The ScanTech AXE versatile industrial scanners are designed for fast and accurate 3D digitizing of large objects. Using the equipment of the Scantech AXE series, the operator can obtain a three-dimensional model of a helicopter or a complex part in a matter of minutes.

Read the review to discover the capabilities and benefits of the ScanTech AXE handheld 3D scanners.

Headquartered in Hangzhou (China), the ScanTech company carries out research, development, and production of modern 3D scanners. The assortment of ScanTech contains only devices for professional use. In 2021, the range of scanners produced by the company is quite extensive: from compact handheld models to automatic measurement systems.

Source: facebook.com

ScanTech professional scanners are used by such corporations as Siemens, Volkswagen, Boeing, General Motors.

Source: 3d-scantech.com

|

AXE-G7 |

AXE-B11 |

AXE-B17 |

|

|

Laser source |

Red, 7 crosses (+1 extra line) |

Blue, 11 crosses (+1 extra line) |

Blue, 17 crosses (+1 extra line) |

|

Measurement rate, points/sec |

800,000 |

1,300,000 |

2,000,000 |

|

Resolution, mm |

0.1 |

0.025 |

0.025 |

|

Accuracy, mm |

0.02 |

0.02 |

0.02 |

|

Volumetric accuracy, mm/m |

0.035 |

0.035 |

0.03 |

|

Scanning area, mm |

550 x 500 |

550 x 600 |

860 x 600 |

|

Scanning area (photogrammetry), mm |

2500 x 3000 |

2500 x 3000 |

3760 x 3150 |

|

Depth of field, mm |

500 |

500 |

500 |

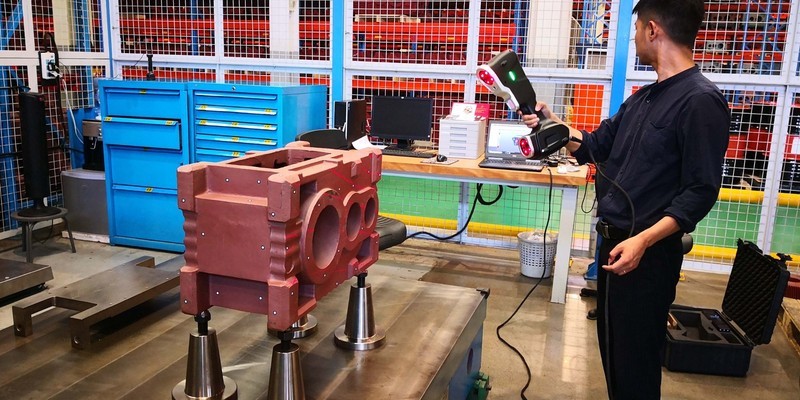

The ScanTech AXE professional 3D scanners represent modern, convenient equipment optimized for fast work with large objects. One operator with a scanner can get a quality 3D model of an aircraft turbine or car body in a few minutes. The ScanTech AXE handheld scanners are versatile — they are designed to digitize dark objects and those with complex hole patterns or a shiny surface. Shiny elements don't need to be matted with a spray — just mark the object. For high-quality scanning, the devices require half the number of markers compared to the average equipment of this class.

Source: 3d-scantech.com

The effective work with different types of surfaces is ensured by the features of the ScanTech AXE optical system — the scanners highlight objects with laser crosses, thanks to which the camera receives data on the nature of the surface. The difference between the ScanTech AXE models lies primarily in the type of laser module. The ScanTech AXE-G7 generates 7 red crosses, the AXE-B11 and AXE-B17 scanners use 11 and 17 blue crosses respectively. The lineup has an additional single-line mode that is used to accurately scan holes and large recesses.

