Hi! Today we will talk about the novelties by Anycubic, one of the most prominent manufacturers of low-cost 3D printers in China. You can learn more by reading this article.

Source: anycubic.com

Founded in 2015 by two childhood friends, Anycubic continues its rapid development. The company is based in China's Shenzhen and now employs more than 300 people, with its offices in America and Europe significantly reducing the time of delivery of the equipment to all key markets. Anycubic constantly invests in its own developments, proprietary technologies, and industrial automation, which allows the company to maintain low prices and high quality of products.

Source: anycubic.com

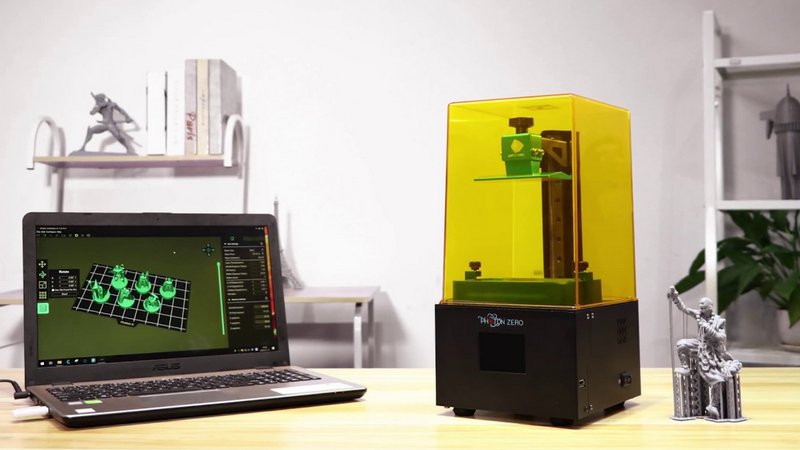

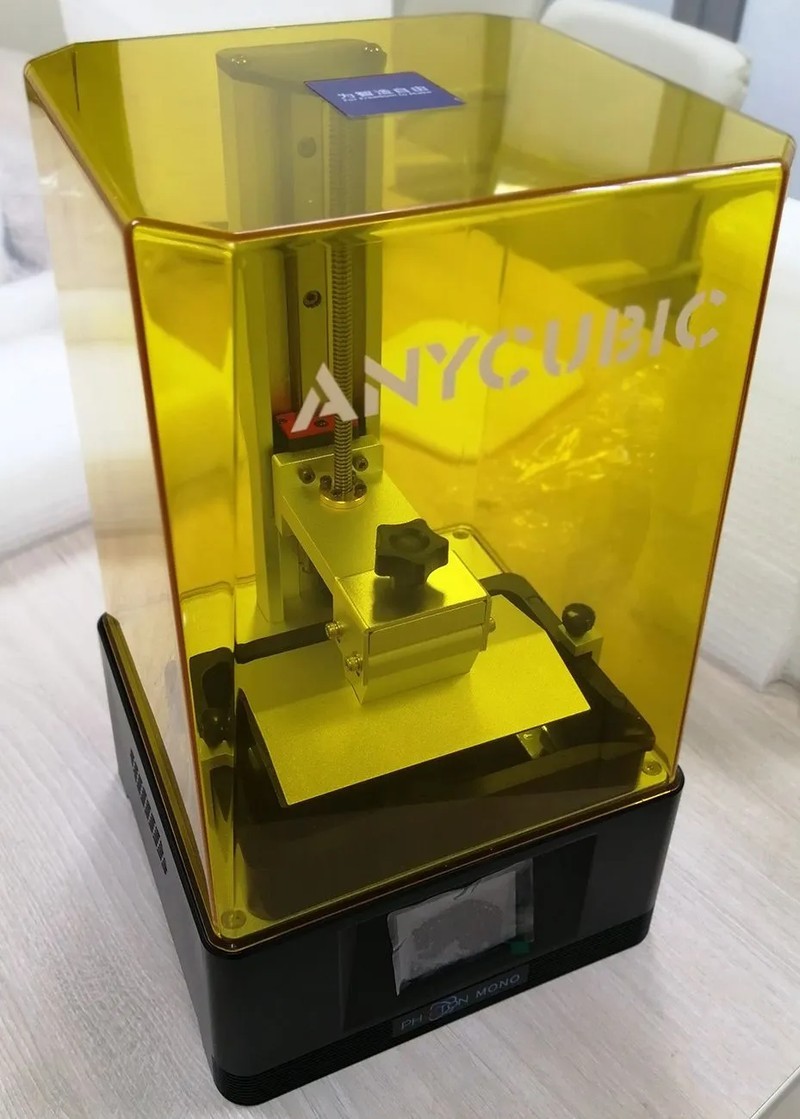

Photon Zero has similar characteristics to its older brother Photon S, being, though, significantly cheaper than it. To date, Photon Zero is one of the cheapest resin printers on the market. The device comes ready to print, and Anycubic seems to have managed to completely solve all the assembly problems — now there are absolutely no complaints about it. The company did a good job on the design as well: a compact black box with a conveniently located touchscreen and UV protection cover, a blue vat for resin, shiny linear rails, and a solid bed look very stylish.

When the cover is removed, the device pauses printing to prevent the negative impact of UV-light on the user. This feature coupled with a really low price makes the machine a great choice for education or home use.

Getting the printer ready for operation is quite easy: you need to slightly loosen the mount of the bed using the supplied tool, lower it all the way (without the resin vat) with a sheet of paper inserted between the plate and the LCD screen, and lightly press it while tightening the four fastening screws.

