on the software’s official website as well as a well-organized forum and vibrant community.

Here is a video of how a model is being processed in 3DF Zephyr Free, a program for 3D scanning by photographs:

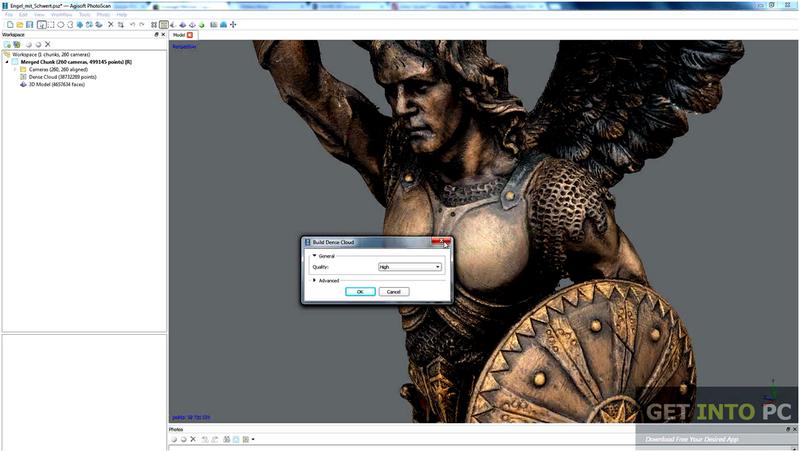

Agisoft PhotoScan portrays itself as a pro-grade solution for creating 3D models using photogrammetric methods. What it involves is not only reverse engineering and other options for using models in production, but also the development of AR and VR solutions for computer games, video, and motion picture industry.

The primary virtue of PhotoScan stems from its ability to ensure an exceptionally high level of detail of the resulting models. It is achieved thanks to the use of special algorithms for processing the scanned results and the absence of any restrictions on the resolution of processed images as well as their number. The possibility to use markers can also dramatically improve the final result.

A video demonstrating the main competencies of this program:

The abovementioned software for creating 3D models requires uploading photographs and runs on the desktop, but modern smartphones are powerful enough to perform similar operations, so making a 3D scanner from an Android smartphone is very easy – just download one of these applications.

This application is more suitable for entertainment purposes. However, the models derived from such a mobile 3D scanner can also be put to good use. This means that this solution will be helpful for owners of 3D printers and CNC milling machines.

Sony 3D Creator is available for free. Users can upload their models to the Sony cloud for post-processing and improving the quality.

Video presentation of this application:

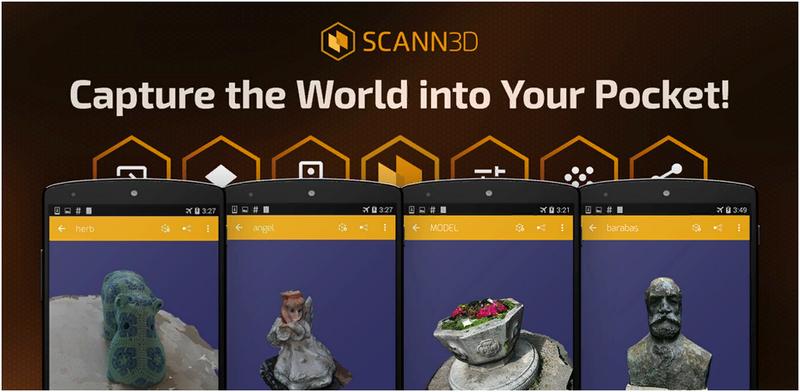

It is another application that delivers decent results while 3D scanning with a smartphone camera. What sets this product apart from the previous one is a paid subscription for upgrading to the Pro-version, which removes restrictions on the quantity of uploaded STL-files.

The general principle of operation is, however, similar to the mentioned above: you will need several dozens of photo images taken at different angles and under even illumination to create a three-dimensional model of the desired object.

Though there are some technical issues with this software for smartphone 3D scanning (for instance, the app may crash at the stage of image processing in certain smartphone models), the scan results are pretty good, while the ability to further edit the STL file in CAD systems allows you to eliminate minor flaws.

The video below demonstrates the abilities of this app for mobile 3d scanning:

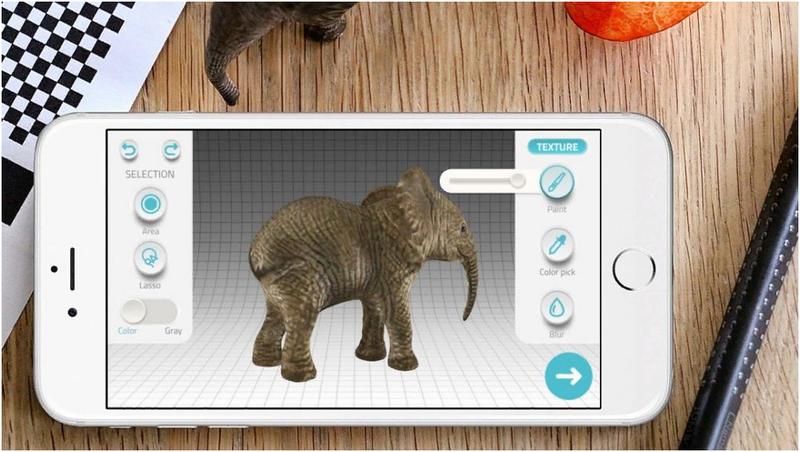

This application allows for getting top-quality models using a special pad – a printable grid. This grid helps the program to distinguish the model from other environments and to recognize this or that edge of the object on each image. When shooting, the program recognizes the presence of the pad and the disposition of the object on it, covering the not yet taken parts with a hemisphere, the sectors of which become transparent when the necessary image has already been taken.

