Founded in 2011, the Chinese-based Flashforge company has become one of the most recognized 3D printer manufacturers around the world. Best known for its FDM consumer machines, Flashforge is constantly expanding its influence in the 3D equipment market. Its latest Guider 3 series FDM printers, as well as the Creator 4 released just before, fully meet the requirements for an industrial-grade machine. Apart from that, the company is developing a lineup of resin-based 3D printers. Flashforge produces DLP and LCD devices both for consumer and professional use.

This is Top 3D Shop, and today, we are going to review the Flashforge Foto 13.3, an LCD-based resin 3D printer with a huge build volume.

The printer comes in a large box, its net weight being 35.5 kg, so it is better to have somebody around to help with unpacking and installation. Despite the impressive size (380 x 380 x 685 mm), this is a desktop machine, so be sure to prepare a suitable surface beforehand. The package is pretty standard for an MSLA 3D printer. The only thing missing is perhaps a funnel to pour the resin left in the vat back into the bottle. There are only paper filters in the box. The Quick start guide contains detailed instructions on print bed calibration, FEP film replacement, and the basics of the printing process. See below for the full list of the box contents.

Credit: Flashforge Denmark / YouTube

For some items, package content may change. In case of any questions, please get in touch.

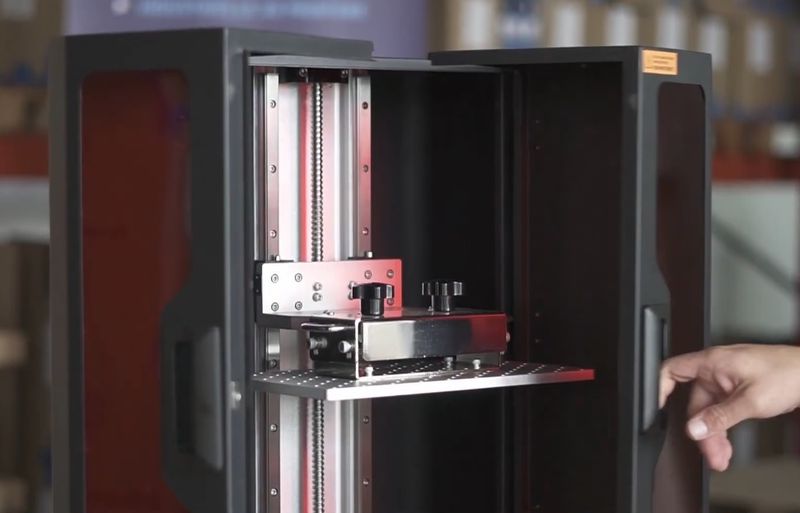

The Flashforge Foto 13.3 is a large-size machine with dark transparent hinged doors that open 180°, providing easy access to the build plate and vat. Do not forget to leave enough room around the printer for the doors to open freely.

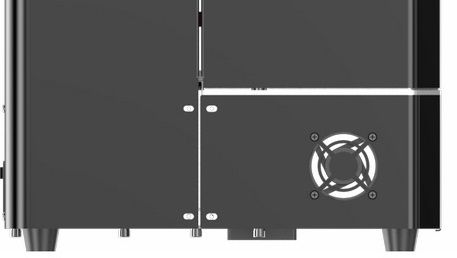

There are three cooling fans located on both side and back panels, and one more on the bottom underneath the printer for efficient heat dissipation from the LCD panel.

