Anycubic was founded by two childhood friends in 2015 and is one of the most popular 3D printer brands worldwide. The company has around 300 employees in Shenzhen, China. You can learn more about Anycubic and its printers from this article.

As one of the leading 3D printer manufacturer, Anycubic is not only known for its technological innovations, but also for flexible marketing strategies — 3D printers rental, financing lease, personal printing and maintenance consultations, and training services.

Source: anycubic.com

Anycubic’s co-founder James Ouyang who holds a PhD of University of Auckland sheds some light on the history of the company:

“Graduated in 2015, I came back to China from New Zealand. I was so excited and full of curiosity when landed in Shenzhen the first time. Lu Ouyang, Anycubic’s Founder and CEO, is my childhood friend. He had a company before Anycubic providing electronic modules and 3D printer accessories for over 4 years.”

“3D printer itself wasn’t our first choice. We hadn’t even had the confidence to rush in. But after seeing clients increasingly relying on us for key components of their DIY printers, we realized we could do it, and do it much better. [...] I didn’t think much but only hope to explore more possibilities with the 3D printing technology. There is nothing to be afraid of. So why not make a difference.”

They founded Anycubic in 2015 without hesitation.

The founders continued: “Following our heart is important. But the real world is harsh. There were so many ups and downs. We cannot remember how many sleepless nights out there at the early stage.” “After a whole year’s hard work, the first model Anycubic Mega came on board in 2016. Fortunately, our work paid off. Mega became so popular in the market in a short period of time and our journey as a professional 3D printer maker officially started. We all were amazed and excited but we did not stop there. The second and third generations were launched soon after along the way.”

Source: phi-hannover.de

Anycubic’s product line includes a wide range of FDM and resin 3D printers, accessories, and services for owners:

