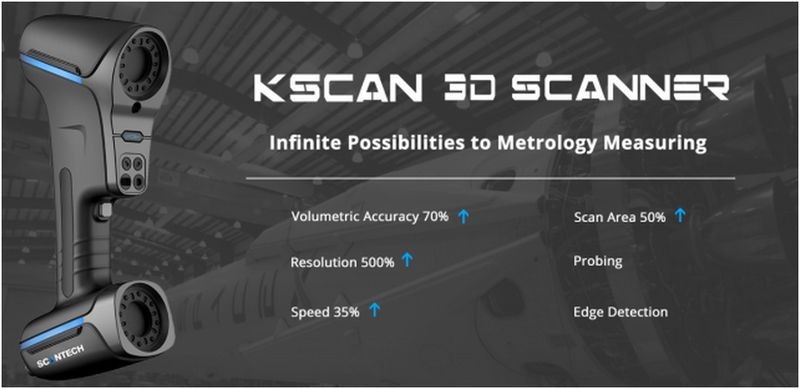

Scantech KSCAN20 is a top-notch 3D scanner for professional makers with a stunning array of possibilities. The machine boasts the photographic mapping function and the double laser scanning mode. In this article, you will learn about this awesome 3D scanner and its second-to-none functionality.

Source: scantech.com

ScanTech specializes in the development, manufacture and sale of intelligent visual inspection equipment and provides professional 3D digital solutions for various industries.

The Scantech R&D team developed a series of 3D digital equipment with self-owned intellectual property rights such as a handheld laser 3D scanner, composite 3D scanner, global 3D scanner, color 3D scanner, tracking 3D scanner and global photogrammetry system. Especially PRINCE series with the capability of capturing extreme details and the AXE series with high volumetric accuracy are global innovations, gaining great attention and recognition in the 3D digital field.

Scantech has been the bestselling handheld 3d scanner brand in China in the last 2 years(since 2018). Their customers are all around the world. Scantech has provided reliable 3D measurement solutions for many famous enterprises such as SIEMENS, VOLKSWAGEN, BOEING, COMAC, AISIN, etc.

Photo source: 3d-scantech.com

Overview

Tech Specs of KSCAN20

Photo source: 3dprintingbusiness.directory

It took the manufacturer more than two years to develop KSCAN20, with colossal efforts pouring into the improvement of the scanner’s performance so that it fully corresponds to the customer requirements and expectations.

The principle of operation is based on a combination of double laser scanning, which ensures high efficiency and an unprecedented level of detail, as well as an integrated photogrammetry function that remarkably expands the scanning area and sharpens volume accuracy.

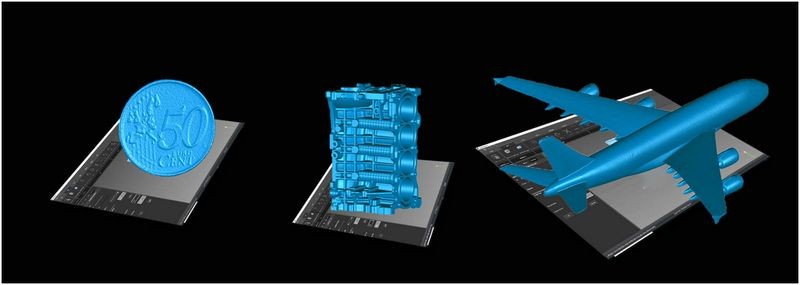

What sets this 3D scanner apart from others is its unique ability to measure objects from 0.02 to 10 m on each axis, which makes KSCAN20 applicable to various branches of industry.

Photo source: https://www.3d-scantech.com/product/kscan20-3d-scanner/

The device is suitable for scanning macro- and micro-objects from 0.02 to 10 m on each axis;

Photo source: 3d-scantech.com

The apparatus supports large scale scanning with high volumetric accuracy — 0.035 mm/m;

