ScanTech is a Chinese company that has been at the forefront of research and development of handheld 3D scanners. Many years of cultivation led to the rise of technologies that are getting more advanced with each generation while covering a wide range of industrial and professional applications. This has brought ScanTech worldwide popularity alongside partnership with famous enterprises and research institutions like NASA, COMAC, BMW, Volkswagen, GM, Apple, Siemens, JCB, and Sany.

To date, the company produces various types of 3D devices with related software, from consumer-grade color 3D scanners to automated measurement stations. In today’s article, we’d like to take a look at ScanTech’s portable 3D systems represented by several prominent series.

ScanTech portable 3D scanning solutions meet the modern need for flexibility and high precision. The company’s handheld 3D scanners are capable of high-quality measuring of tough-to-reach and complex geometrical features with remarkable precision, speed, reliability, and design flexibility.

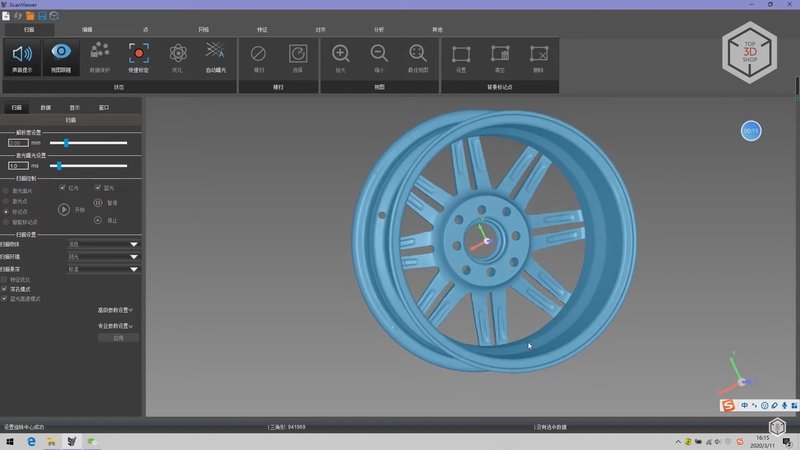

All scanners come with the proprietary ScanViewer software, which is optimized to work with ScanTech products. They can be successfully applied for dimensional measurements, inspection, reverse engineering, quality control, 3D printing, art preservation, and more.

Before we delve into separate product series, here is a short summary table based on the main characteristics of the most prominent ScanTech portable 3D systems:

|

KSCAN-Magic I/II |

SIMSCAN |

AXE-B11/17 |

TrackScan-P42 |

iReal 2E |

MSCAN-L15 |

|

|

Equipment type |

Handheld 3D scanner |

Handheld 3D scanner |

Handheld 3D scanner |

Handheld / Desktop 3D scanner |

Handheld, color 3D scanner |

Industrial camera and lens (not DSLR) |

|

Technology |

Infrared + Blue laser (Class II) |

Blue laser (Class II) |

Blue laser (Class II) + Photogrammetry |

Laser + Tracking |

IR, VCSEL |

Photogrammetry |

|

Accuracy |

Up to 20 microns |

Up to 20 microns |

Up to 20 microns |

Up to 25 microns |

Up to 100 microns |

— |

|

Resolution |

0.01 mm |

0.02 mm |

0.025 mm |

0.02 mm |

Up to 0.2 mm |

— |

|

Volumetric accuracy |

Up to 0.015 mm + 0.03 mm/m |

Up to 0.015 mm + 0.035 mm/m |

0.02 mm + 0.035 mm/m / 0.02 mm + 0.03 mm/m |

From 0.044 mm |

N/A |

0.012 mm/m + depending on the scanner used |

|

Scan speed |

Up to 1.35/1.65 mt/s |

Up to 2.8 mt/s |

Up to 1.3/2 mt/s |

1.9 mt/s |

Up to 1.5 mt/s |

— |

|

Scan area |

Up to 1440 x 860 mm |

Up to 700 x 600 mm |

Up to 550 x 600 / 860 x 600 mm |

Up to 500 x 600 mm |

Up to 580 x 550 mm |

— |

|

Scan depth of field |

925 mm |

550 mm |

500 mm |

Up to 320 mm |

750 mm |

— |

|

Photogrammetry scan area |

3760 x 3150 mm |

— |

2500 x 3000 / 3760 x 3150 mm |

— |

— |

Up to 9.4 x 6.9 m |

|

Photogrammetry depth of field |

2500 mm |

— |

2500 mm |

— |

— |

6.5 m |

|

Working distance |

300 mm |

300 mm |

300 mm |

300 mm |

300–500 mm |

— |

|

Connectivity |

USB 3.0 |

USB 3.0 |

USB 3.0 |

USB 3.0 |

USB 3.0 |

— |

|

Dimensions |

203 x 80 x 44 mm |

203 x 80 x 44 mm |

190 x 98 x 289 mm |

280 x 200 x 60 mm |

140 x 94 x 258 mm |

N/A |

|

Weight |

570 g |

570 g |

1 kg |

1.1 kg |

850 g |

580 g |

KSCAN is a series of metrology-grade professional 3D scanners including such models as KSCAN20 and KSCAN-Magic available in two versions. All of them represent hybrid digitizing devices that combine infrared and blue laser scanning technology while providing wide scan volume and increased volumetric accuracy. Portable and efficient, KSCAN scanners offer both high-efficiency fast 3D scanning and high-precision data capturing.

Being a newer model, the KSCAN-Magic is of particular interest. Alongside its advanced counterpart Magic II, the device supports five operating modes for different purposes. When scanning at high speed, ScanTech recommends using a grid of crossed blue laser lines, with 11 x 11 lines for the base model and 13 x 13 in the Magic II model. 7 parallel blue laser lines are projected in high-precision mode with a resolution of up to 10 microns. A single laser line is used when scanning deep holes and dead angles. Finally, 11 parallel infrared laser lines are recommended for capturing large surfaces.

In addition, the scanners are equipped with a built-in photogrammetry system for digitizing large objects with a diagonal of up to 10 m. This mode is used to minimize accumulated error.

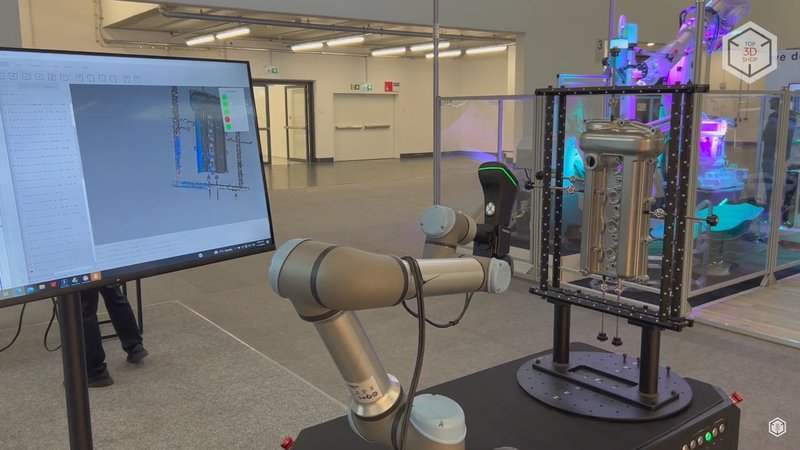

Additionally, the ScanTech KSCAN-Magic can be installed on robotic arms for automated measurement and control, which allows integrating the system into a conveyor-based production environment.

As for the application spheres, KSCAN devices are recommended primarily for professionals in the field of reverse engineering and product inspection. Overall, these 3D scanners can be of use in various areas, including automotive, aerospace, mechanical engineering, oil and gas industries, etc.

The ScanTech SIMSCAN is a professional high-resolution handheld 3D scanner that offers an outstanding acquisition speed in combination with high accuracy data capturing.

The SIMSCAN 3D scanner is an extremely compact device for digitizing objects with metrology-grade accuracy: its length is only 203 mm, and it weighs 570 g. The key parameters of the device — accuracy and resolution — reach 20 microns, while the scanning speed goes up to 2,800,000 measurements per second.

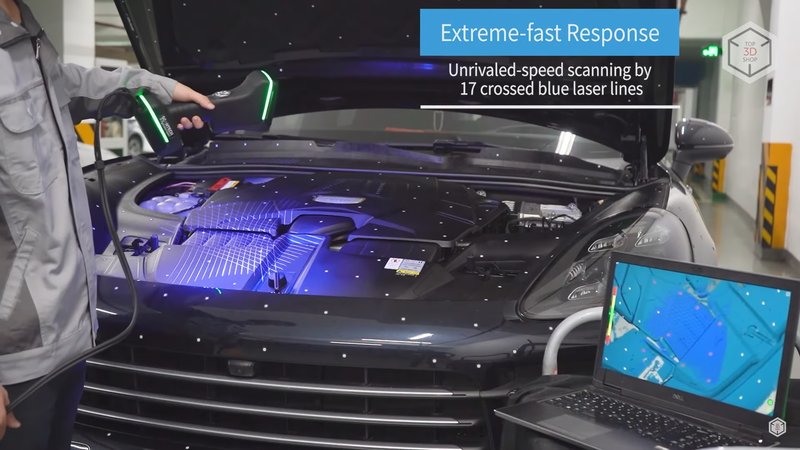

SIMSCAN can work in one of the three dedicated modes. For high-speed scanning, ScanTech recommends using a grid of 17 x 17 crossed laser lines. 7 parallel lines are projected in high-precision scanning mode with a resolution of up to 20 microns. The single laser line mode is designed to scan deep holes and dead angles.