Source: all3dp.com

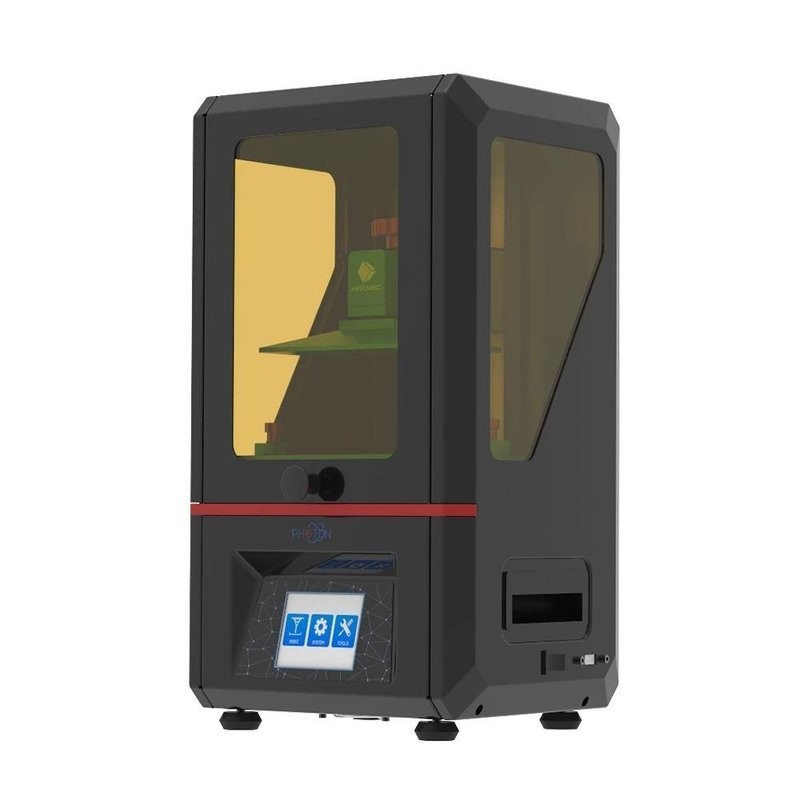

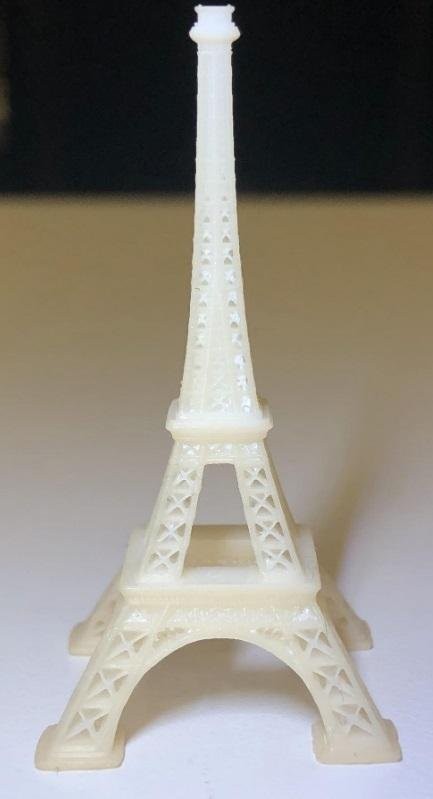

There’s nothing surprising about the fact that the LCD resin printing provides superior quality and resolution compared to FDM printing, but the Anycubic Photon series proves this to be possible even in a lower price range. Even though those who are new to SLA/DLP printing will require some learning, but it’s not going to take long, thanks to the comprehensive documentation and active online community.

Source: anycubic.com

This is a popular and inexpensive workhorse for resin 3D printing. Even though it’s important to keep in mind the specificities of the model, its printing quality and a huge online community that provides tips, tricks and problem-solving solutions, make the device an exceptionally worthwhile machine. Impressive printing quality makes up for more complicated (compared to FDM 3D printers) setup process and workflow and lackluster proprietary software.

Specifications:

Source: anycubic.com

Anycubic Photon S, released in 2019, is a continuation of ideas that formed the basis of its predecessor (Photon). Apart from the new white case, the design fundamentals of the printer remained the same, the manufacturer focused on bringing internal changes.

For example, Anycubic managed to get rid of Z-axis ‘wobble’ that was a target of many complaints, doubling the number of rods on either side. The touch screen is now bigger and has better viewing angles. The software has been upgraded as well – the file manager now shows digital miniatures of the objects prepared for printing. The activated carbon filter eliminates the smells completely. Another nice addition is a longer Z-axis (by 10 mm). The printer has also been upgraded with an ability to manually pause printing and to raise the platform from the liquid bath, which allows the user to look at the result before continuing the process.

Specifications:

Source: all3dp.com

Despite their low price, Anycubic FDM 3D printer are fully functional, being sold as either kits or pre-assembled models. The kits are more complicated to set up and in usage, so it will take some time to calibrate and set them up, but in the end, they provide great results and their quality can compete with more expensive 3D printers.

