Multi-purpose handheld 3D scanners ScanTech HSCAN are the most affordable devices in the manufacturer’s lineup. But they still manage to meet high standards, usually expected by ScanTech products. They can quickly and precisely get a 3D image of an object. For example, they can be utilized for scanning a car's body or a small coin.

Read the review to learn about the pros and capabilities of ScanTech HSCAN professional 3D scanners.

ScanTech is a 3D scanner R&D and manufacturing company with headquarters in Hangzhou, China. Their products are exclusively professionally-oriented devices. Their 2020 lineup includes various solutions for different segments: from compact handheld models to automated robotic scanners AutoScan-SOLO.

Source: facebook.com

Professional 3D scanners by ScanTech are used by globally known brands such as Volkswagen, Boeing, and Siemens.

Source: 3d-scantech.com

|

HSCAN331 |

HSCAN771 |

|

|

Laser source |

3 crossed red lasers (+1 extra laser) |

7 crossed red lasers (+1 extra laser) |

|

Measurements per second |

265,000 |

480,000 |

|

Resolution |

0.05 mm |

0.05 mm |

|

Accuracy |

0.03 mm |

0.03 mm |

|

Volumetric accuracy |

0.08 mm/m |

0.06 mm/m |

|

Scanning area |

225 x 250 mm |

275 x 250 mm |

|

Depth of field |

250 |

250 |

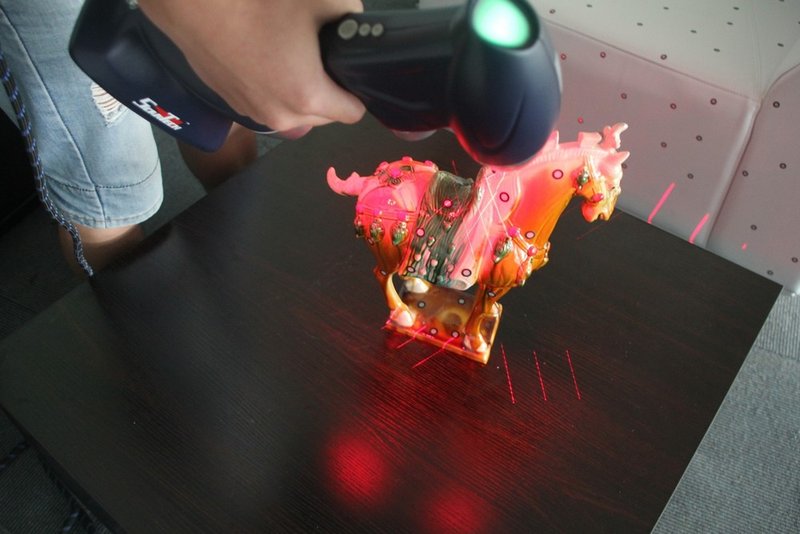

Professional handheld 3D scanners ScanTech HSCAN are modern high-quality pieces of equipment. They are designed to quickly work with the objects of various sizes. Accuracy and speed of the devices allow them to scan machinery and art objects, thus making the ScanTech HSCAN scanners a good choice for various purposes.

The ScanTech HSCAN series has key advantages over more expensive products of the brand. These 3D scanners can work with dark and glossy surfaces, and the latter don’t have to be covered with spray. It’s enough to place marking points over the object if it’s medium-sized. But for working with the large-sized objects (for example, cars) it’s recommended to use a proprietary photogrammetry system named MSCAN to improve volumetric accuracy.

Source: 3d-scantech.com

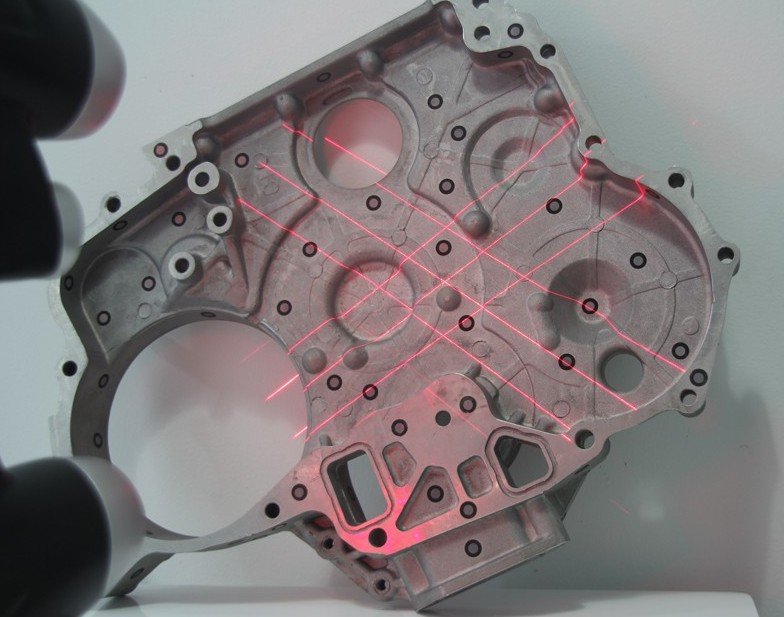

The ScanTech HSCAN 3D scanners use red lasers to get the information about the objects. The HSCAN331 uses 3 crossed lasers, while the HSCAN771 — uses 7. The surface illuminated by the lasers gets scanned by a high-quality optical system. To get a detailed scan of holes and deep elements the HSCAN series uses a one-line mode. It reduces the speed of scanning but allows the users to get a more accurate result.

