Hey everyone! In this review, we are going to tell you about the new Anycubic 4Max Pro 2.0 3D printer — an improved version of the Anycubic 4Max Pro. Explore its capabilities, design features, and differences from previous models.

The Anycubic 4Max Pro 2.0 is a vivid representative of enclosed 3D printers, which have a number of advantages over printers with an open chamber.

Isolating the inside of the device from the environment provides the following benefits:

There are plenty of enclosed 3D printers on the market, against which the Anycubic 4Max Pro 2.0 stands out for its price/quality ratio. Not inferior to products of other manufacturers in print quality, it turns out to be much cheaper than most of them.

The Anycubic 4Max Pro 2.0 comes fully assembled. It takes less than an hour to get the device ready to print — all you need to do is install the spool holder and thermistor, level the print bed, and download the software from the SD card included in the package.

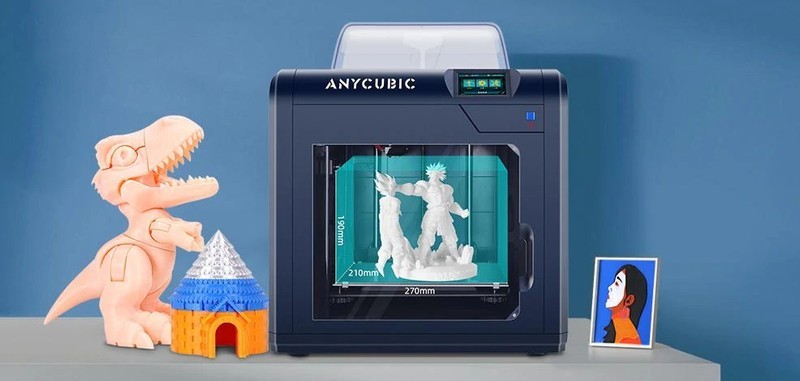

The Anycubic 4Max Pro 2.0 features a build area of 270 x 210 x 190 mm, which is quite a lot for a 3D printer with an enclosed chamber.

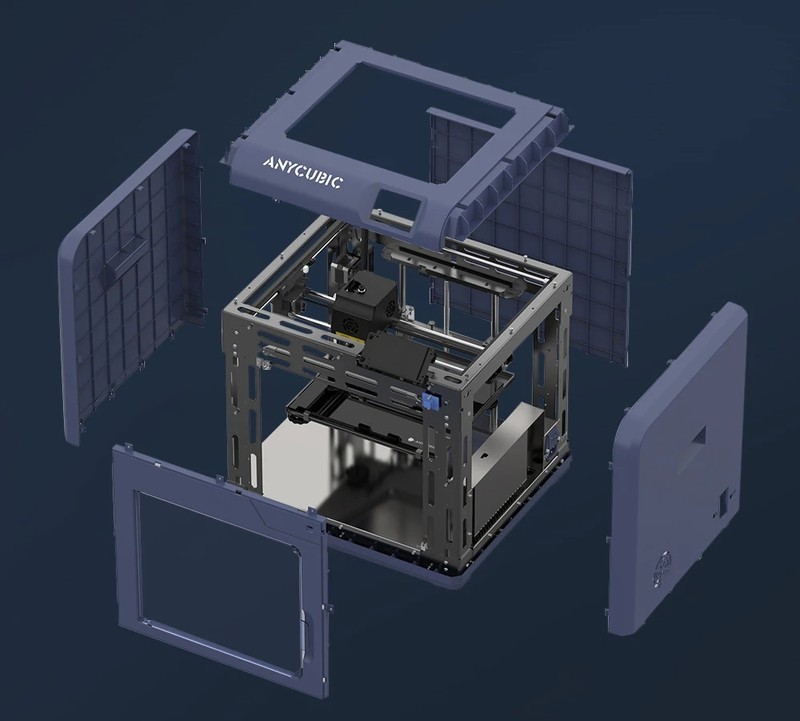

The design of the Anycubic 4Max Pro 2.0 is based on a steel profile frame, which provides high strength with a relatively low weight. Shockproof pads effectively dampen vibrations, ensuring high-quality printing.

The vertical movement of the build plate is implemented by a leadscrew and two guides connected to the plate by means of graphite-lubricated bearings. This design ensures smooth and accurate platform movement.