Source: steemhunt.com

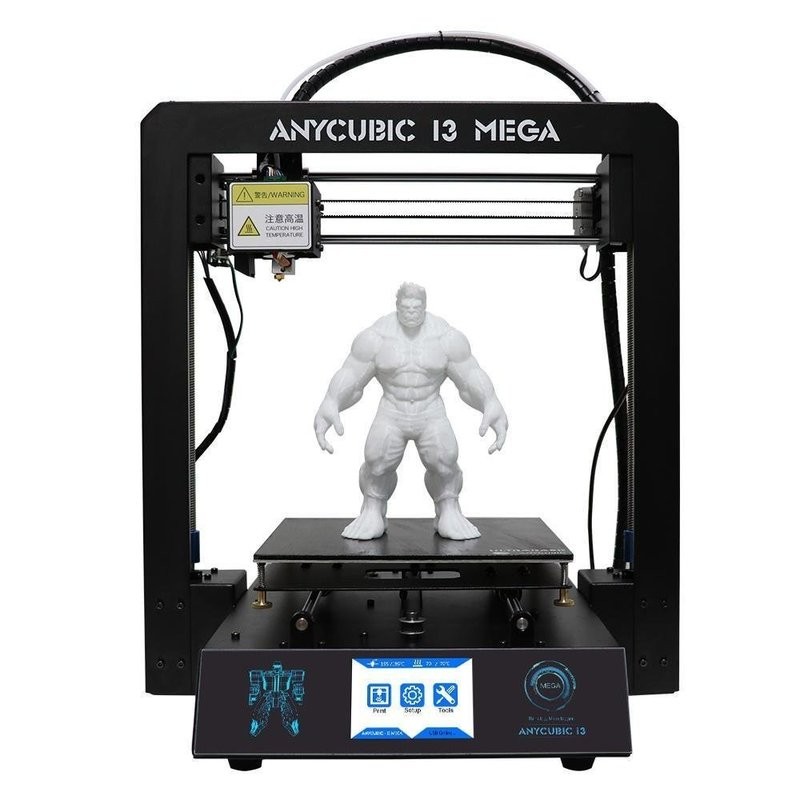

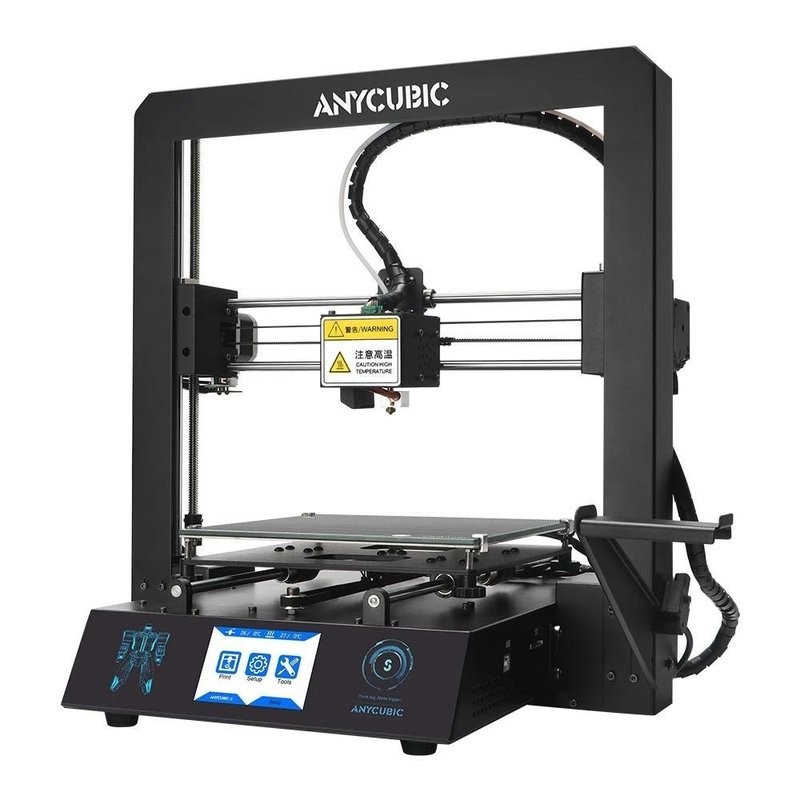

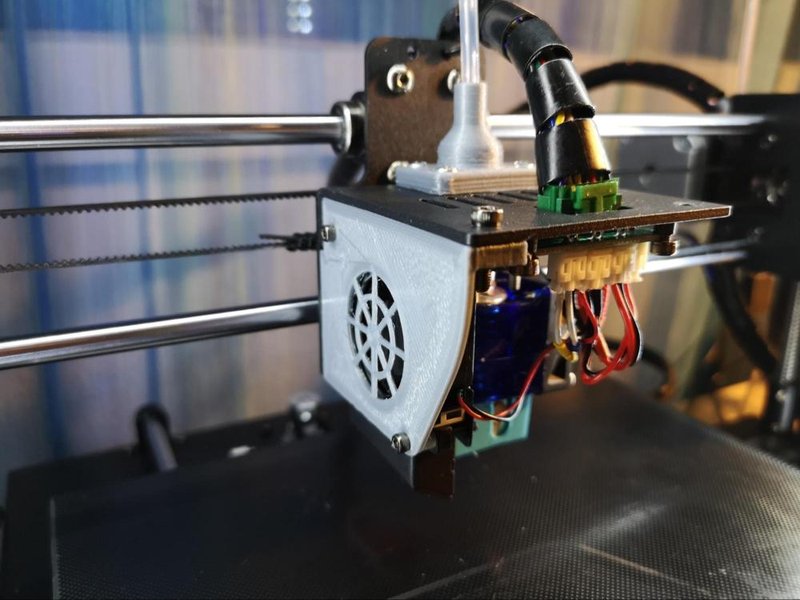

I3 Mega is the third generation of the 3D printers manufactured by a Chinese brand Anycubic. Several significant upgrades have been added to this model:

i3 Mega is a stiff, stable, and well-designed device. The wiring is made of quality materials and is fixed. The touch screen is easy to use and is ergonomically placed. A simple build and reliability make this 3D printer a good tool for different 3D printing tasks.

