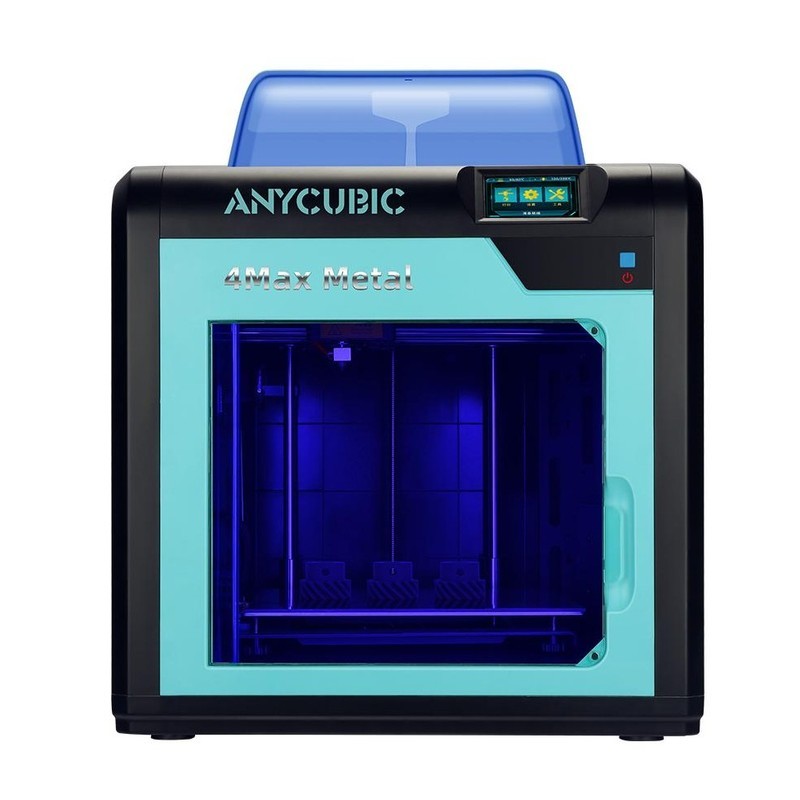

Hi everyone! In this review, we will talk about the new Anycubic 4Max Metal 3D printers that can produce molds for sintering with the results being metal parts. Read this article and learn more about these devices and their capabilities.

Source: anycubic.com

Shenzhen-based Anycubic is a rapidly growing Chinese startup company that manufactures 3D printers and 3D printing materials. The brand has come a long way since 2015 — from two friends with an idea of their first 3D printer to hundreds of employees constantly working on developing new models. Researching modern additive technologies and listening to their users helped Anycubic to become one of the global leaders in the market of 3D printing devices.