Photo source: 3d-scantech.com

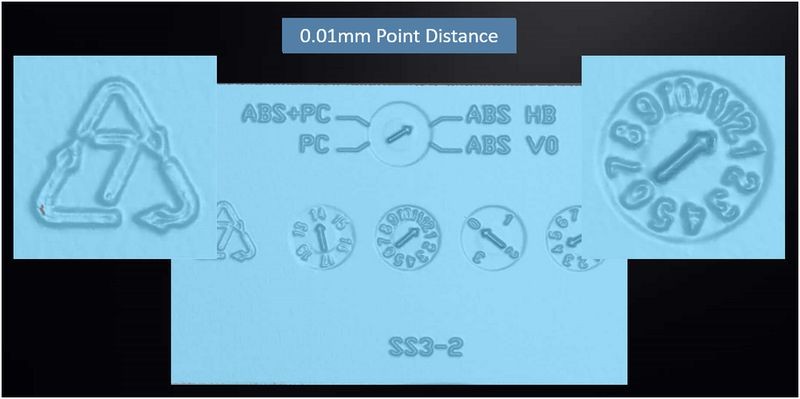

This device is also suited for scanning ultra-small objects with high resolution - 0.01 mm;

The probing process

Photo source: 3d-scantech.com

Probing of the inner part of the hollow elements and the inner surface of the pipes;

Intelligent edge detection system;

Photo source: 3d-scantech.com

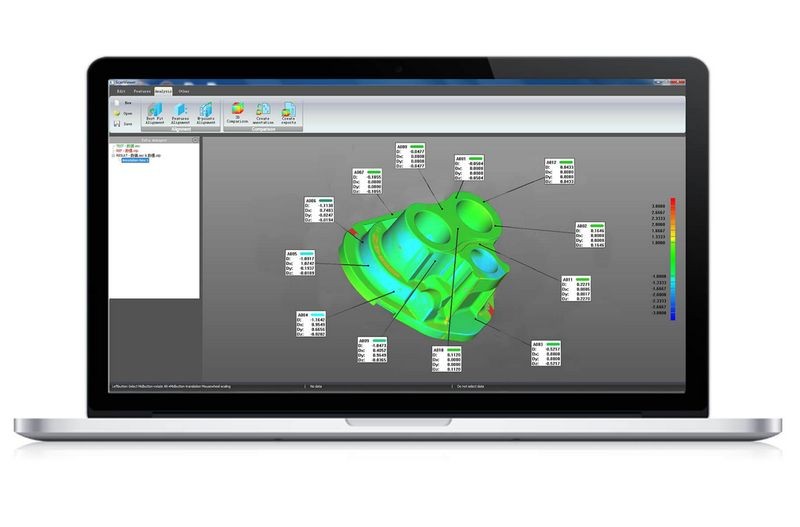

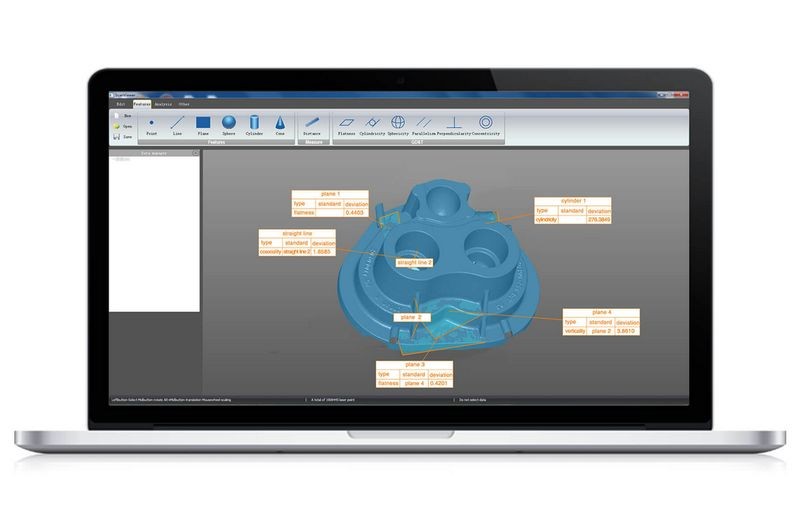

Multifunctional and powerful 3D software ScanViewer.