Specifications:

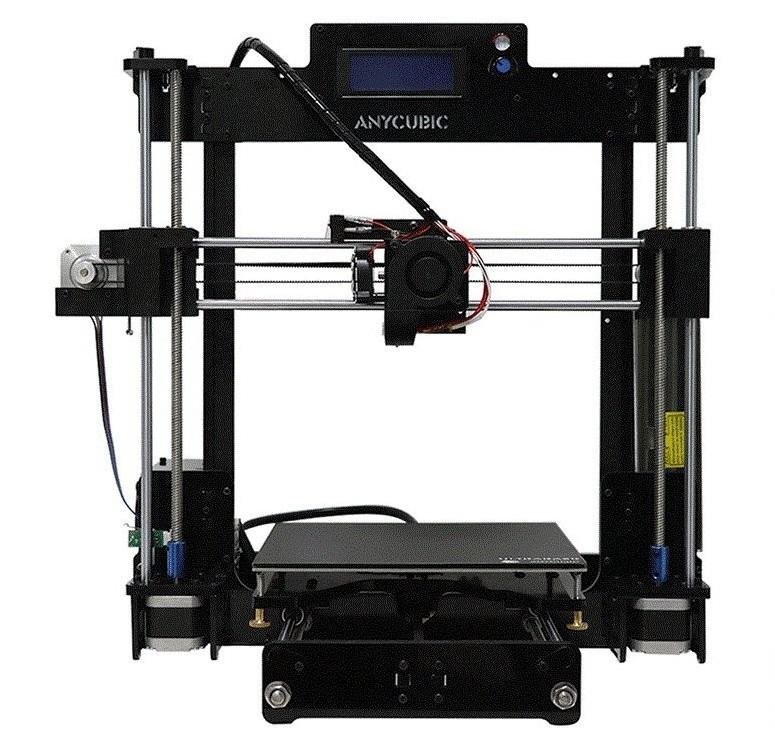

Anycubic Modular I3 is an inexpensive DIY 3D printer kit based on I3 MEGA. The main differences between the Anycubic Modular I3 and I3 MEGA:

The frame of the I3 MEGA is completely metallic, while many parts of the Modular I3 are made of acrylic;

The Modular I3 has an LCD screen and a joystick, while the I3 MEGA has a touch screen;

The I3 Modular comes with pre-assembled parts, while the I3 MEGA has the “3 steps assembly’ system;

The I3 MEGA features a filament sensor and the ability to resume printing after a power failure, while the Modular I3 lacks these features.

The rest is completely identical between the models.

Specifications:

Source: anycubic.com

Even though the Anycubic i3 Mega is marketed and positioned as a DIY 3D printer kit, assembling and calibrating the model is possible within an hour due to many parts being already pre-assembled. The touch screen (that replaces a combination of a screen and trackball) has good readability, and the upgraded software makes using the printer easy and intuitive. Similar to more expensive 3D printer models, this device by default features an ability to resume printing after power failure and a filament sensor. The Anycubic Ultrabase platform with powerful heating allows users to print with a wide variety of materials – the prints easily stick to the bed while printed and are easily removable after the process is finished.

Specifications:

Source: youtube.com

Compared to the Mega which served as a base model, Anycubic X has many differences other than the modern design. The mechanical and electronic parts of the machine have been significantly changed, and the device now has a more rigid metallic frame and reliable drives. The main features of this model are the bigger print volume (30x30x30 cm) and a heated sturdily fixed platform Anycubic Ultrabase which also has great adhesion. All of the printer’s functions can now be accessed with a full-color touch screen. The Anycubic I3 Mega has an ability to resume printing and a filament sensor, similar to many other modern 3D printers. The assembly is very easy as well, even a kid could complete it: screwing in 8 screws and connecting 3 ports make the printer ready to work.

