Greetings and welcome to Top 3D Blog, your trusted source of quality additive manufacturing and 3D scanning insights. This time, we are going to tell you everything there is to know about the Scantech KSCAN Magic and Magic II — a new generation of precise lightning-fast 3D scanners powered by innovative hybrid light source technology.

Continue reading the article to learn more about the features, specs, pros and cons, and application fields of these metrology-grade handheld devices.

Source: 3d-scantech.com

Scantech is a China-based manufacturer of professional 3D scanners and 3D scanning equipment. The company has its own R&D center that is powered by an international team of highly trained specialists that come from the best universities the world has to offer. Besides, Scantech R&D team works in collaboration with Metronor — a privately held Norwegian company that specializes in the creation of high-end optical measurement solutions. Clearly, a partnership that was destined to bear fruits. And indeed, nowadays, the Scantech devices are employed by several well-known companies such as Siemens, Volkswagen, Boeing, General Motors, and JLR.

The KSCAN-Magic is a series of next-generation 3D scanners powered by hybrid structured light technology that employs infrared and blue lasers to create ultra-precise renders of a scanned object in the blink of an eye. The scanners feature the following operation modes:

In terms of capturing speed, the KSCAN-Magic 3D scanners let you create accurate three-dimensional renders a whole lot faster as compared with their predecessors. To be more precise, the KSCAN Magic can scan at up to 1,350,000 measurements/s, and the Magic II boasts its capturing speed of 1,650,000 measurements/s. Besides, both models feature improved scan accuracy alongside increased scan volume and volumetric positioning accuracy. Moreover, the KSCAN-Magic series can be upgraded with the portable CMM K-Probe to provide you with unparalleled data acquisition accuracy when scanning hard-to-reach holes and other hard-to-scan surfaces.

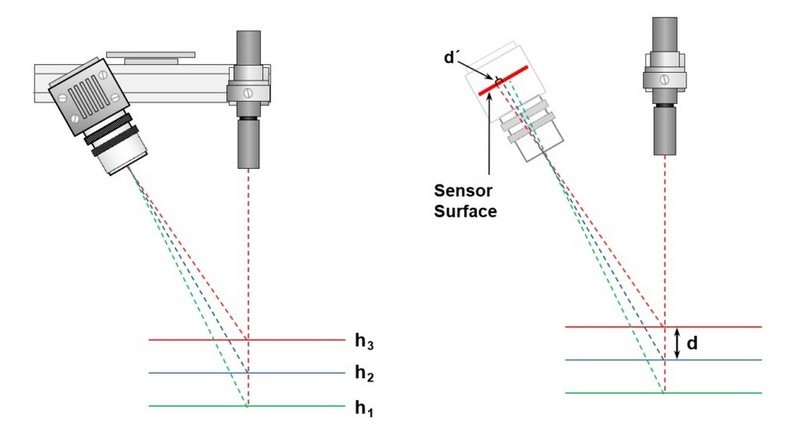

The ScanTech KSCAN-Magic 3D scanners are powered by a leading-edge laser triangulation technology.

Source: movimed.com

Laser Triangulation is a 3D scanning technique that allows for the creation of accurate three-dimensional renders by pairing a laser illumination source with a camera. Employing a special angular offset, the laser beams and the camera are pointed at the inspection target. Then, the beams get reflected from the scanned object’s surface, and the three-dimensional model of the scanned object is built according to the captured data. Take a look at the red, green and blue dotted lines on the image above — they display how the reflected laser light will return to different matrix sensors depending on the distance between the laser source and the scanned object’s surface. After receiving all the necessary data, the 3D scanning software shapes and creates the three-dimensional model for subsequent editing and 3D printing.

|

KSCAN Magic II |

||

|

Output file formats |

stl; ply; obj; igs; stp; wrl; xyz; dae; fbx; ma; asc / customized |

|

|

Depth of field, mm |

base: 925, photogrammetry-powered: 2500 |

|

|

Scanning area, mm |

base: up to 1440 х 860, photogrammetry-powered: 3760 х 3150 |

|

|

Connectivity |

USB 3.0 |

|

|

Light source |

Ultra-fast scanning: 11 blue laser crosses (+1 extra blue laser line) Hyperfine scanning: 7 blue parallel laser lines Large area scanning: 11 parallel infrared laser lines |

Ultra-fast scanning: 13 blue laser crosses (+1 extra blue laser line) Hyperfine scanning: 7 blue parallel laser lines Large area scanning: 11 parallel infrared laser lines |

|

Laser class |

Class Ⅱ (eye safe) |

|

|

Volumetric positioning accuracy |

Base: Up to 0.010 mm + 0.030 mm/m With 1mm reference bar: Up to 0.010 mm + 0.020 mm/m With MSCAN-L15: Up to 0.010 mm + 0.015 mm/m |

|

|

Single point repeatability |

0.030 mm |

|

|

Operating temperature |

-10 ~ 40 °C |

|

|

Resolution |

Up to 0.010 mm |

|

|

Stand-off distance |

300 mm |

|

|

Capture speed |

Up to 1 350 000 measurements/s |

Up to 1 650 000 measurements/s |

|

Scanning accuracy |

20 microns |

|

|

Full-color captures |

No |

|

|

Tracking frequency |

60 Hz |

|

|

Price |

On request |

|

Here’s the list of the items that come in the supply package:

Source: 3d-scantech.com

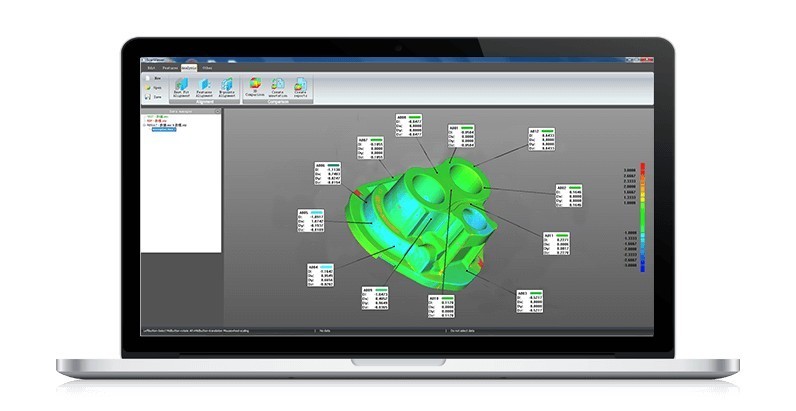

The KSCAN-Magic series are powered by ScanViewer — a professional 3D scanning and modeling software solution that offers a variety of advanced options for data editing. For instance, it lets you manually create features, request a thorough feature analysis, distance measurement, pipe inspection, dimensional and tolerance analysis according to the scanned data, and much more. The received data can be used for rapid prototyping, reverse engineering, metrological validation, and other related applications.

|

KSCAN Magic II |

Creaform HandySCAN Black Elite |

||

|

Output file formats |

stl; ply; obj; igs; stp; wrl; xyz; dae; fbx; ma; asc / customized |

dae, .fbx, .ma, .obj, .ply, .stl, .txt, .wrl, .x3d, .x3dz, .zpr, .3mf |

|

|

Depth of field, mm |

base: 925, photogrammetry-powered: 2500 |

250 |

|

|

Scanning area, mm |

base: up to 1440 х 860, photogrammetry-powered: 3760 х 3150 |

310 х 350 |

|

|

Light source |

Ultra-fast scanning: 11 blue laser crosses (+1 extra blue laser line) Hyperfine scanning: 7 blue parallel laser lines Large area scanning: 11 parallel infrared laser lines |

Ultra-fast scanning: 13 blue laser crosses (+1 extra blue laser line) Hyperfine scanning: 7 blue parallel laser lines Large area scanning: 11 parallel infrared laser lines |

11 blue laser crosses (+1 extra blue laser line) |

|

Volumetric positioning accuracy |

Base: Up to 0.010 mm + 0.030 mm/m With 1mm reference bar: Up to 0.010 mm + 0.020 mm/m With MSCAN-L15: Up to 0.010 mm + 0.015 mm/m |

0,020 mm + 0.040 mm/m |

|

|

Operating temperature |

-10 ~ 40 °C |

5 ~ 40 °C |

|

|

Capture speed |

Up to 1 350 000 measurements/s |

Up to 1 650 000 measurements/s |

Up to 1 300 000 measurements/s |

|

Scanning accuracy |

20 microns |

25 microns |

|

As you can see, the Creaform HandySCAN Black Elite is slightly inferior to KSCAN Magic Series in terms of its main parameters. Nevertheless, the HandySCAN Black Elite is powered by the VXelements software suite, which is more advanced and easier to use. Of course, the final decision should be made according to your requirements and the total amount of money you are willing to invest. If you are not sure which of the scanners will suit you best, feel free to contact us for quality advice and support.

Pros

Cons

Source: 3d-scantech.com

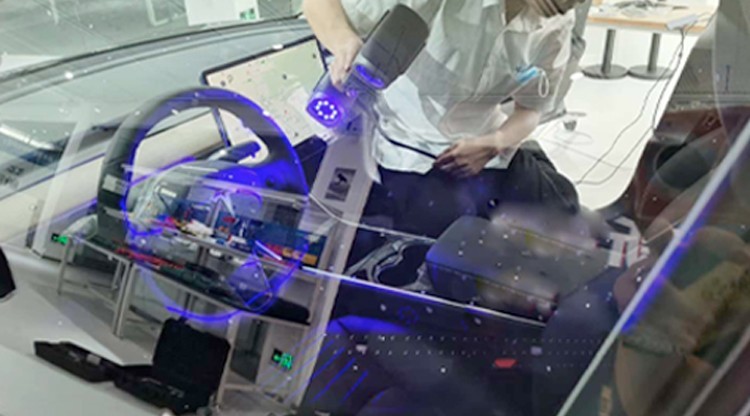

A car tuning company needed a digital model of Tesla Model 3 at a scale of 1:1. The model had to include all the dismantled parts for subsequent modifications and 3D printing.