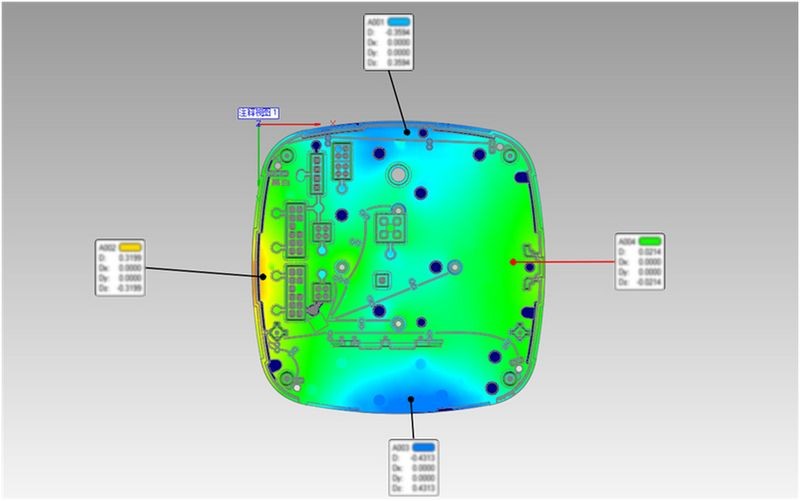

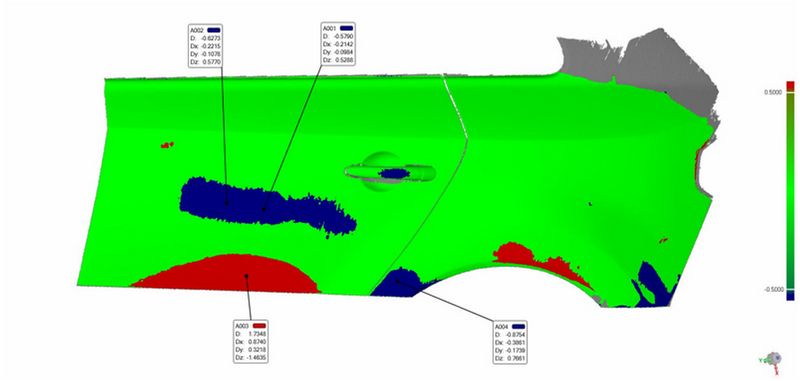

Scans made with KSCAN20 in different modes

Photo source: 3d-scantech.com

Photo source: 3d-scantech.com

ScanViewer is a free, multifunctional software solution by Scantech meant to maximally simplify the utilization of their 3D scanner.

This software can be used at all phases of a production cycle: development, design, and product quality inspection. The obtained data can be used for rapid prototyping, reverse engineering, 3D-displaying, etc.

The GD&T function allows users to directly create and analyze objects, take measures, and determine deviation values based on the data gained through the scanning process.

Photo source: 3d-scantech.com

Dimensional Inspection presents the alignment function that merges the scanning data and the CAD file and carries out an analysis for quick report generation.

Photo source: creaform3d.com

A direct competitor to KSCAN20 is Creaform HandySCAN Black, a portable 3D scanner that proved its worth as a comprehensive, high-performance metrological device.

|

Parameter |

HandySCAN Black |

||

|

Modes |

Standard mode R |

Hyperfine mode B |

One mode |

|

Laser source |

7 red laser crosses (+ 1 extra red line) |

5 blue parallel laser lines |

7 blue laser crosses |

|

Accuracy, mm |

Up to 0,02 |

0,035 |

|

|

Integrated photogrammetry function |

Yes |

No |

|

|

Volumetric accuracy |

0,02 mm + 0,035mm/m |

0,01 mm + 0,035 mm/m |

0,020 mm + 0.060 mm/m |

|

High-precision volumetric accuracy |

0,025 mm/m (optionally) |

No |

|

|

Resolution, mm |

0,05 |

0,01 |

0,1 |

|

Measurements per second |

650000 |

650000 |

800 |

|

Laser class |

2M (safe for eyes) |

2М |

|

|

Scanning area, mm |

550 × 600 |

310 × 350 |

|

|

Stand-off distance, mm |

200 — 420 |

300 |

|

|

Depth of field, mm |

до 550 |

до 250 |

|

|

Single point repeatability, mm |

0,03 |

- |

|

|

Intelligent edge control |

Optionally |

No |

|

|

Edge accuracy, mm |

0,03 |

||

|

Software |

ScanViewer |

VXelements |

|

|

Output formats |

.stl, .ply, .obj, .igs, .stp, .wrl, .xyz, .dae, .fbx, .ma, .asc |

.dae, .fbx, .ma, .obj, .ply, .stl, .txt, .wrl, .x3d, .x3dz, .zpr, .3mf |

|

|

Interface |

USB 3.0 |

USB 3.0 |

|

|

Operating temperature range, °C |

-10 — +40 |

-5 — +40 |

|

Based on this data, the superiority of the Scantech KSCAN20 over the similar 3D scanner HandySCAN Black is evident with the latter being inferior in almost every aspect. The KSCAN20 is a far more accurate and versatile scanner and can rightfully be considered a game-changer in the field of portable 3D scanning.