Specifications:

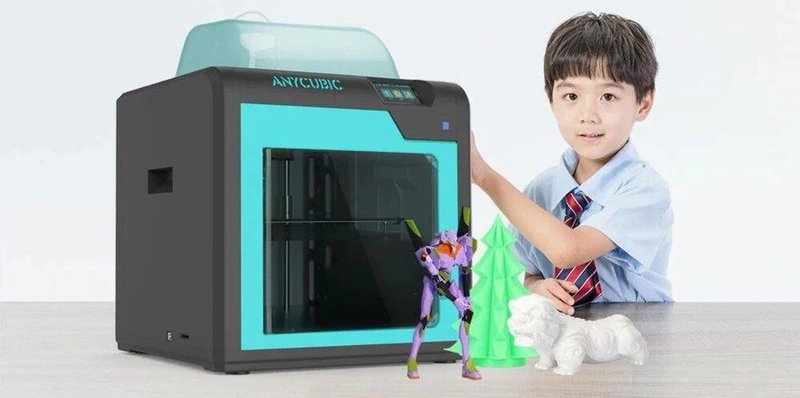

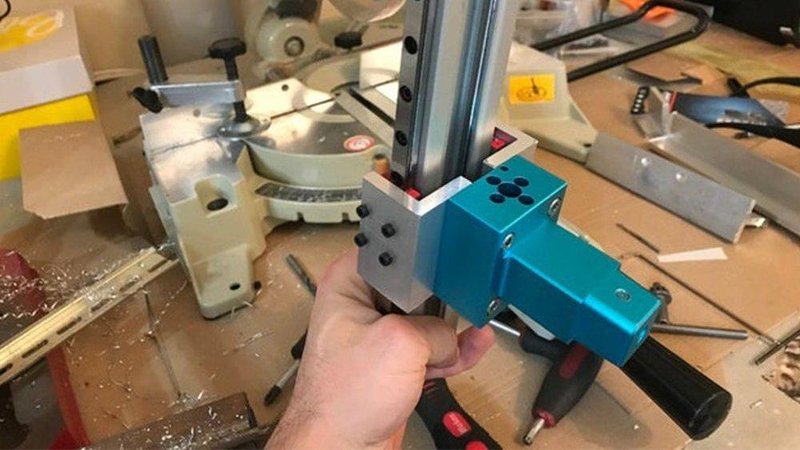

Source: xw925.com

The upgraded Anycubic 4Max Pro painted in turquoise and black, doesn’t look like another 4Max iteration but rather like a brand new product. Not only the colors were changed, but the design itself has also gotten upgrades that provide safer and simple 3D printing. The touch screen interface is now available (the predecessor provided a wheel as a means to navigate the settings), as well as a longer by 60 mm X-axis, smaller distance between the filament and print head, automatic turn off while idle and the ability to resume printing after power failure. According to the manufacturer, Anycubic 4Max Pro is perfect for educational purposes due to full enclosure.

Specifications:

Source: anycubic.com

Anycubic Chiron is a large-sized pre-assembled FDM 3D printer with a print volume of 400 x 400 x 450 mm. It features a titanium extruder and automatic bed leveling by 25 points. Other advantages of this model include:

Filament sensor

Resuming printing after power loss

The Anycubic Ultrabed Pro platform adhesion

Full-color LCD screen

Stiff aluminum frame

Photoelectric endstops

Double Z-axis

Specifications:

Source: tanga.com

The original Delta-design along with affordability make the Anycubic Kossel Plus a good choice for those who need a compact machine with a wide range of functions. The Kossel Plus comes with a heated platform, automatic bed level, powerful and ergonomically located power supply, carbon fiber tubes, and filament holder. Other advantages of this model include well-documented and simple assembly, double fans for better print head cooling, and highly accurate stepper motors.

Specifications:

Source: anycubic.com

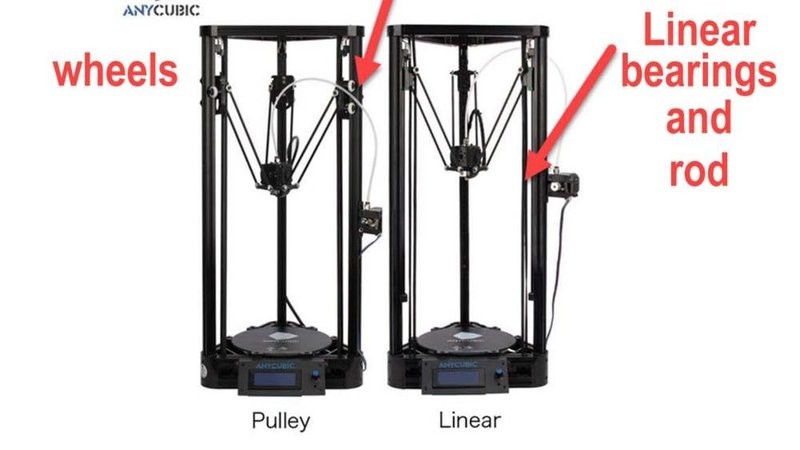

This model differs from Anycubic Kossel Plus in that it uses linear rails and pulleys instead of rods and linear bearings to move levers. It provides better accuracy and reliability and the differences are highlighted in the picture below.