Source: 3d-scantech.com

When it comes to the 3D scanning of such a large object, the total scanning area and capturing speed are the parameters to opt for. Since Tesla Model 3 has a length of 4.7 m and a width of 1.85 m, a scan area too narrow would’ve led to multiple stitchings of the 3D model, which, in its turn, would’ve caused a bunch of errors to accumulate. A car is a complex object that has many curved surfaces, deep holes, black and shiny areas, which makes it difficult to 3D scan.

Source: 3d-scantech.com

To complete the task, the company employed their KSCAN-Magic 3D scanner with a built-in photogrammetry system, using all of the different operation modes the device has to offer. The team used markers to scan shiny surfaces and other hard-to-scan areas. Besides, a matte spray couldn’t have been applied since it could spoil the paint and the interior of the car. In the end, all the acquired data has been thoroughly reviewed and edited with the ScanViewer software suite.

Source: 3d-scantech.com

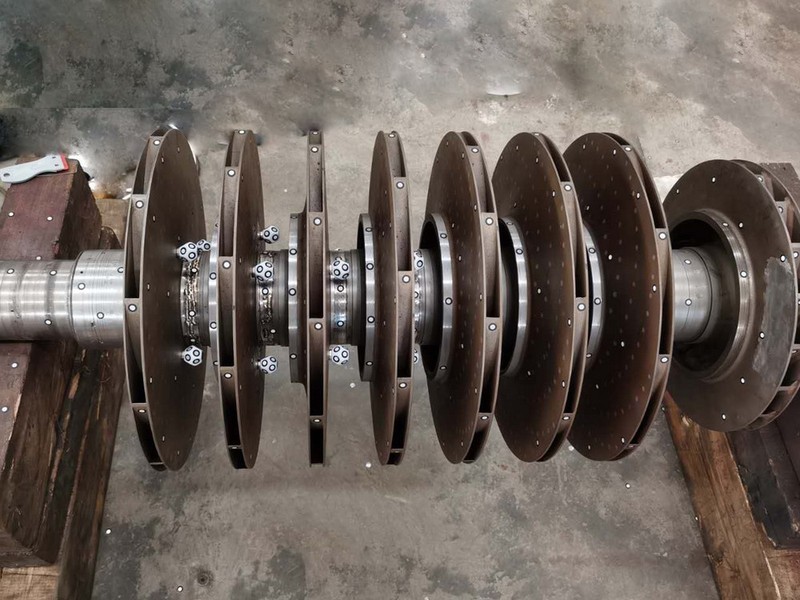

A chemical machinery company needed a complete and accurate 3D model of a compressor rotor for overhaul and quality inspection purposes.

Source: 3d-scantech.com

The main shaft of the compressor rotor had a length of 1.8m and a diameter of 0.96m, besides, the part weighs as much as 300 kg, making it incredibly difficult to accurately measure all the grooves and curved surfaces using traditional methods. Moreover, the main shaft featured multiple impellers located in close proximity to one another. The distance between each impeller was particularly narrow, besides, each impeller had deep flow channels. To provide an accurate three-dimensional model of the part, the employed 3D scanner had to offer a large depth of field and high accuracy.

Source: 3d-scantech.com

To scan the spaces between the impellers and provide a precise representation of other hard-to-scan parts, the deep hole scanning work mode has been employed. The scanner worked with a depth of field of 500 mm, resolution of 0.025 mm, and an accuracy of 0.020 mm, capturing the 3D data of complex and shiny surfaces in an accurate and fast-paced manner. To scan the compressor rotor, the company used one of their AXE 3D scanners, which is a family of KSCAN-Magic predecessors.

To tell the truth, we regard the KSCAN-Magic series to be the best devices Scantech has to offer. These are flexible, fast, and ultra-precise 3D scanners that can easily scan almost any kind of object. Aside from a built-in photogrammetry system, the KSCAN-Magic 3D scanners can be employed for reverse engineering, prototyping, 3D visualization, digital modeling, and a plethora of other related purposes. To achieve the best the devices have to offer, we recommend using them with additional scanning equipment provided by Scantech.

You can purchase the Scantech KSCAN Magic series from Top 3D Shop. These precise, fast, and multifunctional devices come with the manufacturer’s warranty. Besides, our team will provide you with the best service possible, just like we always do.

Update your browser to view this website correctly. Update my browser now

Write a comment