Source: 3d-scantech.com

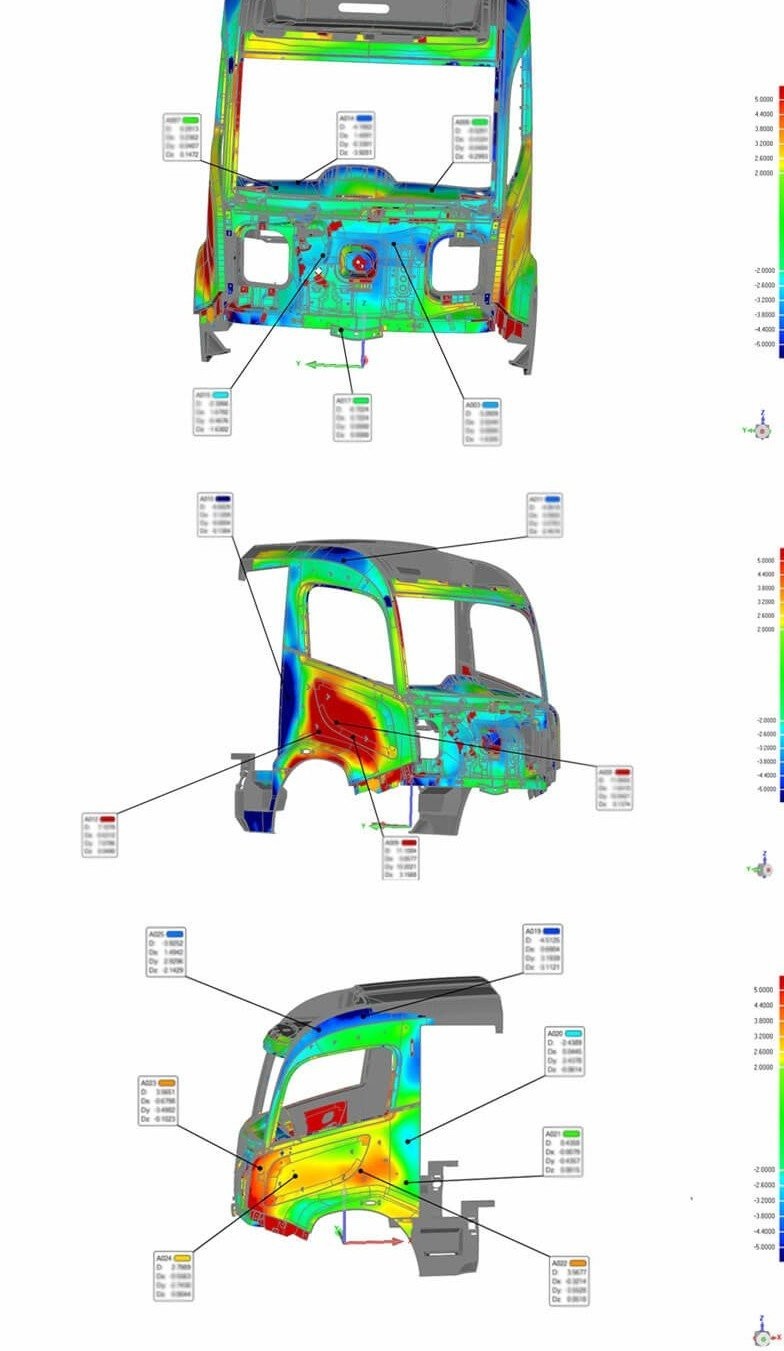

The accuracy of 3D models meets the requirements of various industries. The professional 3D scanners have high volumetric accuracy: up to 0.06 mm/m in the case of the HSCAN771. The ScanTech HSCAN 3D scanners are used for:

Source: 3d-scantech.com

The packages of the ScanTech HSCAN series and more expensive models are similar: there’s a rigid case for storing and transportation, calibration board, power cable, as well as the one for PC connection, electric adapter, 4000 reflective marking points and 2 reference bars.

Source: 3d-scantech.com

Preparing the ScanTech HSCAN devices for scanning is a rather simple process. The first thing to do is to connect the scanner to the PC that has a proprietary ScanViewer 3D Software installed. After that, the calibration process needs to be started (it will take around a minute), while the object will be covered with reflective marking points.