Source: pevly.com

Specifications:

Source: youtube.com

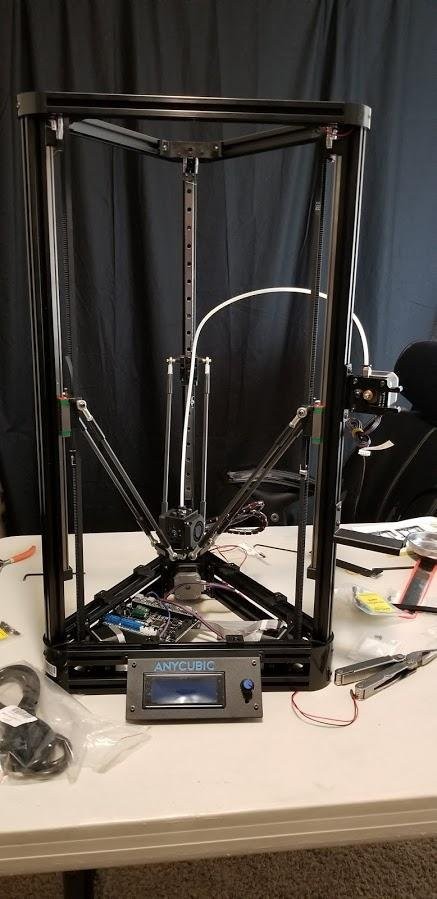

Towering over many desktop 3D printers, the Predator has a massive print area of 370x455 mm. But this is not the only strength of this model. There’s a proprietary platform named Anycubic Ultrabase Pro which provides a great first layer adhesion thanks to its special porous coating that allows for easy release of the prints without waiting for the bed to cool off. The platform is also supposed to heat to 100 °C faster due to the voltage increase from 12 V to 24 V. The bed auto-leveling feature with 37 points is now used before every new print.

Specifications:

Source: makerfun3d.com

According to Kevin: “This printer took me about 2 hours or so to build. It comes about half-built from Anycubic. The instructions do a good job telling you how to run the cables, and install parts. “

“This printer is fast. My first non-calibration print was the Desert Tower. This printed in about 9.75 hours. [...] Watching the 3 arms work in unison is magical. I’m very appreciative to the smart people that were able to figure out this movement to make an awesome 3D Printer.

I also think the parts are strong. It feels very solid wen built. I have some parts to strengthen it further, but quite honestly, I don’t think about it, because it is like a rock already. It’s also very easy to move around with everything bolted on. The covering on the build plate does a good job of sticking prints to it, so they don’t fall off.”

Source: makerfun3d.com

The Anycubic Kossel Linear Plus has quickly become my favorite 3D Printer. Sure, I have run into some issues, but it prints fast, prints really well, has auto-level built in, and mostly… it just works. [...] I wouldn’t recommend a delta style printer for your first printer, but I would highly recommend this one as your second printer. With a 230mm build plate and a 300 mm build height, you can get a lot of items on this build plate.

Source: makerfun3d.com

Source: amazon.com

“This printer is awesome once it is set up correctly.”

“I did have some self-induced problems at first though. Hopefully, you will read this and not make the mistakes I did. The printer frustrated me at first. I couldn't get a good print [...] but I knew that I was doing something wrong. [...] I suggest that before you print your first print you should watch a couple of videos, there are some good ones out there.”

Daniel has also provided some good tips:

“Get a box of latex gloves. Always wear them when working with the resin. Only use one time, trust me.”

“95% or better IPA (alcohol). this is to clean the prints and everything else”

“[Have] Paper towels, and plenty of them. Resin printing is a little messy.”