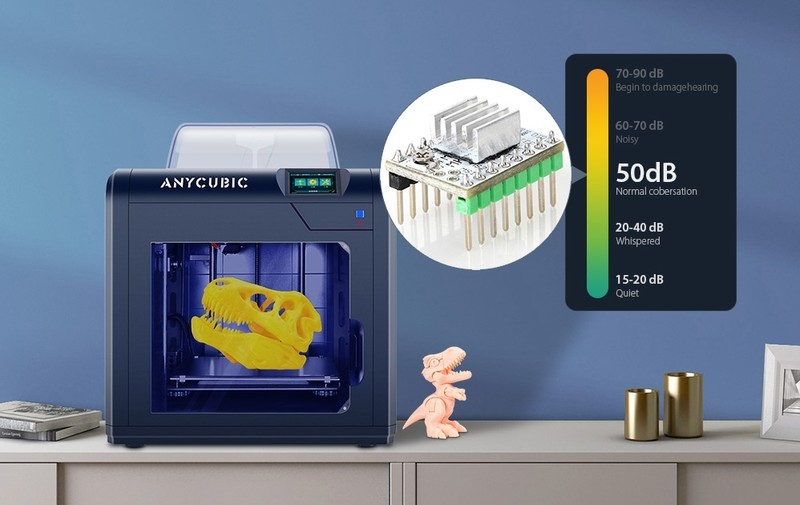

Most 3D printers are so noisy they require a separate room. The Anycubic 4Max Pro 2.0 design uses ultra-quiet TMC2208 stepper drivers to keep noise at less than 50 dB, so the printer can operate anywhere without causing inconvenience.

The closed design dampens not only noise but the smell of heated filament. For the ultimate solution to the odor problem, the Anycubic 4Max Pro 2.0 has a charcoal filter in front of the exhaust fan.

The printer is powered by a highly reliable 350W Meanwell power supply.

Like many other Anycubic 3D printers, the 4Max Pro 2.0 features a practical Ultrabase heated bed. Its surface is dotted with micropores, which improve adhesion and facilitate removal of the finished object. The model adheres to the platform without any difficulties and can be easily removed after cooling.

The bed leveling screws are equipped with convenient knobs, which make the calibration much easier and less time-consuming than usual.

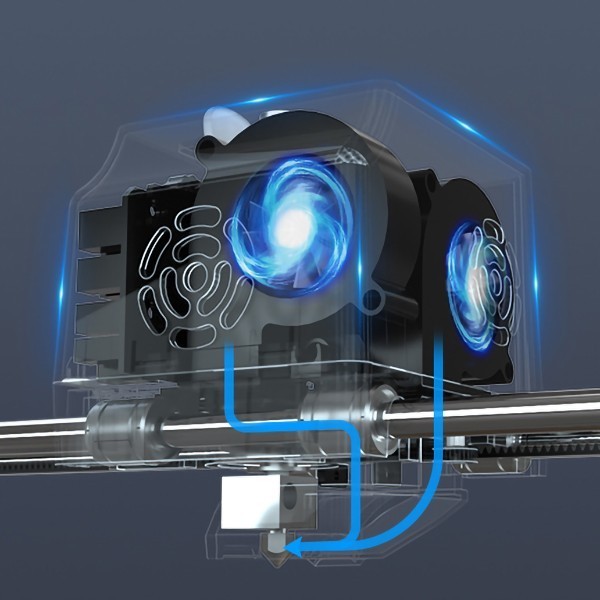

The extruder with torque optimization adjusts the filament feeding rate to match the print speed.

The color touchscreen display with a user-friendly interface makes it easy and quick to configure print settings. The screen is located at the top of the device, making for exceptional convenience.

The fan operates in a way to reduce the vibration of the print head, thereby improving print quality.