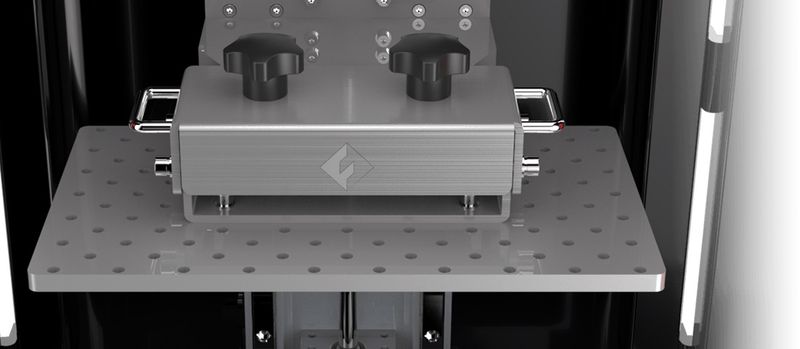

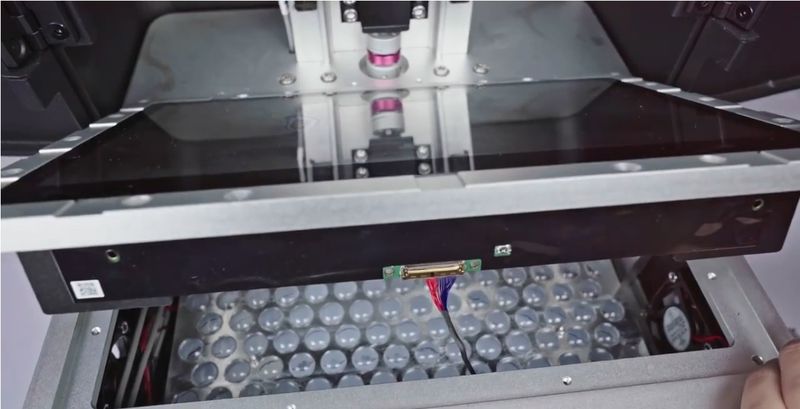

The huge build chamber of the Flashforge Foto 13.3 measures 292 x 165 x 400 mm with 19 L print volume, which allows creating large models or batches of smaller parts. To ensure printing stability while building massive objects, the Z-axis moves on dual-linear guides with a ball-screw design. The perforated aluminum print platform is equipped with two handles and fixed to the base with two thumbscrews.

Before the first use the manufacturer recommends calibrating the build platform to ensure proper adhesion of the first layer and prevent the model from peeling off the plate. The calibration process is the same as with most resin printers. First you need to loosen the four screws on both sides of the build platform, put three A4 sheets of paper on the LCD screen, and lower the Z-axis to zero position by selecting the Homing option in the Z Move menu.

Tighten the four screws, remove the paper and raise the Z-axis by clicking the Max icon to complete the calibration.

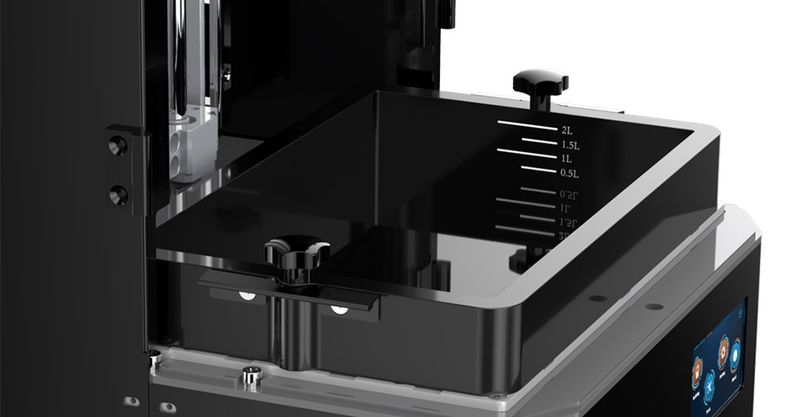

It is only left to install the resin vat to get down to printing. Put the vat onto the screen and tighten the thumbscrews on both sides.

The large vat features a measurement scale on the inside and holds up to two liters of resin.

The Flashforge Foto 13.3, as the name implies, is equipped with a 13.3" monochrome 4K LCD panel. It provides the XY resolution of 76 microns, which is not the highest in the market, but regarding the build volume size, it is fairly enough to print accurate models with smooth surface finish. Using a monochrome screen ensures faster layer curing compared to RGB panels and a longer lifespan. The curing wavelength of 405 nm common for most resin printers allows for the use of third-party materials.

The LCD screen of the Foto 13.3 is specially treated and resistant to scratches. In case the screen needs replacing, the user can do it in a few simple steps.

The Flashforge Foto 13.3 can be connected to the computer wirelessly or via an Ethernet cable. You can also print from a USB flash drive; the USB and Ethernet slots are on the bottom right panel.

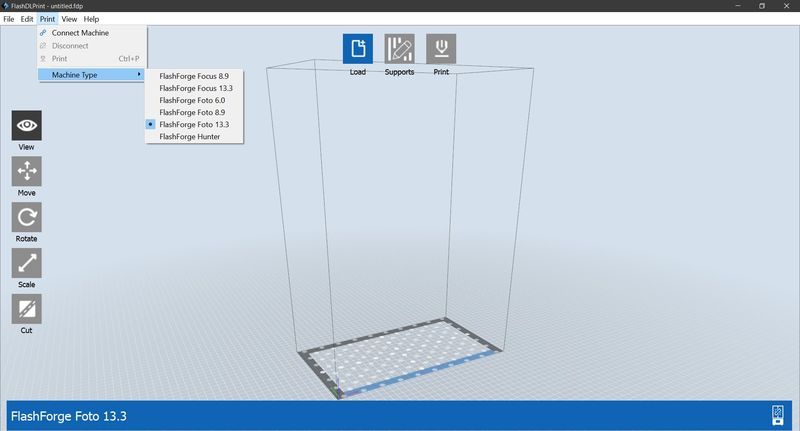

It is recommended to use the printer with the proprietary FlashDLPrint slicer software developed by Flashforge specifically for resin printing. The software provides a standard set of features, including auto support generation, variable layer thickness, and others.