Video, GIF animations, and screenshots with the resulting model can be saved for free, but exporting the model is possible only for money (about $1.2).

Thanks to a unique feature – the presence of a built-in position control system in the form of a foundation grid – this 3D scanner for Android expectedly produces the best-in-breed results.

Qlone can be found in Play Market and iOS App virtual stores. A nice bonus will be the ability to automatically animate the resulting models.

Watch a video presenting the main features of this application:

“Apple” phones are loaded with powerful cameras that always ensure an excellent quality of shooting and good shot depth, which is achieved through the use of special algorithms for working with a dual (and triple) camera. Some 3D scanner apps for iPhone devices are presented below.

It is a user-friendly application for iOS devices with True Depth cameras, which allows you to create three-dimensional models very quickly. Just launch this 3D scanner on an iPhone device to see for yourself a fairly high speed of the scanner’s performance and a sufficiently high level of detailization of the resulting models.

The application works great with all cameras an iPhone is equipped with; it also supports model export, while automatic smoothing algorithms allow you to get even surfaces that require only minor post-processing.

This video shows you how this app works:

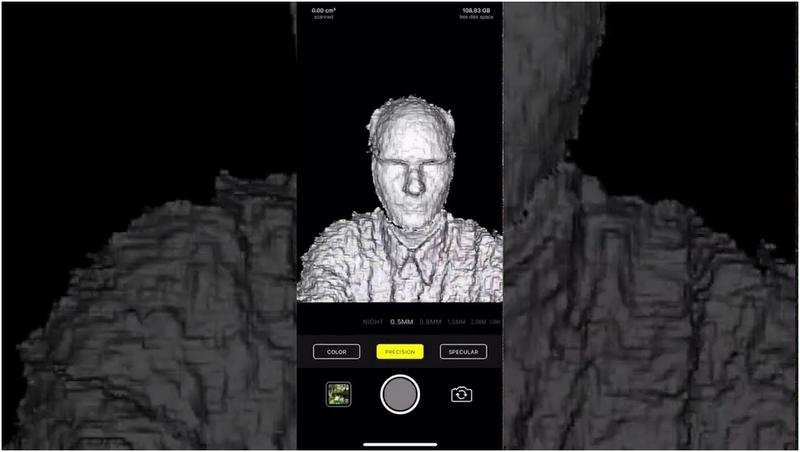

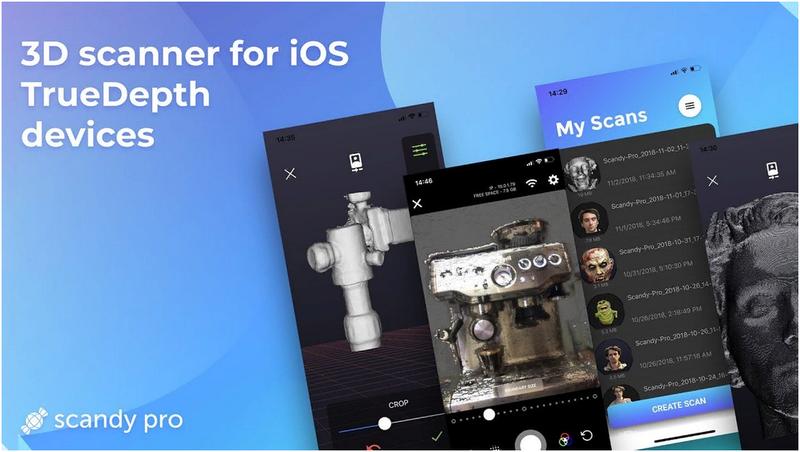

ScandyPro app also works only on devices that support TrueDepth technology. Unlike Heges, ScandyPro ensures a more detailed level of processing of the scanned results on the developer's servers (this feature is provided in a form of a paid subscription that will cost you $6 per month).

Moreover, you have at your disposal a library of ready-to-use models, the ability to easily export models to CAD formats as well as several scanning options each of which differently accommodates to the actual illumination at the shooting location.

A video demonstrating the performance of this application:

The choice of a program for 3D scanning is always determined by the array of tasks that should be solved through this software. If to speak about manufacturing, it is better to opt for one of the packages that, apart from everything else, supports defect identification and non-destructive testing. However, departments that solve problems associated, for example, with reverse engineering, this functionality might be unnecessary.

Now let’s sum up the programs we recommend for the highest quality:

The segment of non-professional 3D scanning programs, in which a 3D scanner from a smartphone or a camera is often the only affordable 3D scanning method for the average user, heavily depends on the characteristics of the available equipment.

It is worth considering that developers apply various photogrammetry processing algorithms, and these algorithms do not always adequately correspond to the performance of a particular mobile device, and the only way to choose a mobile application that will allow you to get the best results is to try as many options as possible.

It is not possible to identify the ideal combination of “device + application”, only because there are hundreds of mobile device manufacturers, and they all try to equip their smartphone cameras with unique features and use different internal algorithms to process the shooting results.

Whatever tasks you plan to solve with the help of 3D scanning programs, it never hurts to ask professionals for expert advice.

Contact Top 3D Shop, and we will find the most suitable 3D scanning software for your unique goals and requirements.

Update your browser to view this website correctly. Update my browser now

Write a comment