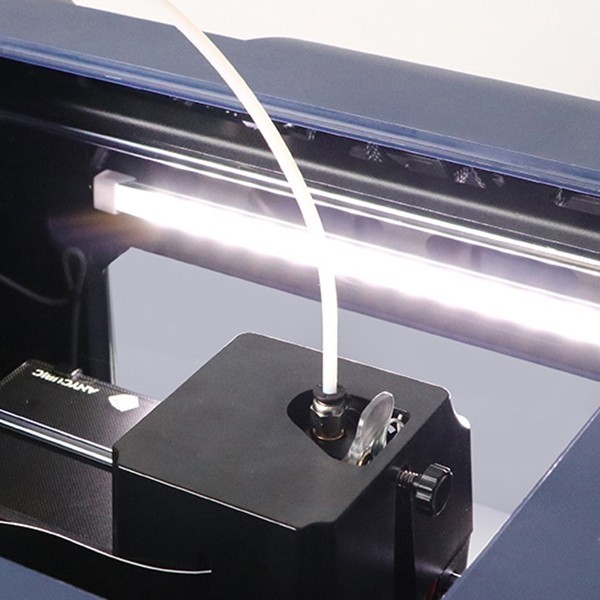

The LED lighting illuminates the print area for real-time assessment of the print result.

If there occurs a power outage, the printer shuts down. When the power is restored, printing resumes automatically from where it stopped.

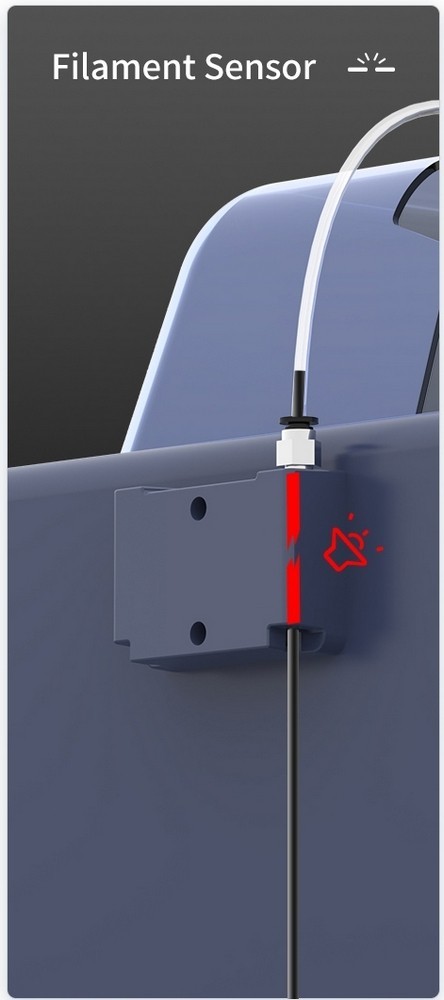

Once the filament runs out, the Anycubic 4Max Pro 2.0 stops printing and gives a sound signal. When a new thread is fed, printing resumes from the point where it left off.

One of the most significant differences between the Anycubic 4Max Pro 2.0 and other 3D printers is the automatic power-off at the end of work, ensuring safety and energy savings.

Anycubic 4Max Pro 2.0 is an improved version of the Anycubic 4Max Pro, so the differences between them are not very significant:

|

Anycubic 4Max Pro |

Anycubic 4Max Pro 2.0 |

|

|

Dimensions, mm |

454 х 466 х 410 |

454 x 466 x 410 |

|

Weight, kg |

22.5 |

18.8 |

|

Software |

Cura |

Cura, Simplify3D, Repetier-HOST |

|

File formats |

.DAE, .AMF, .STL, .OBJ, GCODE |

.JPG, .PNG, .STL, .OBJ, GCODE |

|

Build chamber, mm |

270 х 205 х 205 |

270 х 210 х 190 |

|

Extruder temperature °C |

250 |

260 |

|

Technology |

FDM |

FDM |

|

Min. layer height, µ |

20 |

50 |

|

Positioning accuracy, µ |

X: 12.5 Y: 12.5 Z: 2.0 |

X: 10.0 Y: 12.5 Z: 1.25 |

|

Supported materials |

ABS, PLA, HIPS, Wood |

ABS, PLA, Flex, HIPS, decorative filaments |

|

Print speed, mm/s |

150 |

20–150 |

Pros

Controversies

Be aware that the increased weight of the frame reduces the vibration of the structure.

The ability to switch the lighting on or off during the printing process is hardly an essential feature.

Otherwise, it would be difficult to quickly refill filament and go on printing.