Source: anycubic.com

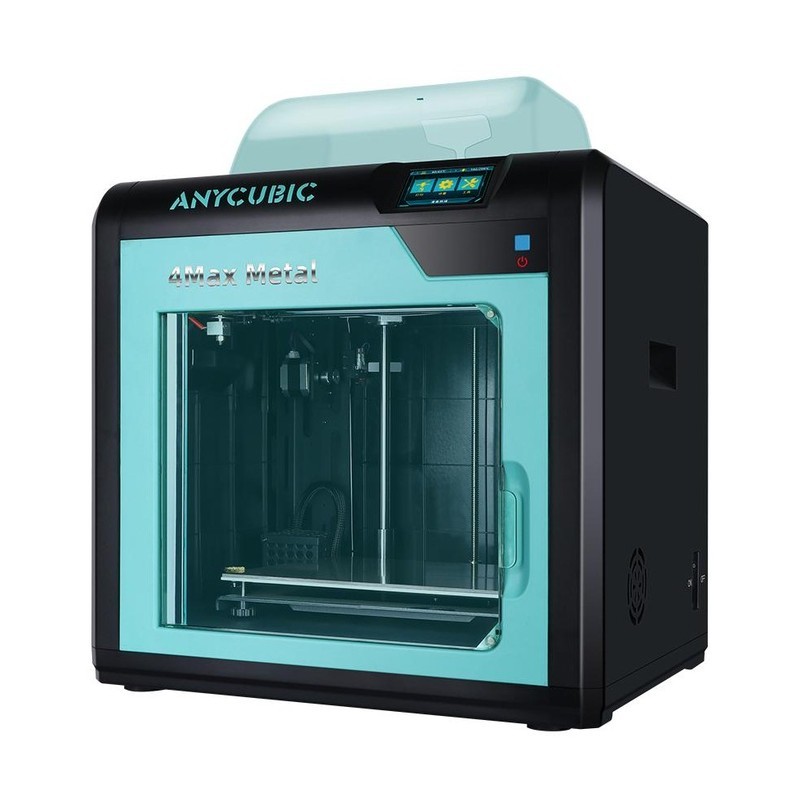

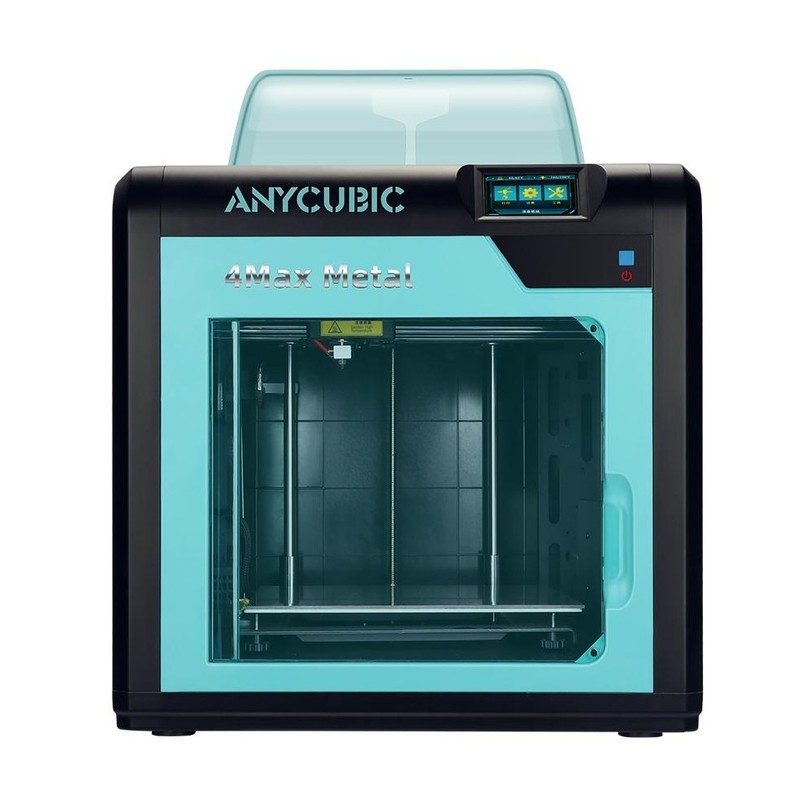

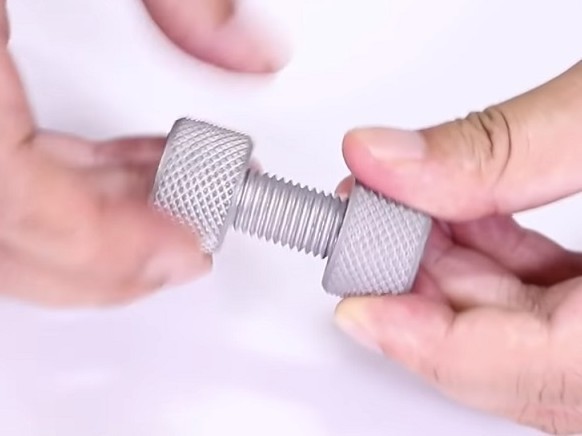

The 4Max Metal by Anycubic is a successor of the 4Max Pro, modified for working with the filaments filled with metal powder. Using these materials is technically a more complex task than printing with regular filaments. Metal-filled filaments (especially the ones with steel powder) are very abrasive and require a printer with a different filament loading mechanism as well as a different print head construction.

Anycubic sells the 316L filament 1.75 mm in diameter for the 4Max Metal. The stainless steel infill was developed jointly with Uprise3D. The prints made using this material have a shrinkage rate from 17% to 25% after molding, which should be kept in mind when designing a 3D model.

After printing a model must go through two additional steps of post-processing:

heat treatment in a chamber oven to evaporate the binder;

high-temperature sintering of the model to achieve the required mechanical properties.

To do all that you will need an oven that can maintain a temperature high enough for debinding (the removal of binders), as well as a furnace for sintering metal parts. These units aren’t included in the package and can be bought separately. To fully evaporate the binder it is recommended to heat the parts to 100-140 °C (but no more than 200 °C) for 4-6 hours. The sintering will require heating the part to 1500 °C (but no more than 1550 °C) in an inert gas environment (nitrogen or argon).

Source: anycubic.com

Source: anycubic.com

The Anycubic 4Max Metal features a build volume of 270 x 210 x 200 mm with slightly shorter (by 5 mm) Y and Z axes compared to the 4Max Pro that wasn’t designed for using metal-filled filaments. The fully enclosed design allows the printer to maintain the temperature required for printing with the 316L filament. The print bed (that can be heated up to 100 °C) is held in place by bulldog clamps that make it easy to remove the platform. The bed is made of special material that provides the best adhesion for printing with the 316L filament. There is no automatic bed leveling option.