Source: 3d-scantech.com

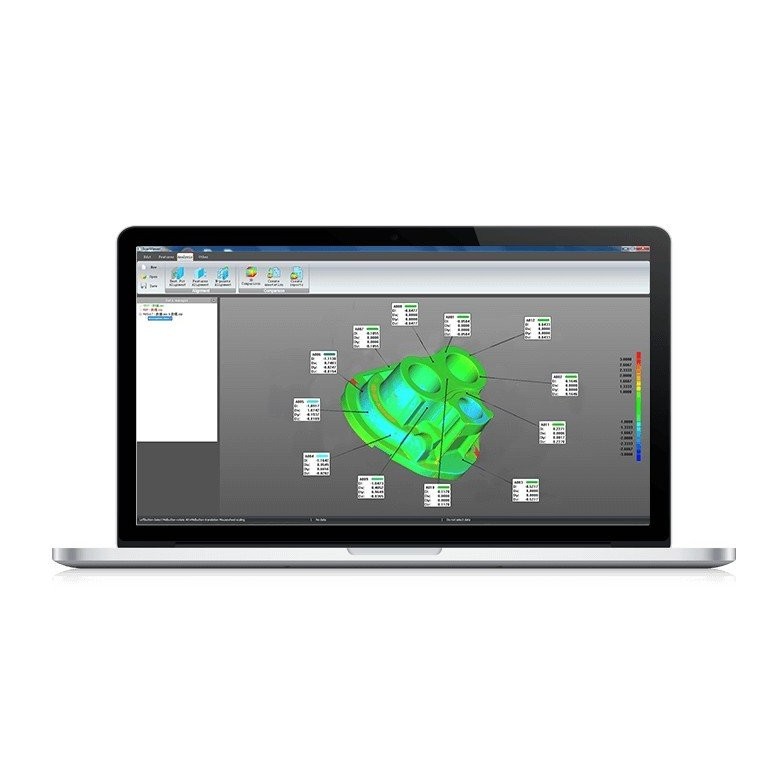

ScanViewer 3D Software is used for working with ScanTech devices. The program features a convenient interface available only in English. It allows users to inspect the scan, create a color map of an object, and to do some basic processing of the final scan. ScanViewer 3D Software can also merge several scans into a single 3D model.

Source: 3d-scantech.com

A car manufacturer has found out that parts of a car weren’t assembled with enough accuracy during development. Since some parts are made of plastic, finding the imperfections isn’t simple. The HSCAN331 3D scanner was used to detect the stress points.

Working time:

Source: 3d-scantech.com

Source: 3d-scantech.com

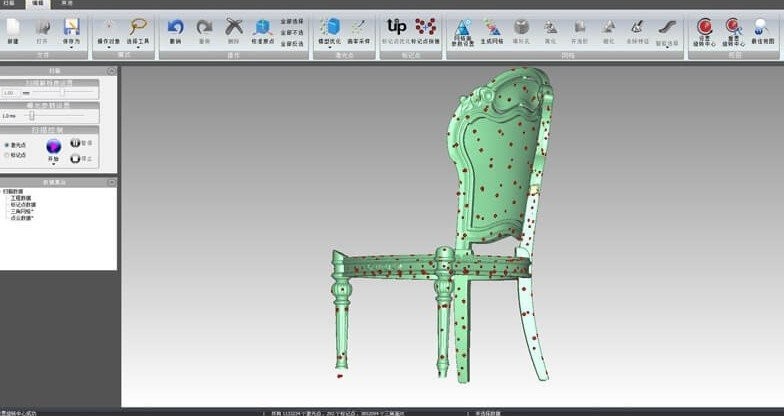

Solid wood furniture manufacturer has decided to automate the process. The scan requirement was to get an accurate set of 3D data of carving and furniture shape to allow the automation to reach the level of an experienced old carpenter. The solution: Scantech used the HSCAN331 3D scanner. The device scanned the furniture and got digital data that allowed for the creation of high-accuracy 3D drawings. The information can be used to automate the manufacturing process.

Source: 3d-scantech.com

Working time:

Source: shining3d.com

Shining 3D FreeScan X5 — is another Chinese 3D Scanner that is very close to the ScanTech HSCAN771 in its specs and abilities. It’s a multi-purpose handheld 3D scanner for professional use. It’s recommended to use the photogrammetry system named DigiMetric to improve volumetric accuracy. When choosing between two models, it’s important to keep in mind that the ScanTech device is slightly more accurate while the speed of scanning is similar in both devices.

Compare the main specifications:

|

ScanTech HSCAN771 |

Shining 3D FreeScan X5 |

|

|

Laser source |

7 crossed red lasers (+1 extra laser) |

10 crossed red lasers |

|

Measurements per second |

480,000 |

350,000 |

|

Resolution |

0.05 mm |

0.1 mm |

|

Accuracy |

0.03 mm |

0.03 mm |

|

Volumetric accuracy |

0.06 mm/m |

0.08 mm/m |

|

Scanning area |

275 x 250 mm |

300 x 250 mm |

|

Scanning area (photogrammetry) |

No |

No |

|

Depth of field |

250 mm |

250 mm |

Let’s summarize the pros and cons of the ScanTech HSCAN series.

Pros:

Cons:

The ScanTech HSCAN 3D scanners have similar capabilities to higher-end models but are much more affordable. Two main differences between the series and top of the line models are a simpler light module and less accurate results. Another thing to consider is the lack of built-in photogrammetry, so the larger objects must be scanned with additional equipment. But the scanners do a good job working with human-sized objects.

Update your browser to view this website correctly. Update my browser now

Write a comment