Source: 3d-scantech.com

The quality of the obtained 3D models meets the requirements of the most demanding customers. The handheld 3D scanners provide volumetric accuracy of up to 0.02 mm/m. The ScanTech AXE are used for:

Source: 3d-scantech.com

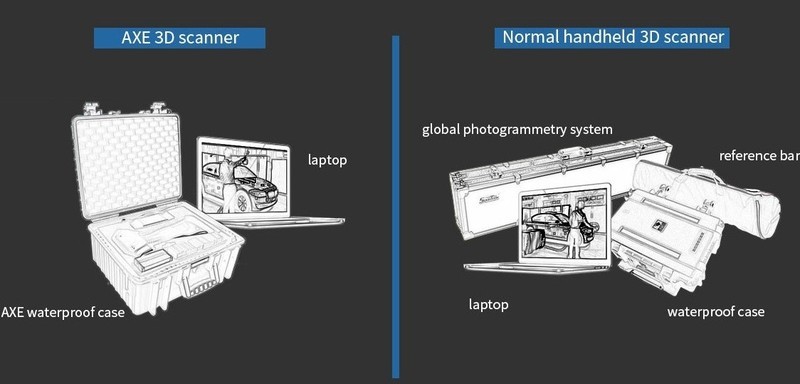

The advantage of the ScanTech AXE delivery set is the presence of a hard case, which makes it convenient to store and transport the scanner with everything you need. The standard package of the ScanTech AXE is complemented with a calibration board, a USB cable, a power cable, an adapter, 4000 reflective marks, and a reference bar.

Source: 3d-scantech.com

The preparation for working with the ScanTech AXE scanners is extremely simple. The operator needs to connect the scanner to a computer with the installed ScanViewer 3D Software and start the calibration process using prompts on the screen.