Source: anycubic.com

Source: anycubic.com

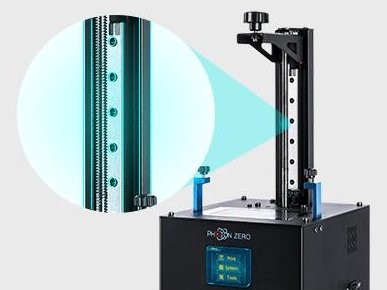

In this budget-friendly printer, Anycubic installed a rigid linear rail to stabilize movement along the Z-axis, more typical for expensive models, which increased resolution and minimized printing errors.

The resin vat received a new plastic design, with an FEP film simplified for replacement and special markings on the side making it easier to control the amount of resin.

Source: anycubic.com

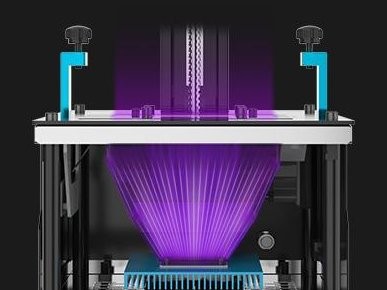

The modernized proprietary UV source provides uniform lighting of the print area at a perfect right angle, which allows for a greater reduction of print distortion compared to previous models.

Source: anycubic.com

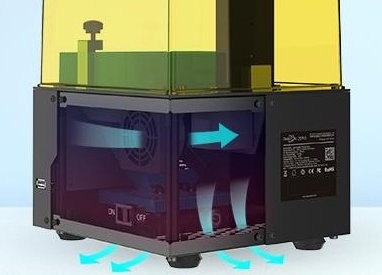

The company significantly increased the power of the UV matrix cooling fans for better stability of results during long printing processes.

Source: anycubic.com

The company keeps on improving the Anycubic WorkShop software — the Photon version got the feature called the Exposure Test for printing eight identical test models with different times of exposure, allowing the user to select the optimal print settings for any resin.

Source: anycubic.com

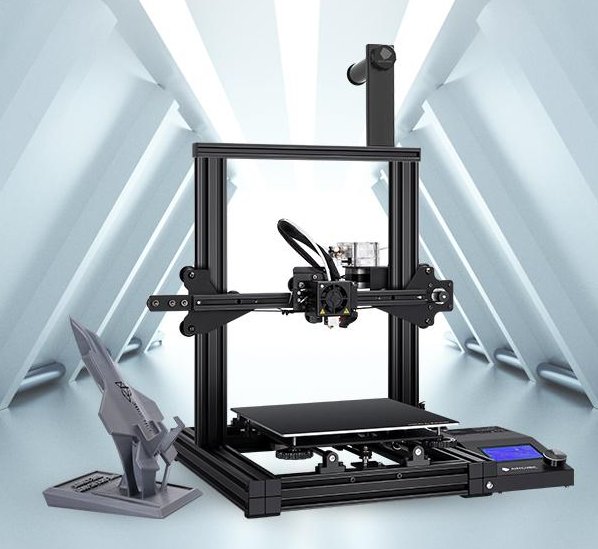

Mega Zero is a further evolutionary development of the Anycubic budget models competing with Wanhao and Creality counterparts. In this model, the developers were able to simplify the design and reduce its cost even more, having increased reliability and rigidity of the product.