Credit: sync-innovation.com

FlashDLPrint is regularly updated and has profiles for all Flashforge resin printers.

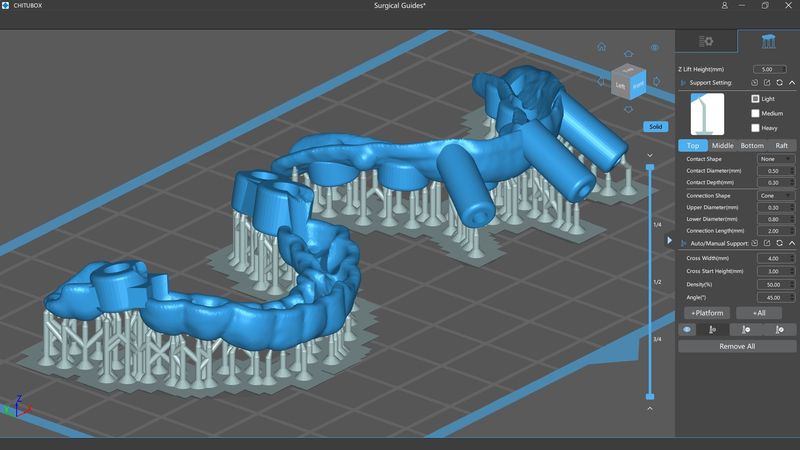

Another option for those who want more versatility is ChiTuBox. The popular slicer has Basic and Pro versions, for the latter you can take advantage of a free trial period to assess all the functions and convenience of use.

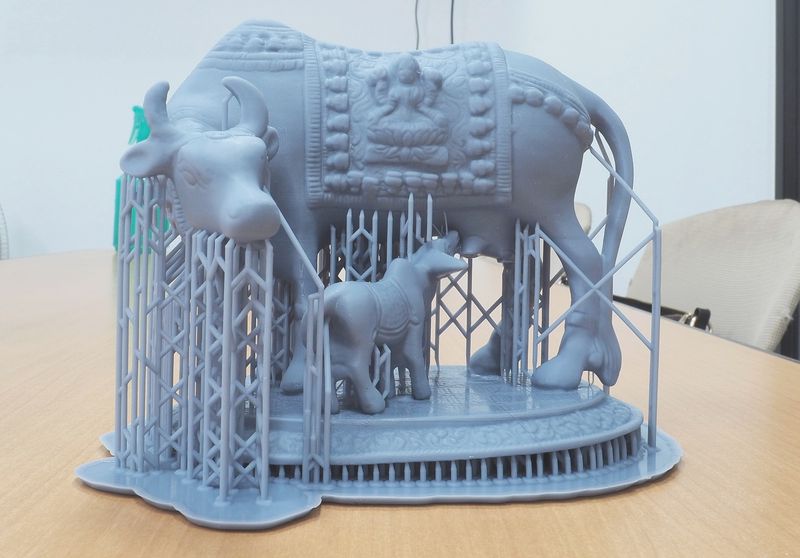

As can be seen from the test prints, the Flashforge Foto 13.3 is capable of producing neat-looking models with a lot of detail and smooth surface finish.

The cow model height is 14 cm, it took 9 hours to print it at 50-micron layer height with the exposure time of 3 seconds per layer.

Credit: sync-innovation.com

The next model took up the entire build plate surface. It was printed with washable resin, the exposure time 4 sec / layer and 8 seconds for the base layer.

Credit: Filaments.ca / Facebook

Here are a few more models printed on the Flashforge Foto 13.3. Despite the impressive size, the level of detail is impeccable.

Credit: 3DD Digital Fabrication / YouTube

Credit: Print3Dd — Digital Fabrication, 3D Printer, 3D Scanner, Laser / Facebook

Credit: 3WAY / Facebook

The main distinguishing feature of the Flashforge Foto 13.3 is its huge build volume. There are not a lot of machines of this size in the market, and the Foto 13.3 is definitely worth considering if you plan to print massive models or batches of small parts. Other strong points of the printer, such as its fast print speed, high print quality, and ease of maintenance make it a good deal at a very competitive price.

Update your browser to view this website correctly. Update my browser now

Write a comment