Source: 3d-scantech.com

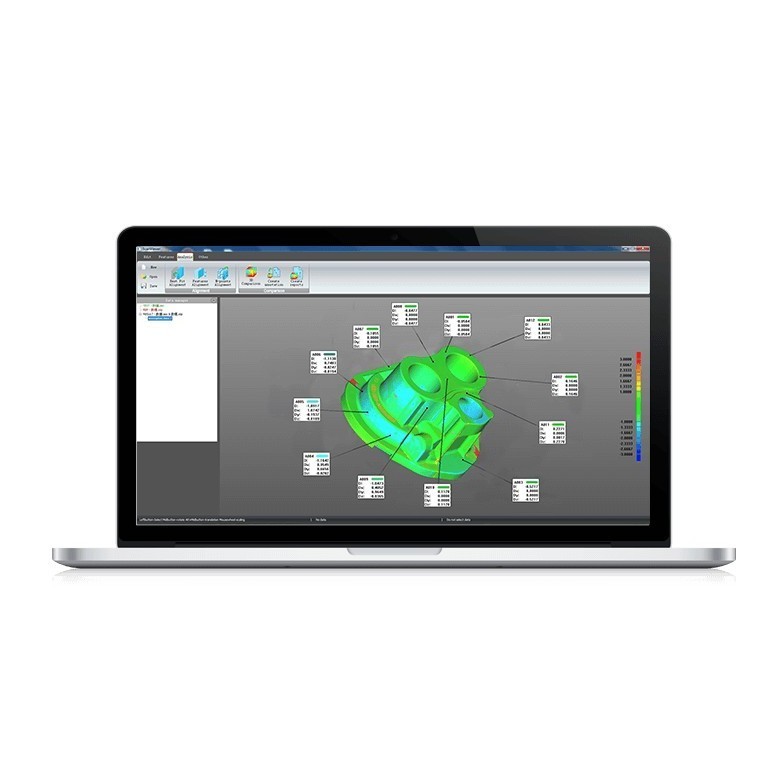

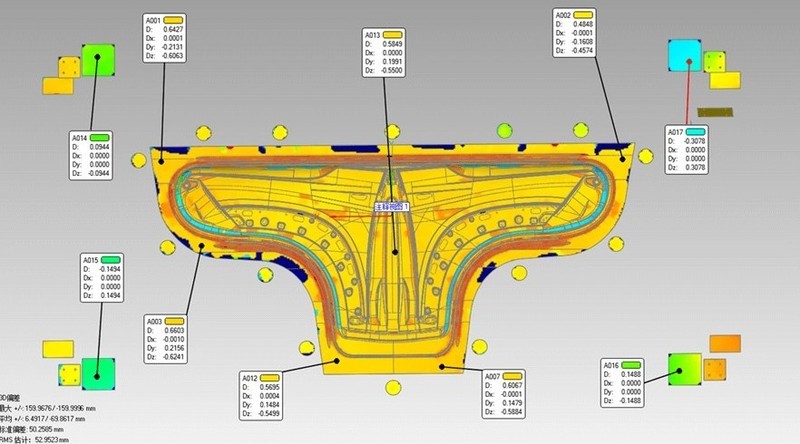

The proprietary ScanViewer 3D Software is designed to operate the equipment. The software has an intuitive and simple interface, although the capabilities of the ScanViewer 3D Software are quite extensive. The program is intended for the analysis of data obtained when scanning and comparison with the initial values, the analysis of measured objects, as well as the inspection of pipelines to look for deformations. The ScanViewer 3D Software can combine separate scans to make a complete 3D model.

Quality work on polished surfaces is one of the advantages of the ScanTech AXE professional 3D scanners. The AXE-B11 was used in the given case.

Source: 3d-scantech.com

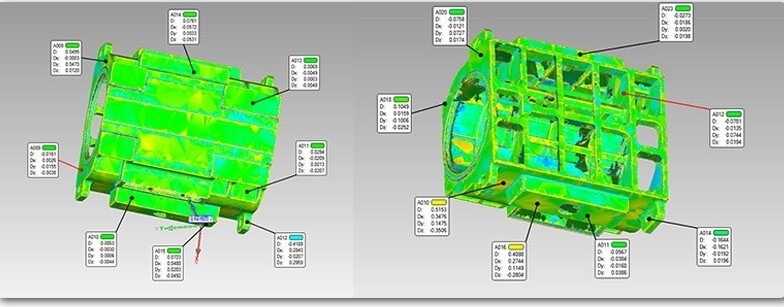

When creating modern industrial equipment, it is crucial that all parts be of the highest accuracy. A customer, Cixi Waylead Electric Motor Manufacturing Co., wanted to check which part of an industrial motor housing was deformed. Thus, they could figure out at which stage of production the error occurred. By means of the AXE-G7 professional scanner, accurate information on product defects was obtained in just 35 minutes.

Source: 3d-scantech.com

The duration of each process:

Source: 3d-scantech.com

Creating a car body requires welding large elements from stamped metal. Regular inspections of finished products are carried out for compliance with design data and quality control. To make measurements, car manufacturers used to employ mechanical devices. Now, with the AXE-G7, accurate data of part dimensions can be obtained in just 11 minutes.

Source: 3d-scantech.com

The time required for the body part inspection:

Source: metrology.news

Currently, the specifications of handheld laser scanners are similar regardless of the manufacturing company. It is rather difficult to make a choice by comparing the specs. For example, the ScanTech AXE-G7 and its Canadian analog Creaform HandySCAN Black show how similar they are in terms of accuracy.

The AXE-G7 provides a large scanning area, which dramatically reduces the time of a workflow. This is an important feature when scanning large objects. Another benefit of the AXE-G7 is its single laser mode for accurate scanning of recesses and holes. Thus, the devices are similar, both ensure high precision and speed of measurements, but the AXE-G7 is a little more optimized for working with large objects.

Compare the main parameters:

|

ScanTech AXE-G7 |

Creaform HandySCAN Black |

|

|

Scanning area, mm |

550 x 500 |

310 x 350 |

|

Laser source |

Red, 7 crosses (+ single-line mode) |

Blue, 7 crosses |

|

Measurement rate, points/sec |

800,000 |

800,000 |

|

Resolution, mm |

0.1 |

0.1 |

|

Accuracy, mm |

0.02 |

0.035 |

|

Volumetric accuracy, mm/m |

0.035 |

0.035 |

|

Scanning area (photogrammetry), mm |

2500 x 3000 |

Optional |

|

Depth of field, mm |

500 |

250 |

Let's summarize the main advantages and disadvantages of the ScanTech AXE series.

Pros:

Cons:

The ScanTech AXE series 3D scanners have many features that facilitate working with particularly large objects. The devices boast a high measurement speed, with their scan areas being one of the largest in the segment of professional handheld scanners. The ScanTech AXE create an extremely accurate image, and the single beam mode is ideal for working with complex surfaces: the operator can slow down the scanning speed and get the perfect image of holes and recesses.

Update your browser to view this website correctly. Update my browser now

Write a comment