Photo source: 3d-scantech.com

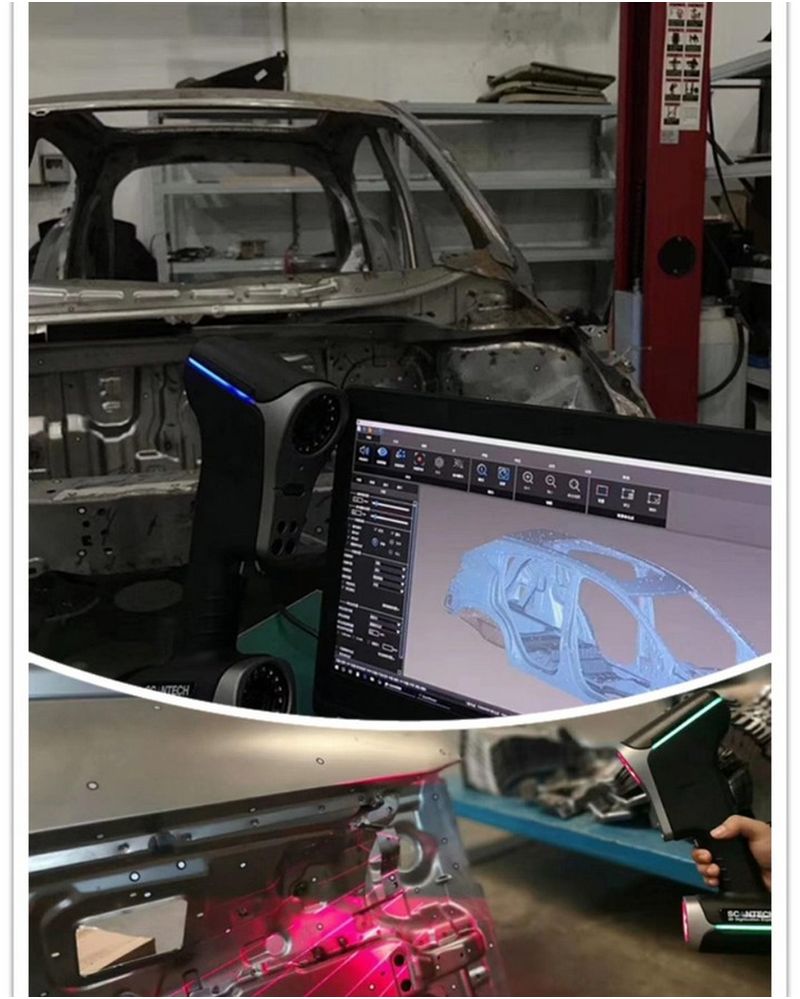

Let’s speak about case studies of the KSCAN20 3D scanner in different industries, precisely for the quality control of die-cast aluminum products mentioned on the Scantech website.

Aluminum die-casting is prevailing in machinery manufacturing but also used in other manufacturing areas such as the automotive industry as well as the production of electronics and domestic appliances.

The process of aluminum die-casting has many nuances, while the quality of finished commodities must comply with numerous standards. This forces the manufacturer to know the exact dimensions and the accurate deviation values in order to identify errors timely and prevent the release of poor-quality products.

The main purpose of the quality control policy in such industries is deformation prevention; and to ensure this, it is necessary to assess different factors including the structure, rigidity, and roughness of the output products. A powerful 3D scanner is a perfect solution to solve this problem.

Stage 1: the attachment of markers (the number of markers is twice as little compared to the use of normal handheld scanners).

An aluminum detail with dimensions of 200 × 200 mm was used for this experiment.