“[Get or make a] Small 405nm nail curing UV station or UV lamp. Make a UV curing box (Optional)”

“Conclusion: After having some self-induced difficulties I am now printing cool little highly detailed prints. This printer is a great value and prints really well. It is made sturdy where it needs to be and is still lightweight. The LCD menu is simple and easy to use. I am very satisfied with my purchase.”

Source: amazon.com

Source: thingiverse.com

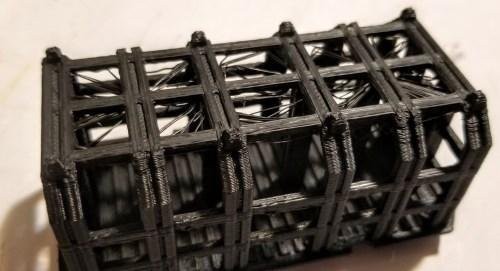

Anycubic 3D printers are among the cheapest and most popular inexpensive DLP printers. Nevertheless, as usually is the case with many low-price 3D printing devices, the Anycubic ones have particular problems. Print problems, cheaper mechanics, and the smell of resin are common complaints that come from the Anycubic users.

These 3D printers have been out for a while, so the user base and the community around keep growing. For many years the owners of Anycubic 3D printers have been working on fixing several problems and finding troubleshooting solutions. Whether on Facebook or GitHub, the online communities provide not only troubleshooting tips but also general recommendations that allow others to use the printers as efficiently as possible. Finding spare parts and accessories is also easy, thanks to qualified online technical support provided by the manufacturer and official resellers. So it’s not difficult to spend some time and “iron out” the possible problems with these time-tested machines. Let’s review several popular mods for the Anycubic 3D printers.

Source: thingiverse.com

The so-called “Z-wobbling” is a common problem for 3D printers in general. In the SLA and DLP 3D printers, this issue usually occurs when the drive that moves the platform up and down wears down or weakens over time. In this case, the platform raises incorrectly which creates weird looking lines between the layers. The first version of the Anycubic Photon had severe cases of this problem, so the manufacturer had to add dual Z-axis linear rails to the Photon-S model to eliminate the issue.

A common way to deal with this problem is to replace the original slider with the dual linear rail. Linear rails are very stable and don’t require calibrating over time. The used named Keith Hebard has developed a very popular mod that requires disassembling the 3D printer and drilling holes. The mod is so popular that the other members of the community have contributed as well.

The Physics Anonymous has developed a mount that replaces some metal parts and can make the upgrade process faster. If you can’t buy the mount, there’s a 3D printed alternative available online by Sascha Beez.

Source: youtu.be

Whether the resin smell is harmful or not – is the point up to discussion, but even if you don’t mind the potential health issues, the smell itself isn’t enjoyable. Although Anycubic recommends using their 3D printers in well-ventilated spaces, it’s not always possible. The most common “solution” for dealing with the smell is turning off the cooler inside the chamber. Obviously, it will lessen the smell inside the room but the point of a cooling fan is to cool off the parts of the printer that are located at its base. So turning it off will likely overheat the system which will force the device to shut off. So what is the correct way to deal with the problem?

Source: wixsite.com

Matt Grisham of Rusty Raptor suggests using a vent hose. Instead of turning the built-in cooler off to lessen the amount of the intake air, this thing will remove the fumes from the printer. It will also help to cool the printer and to minimize the resin smell inside the room. The package includes a duct tape, an air duct, and a bracket. Matt has even made a tutorial that explains how to install the mod.

Source: bryscus.com

Those who are unable to use place the hose to extract the fumes out of the room, can use an air filter with activated carbon. Instead of getting the fumes outside, this system will filter them out making the air clear of smell and safe to inhale. The author of the idea, Bryce B, shows how this works.

Source: bryscus.com

Source: instagram.com

The rising trend among Chinese manufacturers is to get rid of the low-quality stereotype associated with Chinese products. The brands have invested a lot of money into proprietary high-tech developments, upgraded quality, servicing and technical support.

Anycubic is also among the new generation of Chinese manufacturers that develop high-quality and inexpensive 3D printers for different purposes and price segments and provide competition for other famous brands.

You can get an inexpensive and high-quality 3D printer from Anycubic at Top 3D Shop and get the official warranty and the best service available.

Update your browser to view this website correctly. Update my browser now

Write a comment