To reliably work with abrasive plastics, the 3D printer features an improved extruder and a steel nozzle with a diameter of 0.5 mm. Unpleasant smells that appear during printing are held off by an air filtering system. A special brass brush for clearing the nozzle before printing is mounted to the print platform. The user manual includes recommendations to add automatic cleaning comands into the escape sequence.

Source: anycubic.com

Pros

Cons

|

4Max Metal |

Zenit 3D HT |

||

|

Build volume |

270 x 210 x 200 |

200 x 200 x 210 |

240 x 215 x 220 |

|

Maximum hot end temperature |

260 °C |

410 °C |

410 °C |

|

Maximum print bed temperature |

100 °C |

150 °C |

|

|

Minimum layer height |

50 microns |

10 microns |

15 microns |

|

Supported materials |

316L |

ABS, PLA, HIPS, PVA, ULTRAN 630, ULTRAN 6130, ASA, ABS/PC, PET, PC, FRICTION, CAST, RELAX,ETERNAL, FLEX, RUBBER, SEALANT, PETG, AEROTEX, CERAMO, WAX, SBS, SBS PRO, PROTOTYPERSOFT, PRO-FLEX, TOTAL PRO, NYLON, PEEK, etc. |

ABS, PLA, PVA, HIPS, Flex, NYLON, etc. |

|

Case design |

Enclosed |

Enclosed |

Open |

|

Price |

On request |

On request |

On request |

The Picaso Designer X 3D printer can work with the metal-filled filaments when using a replaceable steel nozzle with a diameter of 0.5 mm. While the printer’s build volume might be smaller than that of the 4Max Metal, the Designer X is more accurate and has a wider range of functions thanks to the higher hot end and print platform temperatures.

The choice is meant to be between a device with a smaller build volume, high accuracy and a wide range of materials and a device optimized for working with metal-filled filaments and larger build volume.

The Zenit 3D HT 3D printer is also able to print with the metal-filled filaments but due to the open-frame design, the number of supported materials is significantly smaller.

Source: wishqatar.org

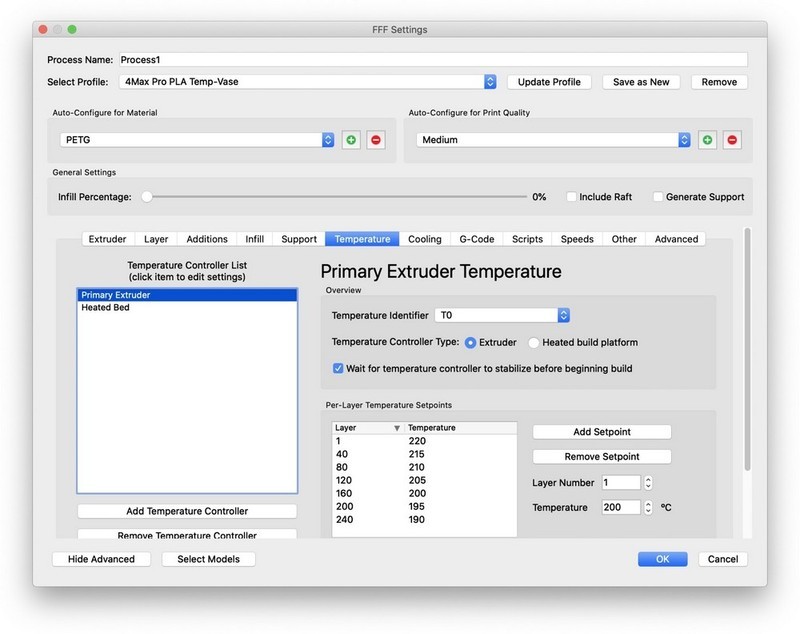

Cura is one of the most advanced open-source slicing solutions for preparing 3D models for printing. It’s distributed by Ultimaker. The program has a large library of presets for various materials and 3D printers that is regularly updated by thousands of users worldwide. The plugins allow for transparent integration of Cura with popular CAD programs.

Source: anycubic.com

Anycubic 4Max Metal is a very inexpensive 3D printer compared to professional SLS solutions that print with metal, and a useful tool for prototyping metal parts. Obviously, the 4Max Metal couldn’t reach the level of accuracy provided by the SLS printers due to the non-linear shrinkage, but the low prices of the machine and resources can make up for this disadvantage.

Buy a unique and inexpensive Anycubic 4Max Metal 3D printer from Top 3D Shop and get an official warranty and the best possible service.

Update your browser to view this website correctly. Update my browser now

Write a comment