Cons

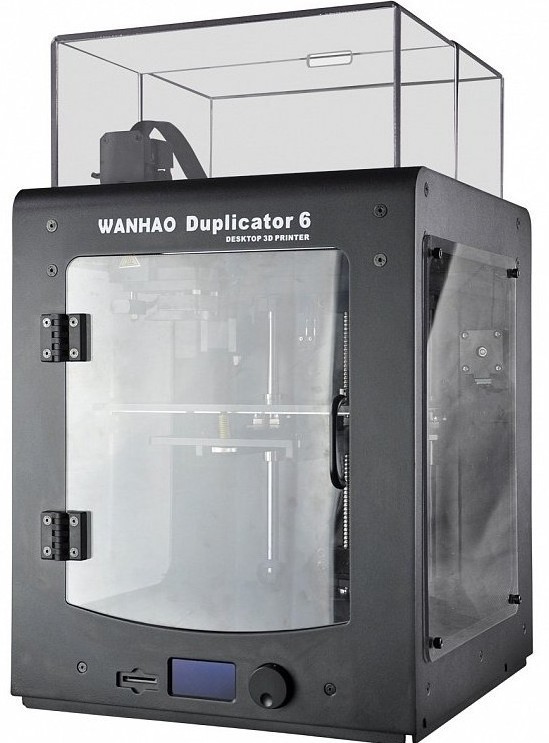

The closest alternative to ANYCUBIC 4Max Pro 2.0 is Wanhao Duplicator 6 Plus, so it should be relevant to compare these two devices.

|

ANYCUBIC 4Max Pro 2.0 |

Wanhao Duplicator 6 Plus |

|

|

Dimensions, mm |

454 x 466 x 410 |

348 х 364 х 480 |

|

Weight, kg |

18,8 |

18 |

|

Software |

Cura, Simplify3D, Repetier-HOST |

CURA Wanhao edition, Simplify 3D |

|

File formats |

.STL, .OBJ, .JPG, .PNG, GCODE |

.STL, .OBJ, .DAE, .AMF, GCODE |

|

Extruder type |

Single |

Single |

|

Build chamber, mm |

270 х 210 х 190 |

200 х 200 х 175 |

|

Bed temperature, °С |

100 |

100 |

|

Extruder temperature, °С |

260 |

180–260 |

|

Technology |

FDM/FFF |

FDM |

|

Layer height, µ |

50–300 |

20–300 |

|

Positioning accuracy, µ |

X: 10.0 Y: 12.5 Z: 1.25 |

X: 10.0 Y: 10.0 Z: 5.0 |

|

Supported materials |

ABS, PLA, Flex, HIPS, decorative filaments |

ABS, PLA, HIPS, PVA |

|

Filament diameter, mm |

1.75 |

1.75 |

|

Nozzle diameter, mm |

0.4 |

0.4 |

|

Connectivity |

USB, SD |

USB, SD |

|

Print speed, mm/s |

20–150 |

30–150 |

As can be seen from the data, the printers have roughly the same properties, the differences being insignificant.

The most noticeable difference lies in the convenience of use. On the one hand, the Duplicator 6 Plus has an auto bed leveling function: the user doesn't have to bother with level control knobs. On the other hand, it has a rather inconvenient interface: instead of a touchscreen, there is a regular display with a knob for selecting a menu bar, which often malfunctions. Both the screen and the knob are located very uncomfortably — at the very bottom of the front panel. The menu itself, judging by reviews, also seems to be inconvenient and illogical. In addition, the Duplicator 6 Plus lacks important parts such as a filter for cleaning the exhaust air and a porous coating on the print bed.

To understand the difference, it might be appropriate to mention the cost of the printers: the retail price for the ANYCUBIC 4Max Pro 2.0 goes for $499.00, while that for the Wanhao Duplicator 6 Plus amounts to $899.00. (The prices are relevant for the day of publication — find out the current ones by the links.)

ANYCUBIC 4Max Pro 2.0 is an excellent choice for those who need a compact and relatively inexpensive 3D printer notable for the ease of use and the high quality of printing.

The device is great for small-scale production of various models and prototypes, it can serve as professional equipment of production and technical personnel.

Update your browser to view this website correctly. Update my browser now

Write a comment