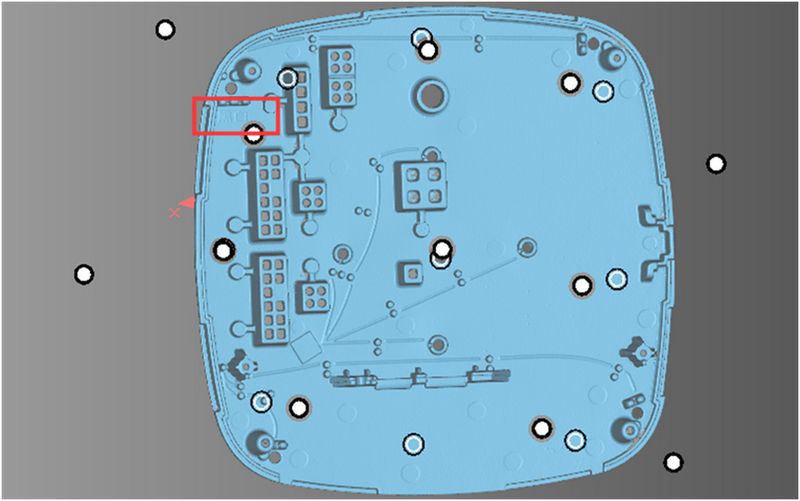

Stage 2: scanning both sides of the detail with a blue laser.

Real-time visualization

Stage 3: the obtaining of the full 3D point cloud data using ScanViewer (the picture depicts the front side of the detail).

The back side.

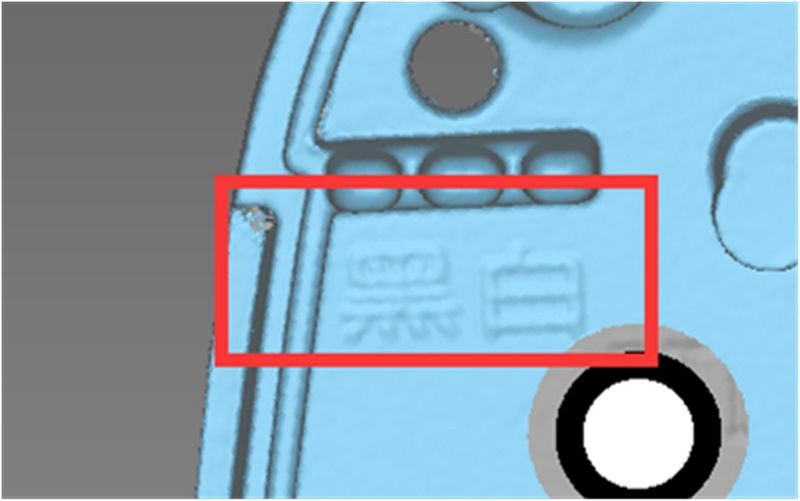

The highlighted area in zoom

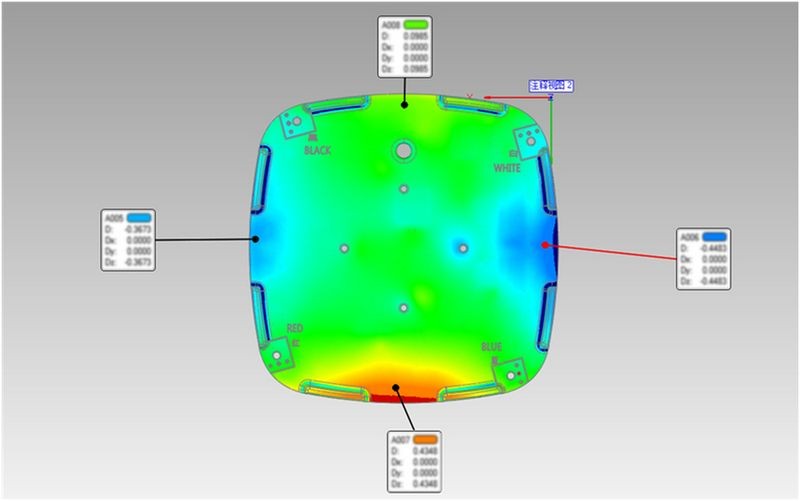

Stage 4: the calculation of deviation values (the front side).

The back side

Photo source: 3d-scantech.com

The top-notch KSCAN 3D scanner dramatically cuts down the scanning time thanks to very few markers. The whole process from the attachment of markers to the report generation took no longer than 16 minutes.

The Vietnamese company ThinkSmart developed an intelligence system of the production of body parts to repair different vehicles. Using the KSCAN 3D scanner and SLA 3D printing, the company gets a virtual model of the necessary part, then transfers it to the 3D printer and receives the desired, ready-to-use detail made of ABS plastic.

Photo source: thinksmart.com

The use of KSCAN together with SLA allows for high printing accuracy, while the properties of ABS plastic ensure that the obtained detail is durable and resistant to heat.