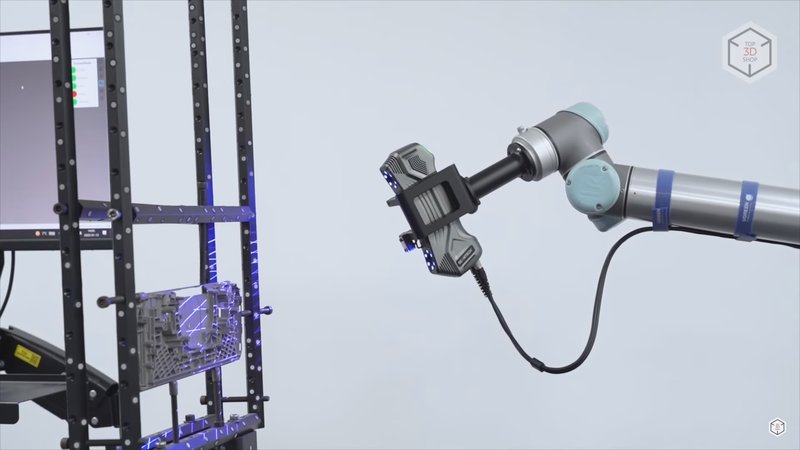

The scanner boasts an ergonomically balanced form factor, making it easy to wield and reducing the load on the operator. With the body of the device made of strong and durable composites, the whole system is ready for use in field conditions. Furthermore, SIMSCAN can be installed on robotic arms for automated measurement and control.

The scanner can be used both in extremely limited space and for digitizing large objects. It is designed for reverse engineering and geometry control when developing new products in such industries as automotive, aerospace, oil and gas, mechanical engineering, and others.

The AXE-B lineup currently consists of two models — AXE-B11 and B17. They combine the capabilities of laser digitizing and photogrammetry systems allowing for 3D scanning with metrological accuracy and capturing large objects of up to 10 m in size, reducing the accumulated error at the same time.

The scan speed of the AXE-B17 model reaches 2,000,000 measurements per second, with the accuracy of both scanners reaching 20 microns, while the scan area is 550 x 600 and 860 x 600 mm for the base and premium model, respectively.

The main operation mode for the lineup is projecting a grid of crossed blue laser lines: 11 x 11 lines for the base model, and 17 x 17 for the second one. An additional mode is a single laser line scanning used to reach deep holes and dead angles.

The ScanTech AXE-B series is recommended primarily for reverse engineering projects and quality control. This metrology-grade digitizing equipment is applicable in a wide array of industries, from automotive, aerospace, and mechanical engineering to oil and gas, medicine, and cultural preservation.

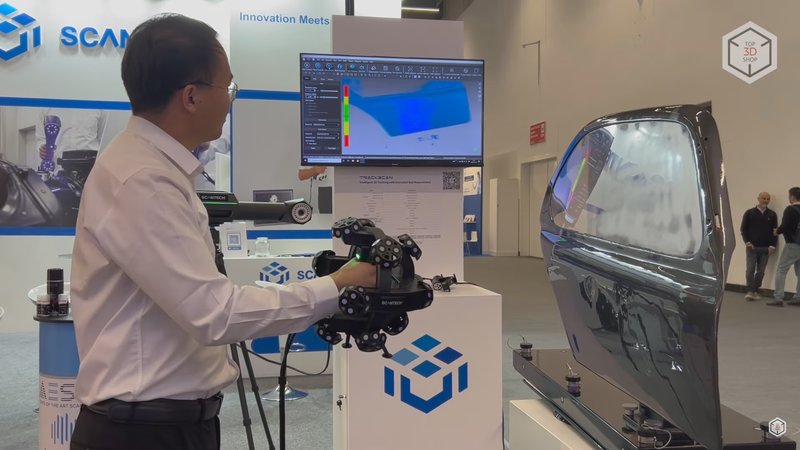

The TrackScan-P lineup features professional high-definition 3D scanners that employ eye-safe 3D scanning technology powered by three different scan modes. They boast outstanding accuracy, a large scanning area, unbelievable level of precision, and unmatched scanning speed.