Source: anycubic.com

Source: anycubic.com

The installation from factory-assembled modules saves your time and allows you to quickly begin your work process. The double-gear printhead in the extrusion mechanism and the increased torque allows for printing with complex filaments such as TPU. The dual Y-axis installation ensures smooth motion, high reliability and repeatability. The function of resuming the printing process after power outages will allow the user to continue printing from the very point at which it was interrupted. The printer does not have the function of automatic bed-leveling, but manual calibration is not difficult, thanks to the enlarged knobs on the adjustment screws. This model is not equipped with heating, but the manufacturer claims that the metal plate provides good adhesion to all materials.

Source: anycubic.com

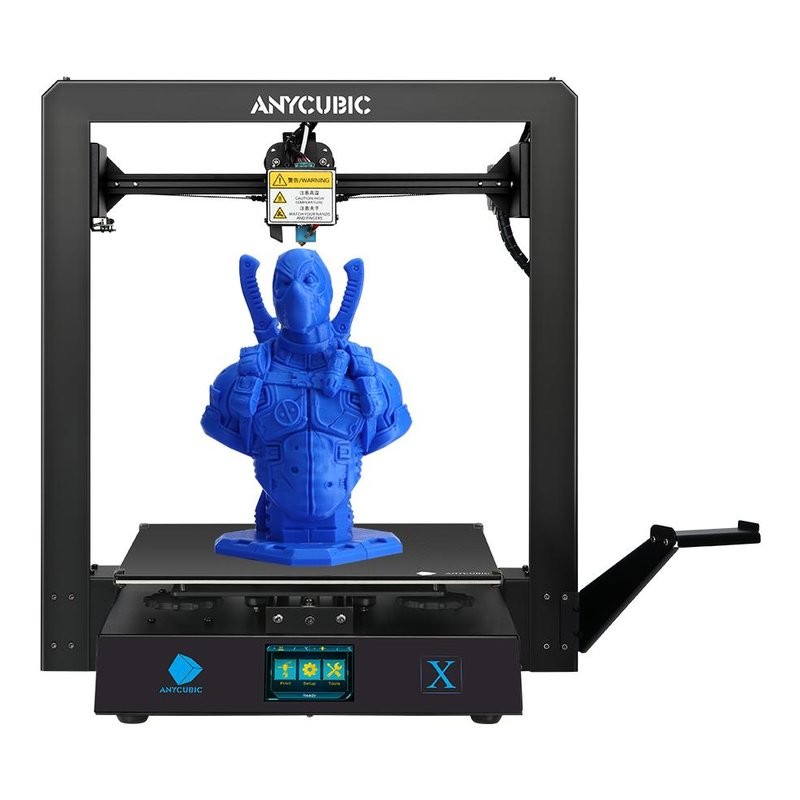

Although the Mega Zero and Mega X models boast similar structure and hardware components, there are significant differences between them. First of all, it is the size of the printing area — Mega X has a build volume of 300 x 300 x 305 mm. The design of the devices is also different: Mega X has all the electronic components and controls mounted directly on the frame. In addition, the device is equipped with a heated bed with a maximum temperature of up to 90 ºC.

Source: anycubic.com

Source: anycubic.com

Mega X also has dual Z-axis screw drives. The reinforced linear guide of the printing bed along the Y-axis provides accurate and smooth bed movement.

Source: anycubic.com

Anycubic Wash and Cure is used to remove residue from parts printed with resin 3D printers, as well as for subsequent additional exposure to UV-light for final curing. You can manage the device via the LED-illuminated touch buttons. For the safety of use, the device stops and locks down the operation when the protective cover is removed.

Source: anycubic.com

Source: anycubic.com

A series of powerful UV LEDs with wavelengths of 365 and 405 nm allows using Wash and Cure with 3D printers of any manufacturer. The rotating platform serves to evenly cure parts. The device is equipped with a sealed container for washing liquid with a built-in mixer and a special adjustable bracket that will allow you to fully submerge your prints in liquid.

Figurine printed on the Anycubic Photon Mono without post-processing

The new Anycubic equipment models are becoming ever more convenient in use, remaining highly functional and reliable, which is quite important for consumers who are aware of what repair and modernization take. Products by Anycubic compete on par with the “classmates” Wanhao and Creality, sometimes even surpassing their counterparts.

Order Anycubic 3D equipment at Top 3D Shop to get the original products with an official warranty as well as the best service and technical support.

Update your browser to view this website correctly. Update my browser now

Write a comment