Thus, a small number of car body parts can be produced at a significantly lower cost compared to the aluminum die-casting technology.

Photo source: picuki.com

Dongfeng Honda, a subsidiary enterprise of a globally-known manufacturer of automobiles and motor vehicles, was searching for the opportunities to optimize its quality control system. The company's engineers decided to use a 3D scanner to identify defects in body parts, as well as to take some other measurements. Scantech KSCAN20 proved to be better than other alternatives due to its versatility and accuracy of measurements compared to the one of state-of-the-art metrological equipment.

Now, let’s speak about the main benefits and drawbacks of the Scantech KSCAN20 3D scanner:

Strengths:

Weaknesses:

Sometimes, it is easier to make a choice when comparing a model in question with some of its competitors on the market.

Let’s compare the ScanTech KSCAN20 to its closest competitor: the Creaform HandyScan Black Elite. It’s a higher-end version of the regular HandyScan Black, which is a powerful metrological machine.

|

Parameter |

ScanTech KSCAN20 |

CreaForm HandyScan Black Elite |

|

|

Modes |

Mode R |

Mode B |

|

|

Laser source |

7 red laser crosses (+ 1 extra red line) |

5 blue parallel laser lines |

11 blue laser crosses (+ 1 extra blue line) |

|

Accuracy |

0.02 mm |

0.02 mm |

0.025 mm |

|

Volumetric accuracy |

0.02 mm + 0.035mm/m |

0.01 mm + 0.035 mm/m |

0.020 mm + 0.040 mm/m |

|

Integrated photogrammetry function |

Yes |

No |

|

|

High-precision volumetric accuracy |

0.025 mm/m (optionally) |

No |

|

|

Measurements per second |

650,000 |

650,000 |

1,300,000 |

|

Laser class |

2M (safe for eyes) |

||

|

Scanning area |

550 × 600 mm |

250 x 300 mm |

310 × 350 mm |

|

Object size |

0.05 - 10 m |

0.05 - 4 m |

|

|

Support of proprietary markers |

Yes |

No |

|

|

Operating temperature range |

-10 — +40 °C |

+5 — +40 °C |

|

One of the selling points of the KSCAN20 is built-in photogrammetry. It significantly expands the scanning area and versatility of the device. The HandyScan Black Elite offers no similar features. The KSCAN20 can scan very large objects of up to 10 meters along each axis, while the maximum object size for the HandyScan Black Elite is around 4 meters.

The KSCAN20 boasts a better accuracy in both modes compared to the HandyScan Black Elite. This also applies to volumetric accuracy where the KSCAN20 comes as the winner as well. The KSCAN20 users can buy an additional feature called the Scale Bar, that will improve accuracy, making it 0.02 mm + 0.02 mm/m

Source: 3d-scantech.com

ScanTech’s product offers a superior resolution. Even the faster and less accurate Standard Mode (Mode R) can reach the resolution of 0.05 mm, while the best resolution the HandyScan Black Elite can provide is 0.1 mm. One also shouldn’t forget that the KSCAN20 has the HyperFine Mode (Mode B) which can offer a resolution of 0.01 mm.

The scanning area of the KSCAN20 in the Mode R is significantly larger than what the Creaform’s product can provide (550 x 600 mm vs. 310 x 350 mm). This also reduces the amount of markers that will be used, making the process cheaper. But on the other hand, the HyperFine Mode B’s scanning area is smaller (250 x 300 mm vs. 310 x 350 mm).

The KSCAN20 has a lower operating temperature (-10 °C compared to the HandyScan Black Elite’s +10°C), which allows the device to be used even in extreme conditions, expanding the versatility of the scanner, making it usable even in the conditions of unheated factory rooms.

Another important thing to mention is ScanTech’s software, which is better optimized for low-end PCs and also cheaper to use, since many of its features are free: such as the ability to compare scans.

Photo source: 3d-scantech.com

Scantech KSCAN20 portable 3D scanners present cutting-edge, comprehensive equipment of the highest quality. Such a scanner allows for creating 3D models and taking measurements in any industry where quality control of the element surfaces is mandatory.

Get Scantech KSCAN20 at Top 3D Shop and get a high-precision 3D scanner coupled with an official guarantee and the best service possible.

Update your browser to view this website correctly. Update my browser now

Write a comment