All models including the basic TrackScan-P42 operate without the use of markers. The solution combines laser 3D scanning technology and high-precision dynamic tracking powered by the E-Track optical tracker to provide fast and accurate data collection. The use of additional trackers helps to significantly expand the measurement area.

These systems can operate in one of three dedicated modes. For high-speed scanning, ScanTech recommends using a grid of 17 x 17 crossed laser lines. 7 parallel lines are projected in high-precision scanning mode with a resolution of up to 25 microns. The single laser line mode is designed to scan deep holes and dead angles.

The scanner features an ergonomically balanced form factor, making it easy to wield and reducing the load on the operator. In addition, the system comes with the T-Probe portable wireless coordinate measuring machine with up to 0.03 mm point repeatability. The module provides accurate data collection when working with complex surfaces, gaps, and grooves.

The TrackScan-P systems are designed for reverse engineering and geometry control in a variety of fields, including the automotive, aerospace, mechanical engineering, oil and gas industries. More than that, the scanner can be installed on robotic arms for automated measurement and control.

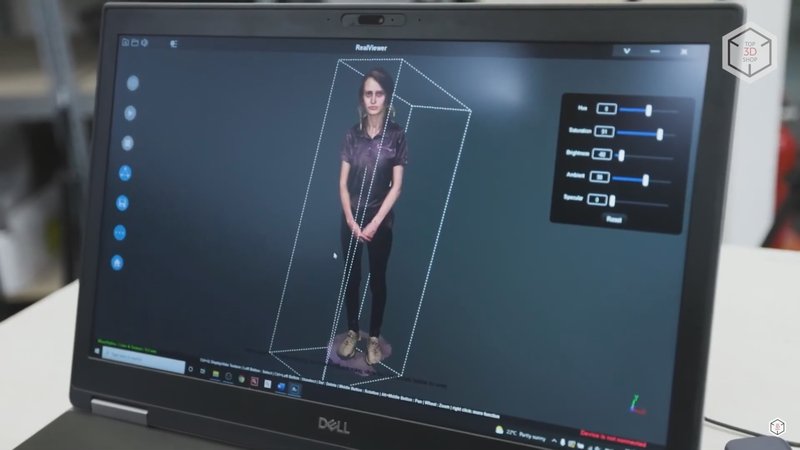

The Scantech iReal 2E is a professional high-precision 3D scanner that employs eye-safe invisible infrared structured light technology and provides outstanding accuracy, large scanning area, and impressive capturing speed. In addition, working with the iReal 2E scanner does not require placing markers on the surface of the object, which can significantly speed up the process.

The scanner is equipped with a smart function to automatically align the geometry of the object or its color. The scan speed reaches 1,500,000 measurements per second, with an accuracy of 100 microns and the capture area of 580 x 550 mm.

The VCSEL infrared structured light technology is completely safe for the eyes, so the device is recommended for digitizing the human body — face and hair in particular.

ScanTech also recommends using the iReal 2E for medical and utility applications when creating virtual objects, as well as for cultural artifact preservation, art, and education. Moreover, the engaged technology makes it an excellent choice for scanning black objects.

The ScanTech MSCAN-L15 is an industrial-grade photogrammetry system used to greatly improve the parameters of your 3D scanning devices. Featuring increased volumetric accuracy, extended scanning area, and a greatly improved depth of field, the system lets you benefit from more accurate 3D renders of large objects.

This efficient photogrammetry system can deliver a maximum volumetric accuracy of 0.015 mm/m and accounts for an increased depth of field of 6.5 m, making it great for any application that requires millimeter-precise renders of large-scale parts.

Due to its unique HDR mode as well as highly ergonomic design, the device boasts strong environment adaptability and can be held by the operator for a long time.

The MSCAN-L15 system is compatible with a number of company’s 3D scanners tailored for inspection, including PRINCE335, PRINCE775, KSCAN20, HSCAN331, HSCAN771, AXE-G7, AXE-B11, and the TrackScan-P22. It can be efficiently used for large-scale projects in 3D inspection, product development, quality control, etc.

Productive and reliable, ScanTech’s portable devices are definitely designed to improve and accelerate your 3D scanning experience while making it more comfortable. Their non-contact 3D measurement technology ensures strict compliance with modern quality control requirements even in the most demanding spheres, like automotive, aviation, medicine, and engineering. Along with optimization and cost reduction in the development process, the ScanTech 3D scanners offer advanced software available for free and generally come at budget-friendly prices, which makes them ideal for a variety of users.

Update your browser to view this website correctly. Update my browser now

Write a comment